In the highly specialized world of semiconductor manufacturing, every component plays a critical role in ensuring precision, efficiency, and yield. Among these, the metal Teflon cassette stands out as a vital tool for wafer handling, storage, and transport. As the industry pushes toward smaller nodes and higher purity standards, understanding the nuances of these cassettes becomes paramount. This article delves into the key aspects of metal Teflon cassettes, covering their benefits, applications, customization options, and cost considerations, with a focus on how Hiner-pack excels in providing tailored solutions for semiconductor facilities globally.

What is a Metal Teflon Cassette?

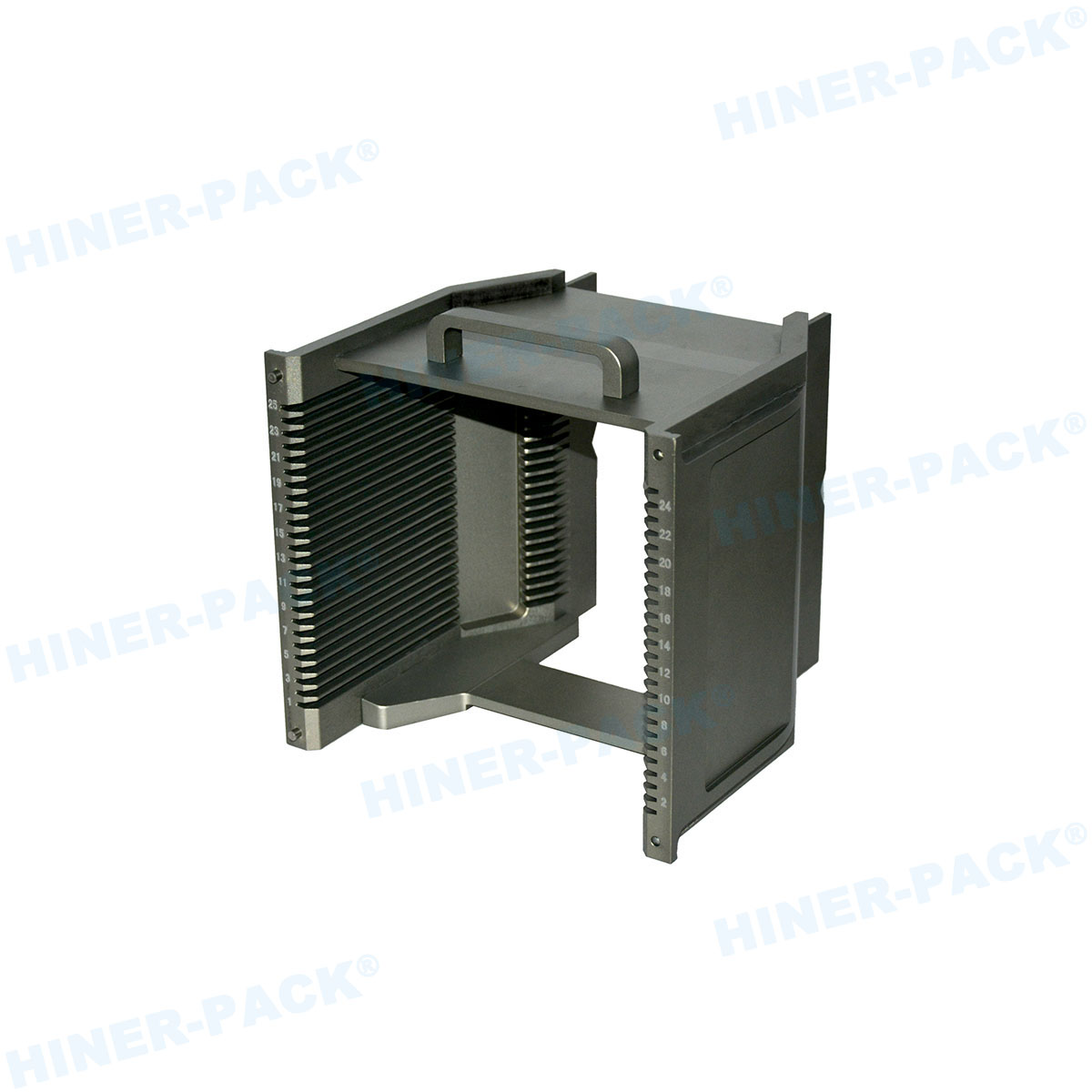

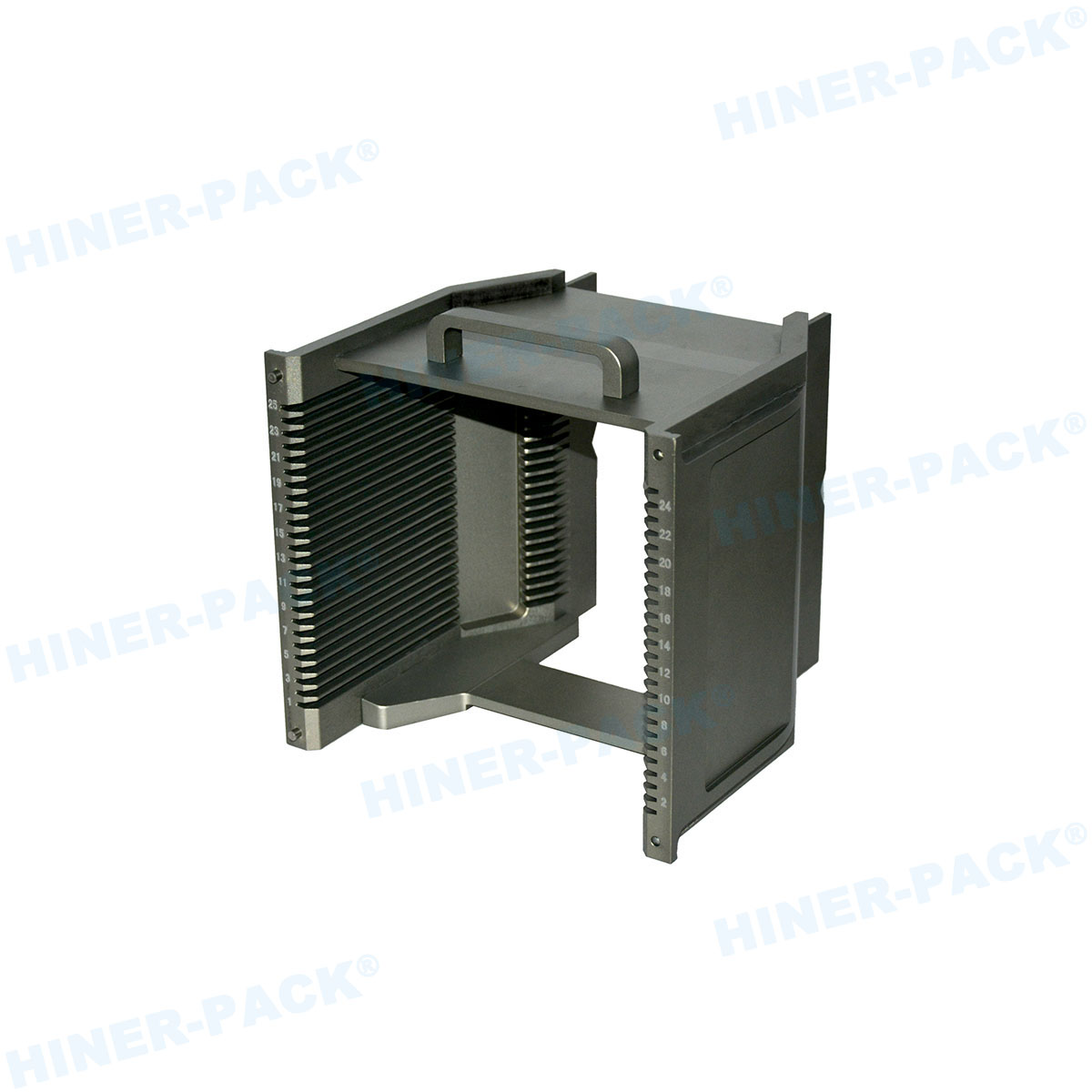

A metal Teflon cassette is a specialized wafer carrier designed to hold and protect semiconductor wafers during various stages of production, such as etching, cleaning, and inspection. Typically constructed from a durable metal frame—often stainless steel or aluminum—coated with Teflon (polytetrafluoroethylene or PTFE), these cassettes combine structural integrity with exceptional chemical resistance. The Teflon coating minimizes particulate generation and prevents wafer adhesion, making it ideal for high-purity environments like cleanrooms. In semiconductor fabrication, where contaminants can lead to catastrophic failures, the metal Teflon cassette serves as a reliable safeguard against defects, ensuring wafers remain unscathed through rigorous processes.

Advantages of Metal Teflon Cassettes in Semiconductor Applications

The adoption of metal Teflon cassettes in the semiconductor industry is driven by their unique properties. First, Teflon’s non-stick surface reduces the risk of wafers sticking to the cassette, which is crucial during automated handling. This feature enhances throughput in high-volume manufacturing lines. Second, the material’s resistance to aggressive chemicals—such as acids, solvents, and plasmas—extends the cassette’s lifespan, reducing replacement frequency and downtime. Additionally, the metal core provides mechanical strength, supporting wafers without deformation, even under thermal stress. For companies like Hiner-pack, offering custom metal Teflon cassette solutions means addressing specific client needs, such as compatibility with 200mm or 300mm wafers, and integrating features like RFID tracking for smart factory initiatives.

Key Applications in Wafer Processing

Metal Teflon cassettes are integral to multiple semiconductor processes. In wet benches, they hold wafers during chemical baths for cleaning and etching, where Teflon’s inertness prevents reactions with process fluids. During chemical mechanical planarization (CMP), these cassettes help in transporting wafers without introducing contaminants. They also play a role in metrology and inspection stages, where precision alignment is essential. As the industry advances toward 3D NAND and FinFET technologies, the demand for custom metal Teflon cassette designs grows, enabling tighter tolerances and compatibility with advanced tooling. Hiner-pack, for instance, works closely with fabs to develop cassettes that meet evolving requirements, such as low-outgassing versions for vacuum environments.

How to Choose the Right Metal Teflon Cassette

Selecting an appropriate metal Teflon cassette involves several factors. Start by assessing wafer size and thickness; standard cassettes suit 150mm to 300mm wafers, but custom metal Teflon cassette options can accommodate thinner wafers or irregular shapes. Consider the operating environment—for instance, high-temperature processes may require cassettes with enhanced thermal stability. Purity levels are another critical aspect; look for cassettes certified for low particulate and ionic contamination. Cost is also a consideration; while metal Teflon cassettes may have a higher upfront cost than plastic alternatives, their durability often leads to lower total cost of ownership. Hiner-pack emphasizes collaborative design, helping clients evaluate these factors to optimize performance and budget.

Cost and Pricing Considerations

The price of a metal Teflon cassette varies based on materials, customization, and volume. Standard units might range from $50 to $200 per cassette, but custom metal Teflon cassette designs can exceed this due to engineering inputs and specialized coatings. Factors influencing cost include the type of metal (e.g., 316L stainless steel for corrosive environments), Teflon thickness, and additional features like anti-static properties. In bulk orders, economies of scale can reduce per-unit costs. Hiner-pack offers transparent pricing models, providing quotes that align with client specifications and long-term operational savings. By investing in quality metal Teflon cassettes, fabs can minimize downtime and scrap rates, ultimately boosting profitability.

Technological and Manufacturing Insights

The production of metal Teflon cassettes involves advanced techniques to ensure precision and reliability. Metal frames are typically machined using CNC processes for exact dimensions, followed by surface treatments to enhance adhesion of the Teflon coating. The Teflon application often employs spray or dip coating, cured at controlled temperatures to achieve a uniform, pinhole-free layer. Quality control steps, such as particle counting and adhesion testing, are critical to meet semiconductor standards like SEMI. Hiner-pack leverages state-of-the-art manufacturing, including automated inspection systems, to deliver metal Teflon cassettes that consistently perform in demanding fab environments. Innovations in this space include hybrid designs that integrate polymer components for weight reduction without compromising strength.

Hiner-pack: Your Partner for Custom Metal Teflon Cassettes

As a trusted name in semiconductor components, Hiner-pack specializes in custom metal Teflon cassette solutions tailored to diverse industry needs. With decades of experience, the company offers end-to-end services—from design and prototyping to mass production and support. Hiner-pack’s cassettes are known for their robustness, compliance with international standards, and adaptability to client-specific workflows. Whether you need cassettes for legacy equipment or next-generation tools, Hiner-pack collaborates to ensure seamless integration. Their global supply chain and responsive customer service make them a go-to supplier for fabs seeking reliable metal Teflon cassette products.

Future Trends in Wafer Cassette Technology

The evolution of metal Teflon cassettes is closely tied to semiconductor industry trends. As nodes shrink below 5nm, requirements for contamination control and precision will intensify. Expect to see smarter cassettes with embedded sensors for real-time monitoring of wafer conditions. Sustainability is another driver; Hiner-pack is exploring recyclable materials and energy-efficient manufacturing for metal Teflon cassettes. Additionally, the rise of IoT in fabs may lead to cassettes with enhanced data connectivity, supporting predictive maintenance and yield optimization.

Frequently Asked Questions (FAQs)

Q1: What is a metal Teflon cassette, and how does it differ from standard cassettes?

A1: A metal Teflon cassette is a wafer carrier made from a metal frame coated with Teflon (PTFE), offering superior chemical resistance and non-stick properties compared to standard plastic or bare metal cassettes. This makes it ideal for semiconductor processes involving harsh chemicals, reducing contamination risks and extending equipment life.

Q2: Why should I consider a custom metal Teflon cassette for my facility?

A2: Custom metal Teflon cassettes allow for tailored designs to fit specific wafer sizes, tool configurations, and process requirements. This customization enhances efficiency, minimizes handling errors, and can integrate features like alignment pins or branding, ensuring optimal performance in unique operational environments.

Q3: How does the cost of a metal Teflon cassette impact overall semiconductor manufacturing expenses?

A3: While metal Teflon cassettes may have a higher initial cost than alternatives, their durability and low maintenance reduce long-term expenses by decreasing replacement frequency and downtime. This leads to a lower total cost of ownership, improved yield, and better return on investment in high-stakes semiconductor production.

Q4: What maintenance is required for metal Teflon cassettes?

A4: Metal Teflon cassettes require minimal maintenance, typically involving regular cleaning with compatible solvents to remove residues. Inspections for coating wear or damage are recommended to prevent particulate generation. Hiner-pack provides guidelines and support for upkeep, ensuring prolonged cassette lifespan.

Q5: Can Hiner-pack supply metal Teflon cassettes for advanced nodes like 3nm or 5nm processes?

A5: Yes, Hiner-pack designs metal Teflon cassettes to meet the stringent demands of advanced semiconductor nodes, including ultra-low contamination levels and precision tolerances. Their custom solutions are tested for compatibility with cutting-edge tools, supporting high-yield production in next-generation fabs.

In summary, the metal Teflon cassette is a cornerstone of modern semiconductor manufacturing, balancing performance, cost, and customization. By partnering with experts like Hiner-pack, fabs can leverage these tools to achieve higher efficiency and reliability. As technology advances, the role of metal Teflon cassettes will only grow, underscoring their importance in the global semiconductor landscape.