- HOME

- ABOUT US

-

PRODUCTS

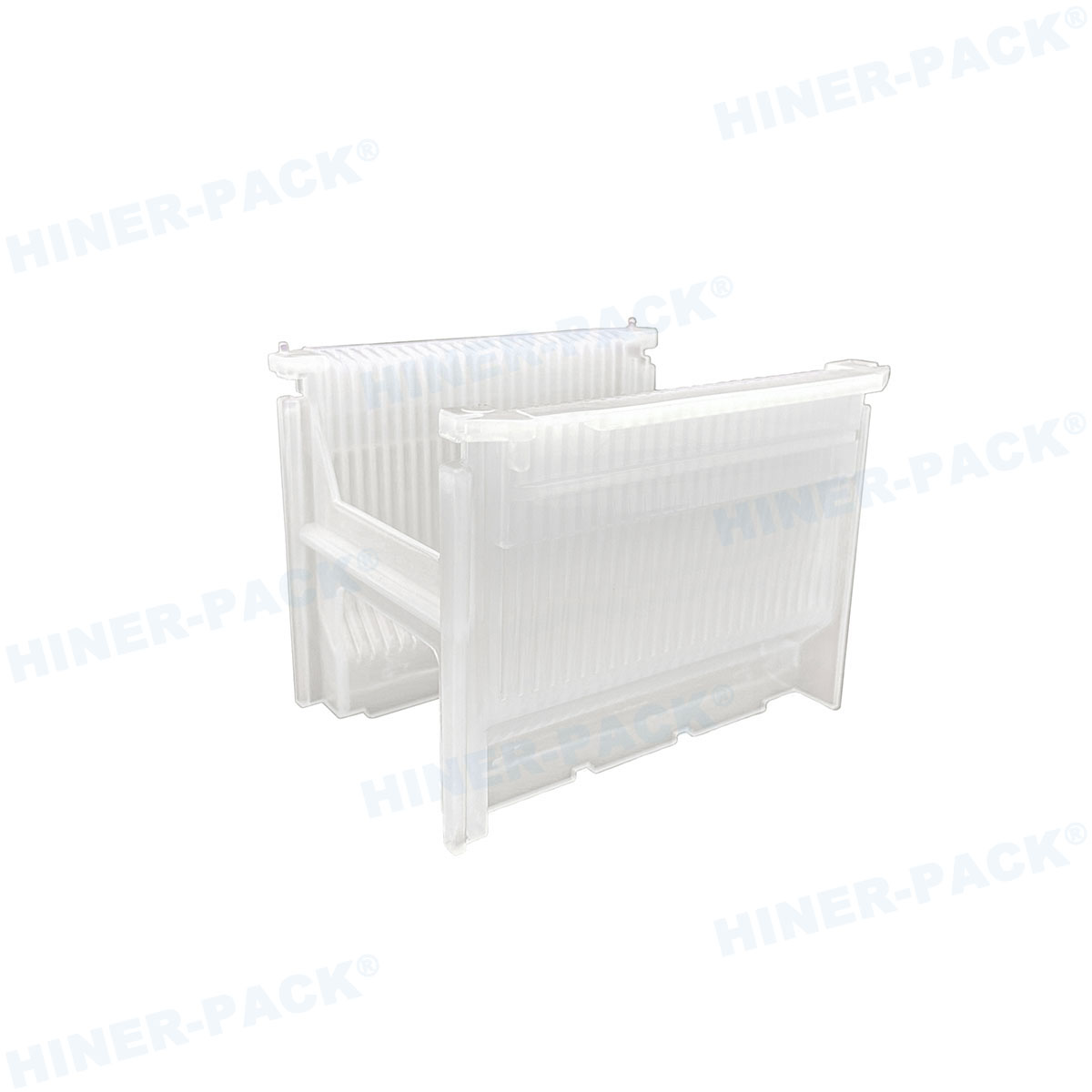

- Wafer Carrier Series

- Wafer Shipper Accessories

- JEDEC Tray/lC Tray

- Waffle Pack/Chip Tray

- Gel Box/Vacuum Release Box

- CASES

- NEWS

- DOWNLOADS

- CONTACT US

LANGUAGE