In the ultra-precise world of semiconductor fabrication, where a single particle can compromise an entire wafer, the choice of handling equipment becomes a strategic decision. Among the various options available, the PFA wafer cassette has emerged as a gold standard for critical process steps demanding the highest levels of chemical purity and thermal stability. For engineers and procurement specialists at fabs worldwide, understanding the nuances of this essential tool is key to optimizing yield and process reliability. This deep-dive explores the seven fundamental benefits of using a PFA wafer cassette, providing a clear rationale for their adoption in advanced semiconductor manufacturing, with a focus on the high-performance solutions developed by Hiner-pack.

Understanding the PFA Wafer Cassette: More Than Just a Plastic Carrier

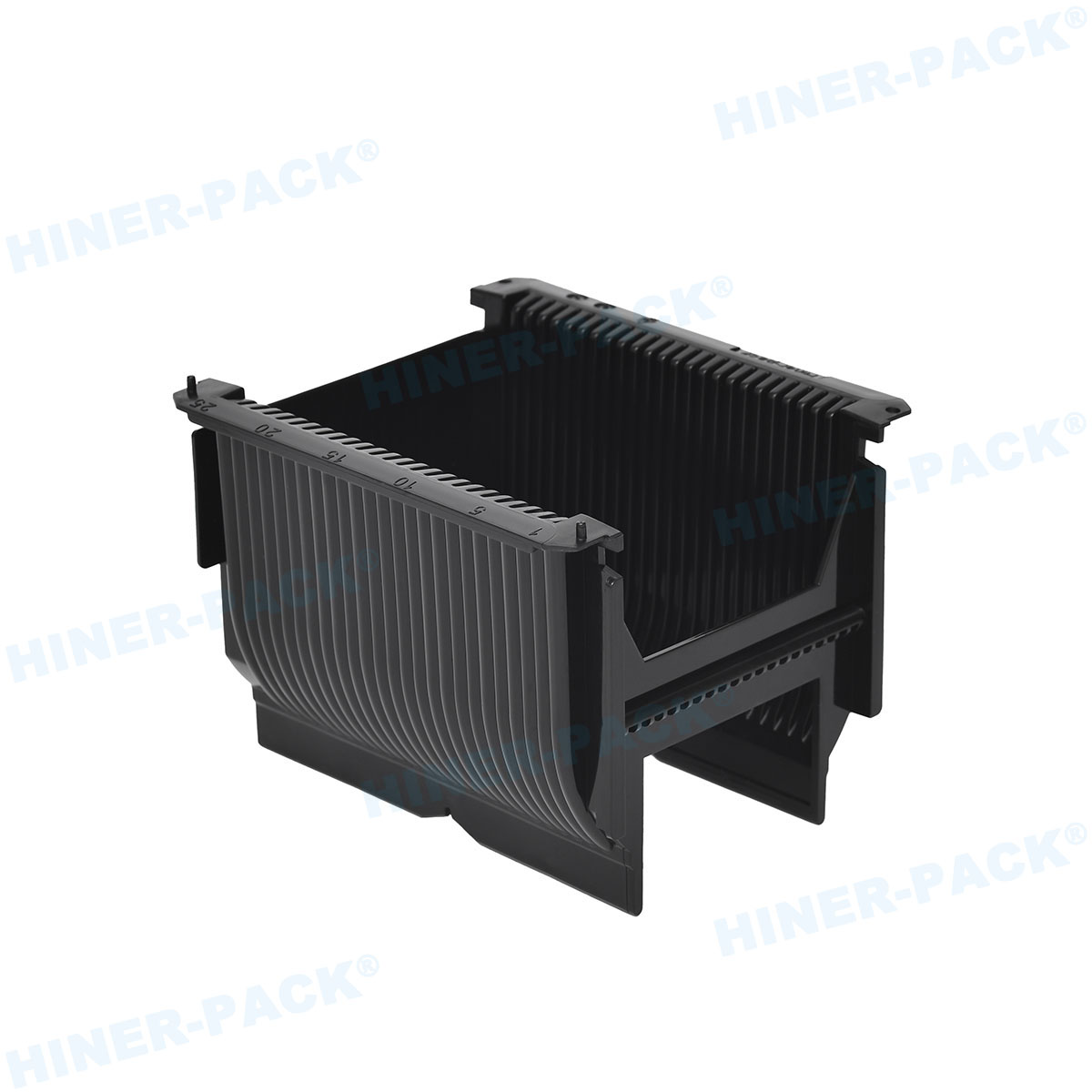

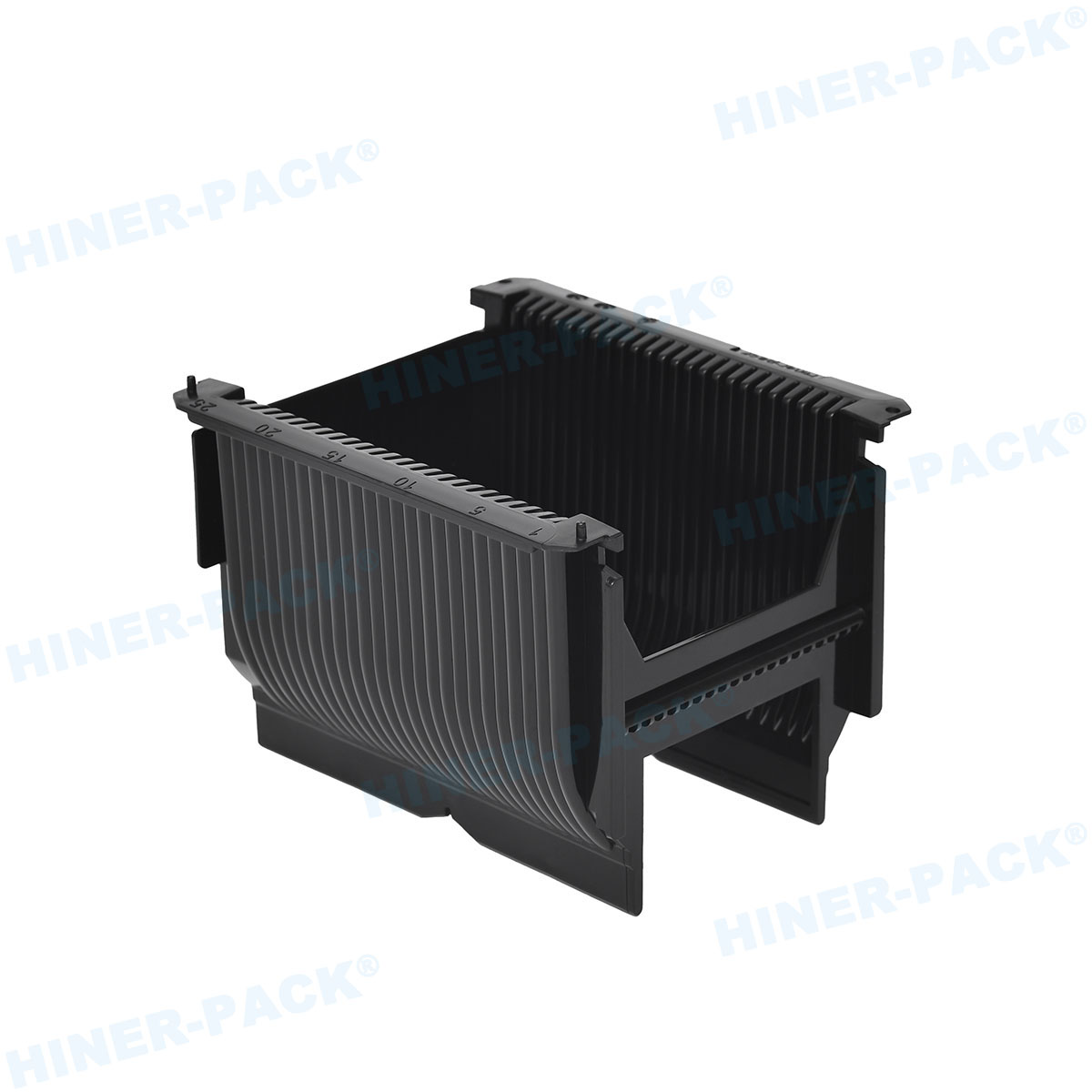

A PFA wafer cassette is a wafer carrier meticulously manufactured from Perfluoroalkoxy alkane, a fully fluorinated plastic. While often grouped with other fluoropolymers like PTFE (Teflon®), PFA offers a unique combination of properties that make it exceptionally suitable for semiconductor applications. Its fully fluorinated structure grants it incredible inertness, while its melt-processability allows for the creation of complex, high-purity designs with smooth, particle-free surfaces. In essence, a PFA wafer cassette is not just a container; it's a critical component of the contamination control strategy.

Companies like Hiner-pack specialize in engineering these cassettes to meet the rigorous demands of handling 200mm, 300mm, and the emerging 450mm wafers. The goal is to provide a carrier that protects the multi-billion-dollar value of the wafers it holds throughout processes like wet etching, cleaning, and stripping. The transition to smaller process nodes (5nm and below) has made this protective role even more critical, as feature sizes become smaller than the particles that a lesser cassette might shed.

The 7 Unmatched Benefits of Using a PFA Wafer Cassette

1. Exceptional Purity and Low Extractables

The foremost advantage of a PFA wafer cassette is its unparalleled purity. High-quality PFA resin, such as that used in Hiner-pack cassettes, contains extremely low levels of metallic ions and other extractable contaminants. During processes involving hot, ultra-pure water (UPW) or aggressive chemicals, inferior materials can leach out impurities that redeposit onto wafer surfaces. A PFA wafer cassette effectively eliminates this risk, preserving the electrical properties and yield of the devices being fabricated.

2. Superior Chemical Resistance Across the Board

Semiconductor manufacturing employs some of the most aggressive chemistries known, including hot sulfuric acid, hydrofluoric acid (HF), nitric acid, and potent solvents. PFA is resistant to virtually all of them. This broad-spectrum chemical resistance ensures that a PFA wafer cassette maintains its structural integrity and does not degrade, swell, or become brittle over time. This translates to a longer service life and reduced risk of catastrophic failure that could lead to wafer loss. Hiner-pack tests its cassettes against a wide array of process chemicals to guarantee performance in specific customer applications.

3. Outstanding Thermal Stability for High-Temp Processes

From high-temperature cleans to plasma ashing, many fab processes operate well above the thermal limits of standard plastics like polypropylene or PEEK. A PFA wafer cassette can continuously operate at temperatures up to 260°C (500°F), with short-term peaks even higher. This thermal resilience prevents warping, deformation, or outgassing that could misalign wafers in an automated handling system or deposit VOCs onto sensitive surfaces.

4. Minimal Particulate Generation and Static Buildup

The smooth, low-friction surface of PFA is inherently resistant to scratching and abrasion. As cassettes are loaded, unloaded, and transported, this characteristic drastically reduces the generation of particulate contaminants. Furthermore, PFA’s electrical properties help dissipate static charge, preventing the attraction of airborne particles to the wafer surface. Hiner-pack enhances this by designing cassettes with rounded corners and reinforced slot edges to minimize contact points and potential particle sources.

5. Mechanical Durability and Long Service Life

While representing a higher initial investment, a high-quality PFA wafer cassette from a trusted supplier like Hiner-pack offers a superior total cost of ownership. The material's toughness and resistance to stress cracking mean it can withstand thousands of process and cleaning cycles without significant wear. This durability reduces the frequency of cassette replacement and the associated costs of procurement, qualification, and downtime.

6. Excellent Cleanability and Maintenance Simplicity

Over time, cassettes require cleaning to remove process residues. The non-stick, non-porous nature of PFA makes this task straightforward. Residues do not bond strongly to the surface, allowing for effective removal with standard cleanroom detergents or DI water, often in ultrasonic baths. Hiner-pack provides detailed cleaning and maintenance protocols to help fabs maximize the usable life of their PFA wafer cassette inventory.

7. Design Flexibility for Advanced Applications

The ability to be injection-molded allows for the creation of sophisticated PFA wafer cassette designs. This includes custom slot profiles for thin wafers, integrated handling features for robotics, and specific geometries for single-wafer processing tools. Hiner-pack leverages this flexibility to work with customers on developing custom cassette solutions for unique process challenges, such as those found in MEMS or power device manufacturing.

Key Applications in the Semiconductor Fab

The properties of the PFA wafer cassette make it indispensable in several key areas of the fab:

Wet Benches: This is the primary domain of the PFA wafer cassette. In baths for RCA cleaning, oxide etching with HF, and photoresist stripping, the cassette's chemical and thermal resistance is paramount.

Front-End-of-Line (FEOL) Processes: During high-temperature diffusion, oxidation, and implant steps, the thermal stability of PFA ensures wafers are not contaminated by the carrier itself.

Advanced Packaging: For processes like flux cleaning and wafer-level packaging, where chemical exposure remains a factor, the PFA wafer cassette provides a reliable handling solution.

Compound Semiconductor Manufacturing: The processing of GaAs, GaN, and SiC wafers often involves even harsher chemistries, making the inertness of a PFA wafer cassette a necessity.

Selecting the Right Supplier: Why Hiner-pack Stands Out

Not all PFA cassettes are created equal. The purity of the raw resin, the cleanliness of the molding process, and the precision of the final design are critical differentiators. Hiner-pack has built a reputation on:

High-Purity Materials: Sourcing only the highest grade of PFA resin with certified low extractable levels.

Precision Manufacturing: Utilizing state-of-the-art molding equipment and cleanroom assembly to ensure every PFA wafer cassette meets strict particulate standards.

Rigorous Quality Control: Implementing a 100% inspection regime for critical dimensions and visual defects, often aligning with SEMI standards.

Proven Track Record: A history of successful deployments in leading fabs across Asia, Europe, and North America.

In the relentless pursuit of higher yields and smaller geometries, the PFA wafer cassette has proven to be more than a mere accessory. It is a foundational element of a robust contamination control strategy. Its unique blend of purity, chemical resistance, thermal stability, and durability makes it the unambiguous choice for the most demanding semiconductor processes. By partnering with an expert manufacturer like Hiner-pack, fabs can ensure they are leveraging this critical technology to its fullest potential, safeguarding their product and their profitability.

Frequently Asked Questions (FAQs)

Q1: What is the main difference between a PFA wafer cassette and a PTFE (Teflon) cassette?

A1: While both are high-performance fluoropolymers, PFA is melt-processable, allowing for more complex and consistent injection-molded designs with smoother surfaces. PTFE must be sintered, which can lead to more porous structures. PFA generally offers slightly better mechanical properties and purity for a PFA wafer cassette, while PTFE has a marginally higher continuous service temperature.

Q2: Can a PFA wafer cassette be used in HF (hydrofluoric acid) processes?

A2: Yes, this is one of its primary applications. PFA is highly resistant to hydrofluoric acid, making a PFA wafer cassette the standard carrier for oxide etch and cleaning steps involving HF. However, it is always recommended to verify compatibility with your specific acid concentration and temperature with your supplier, such as Hiner-pack.

Q3: How often should a PFA wafer cassette be cleaned or replaced?

A3: The cleaning frequency depends on the specific process. A rigorous preventive maintenance schedule should be established, often after a set number of process cycles or based on monitoring particle counts. With proper care, a high-quality PFA wafer cassette from Hiner-pack can last for thousands of cycles before replacement is necessary due to mechanical wear or a permanent loss of surface quality.

Q4: Are PFA cassettes suitable for automated material handling systems (AMHS)?

A4: Absolutely. In fact, their dimensional stability and resistance to warping make them excellent for AMHS. Hiner-pack can manufacture PFA wafer cassettes with precise mechanical tolerances and features (like notches and handling flats) designed for seamless integration with specific robotic end-effectors and stocker systems.

Q5: Is the higher cost of a PFA wafer cassette justified compared to a cheaper alternative?

A5: When considering total cost of ownership, yes. The initial cost is offset by significantly longer lifespan, reduced particle-induced yield loss, and elimination of contamination events that can scrap entire lots of wafers. The investment in a reliable PFA wafer cassette from Hiner-pack is an investment in process stability and product yield.