In the highly precise and sensitive semiconductor industry, the safe handling and transportation of silicon wafers are paramount. Any contamination, physical damage, or environmental exposure can lead to significant financial losses and production delays. This is where the wafer transport box plays a critical role. Designed to protect these delicate substrates during storage, transit, and between process tools, a high-quality wafer transport box is not just a container but a vital component of the manufacturing ecosystem. For engineers, procurement managers, and facility operators, selecting the right box involves understanding its design, the credibility of the wafer transport box manufacturer, the conditions inside a wafer transport box factory, where to find a wafer transport box for sale, the factors affecting wafer transport box price, and the advantages of opting for a China wafer transport box. This article provides a detailed, practical approach to navigating these aspects, helping you make an informed decision that ensures operational efficiency and cost-effectiveness. We will also highlight Hiner-pack, a renowned brand known for its reliability in this niche.

What is a Wafer Transport Box and Why is it Crucial?

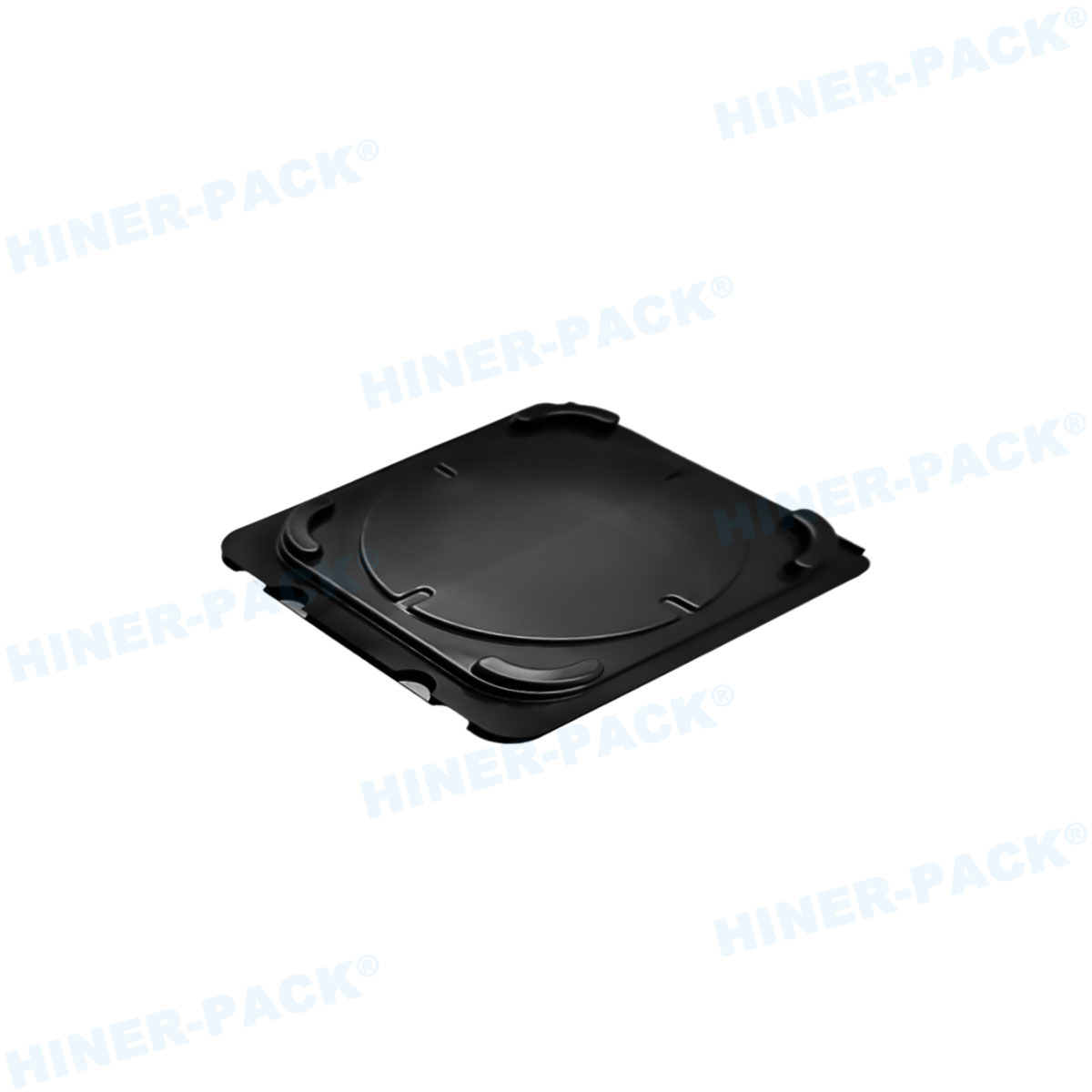

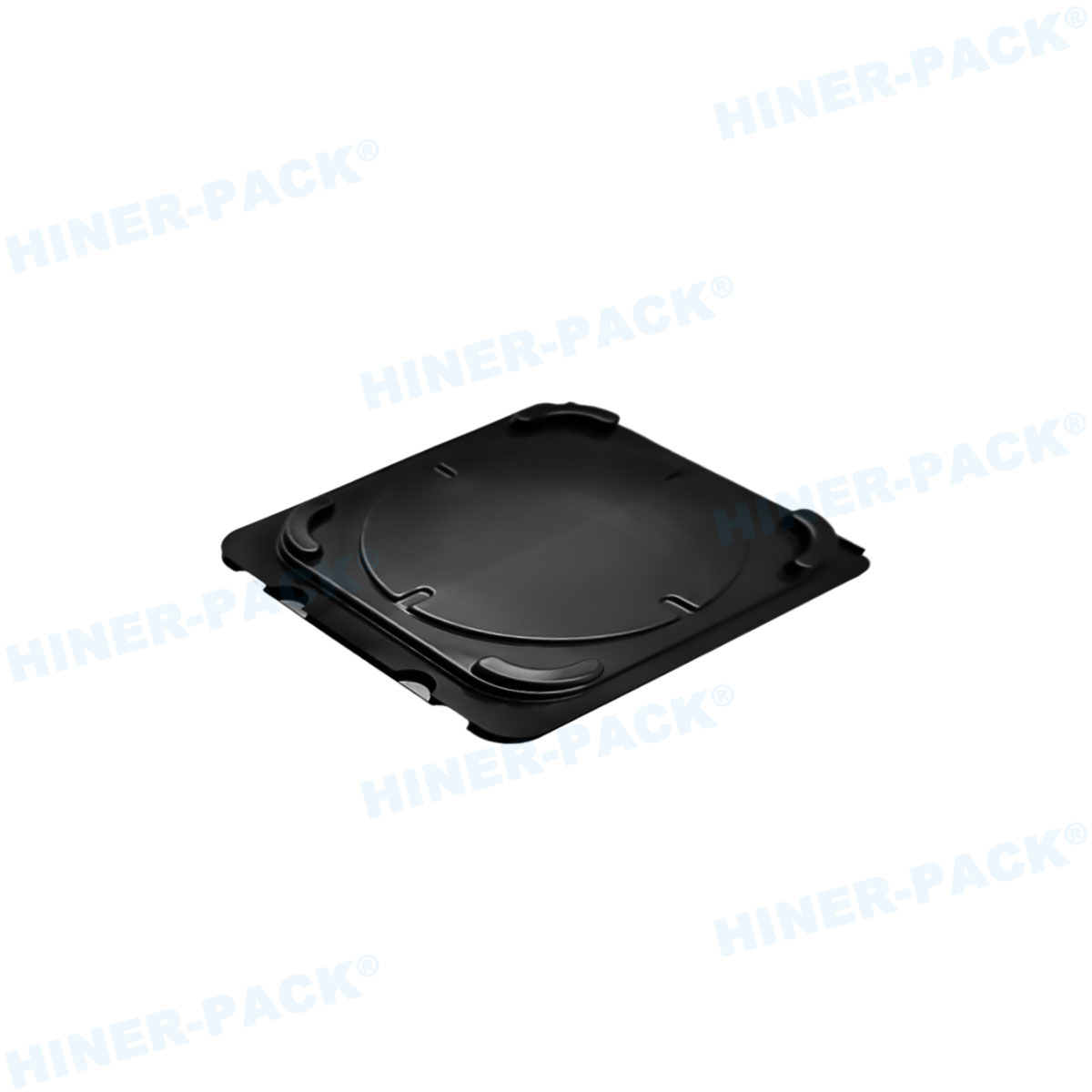

A wafer transport box, also known as a wafer carrier or FOUP (Front Opening Unified Pod), is a specialized container used to house and transport silicon wafers in semiconductor fabrication plants (fabs). These boxes are engineered to provide a controlled microenvironment, shielding wafers from particulate contamination, moisture, static electricity, and mechanical shocks. Typically made from high-purity materials like polycarbonate or PEEK (polyether ether ketone), they feature precise slots to hold wafers securely without contact, ensuring integrity during movement. The importance of a wafer transport box cannot be overstated; it directly impacts yield rates and product quality. In modern fabs, where wafers undergo hundreds of process steps, a single defect caused by inadequate packaging can cascade into millions in losses. Thus, investing in a robust wafer transport box is a strategic necessity for any semiconductor operation.

Key Features to Evaluate in a Wafer Transport Box

When selecting a wafer transport box, several features demand attention to ensure optimal performance. First, material compatibility is essential—the box must be made from low-outgassing, static-dissipative plastics to prevent chemical contamination and electrostatic discharge. Second, design aspects such as latch mechanisms, sealing gaskets, and handling ergonomics affect usability and contamination control. For instance, a well-designed latch ensures easy opening and closing without particle generation. Third, capacity and wafer size compatibility (e.g., 200mm, 300mm, or 450mm wafers) must align with your production needs. Additionally, look for boxes with RFID integration for tracking and automation compatibility. A reliable wafer transport box manufacturer will provide detailed specifications and certifications, such as SEMI standards, guaranteeing compliance with industry norms. By focusing on these features, you can minimize risks and enhance throughput in your fab.

The Role of a Wafer Transport Box Manufacturer in Quality Assurance

Choosing a reputable wafer transport box manufacturer is as important as the box itself. A trusted manufacturer invests in research and development to innovate designs that meet evolving industry demands, such as higher wafer counts or enhanced cleanroom compatibility. They adhere to strict quality control protocols, including particle counting tests, mechanical durability assessments, and environmental simulation. For example, a leading wafer transport box manufacturer like Hiner-pack employs ISO 9001 and cleanroom assembly processes to ensure each unit meets high purity standards. Moreover, manufacturers often offer customization options, allowing you to tailor boxes for specific applications, such as extreme temperature resistance or unique wafer geometries. By partnering with an established wafer transport box manufacturer, you gain access to technical support, warranty services, and consistent supply chains, which are vital for maintaining uninterrupted production.

Inside a Wafer Transport Box Factory: Production and Standards

A visit to a wafer transport box factory reveals the meticulous processes behind these critical components. Typically, production begins with raw material selection—high-grade polymers that are tested for purity and mechanical properties. Injection molding is commonly used to form the box bodies, followed by precision machining to create wafer slots and interfaces. In a state-of-the-art wafer transport box factory, cleanrooms of Class 100 or better are maintained to prevent contamination during assembly. Workers wear full bunny suits, and automated systems handle parts to minimize human contact. Quality checks at every stage, including visual inspections, dimensional verifications, and functional tests, ensure that each wafer transport box meets SEMI standards. For instance, Hiner-pack's factories in China integrate advanced robotics and real-time monitoring to achieve high throughput without compromising quality. Understanding these processes can help you appreciate the value of a well-run wafer transport box factory and its impact on product reliability.

Where to Find Wafer Transport Box for Sale

Finding a wafer transport box for sale involves exploring various channels, each with its pros and cons. Direct purchases from manufacturers are often the most reliable, as they offer genuine products, technical guidance, and bulk discounts. Many wafer transport box manufacturer entities, including Hiner-pack, have online catalogs and sales teams for direct inquiries. Alternatively, distributors and B2B platforms like Alibaba or Thomasnet list multiple wafer transport box for sale options, providing a range of brands and prices. Trade shows and industry expos are also excellent venues to see products firsthand and negotiate deals. When searching for a wafer transport box for sale, prioritize suppliers with proven track records and positive customer feedback to avoid counterfeit or substandard items. For those considering a China wafer transport box, e-commerce portals often feature competitive listings, but due diligence on supplier credentials is crucial.

Factors Influencing Wafer Transport Box Price

The wafer transport box price can vary significantly based on several factors. Material costs are a primary driver—premium polymers and additives for static control or UV resistance increase the wafer transport box price. Design complexity, such as integrated sensors or custom dimensions, also adds to the cost. Volume orders typically reduce the per-unit wafer transport box price due to economies of scale. Additionally, brand reputation and certifications can command higher prices; for example, boxes from established manufacturers like Hiner-pack may cost more but offer better longevity and support. Geographic factors play a role too; a China wafer transport box often comes at a lower wafer transport box price due to competitive manufacturing landscapes, but shipping and import duties should be factored in. On average, prices range from $50 to $500 per box, depending on specifications. By analyzing these elements, you can budget effectively and avoid overpaying for unnecessary features.

Advantages of Sourcing from China Wafer Transport Box Suppliers

Opting for a China wafer transport box presents numerous benefits, especially in terms of cost and scalability. China has emerged as a global hub for semiconductor accessories, with a robust ecosystem of wafer transport box manufacturer facilities equipped with advanced technology. The wafer transport box price from Chinese suppliers is often more competitive due to lower labor and production costs, without sacrificing quality. Many China wafer transport box producers adhere to international standards and export to major markets worldwide. For instance, Hiner-pack, based in China, combines affordable pricing with high-performance products, making it a popular choice. Moreover, China's logistics infrastructure enables efficient shipping, and suppliers often offer flexible MOQs (Minimum Order Quantities). However, it's essential to verify certifications and conduct factory audits to ensure compliance. By leveraging a China wafer transport box, you can achieve significant savings while maintaining reliability.

Spotlight on Hiner-pack: A Trusted Name in Wafer Transport Boxes

Hiner-pack has built a strong reputation as a leading wafer transport box manufacturer, known for its commitment to quality and innovation. Specializing in high-purity containers for the semiconductor industry, Hiner-pack offers a diverse portfolio of wafer transport box solutions tailored to various wafer sizes and fab requirements. Their products feature advanced materials, ergonomic designs, and compatibility with automation systems, ensuring seamless integration into production lines. The company's wafer transport box factory in China operates under stringent cleanroom conditions, with rigorous testing for particle counts and mechanical strength. Customers appreciate Hiner-pack's competitive wafer transport box price, responsive customer service, and ability to handle custom orders. Whether you need standard carriers or specialized versions for harsh environments, Hiner-pack provides reliable options that align with industry benchmarks. By choosing Hiner-pack, you invest in a partner dedicated to safeguarding your wafer investments.

Frequently Asked Questions About Wafer Transport Boxes

Q1: What is the typical lifespan of a wafer transport box, and how can I extend it?

A1: The lifespan of a wafer transport box depends on usage frequency, handling practices, and environmental conditions. High-quality boxes from reputable manufacturers like Hiner-pack can last 3-5 years or more with proper care. To extend longevity, avoid dropping or impacting the box, clean it regularly in a controlled environment using approved solvents, and store it in a dry, particle-free area. Regular inspections for cracks or wear can also help identify issues early.

Q2: How do I verify the credibility of a wafer transport box manufacturer before purchasing?

A2: To verify a wafer transport box manufacturer, check for industry certifications such as ISO 9001, SEMI compliance, and cleanroom ratings. Review their customer testimonials, case studies, and history in the market. It's also advisable to request samples for testing or conduct a factory audit to assess production processes. Manufacturers like Hiner-pack often provide transparency through detailed documentation and third-party validations.

Q3: Where can I find a reliable wafer transport box for sale online?

A3: You can find a wafer transport box for sale on B2B platforms like Alibaba, Made-in-China, or industry-specific sites such as Thomasnet. Ensure the seller is authorized or has direct ties to manufacturers. For assurance, purchase from the manufacturer's official website or trusted distributors. Always check return policies and warranty terms to protect your investment.

Q4: What are the main factors that cause variations in wafer transport box price?

A4: The wafer transport box price varies due to material quality (e.g., premium plastics vs. standard grades), design features (e.g., RFID integration or custom slots), order volume, and brand reputation. Additional costs may include shipping, taxes, and certification fees. For a China wafer transport box, currency exchange rates and logistics can also influence the final price.

Q5: Why are China wafer transport box suppliers considered cost-effective, and how do I ensure quality?

A5: China wafer transport box suppliers are cost-effective due to economies of scale, efficient manufacturing processes, and competitive labor markets. To ensure quality, select suppliers with proven export experience, request product samples for evaluation, and verify compliance with international standards like SEMI. Partnering with established brands like Hiner-pack can provide a balance of affordability and reliability, backed by quality assurances.

In conclusion, selecting the right wafer transport box involves a holistic approach that considers design, manufacturer credibility, production standards, purchasing channels, pricing, and geographic sourcing. By applying the insights shared here, you can optimize your choices for enhanced semiconductor operations. Whether you're evaluating a wafer transport box for sale or assessing a China wafer transport box option, remember that quality and suitability should always precede cost. With brands like Hiner-pack leading the way, the industry has access to solutions that combine innovation with practicality.