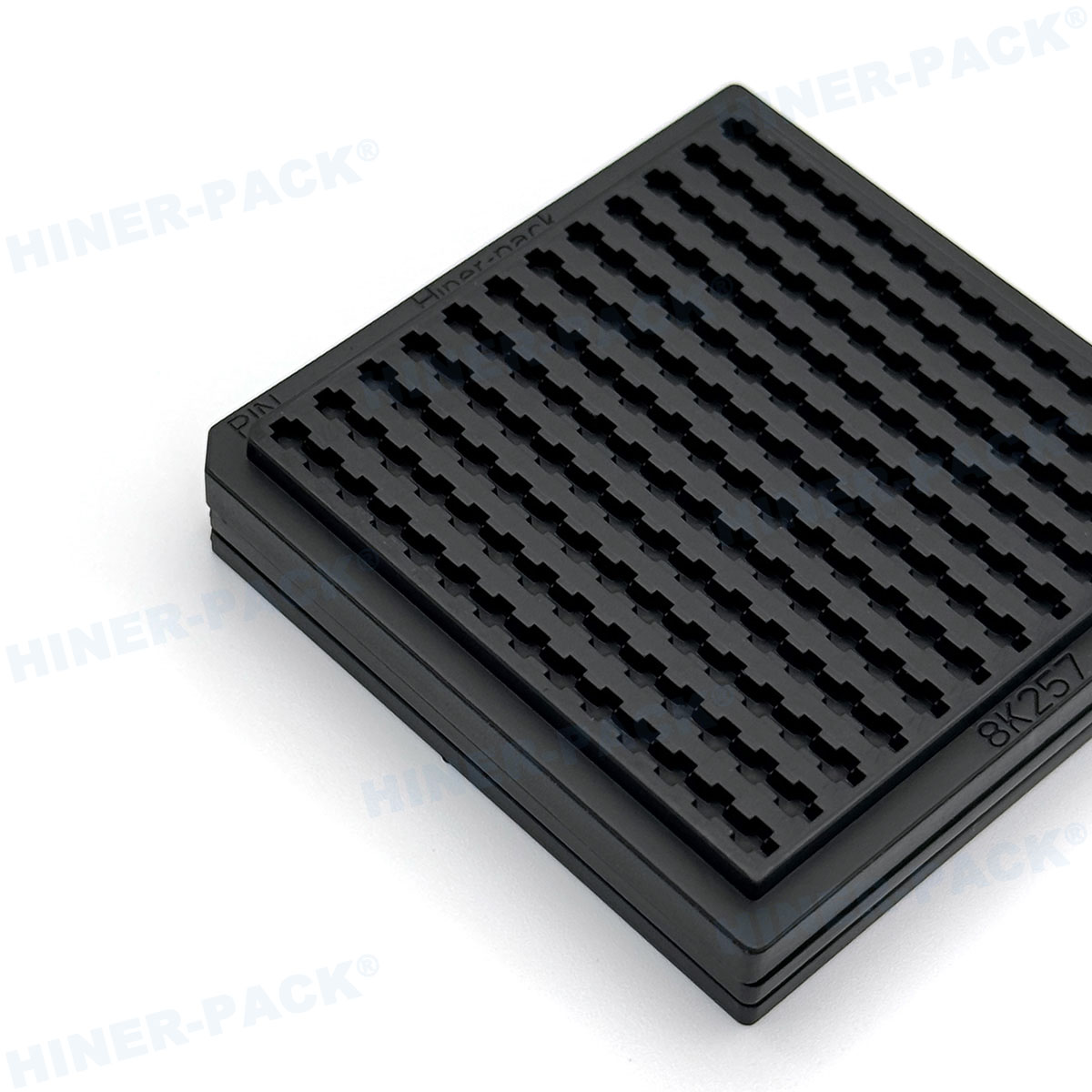

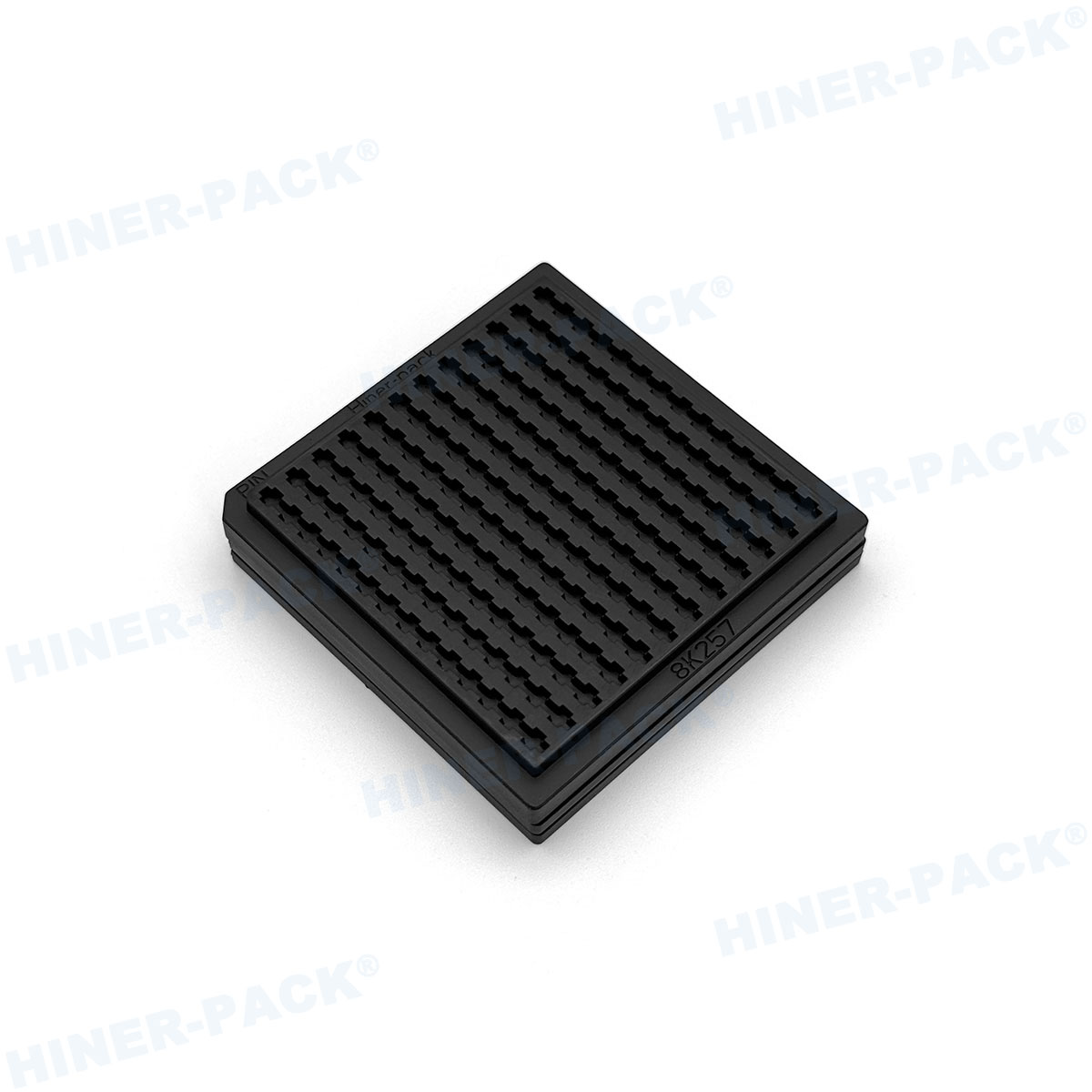

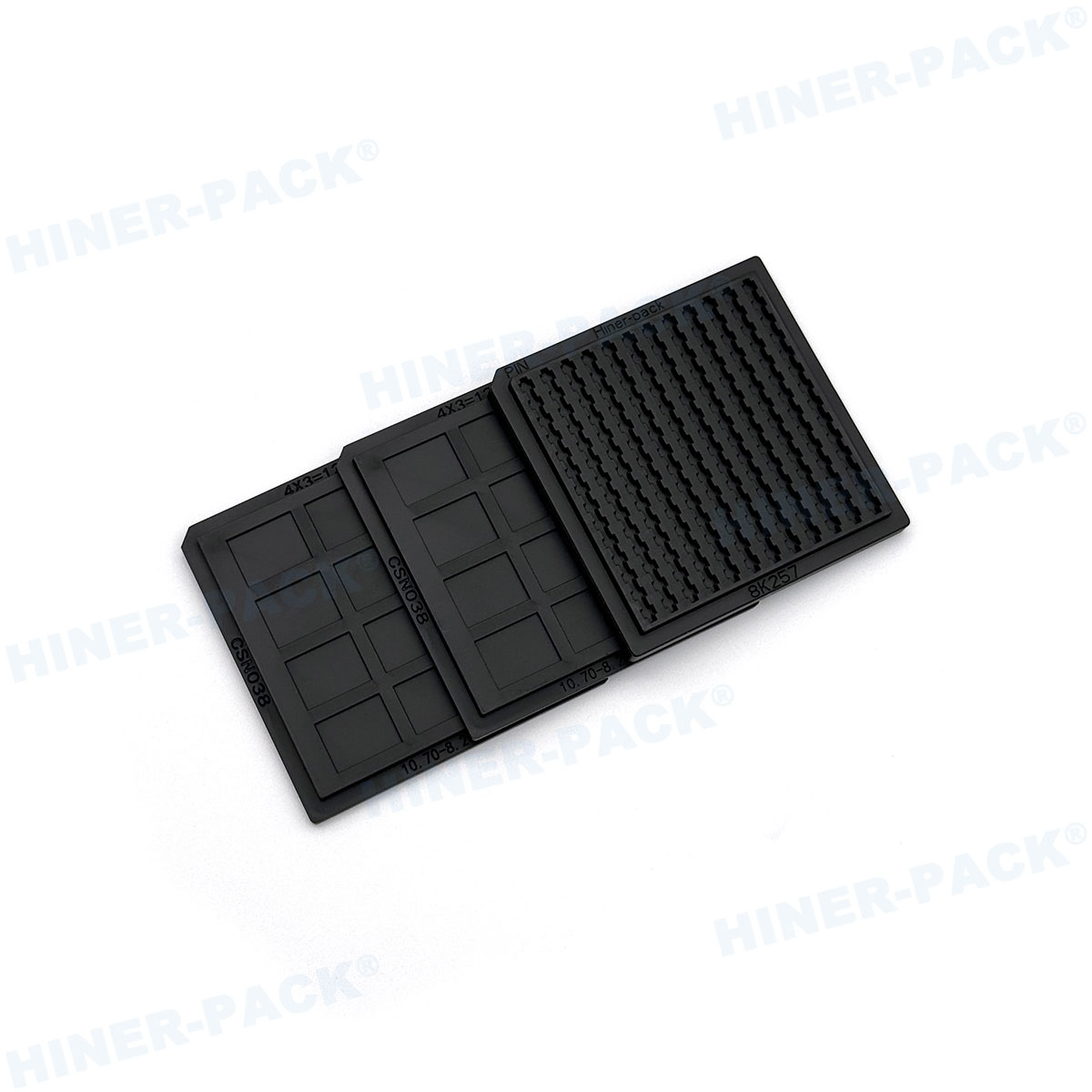

Why Waffle Pack Uses ABS Material (Acrylonitrile Butadiene Styrene)

Impact Resistance

ABS offers excellent toughness and impact resistance.

Waffle packs made with ABS can withstand mechanical shocks during shipping and handling without cracking.

Dimensional Stability

ABS maintains structural integrity under normal operating conditions.

Ensures pocket accuracy and tray flatness required for chip protection.

Good Processability

ABS is easy to mold into precise pocket designs.

This ensures compatibility with automated pick-and-place systems.

Cost-Effective Choice

Compared with engineering plastics like PC or PES, ABS provides a balance between performance and affordability.

Well-suited for high-volume chip packaging.

ESD-Compatibility

ABS can be compounded with conductive fillers or antistatic agents.

Surface resistivity can be controlled for safe chip handling.