In the fast-paced world of semiconductor manufacturing, precision and reliability are paramount. Wafer handling boxes play a critical role in safeguarding delicate silicon wafers during transportation, storage, and processing. These specialized containers are designed to prevent contamination, physical damage, and electrostatic discharge, ensuring that wafers remain in pristine condition from fabrication to assembly. As the demand for smaller, more powerful electronic devices grows, the importance of efficient wafer handling boxes cannot be overstated. This article delves into essential aspects of these containers, including the benefits of Custom waffle pack solution offerings and the role of IC tray manufacturer partners. We will also explore common challenges faced in this domain and provide practical solutions to enhance operational efficiency. Whether you are a seasoned engineer or a newcomer to the field, understanding these elements can significantly impact your production line's success.

What Are Wafer Handling Boxes and Why Are They Crucial?

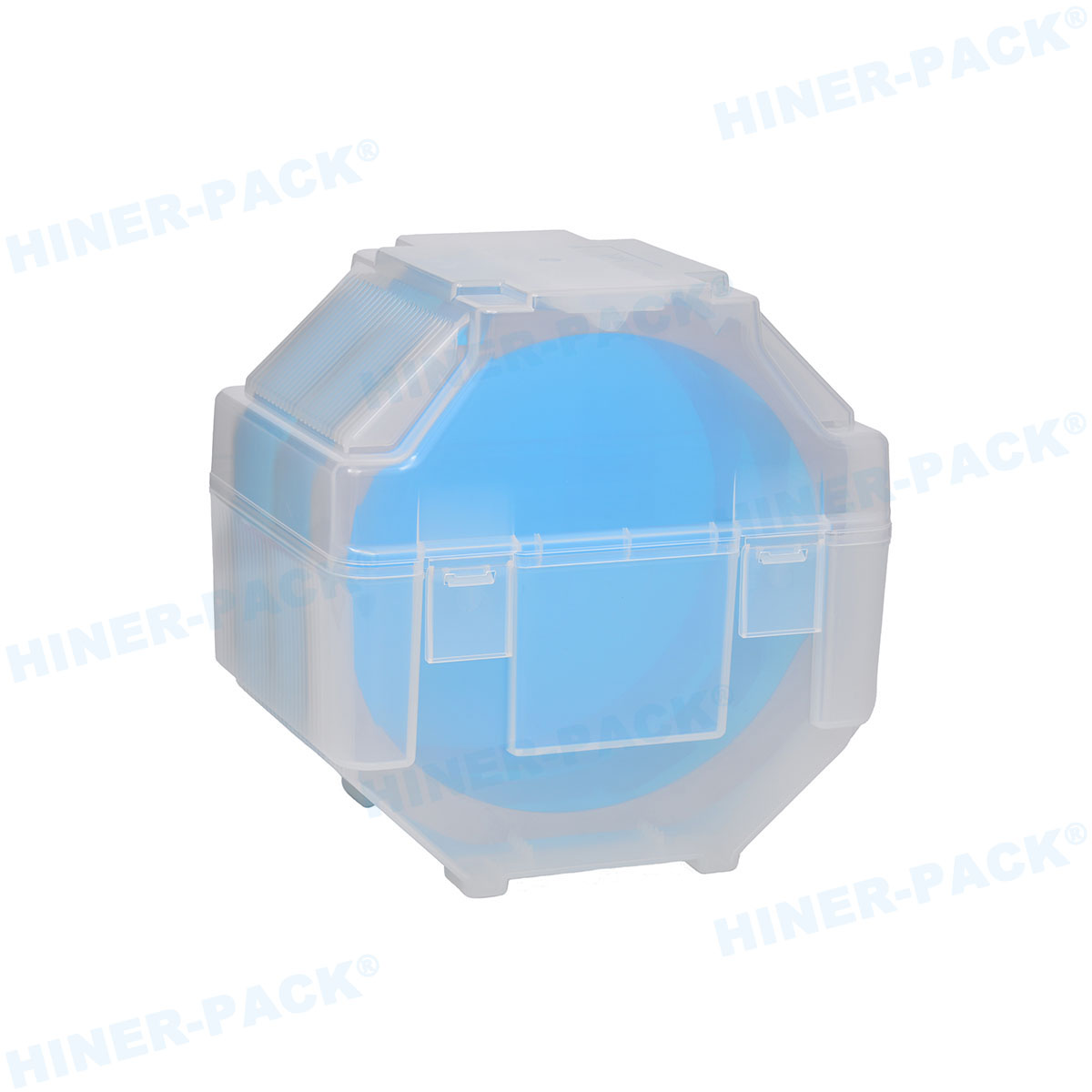

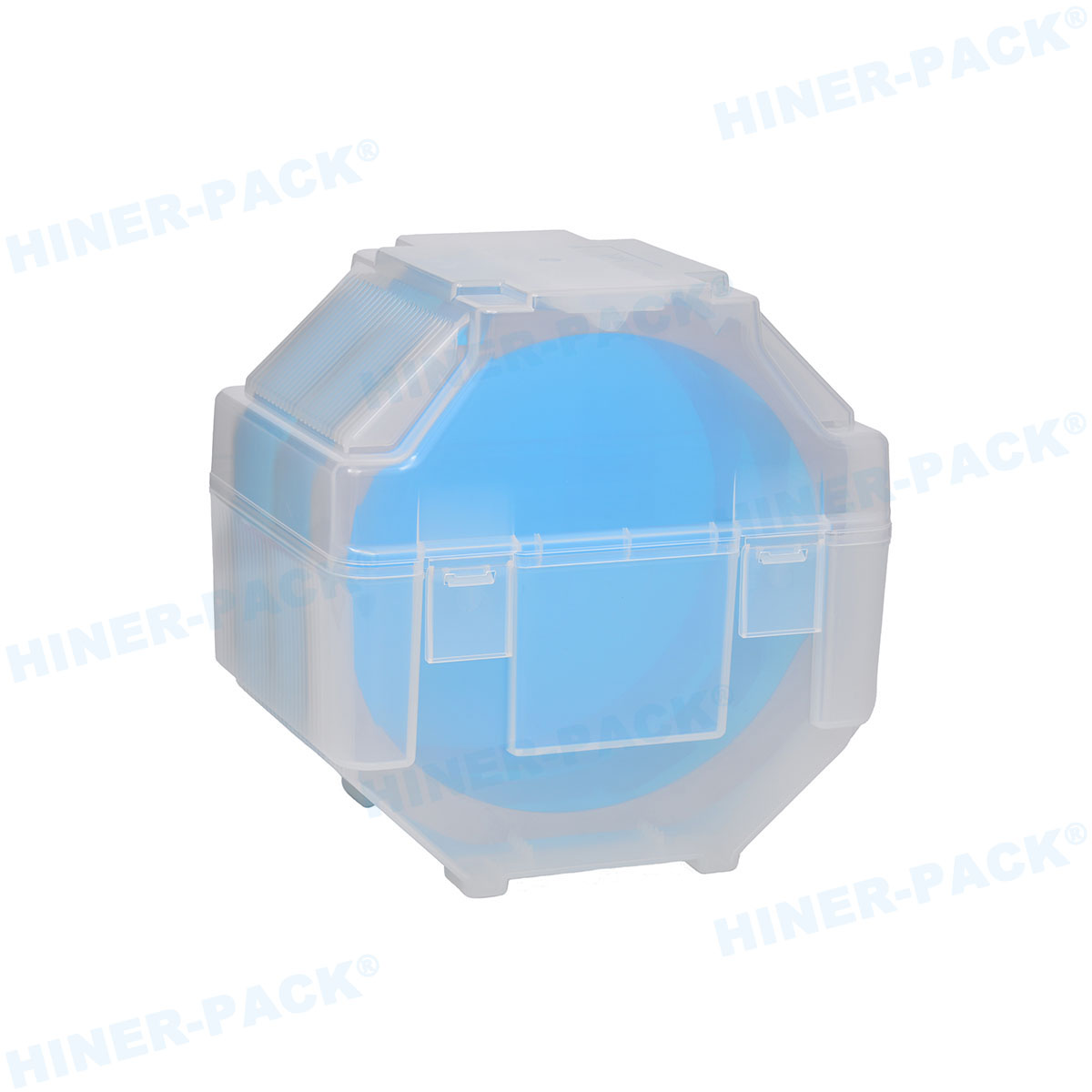

Wafer handling boxes, also known as wafer carriers or cassettes, are containers specifically engineered to hold and protect silicon wafers used in semiconductor manufacturing. Typically made from materials like polycarbonate or PEEK (polyether ether ketone), these boxes are designed to meet stringent industry standards for cleanliness and durability. They come in various sizes to accommodate different wafer diameters, such as 200mm, 300mm, or even larger formats for advanced applications. The primary function of wafer handling boxes is to minimize handling-induced defects, which can lead to costly yield losses. For instance, in high-volume fabrication facilities, a single contaminated wafer can result in millions of dollars in damages. Thus, investing in high-quality wafer handling boxes is not just a logistical consideration but a strategic one.

Moreover, the integration of Custom waffle pack solution designs has revolutionized how wafers are managed. These solutions offer tailored packaging that fits specific wafer types and processing equipment, reducing the risk of misalignment or damage during automated handling. As semiconductor technologies evolve, the need for specialized wafer handling boxes becomes more pronounced, driving innovation in materials and design. Collaborating with an experienced IC tray manufacturer can further enhance this ecosystem, as these manufacturers often produce complementary components that ensure seamless integration across the supply chain. In summary, wafer handling boxes are indispensable tools that support the entire semiconductor lifecycle, from initial production to final testing.

The Advantages of Custom Waffle Pack Solutions

A Custom waffle pack solution refers to a tailored packaging system designed to address unique requirements in wafer handling. Unlike standard off-the-shelf options, these solutions are engineered based on specific parameters, such as wafer size, material sensitivity, and environmental conditions. One of the key benefits is enhanced protection against mechanical stress and electrostatic discharge. For example, a Custom waffle pack solution might incorporate anti-static materials or shock-absorbing features to prevent wafer slippage or cracking during transit. This level of customization is particularly valuable in industries like aerospace or medical devices, where precision is non-negotiable.

Additionally, Custom waffle pack solution offerings can improve workflow efficiency. By designing boxes that integrate seamlessly with existing automation systems, companies can reduce manual handling and minimize the risk of human error. This is especially important in cleanroom environments, where contamination control is critical. Statistics show that customized packaging solutions can reduce wafer breakage rates by up to 30%, leading to significant cost savings over time. Furthermore, partnering with a reliable IC tray manufacturer for complementary components ensures that the entire handling system operates cohesively. For instance, a Custom waffle pack solution might be designed to work in tandem with IC trays that hold finished chips, creating a unified approach to component management. In essence, adopting a Custom waffle pack solution not only safeguards valuable wafers but also optimizes overall production efficiency.

The Role of IC Tray Manufacturers in the Semiconductor Ecosystem

IC tray manufacturer companies are vital players in the semiconductor industry, producing trays that secure integrated circuits (ICs) during various stages of manufacturing and distribution. These trays are often used in conjunction with wafer handling boxes to create a comprehensive handling system. For example, after wafers are diced into individual chips, they are placed into IC trays for testing, packaging, and shipping. A high-quality IC tray manufacturer ensures that these trays are made from materials that resist moisture, static, and physical impact, thereby protecting the delicate ICs from damage.

The collaboration between wafer handling boxes suppliers and IC tray manufacturer firms is essential for maintaining product integrity. Many IC tray manufacturer providers offer customized solutions that align with specific wafer handling boxes designs, enabling a smooth transition from wafer-level to chip-level handling. This synergy reduces the risk of misalignment or contamination during transfer processes. Moreover, as the industry moves toward smaller node sizes and more complex IC designs, the expertise of an IC tray manufacturer becomes increasingly important. They must innovate to keep pace with evolving standards, such as those for 5G or IoT devices, where precision handling is crucial. By understanding the interplay between wafer handling boxes and IC trays, companies can build a resilient supply chain that minimizes downtime and maximizes yield.

Common Problems with Wafer Handling Boxes and How to Address Them

Despite their importance, wafer handling boxes can present several challenges that impact manufacturing efficiency. Below, we outline some of the most common problems and practical solutions to mitigate them.

Contamination Issues: One of the top concerns with wafer handling boxes is the risk of particulate contamination, which can arise from dust, fibers, or residual chemicals. This is especially problematic in cleanrooms where even microscopic particles can cause defects. To address this, regular cleaning and maintenance of wafer handling boxes are essential. Using materials with low particle generation and implementing strict handling protocols can reduce contamination. Additionally, a Custom waffle pack solution can include built-in filtration or sealing mechanisms to further protect wafers.

Electrostatic Discharge (ESD): Wafer handling boxes made from non-conductive materials can accumulate static electricity, leading to ESD events that damage sensitive wafers. This is a frequent issue in dry environments. Solutions involve using anti-static materials or incorporating grounding features into the box design. Collaborating with an IC tray manufacturer that offers ESD-safe trays can also help create a consistent protective environment throughout the handling process.

Mechanical Damage: Wafers are fragile and prone to cracking or chipping if wafer handling boxes are not designed properly. Common causes include improper lid closure, rough handling, or inadequate cushioning. Implementing a Custom waffle pack solution with shock-absorbent liners and precision-fit compartments can minimize this risk. Training staff on correct handling techniques and using automated systems where possible are also effective strategies.

Incompatibility with Equipment: As semiconductor machinery evolves, wafer handling boxes must keep pace to ensure compatibility. Problems arise when boxes do not fit into new automation systems or processing tools. Working with suppliers who offer Custom waffle pack solution options can resolve this by tailoring designs to specific equipment specifications. Engaging with an IC tray manufacturer for integrated solutions can further enhance compatibility.

Cost and Supply Chain Delays: High-quality wafer handling boxes can be expensive, and supply chain disruptions may lead to shortages. To mitigate this, companies can diversify their supplier base, including partnerships with multiple IC tray manufacturer vendors. Investing in durable, reusable wafer handling boxes made from robust materials can also reduce long-term costs.

Regulatory Compliance: The semiconductor industry is subject to strict regulations, such as those from SEMI or ISO standards. Non-compliant wafer handling boxes can result in fines or rejected shipments. Ensuring that boxes meet relevant standards through regular audits and certifications is crucial. A Custom waffle pack solution can be designed to comply with specific regulatory requirements, providing peace of mind.

Temperature and Humidity Sensitivity: Wafer handling boxes may be exposed to varying environmental conditions during storage or shipping, which can affect wafer integrity. For instance, humidity can lead to oxidation, while extreme temperatures may cause material warping. Using boxes with climate-controlled features or desiccant packs can help. A Custom waffle pack solution might include thermal insulation or humidity indicators for better control.

By proactively addressing these issues, companies can enhance the reliability of their wafer handling boxes and improve overall production outcomes. Implementing a Custom waffle pack solution and collaborating with a trusted IC tray manufacturer are key steps in this process.

Best Practices for Maximizing the Lifespan of Wafer Handling Boxes

To get the most out of your wafer handling boxes, it's important to follow best practices that extend their usability and maintain performance. First, conduct regular inspections for signs of wear, such as cracks or discoloration, and replace boxes as needed. Cleaning should be done using approved methods to avoid introducing contaminants—for example, using ultrapure water and lint-free wipes in controlled environments. Storing wafer handling boxes in clean, dry areas away from direct sunlight can prevent material degradation.

Another key practice is to invest in a Custom waffle pack solution that aligns with your specific operational needs. This might include features like RFID tracking for inventory management or ergonomic designs for easier handling. Training personnel on proper usage, including how to load and unload wafers without causing stress, is also vital. Additionally, working closely with an IC tray manufacturer to ensure that trays and boxes are compatible can prevent issues during transfers. By adopting these strategies, you can reduce downtime and costs associated with wafer handling boxes, ultimately supporting a more efficient manufacturing process.

The future of wafer handling boxes is shaped by advancements in materials science, automation, and sustainability. For instance, the development of smart wafer handling boxes embedded with sensors for real-time monitoring of temperature, humidity, and shock is gaining traction. These innovations allow for proactive maintenance and reduce the risk of unexpected failures. Similarly, the rise of Custom waffle pack solution offerings is driving personalization, with companies leveraging 3D printing and AI to create boxes that adapt to specific wafer geometries.

Environmental concerns are also influencing the industry, leading to a push for recyclable and biodegradable materials in wafer handling boxes. Collaborations with IC tray manufacturer partners are essential here, as they can develop eco-friendly trays that complement these efforts. Moreover, as semiconductor nodes shrink to 3nm and below, the precision required in wafer handling boxes will increase, necessitating tighter tolerances and cleaner materials. By staying abreast of these trends, businesses can future-proof their operations and maintain a competitive edge.

In conclusion, wafer handling boxes are fundamental to the semiconductor industry, providing essential protection for wafers throughout their lifecycle. Embracing a Custom waffle pack solution can address unique challenges and enhance efficiency, while partnerships with a reliable IC tray manufacturer ensure a cohesive handling system. By understanding and mitigating common problems—such as contamination, ESD, and mechanical damage—companies can improve yield and reduce costs. As technology evolves, staying informed about trends and best practices will be key to leveraging wafer handling boxes effectively. We hope this article has provided valuable insights to help you optimize your wafer handling processes and achieve greater success in your operations.