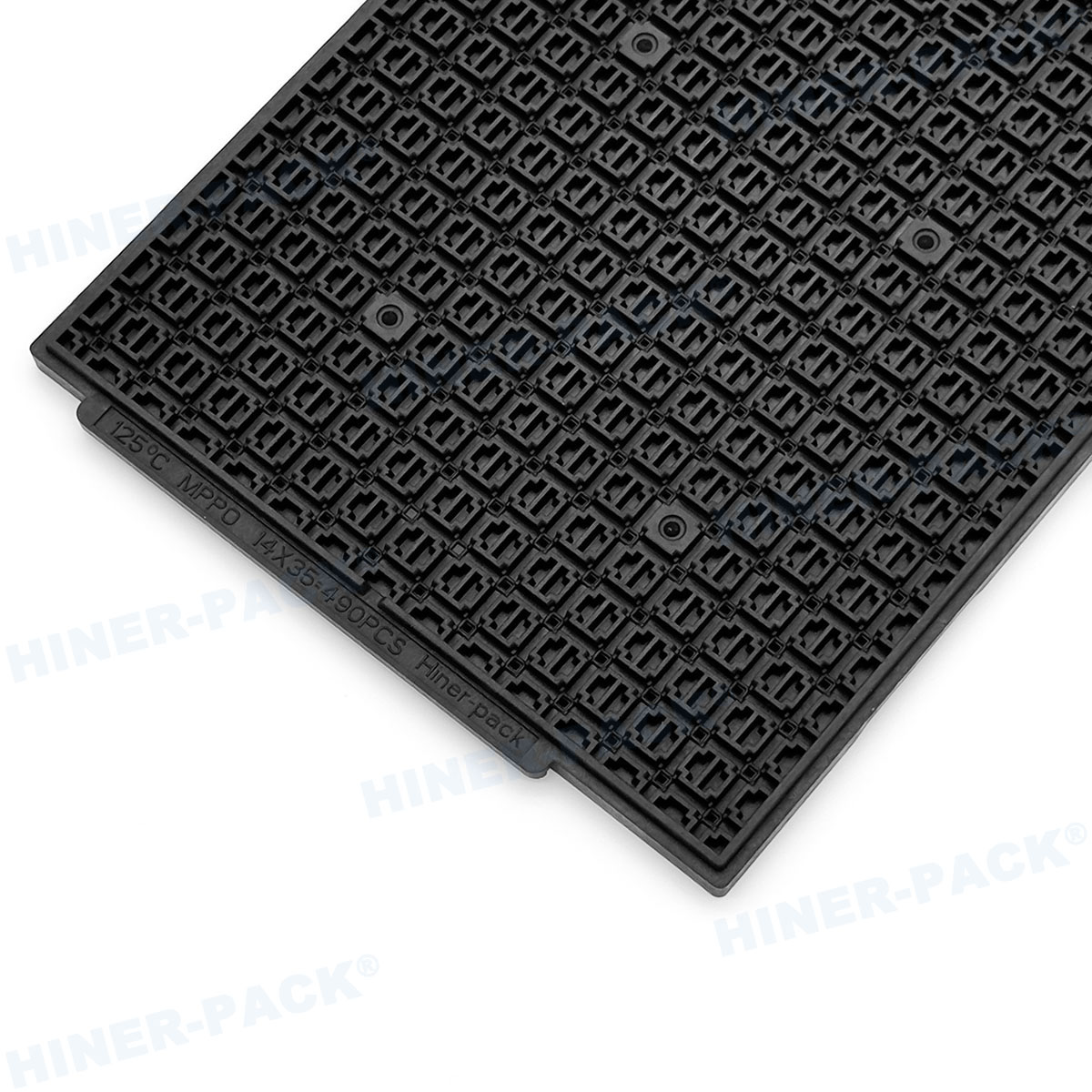

Why JEDEC trays use MPPO Material (Modified PPO)

High Heat Resistance

MPPO has a high glass transition temperature (BAKE/12H MAX 150 °C).

Trays can withstand reflow soldering and baking processes without warping.

Low Moisture Absorption

Water uptake is extremely low (<0.1%).

Ensures dimensional stability in humid environments (important for IC packaging and storage).

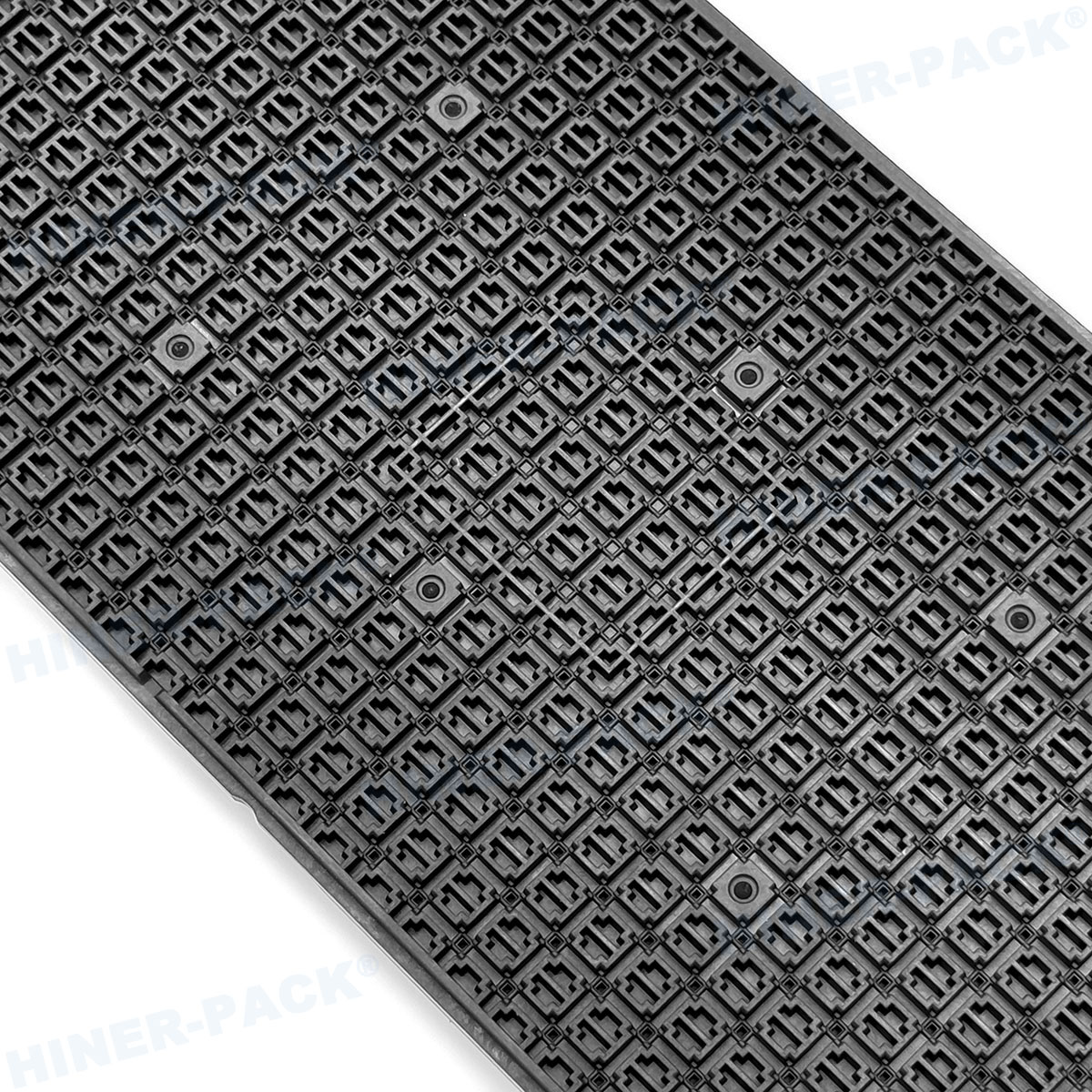

Excellent Dimensional Stability and Low Coefficient of Thermal Expansion (CTE)

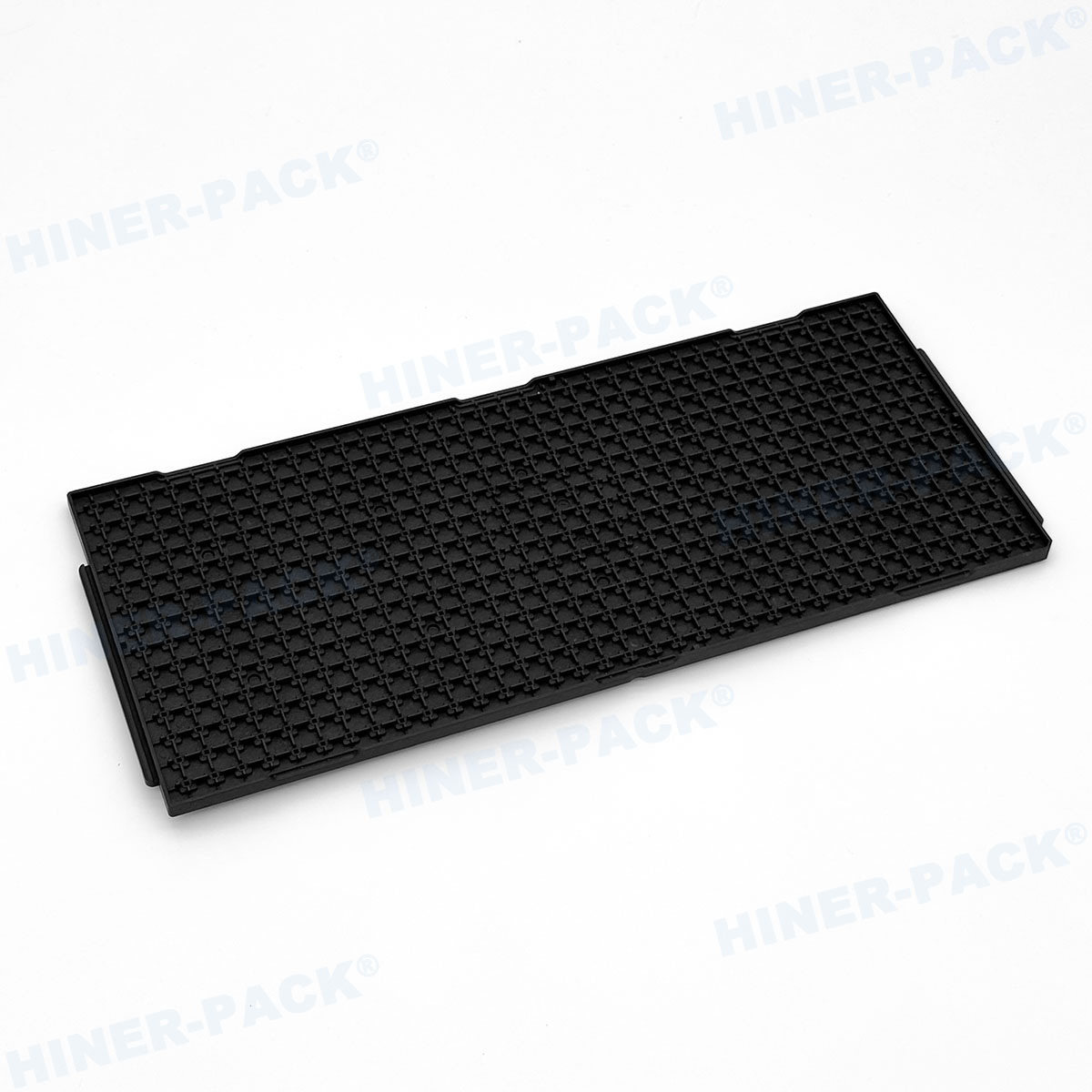

JEDEC trays need tight tolerances for cavity fit, stacking, and automated pick-and-place — MPPO provides that.

Good Mechanical Strength

Rigid but not brittle.

Withstands stacking pressure, robotic handling, and shipping vibration without cracking.

ESD Protection

Easily compounded with carbon fibers, carbon black, or antistatic agents.

Surface resistivity can be tuned from 10⁴–10¹¹ Ω/sq, which is the required range for safe IC handling.

Chemical Resistance

Resistant to fluxes, cleaning solvents, and chemicals used in semiconductor processing.

Extends the service life of trays.

Balanced Cost-Performance

Compared to exotic materials like PEEK, PES, or PI, MPPO offers a much lower cost while still meeting JEDEC’s thermal, ESD, and mechanical requirements.