In the semiconductor and electronics industries, the wafer canister plays a critical role in safeguarding delicate silicon wafers during storage, transport, and processing. These specialized containers are designed to protect wafers from contaminants, physical damage, and environmental factors, ensuring the integrity of microchips and other components. As global demand for electronics surges, understanding the nuances of wafer canister sourcing, including options like China wafer canister suppliers, wafer canister manufacturer capabilities, wafer canister price considerations, and Custom wafer canister solutions, becomes essential for businesses aiming to optimize their supply chains. This article delves into these key aspects, providing a comprehensive overview to help you make informed decisions. We'll explore the market dynamics, manufacturing processes, cost factors, and customization possibilities, while addressing common questions and challenges faced by industry professionals. By the end, you'll have a clear perspective on how to navigate the wafer canister landscape effectively.

What Is a Wafer Canister and Why Is It Important?

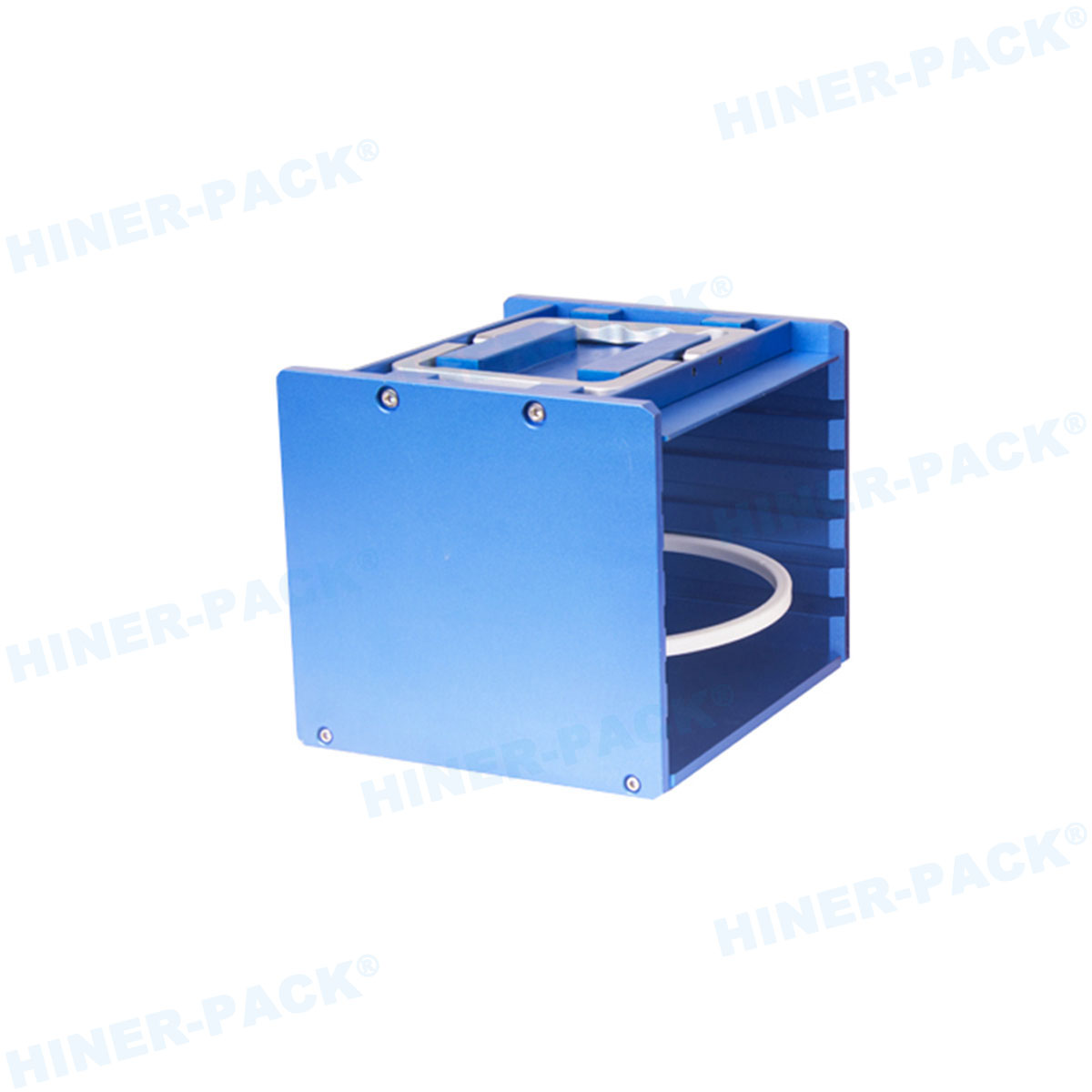

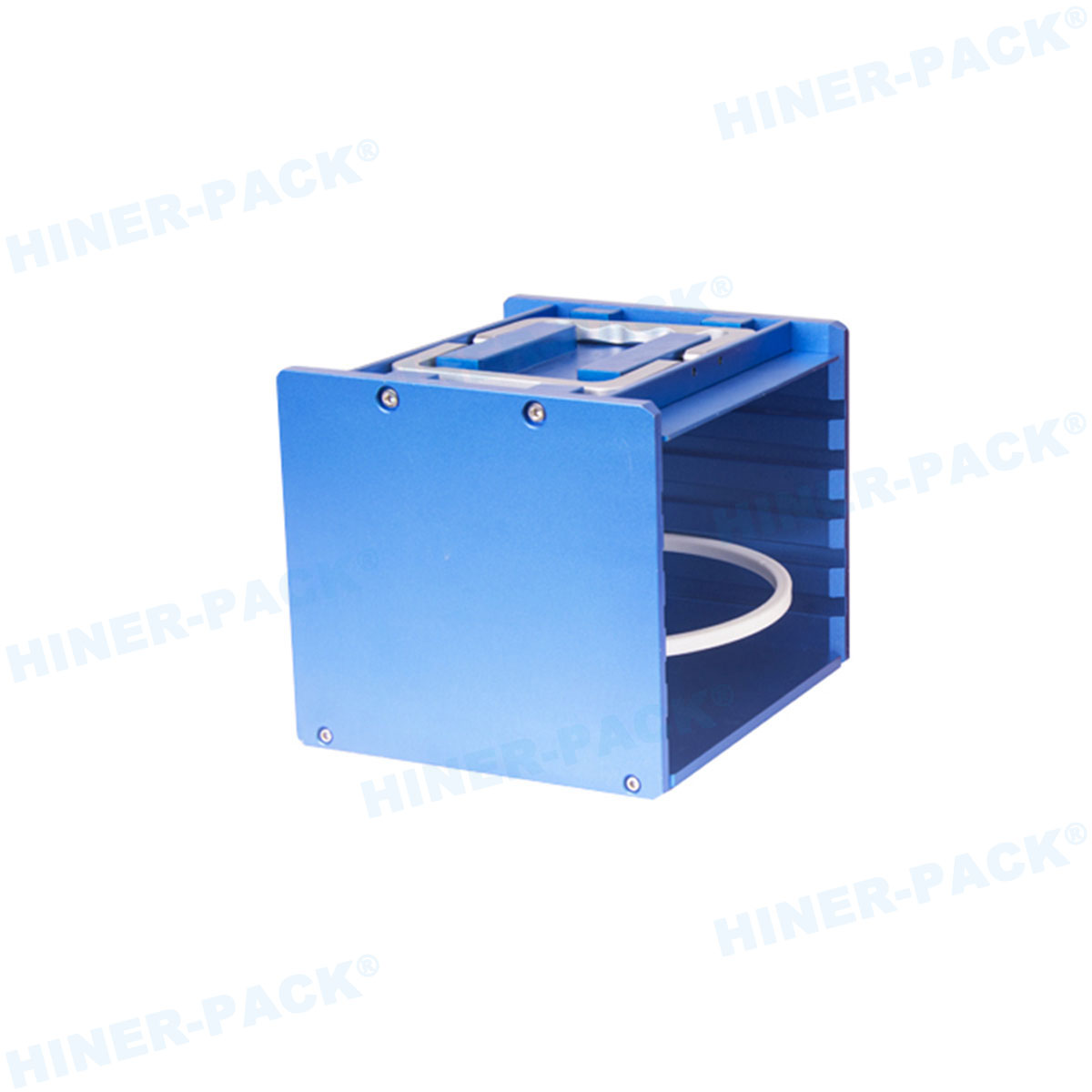

A wafer canister, often referred to as a wafer carrier or cassette, is a container specifically engineered to hold semiconductor wafers securely. Typically made from materials like polypropylene, polycarbonate, or other high-purity plastics, these canisters prevent static buildup, minimize particle generation, and maintain a clean environment. They are used in various stages of wafer production, from fabrication to assembly, and are crucial for maintaining yield rates in manufacturing. The design of a wafer canister includes features such as precision slots for wafer placement, handles for easy transport, and compatibility with automated systems. Without reliable wafer canisters, the risk of wafer damage or contamination could lead to significant financial losses and production delays. As industries like consumer electronics, automotive, and healthcare rely more on semiconductors, the importance of high-quality wafer canisters cannot be overstated. This foundational understanding sets the stage for exploring specific aspects like China wafer canister options and custom designs.

The Rise of China Wafer Canister in the Global Market

The China wafer canister market has experienced remarkable growth over the past decade, positioning the country as a dominant player in the global semiconductor supply chain. China's manufacturing prowess, coupled with cost-effective production capabilities, has made it a go-to destination for sourcing wafer canisters. Factors driving this trend include government investments in high-tech industries, the establishment of specialized industrial zones, and a robust network of suppliers. When considering a China wafer canister, businesses often benefit from competitive pricing and scalability. However, it's essential to evaluate quality standards, as not all suppliers adhere to international certifications like ISO Class cleanroom requirements. The China wafer canister sector is also evolving with advancements in material science, offering options that meet stringent industry norms. For companies looking to source from this region, due diligence in supplier vetting and quality assurance is crucial to avoid issues like inconsistent product quality or logistical delays. Overall, the China wafer canister market presents opportunities for cost savings and supply chain diversification, but it requires careful navigation to maximize benefits.

Choosing a Reliable Wafer Canister Manufacturer

Selecting a trustworthy wafer canister manufacturer is a pivotal decision that impacts product quality, lead times, and overall operational efficiency. A reputable wafer canister manufacturer typically offers a range of services, including design consultation, prototyping, and mass production. Key criteria to consider include the manufacturer's experience in the semiconductor industry, compliance with standards such as SEMI guidelines, and their ability to handle custom requirements. For instance, some manufacturers specialize in producing wafer canisters for specific wafer sizes, like 200mm or 300mm, while others focus on eco-friendly materials. When evaluating a wafer canister manufacturer, it's advisable to review their client testimonials, visit facilities if possible, and assess their quality control processes. Many businesses turn to a China wafer canister manufacturer for cost advantages, but it's important to ensure they have a track record of reliability. Additionally, a good manufacturer will provide support for issues like design modifications or rapid order fulfillment. By partnering with a skilled wafer canister manufacturer, companies can secure a steady supply of high-quality containers that align with their production needs.

Understanding Wafer Canister Price Factors

The wafer canister price is influenced by a variety of elements, making it essential for buyers to analyze cost drivers to budget effectively. Primary factors affecting wafer canister price include material type, production volume, customization level, and geographic sourcing. For example, canisters made from premium, static-dissipative plastics tend to be more expensive than standard models. Ordering in bulk often reduces the per-unit wafer canister price due to economies of scale, while small batches or rush orders may incur higher costs. Custom wafer canister designs, which require specialized tooling or unique features, also elevate the price. Sourcing from a China wafer canister supplier might offer lower prices due to reduced labor and overhead costs, but buyers should factor in shipping, tariffs, and potential quality checks. Additionally, market fluctuations in raw material costs, such as polymer resins, can cause wafer canister price variations. To get the best value, it's recommended to request quotes from multiple suppliers, compare specifications, and consider long-term partnerships that might include discounts. Understanding these dynamics helps in making cost-effective decisions without compromising on quality.

Benefits of Opting for a Custom Wafer Canister

A Custom wafer canister provides tailored solutions that address specific operational challenges, enhancing efficiency and product protection. Unlike standard off-the-shelf options, a Custom wafer canister can be designed to fit unique wafer sizes, accommodate specialized handling equipment, or incorporate features like RFID tracking or anti-static coatings. This level of personalization is particularly valuable in industries with stringent cleanliness requirements, such as aerospace or medical device manufacturing. When working with a wafer canister manufacturer on a Custom wafer canister project, businesses can specify materials, colors, and structural modifications to meet exact needs. For instance, a Custom wafer canister might include additional padding for fragile wafers or integrated sensors for environmental monitoring. Although the initial wafer canister price for custom orders may be higher, the long-term benefits—such as reduced breakage, improved workflow, and compliance with regulatory standards—often justify the investment. It's important to collaborate closely with manufacturers during the design phase to ensure feasibility and cost-effectiveness. By opting for a Custom wafer canister, companies can achieve a competitive edge through optimized storage and transport solutions.

Common Questions and Challenges with Wafer Canisters

When dealing with wafer canisters, businesses often encounter several common questions and challenges. Addressing these can help in avoiding pitfalls and maximizing the value of these containers.

What are the key quality standards for a wafer canister?

Industry standards like SEMI E1.9 for dimensional consistency and ISO Class cleanroom compliance are critical. Ensuring that a wafer canister manufacturer adheres to these can prevent contamination issues.

How does the China wafer canister market compare to other regions?

While China offers cost benefits, buyers should verify certifications and conduct audits to mitigate risks. Other regions might provide higher consistency but at a premium wafer canister price.

What factors affect the wafer canister price the most?

Material costs, customization, and order volume are major influencers. For a Custom wafer canister, tooling and design fees can add to the expense.

How can I ensure compatibility with existing systems?

Provide detailed specifications to your wafer canister manufacturer, including wafer size and automation interface requirements. Testing prototypes is advisable.

What are common maintenance issues?

Over time, wafer canisters may wear out, leading to particle generation or static buildup. Regular inspections and cleaning protocols can extend their lifespan.

Is sourcing a Custom wafer canister worth the investment?

For specialized applications, yes. It reduces waste and improves efficiency, though it requires upfront planning.

How do I handle logistics when ordering from a China wafer canister supplier?

Consider working with logistics partners experienced in semiconductor goods to manage shipping, customs, and delivery timelines.

By anticipating these questions, businesses can streamline their procurement process and avoid common setbacks.

In summary, the wafer canister is a vital component in the semiconductor ecosystem, with its sourcing and selection involving multiple considerations. From the expanding China wafer canister market to the expertise of a reliable wafer canister manufacturer, and from analyzing the wafer canister price to exploring Custom wafer canister options, each aspect requires careful evaluation. By understanding these elements and addressing common challenges, companies can enhance their supply chain resilience and product quality. As technology evolves, staying informed about trends like sustainable materials or smart canisters will be key. Whether you're a startup or an established firm, leveraging this knowledge will help you make strategic decisions that align with your operational goals. Remember, investing time in research and partnerships today can lead to significant long-term benefits in the competitive world of semiconductor manufacturing.