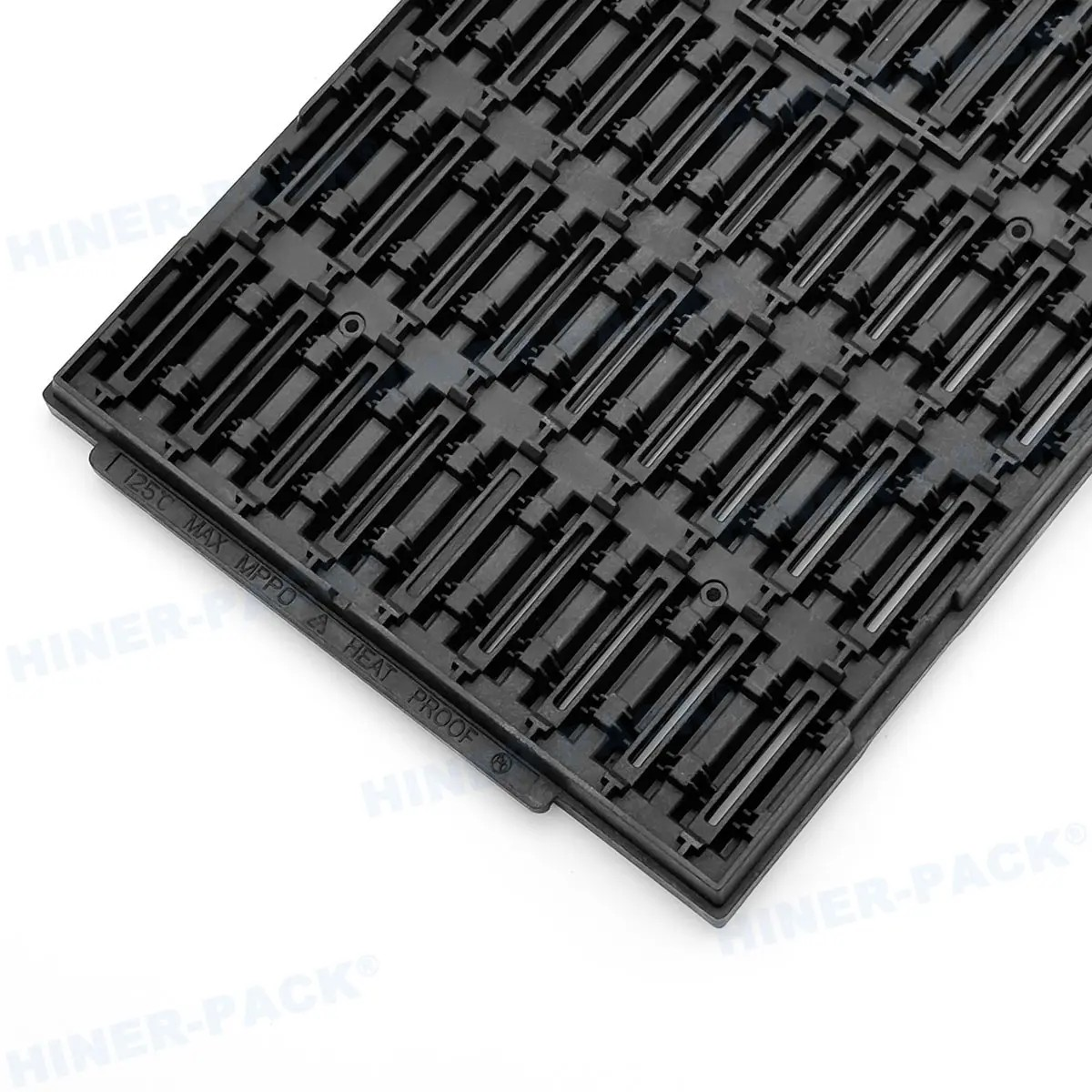

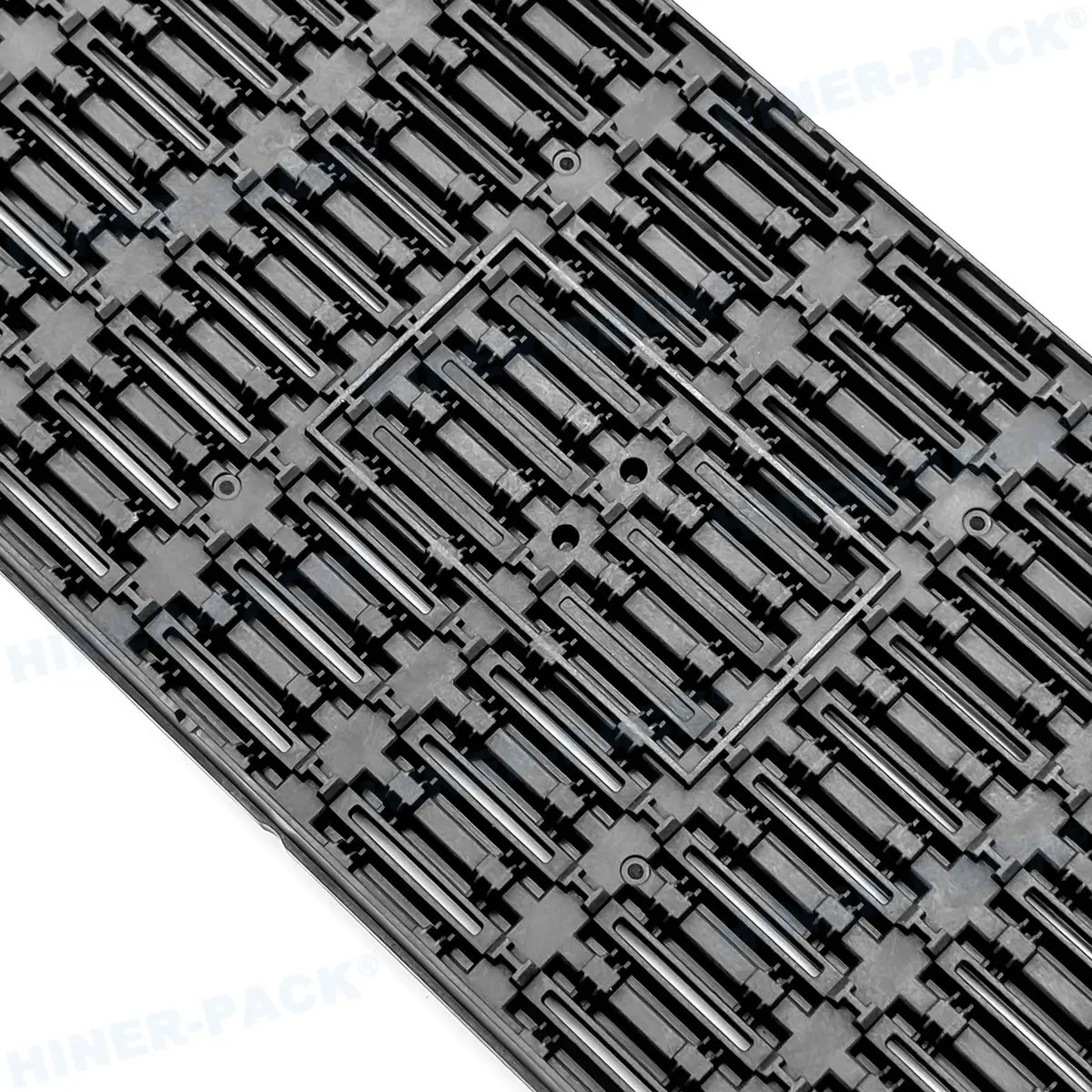

Reference Factors for Designing JEDEC TRAYs Compatible with DIP Packaging

Absolutely do not contact or compress the leads: Any positioning/supporting surface of the tray should support the chip body rather than the leads.

Maintain the integrity of lead shape and spacing: prevent bending, scratching, or plastic deformation.

Ensure compatibility with upstream and downstream equipment (picking and placing, vision, baking, sorting, testing) and meet ESD and cleanliness requirements.

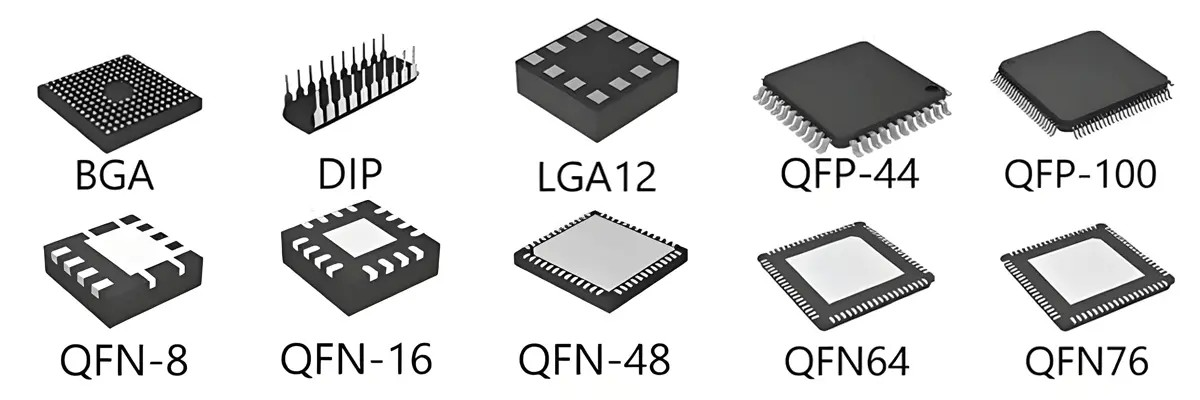

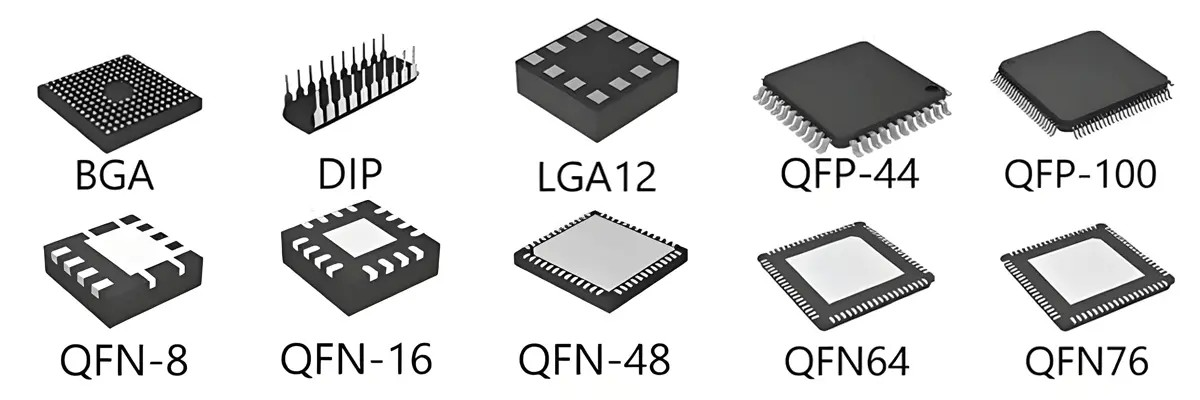

Dual In-line Package (DIP):

DIP is a long-standing through-hole package with leads extending vertically from both sides of the package in a double-row arrangement, needing to be inserted into chip sockets with a DIP structure or directly into PCB through-holes for soldering. It is suitable for through-hole soldering on PCBs, offering convenient operation, mature processing, and ease of maintenance and replacement.