In semiconductor manufacturing, even the smallest component can have an outsized impact on yield and operational efficiency. The wafer process boat, a seemingly simple piece of equipment, is one such critical component. Often called a wafer carrier or boat, it is responsible for safely holding and transporting silicon wafers through high-temperature and corrosive environments in furnaces. Selecting the right one and using it correctly is not an option—it's a necessity for any fab looking to minimize contamination and maximize productivity. This guide breaks down the essential factors for selection and highlights frequent errors to avoid in your wafer process line.

What Exactly is a Wafer Process Boat?

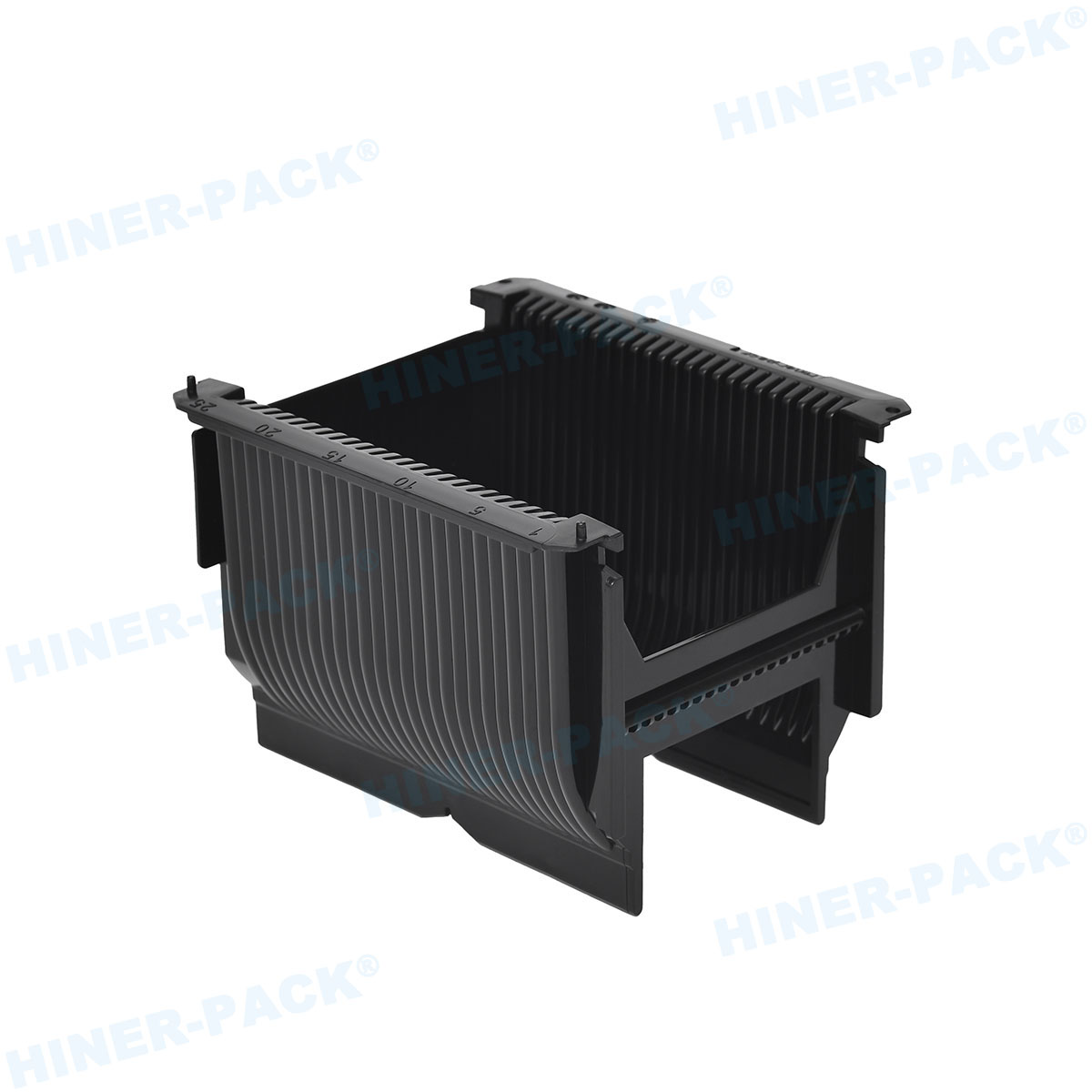

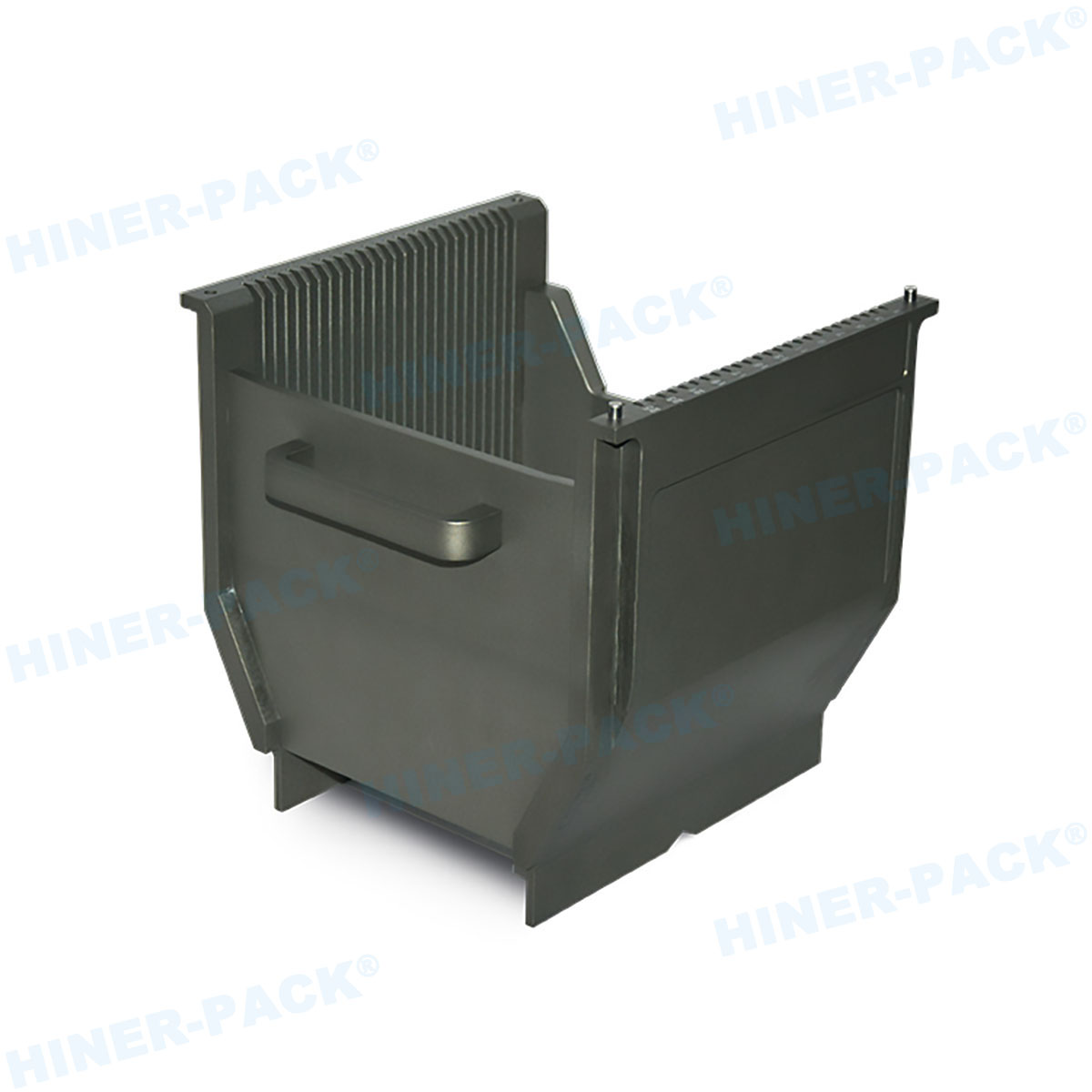

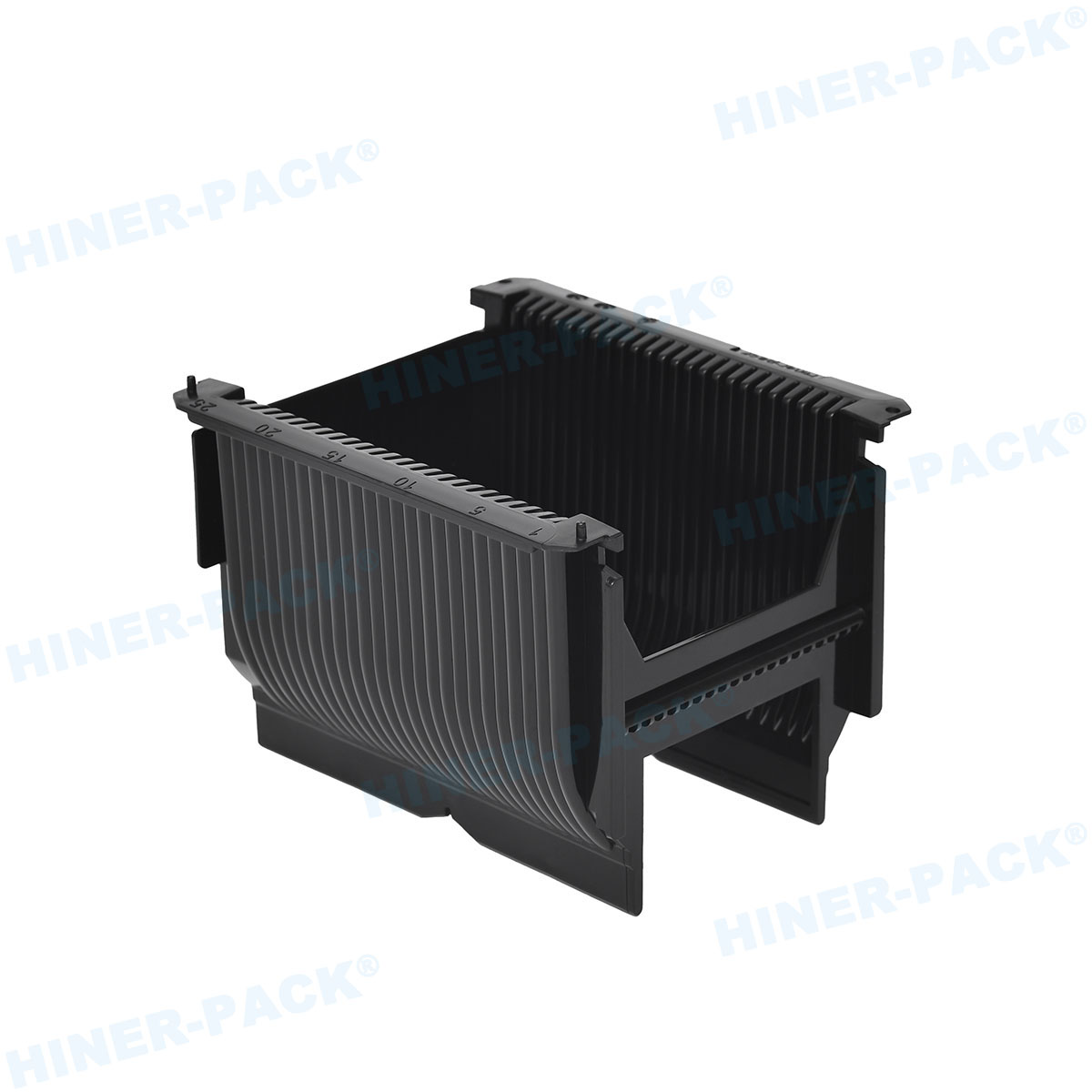

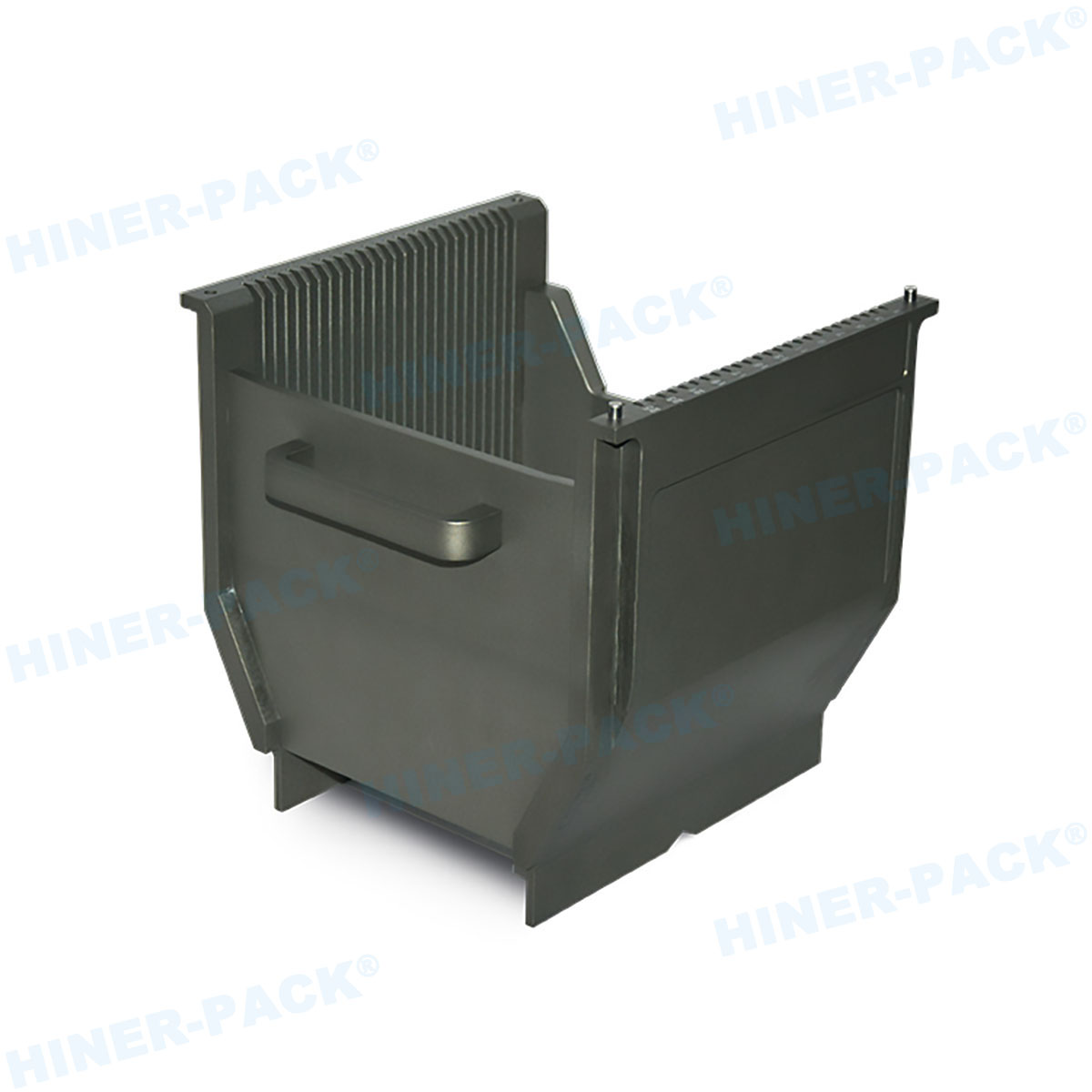

Before diving into the selection criteria, let's establish a clear understanding. A wafer process boat is a precision-engineered fixture, typically made from high-purity materials like quartz, silicon carbide, or silicon. Its primary function is to hold multiple silicon wafers in a precisely spaced, vertical position as they are processed in diffusion furnaces, LPCVD systems, and other thermal processing units.

The design ensures that process gases can flow uniformly over each wafer's surface, which is critical for achieving consistent deposition or diffusion results across the entire batch. The integrity of the wafer process boat directly influences:

Particle Contamination: Chips or wear from the boat can become deadly particles.

Wafer Warpage: Improper support during high heat can permanently distort wafers.

Process Uniformity: Uneven spacing leads to inconsistent film thickness or dopant concentration.

5 Critical Factors for Choosing Your Next Wafer Process Boat

Making an informed decision requires evaluating several technical and operational aspects.

1. Material Composition and Purity

The material is the first and most crucial choice. It must withstand extreme thermal cycles and aggressive chemistries without degrading.

High-Purity Quartz: Excellent for a wide range of processes but can slowly devitrify (crystallize) at very high temperatures, leading to particle shedding.

Silicon Carbide (SiC): Offers superior high-temperature strength and resistance to thermal shock. It is less prone to contamination but comes at a higher cost.

Pure Silicon: Used in specific applications where matching the wafer's coefficient of thermal expansion is vital to prevent slip.

For all materials, the purity level is non-negotiable. Low-purity materials can introduce metallic contaminants that diffuse into wafers, ruining entire batches. Manufacturers like Hiner-pack specialize in producing boats from certified, high-purity raw materials to mitigate this risk.

2. Thermal Stability and Coefficient of Thermal Expansion (CTE)

A wafer process boat experiences repeated heating and cooling cycles from room temperature to over 1200°C. The boat's material must have excellent thermal stability to resist warping, sagging, or cracking under its own weight and the weight of the wafers. Furthermore, its CTE should be as close as possible to that of the silicon wafers it holds. A significant mismatch can cause stress, leading to wafer bowing or the generation of dislocations in the silicon crystal structure.

3. Design and Structural Integrity

Not all boats are created equal. The design dictates gas flow dynamics and mechanical stability.

Wafer Slot Profile: The slots must hold wafers securely without gripping them too tightly, which can cause edge chipping, or too loosely, which can allow movement.

Structural Supports: The boat must have sufficient ribs and supports to prevent sagging during high-temperature cycles. A sagging boat can cause wafers to touch, resulting in catastrophic loss.

Gas Flow Pattern: A well-designed boat promotes laminar gas flow across every wafer, ensuring uniform processing. Poor design can create dead zones or turbulent flows.

4. Load Capacity and Footprint

The boat must fit your specific furnace tube while holding the required number of wafers. Pushing for a higher wafer capacity in a limited space can compromise the structural integrity or the slot design, leading to the problems mentioned above. It's a balance between productivity and process safety.

5. Cleanability and Service Life

A wafer process boat is a consumable item, but its service life matters. How many process cycles can it endure before it needs to be replaced or refurbished? The surface smoothness and the material's ability to be cleaned effectively—often with HF or other harsh chemicals—without degrading are key. A longer-lasting boat from a reputable supplier like Hiner-pack provides a lower total cost of ownership, even if the initial price is higher.

3 Common Handling Mistakes That Destroy Your Wafer Process Boats

Even the best boat can be ruined by poor handling. Avoid these costly mistakes.

Mistake 1: Improper Cleaning Procedures

Using the wrong cleaning chemicals or techniques is a primary killer of wafer process boats. Aggressive scrubbing can create micro-scratches that become particle nucleation sites. Incomplete rinsing can leave chemical residues that contaminate the next batch of wafers. Always follow the manufacturer's recommended cleaning protocol.

Mistake 2: Manual Loading without Proper Training

The manual loading of wafers into the boat using wands is a delicate skill. Dropping a wafer, scraping it against a slot, or applying uneven pressure can chip the wafer and damage the boat's precision slots. This damage creates a recurring source of particles. Automated loading systems are preferred, but if manual loading is necessary, rigorous training and certification are essential.

Mistake 3: Ignoring Scheduled Inspections and Maintenance

Boats don't last forever. Operating a wafer process boat until it visibly fails is a recipe for disaster. Fab engineers should implement a strict preventive maintenance schedule. This includes regular inspections under a high-intensity light for micro-cracks, checking for signs of devitrification (a milky white appearance on quartz), and measuring the boat for any dimensional deformation.

Why Partnering with an Expert Manufacturer Matters

Given the critical role of the wafer process boat, your choice of supplier is as important as the choice of the boat itself. A specialist manufacturer brings more than just a product; they bring expertise. Companies like Hiner-pack invest in R&D to optimize boat designs for specific processes, use advanced manufacturing techniques for superior consistency, and provide full traceability of their high-purity materials. This partnership ensures you get a component that is not just a holder, but an active contributor to your process stability and yield.

The wafer process boat is a foundational element of semiconductor thermal processing. By carefully considering the five factors of material, thermal properties, design, capacity, and cleanability, and by rigorously avoiding the three common handling mistakes, fabs can significantly reduce a major source of contamination and defect. In an industry where margins are thin and yields are paramount, paying close attention to these details is what separates leading manufacturers from the rest.

Frequently Asked Questions (FAQs)

Q1: How often should a wafer process boat be replaced?

A1: There is no universal timeframe, as it depends on the process conditions (temperature, chemicals) and the boat's material. A general rule is to monitor the boat's condition regularly. Replacement is typically needed when visual inspection reveals significant devitrification (for quartz), cracks, or warping, or when particle counts on processed wafers show a consistent upward trend. Manufacturers like Hiner-pack often provide an estimated service life based on your specific process parameters.

Q2: Can a damaged wafer process boat be repaired, or must it be replaced?

A2: Minor issues on certain boat types can sometimes be repaired by the manufacturer through processes like re-polishing. However, significant structural damage, deep cracks, or severe warping usually necessitates a full replacement. Attempting to use a compromised boat poses too high a risk of wafer loss and contamination.

Q3: What is the difference between a FOUP and a wafer process boat?

A3: A FOUP (Front-Opening Unified Pod) is used for storing and transporting wafers in a clean, ambient environment between process tools. A wafer process boat, on the other hand, is designed to hold wafers inside the process tool itself, enduring extreme temperatures and harsh chemical environments that a FOUP cannot withstand.

Q4: Why is quartz the most common material for wafer boats?

A4: Quartz is widely used because it offers an excellent balance of high purity, good high-temperature performance, and relatively low cost for many standard processes. It is highly resistant to thermal shock and performs well in oxidizing atmospheres. Its main drawback is a tendency to devitrify in certain conditions, which limits its lifespan in very high-temperature applications.

Q5: How does the design of a wafer process boat impact film thickness uniformity?

A5: The design of the wafer process boat directly affects gas flow dynamics within the furnace tube. An optimized design ensures laminar flow and uniform gas distribution across every wafer slot. Poor design can create shadowing effects or turbulent zones, leading to variations in gas concentration and, consequently, inconsistent film thickness from wafer-to-wafer and across the surface of individual wafers.