Storing and shipping wafer cassettes seems straightforward. You need a clean, sturdy container. But the reality inside a busy fab or OSAT facility is far more complex. WIP piles up, space is at a premium, and every handling step introduces contamination risk.

This is where the conventional rigid shipper often falls short. It’s bulky, space-inefficient, and can be a hassle in dynamic environments. A smarter solution has emerged as a workhorse: the single flex frame shipper.

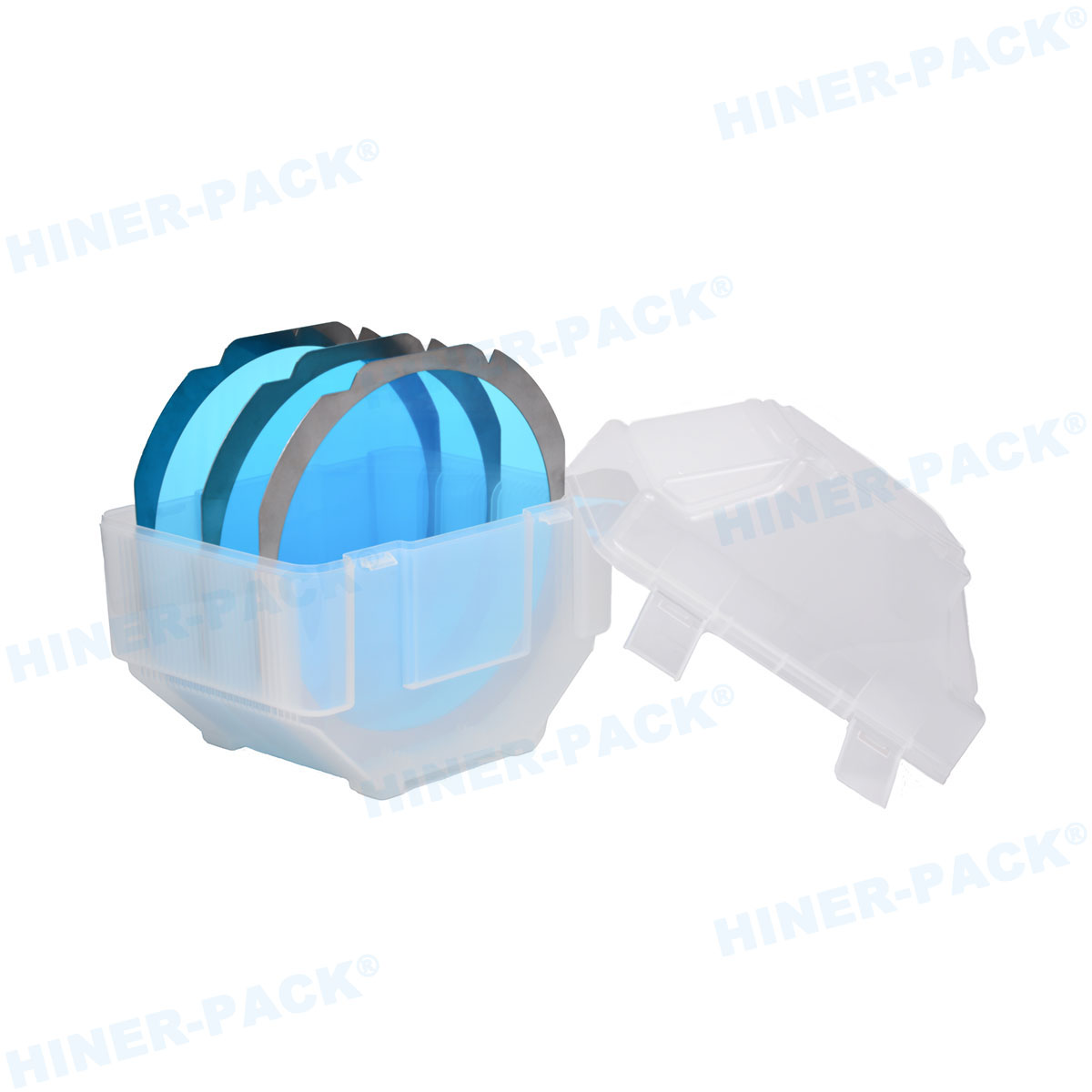

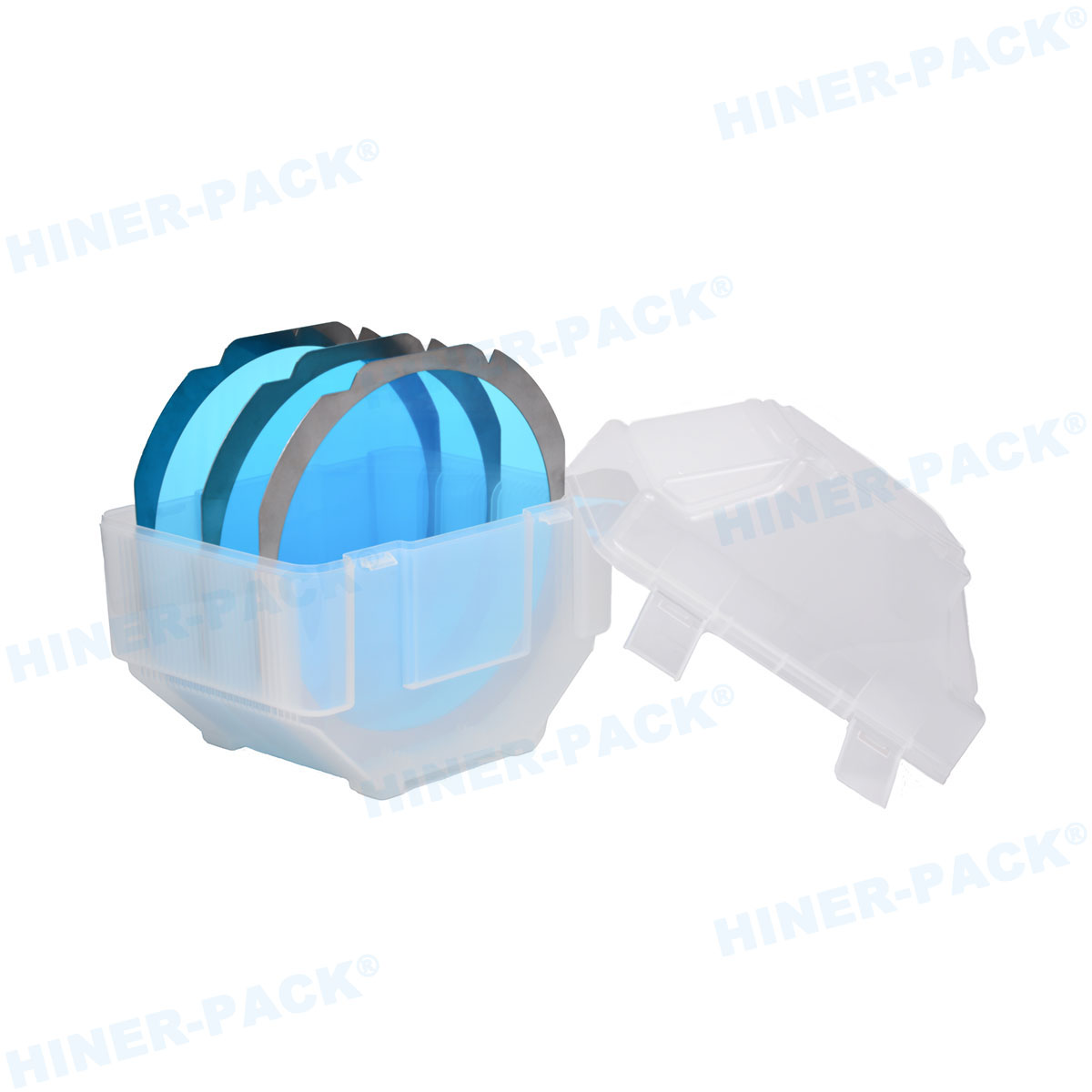

What exactly is it? At its core, a single flex frame shipper is a cleanroom-compatible storage and transport container designed with a collapsible or foldable internal frame. It typically holds one standard wafer cassette or FOSB (Front Opening Shipping Box). When empty, the frame folds down, slashing its storage footprint by up to 80% compared to a rigid box.

The Core Problem with Traditional Rigid Carriers

Traditional shippers are like empty suitcases. They take up the same amount of valuable cleanroom or warehouse space whether they are full or empty. This leads to:

Cluttered workstations and storage areas.

Higher logistics costs for returning empty containers.

Inefficient use of costly cleanroom real estate.

Increased inventory management complexity.

The single flex frame shipper directly addresses this waste. It is built for efficiency in high-volume, flow-critical semiconductor operations.

Head-to-Head: Single Flex Frame Shipper vs. Standard Rigid Container

Let’s break down the practical differences on the fab floor.

Storage Efficiency (Empty State): This is the biggest win. A rigid container remains full-size. A collapsed single flex frame shipper reduces to a fraction of its height, allowing dozens to be stored in the space of a few rigid ones.

Cleanliness & Particle Control: Both must meet high standards. However, the design of a quality single flex frame shipper minimizes moving parts that could generate particles. Look for models with smooth folding actions and no metal-on-metal contact.

Durability & Cassette Protection: Rigid shippers feel strong. Modern single flex frame designs, however, use engineered polymers that provide excellent crush resistance when locked in the "use" position, while offering flexibility for collapsing.

Ergonomics & Handling: A stack of collapsed frames is light and easy to move. Setting one up is typically a quick, one-motion task. This speeds up packing operations and reduces operator fatigue.

Key Applications: Where the Single Flex Frame Shipper Excels

This isn't a niche product. It solves real problems in specific scenarios:

High-Volume Internal WIP Transport: Moving cassettes between lithography, etch, and deposition bays within a large fab.

OSAT and Test Operations: Where thousands of units flow daily, and efficient empty container management is crucial for throughput.

Limited Space Cleanrooms: Older fabs or R&D labs where every square meter is precious.

Return Logistics: Shipping empty containers back to the source (e.g., from customer fab to supplier) at a dramatically lower cost due to reduced volume.

The 5 Tangible Advantages for Your Bottom Line

Adopting a single flex frame shipper system delivers measurable benefits:

Radical Space Savings: Free up cleanroom benches and storage cabinets. This can delay or eliminate the need for costly facility expansions.

Reduced Logistics Costs: Shipping and storing empties becomes 3-4 times more efficient. This cuts freight bills and carbon footprint.

Improved Workflow and 5S: A cleaner, more organized workspace reduces handling errors and supports lean manufacturing principles.

Lower Total Cost of Ownership (TCO): While unit cost may be comparable, the operational savings in space, logistics, and efficiency make the TCO superior.

Scalability: Easily scale your container fleet up or down without drowning in empty rigid boxes.

Understanding Cost: Investment vs. Operational Savings

The initial purchase price of a single flex frame shipper is often comparable to a quality rigid counterpart. The financial analysis shouldn't stop there.

Calculate the "cost of space" in your cleanroom per square meter. Factor in the annual freight cost for sending thousands of empty rigid boxes across the globe. The payback period for switching to a collapsible system is often surprisingly short. The savings are operational and recurring.

Technology and Design: What Makes a Reliable Frame?

Not all flex frames are equal. Key engineering considerations include:

Hinge Design: The most critical component. It must withstand thousands of flex cycles without fatigue, wobble, or particle generation. Over-molded or composite hinges are common in high-end models.

Material Selection: Must be static-dissipative, low-outgassing, and chemically resistant to standard cleanroom cleaners. The polymer blend needs the right balance of stiffness for protection and flexibility for collapse.

Locking Mechanism: A positive, audible lock in the operational state is non-negotiable for safety. It must be glove-friendly and foolproof.

Sealing: While not always a hermetically sealed gasket, the design should minimize gaps to prevent large particle ingress during transport.

Suppliers who master these details, like Hiner-pack, focus on cycle life and contamination control, ensuring the shipper lasts for years without compromising wafer safety.

Choosing a Supplier: More Than Just a Box Vendor

Your supplier should be a partner in optimizing your material flow. Ask these questions:

Can you provide lifecycle test data? (e.g., hinge cycle reports).

Do you offer compatibility validation with our specific cassette/FOSB models?

What is your consistency in molding to ensure every unit performs identically?

Can you support with racking or cart systems designed for collapsed frames?

A good vendor understands the application and will ask about your pain points with your current process.

Conclusion: Embracing Efficiency in Wafer Logistics

The single flex frame shipper represents a pragmatic evolution in wafer handling. It replaces the static, wasteful model of the past with a dynamic, efficient solution. It tackles the often-overlooked costs of emptiness—wasted space and wasted transport.

For fabs and OSATs focused on lean operations and cost containment, it’s a strategic upgrade. It’s a simple idea with a profound impact: work smarter with the space you have. As wafer logistics grow more complex, tools that offer innate efficiency, like those developed by Hiner-pack, become essential components of a competitive manufacturing flow.

Frequently Asked Questions (FAQ)

Q1: What is a single flex frame shipper primarily used for?

A1: It is primarily used for the internal cleanroom transport and short-term storage of a single wafer cassette or FOSB. Its standout feature is the collapsible frame, which saves enormous space when the container is empty, making it ideal for high-volume workflows.

Q2: How does a single flex frame shipper protect wafers compared to a standard box?

A2: When locked in the upright position, a well-designed frame provides secure, suspended support for the cassette, protecting against shock and vibration. The main difference isn't protection in use—it's efficiency when not in use. Both types must meet stringent cleanliness standards for particle generation.

Q3: Are these shippers compatible with all wafer cassette types?

A3: They are typically designed to fit industry-standard cassettes for 150mm, 200mm, and 300mm wafers. However, it is crucial to verify compatibility with your specific cassette model (e.g., specific FOSB brand) as latch locations and dimensions can have slight variances. Suppliers like Hiner-pack often offer test samples for validation.

Q4: Is the cost savings mostly from purchasing or from operations?

A4: The most significant savings are operational, not in unit purchase price. The major financial benefits come from reduced storage space requirements (freeing up expensive cleanroom area) and dramatically lower shipping costs for empty container returns.

Q5: Can these frames be automated? Are they SMIF-compatible?

A5: Standard single flex frame shippers are generally manual handling tools for operator transport. They are not typically designed for direct integration with SMIF (Standard Mechanical Interface) pod loaders on tools. For automated tool loading, dedicated FOUPs and rigid SMIF pods are used. The flex frame is for the transport steps in between.