In the semiconductor industry, the 8 inch wafer carrier plays a critical role in protecting and transporting delicate wafers during manufacturing processes. As technology advances, the demand for reliable handling solutions like the 200mm wafer carrier continues to grow, driven by the need for precision and contamination control. This article delves into the intricacies of 8 inch wafer carrier systems, covering aspects such as selection, customization, and maintenance. We'll explore key topics including the role of a 200mm SMIF Pod manufacturer, the benefits of a Custom 8 inch wafer cassette, the importance of wafer carrier cleaning service, and factors influencing wafer carrier price. By the end, you'll have a comprehensive understanding of these components, along with answers to common questions that industry professionals frequently encounter.

What Is an 8 Inch Wafer Carrier and Why Is It Important?

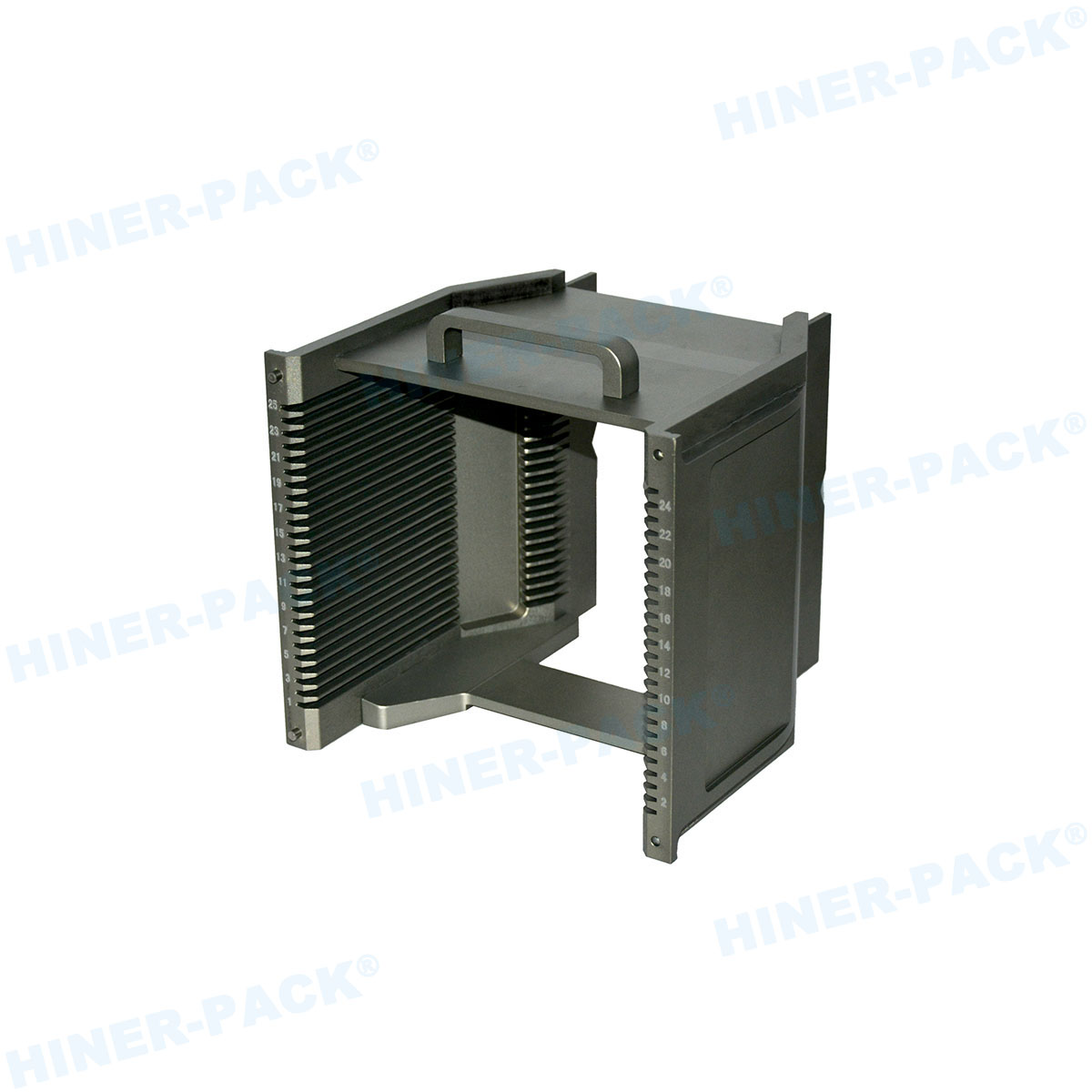

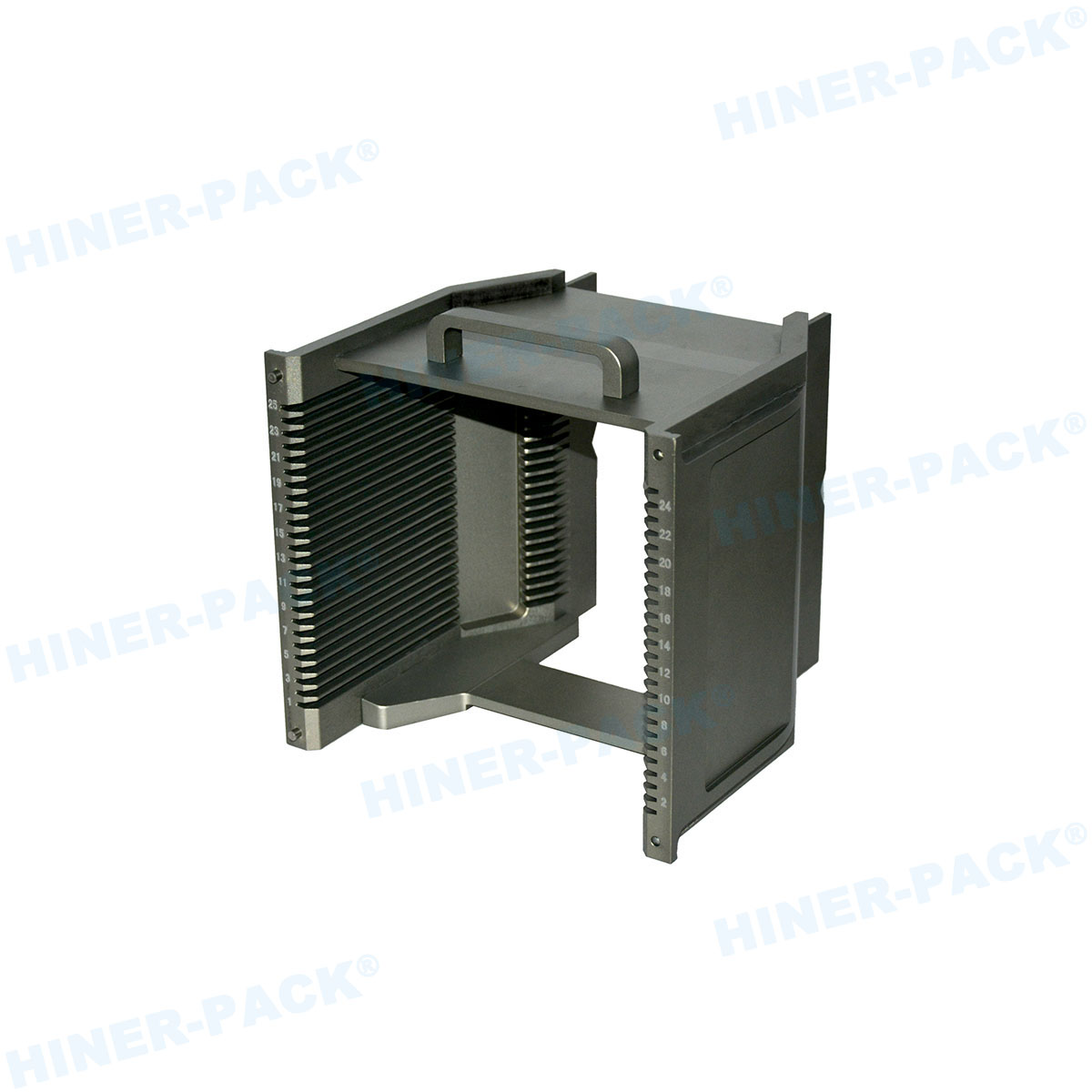

An 8 inch wafer carrier, often referred to as a wafer cassette or pod, is a specialized container designed to hold and safeguard 200mm silicon wafers during storage, transport, and processing in cleanroom environments. These carriers are essential for preventing contamination, physical damage, and electrostatic discharge, which can compromise wafer integrity and yield. The 200mm wafer carrier is a standard in many fabrication facilities due to its compatibility with older and some modern equipment, offering a balance between cost and performance. Typically made from materials like polycarbonate or PEEK, these carriers feature precise slot configurations to ensure wafers are securely spaced, minimizing contact and friction. As semiconductor nodes shrink, the need for high-precision carriers becomes even more pronounced, making the 8 inch wafer carrier a cornerstone of efficient production lines. Understanding its design and functionality is the first step toward optimizing your wafer handling processes.

The Relationship Between 200mm Wafer Carrier and 8 Inch Wafer Carrier

When discussing wafer carriers, the terms 200mm wafer carrier and 8 inch wafer carrier are often used interchangeably, as 200mm equates to approximately 8 inches. This standardization stems from historical industry practices where wafer sizes were measured in inches, but metric units are now commonly used in specifications. The 200mm wafer carrier is widely adopted in sectors such as MEMS, power devices, and legacy IC production, where it supports wafers through etching, deposition, and inspection stages. Key differences might arise in design variations, such as load port compatibility or material choices, but fundamentally, both refer to the same product category. For instance, a 200mm SMIF Pod manufacturer might produce carriers that integrate with Standard Mechanical Interface (SMIF) systems, ensuring a sealed environment to maintain cleanliness. By recognizing this relationship, you can better navigate product specifications and ensure compatibility with your equipment, whether you're upgrading existing lines or integrating new tools.

Choosing the Right 200mm SMIF Pod Manufacturer

Selecting a reliable 200mm SMIF Pod manufacturer is crucial for ensuring the longevity and performance of your wafer handling systems. A reputable manufacturer will offer products that meet industry standards like SEMI guidelines, providing carriers with tight tolerances and low particle generation. When evaluating a 200mm SMIF Pod manufacturer, consider factors such as their experience in the semiconductor sector, quality control processes, and ability to provide certifications for materials and cleanliness. Many manufacturers also offer customization options, which can include tailored dimensions or materials to suit specific process requirements. For example, partnering with a trusted 200mm SMIF Pod manufacturer can lead to improved yield rates by reducing contamination risks. Additionally, assess their support services, such as technical assistance and lead times, as these can impact your overall operational efficiency. By conducting thorough due diligence, you can secure a partnership that enhances your production line's reliability and reduces downtime.

Benefits of a Custom 8 Inch Wafer Cassette

A Custom 8 inch wafer cassette offers tailored solutions for unique manufacturing challenges, providing advantages over off-the-shelf options. Customization can involve adjustments in slot pitch, material composition, or additional features like RFID tagging for traceability. For instance, in applications requiring high-temperature resistance, a Custom 8 inch wafer cassette made from advanced polymers can withstand harsh processes without degrading. This flexibility is particularly valuable in R&D environments or when integrating with non-standard equipment. Moreover, a Custom 8 inch wafer cassette can optimize space utilization in storage and transport, leading to cost savings and improved workflow efficiency. When sourcing such products, it's essential to collaborate with suppliers who understand your specific needs and can deliver precision-engineered solutions. This approach not only enhances performance but also extends the carrier's lifespan, contributing to a better return on investment.

Importance of Wafer Carrier Cleaning Service

Regular maintenance through a professional wafer carrier cleaning service is vital for sustaining the performance and cleanliness of your 8 inch wafer carrier. Over time, carriers accumulate particles, residues, and contaminants from processing environments, which can lead to wafer defects and yield loss. A dedicated wafer carrier cleaning service employs methods like ultrasonic cleaning, chemical baths, and deionized water rinses to restore carriers to their original state, often meeting stringent cleanliness standards such as Class 1 cleanroom requirements. Utilizing a wafer carrier cleaning service can also help identify wear and tear early, preventing costly replacements and downtime. Many semiconductor facilities opt for scheduled cleaning cycles as part of their preventive maintenance programs, ensuring consistent quality. When selecting a service provider, look for those with expertise in handling 200mm wafer carrier components and certifications that validate their processes. This proactive approach not only protects your wafers but also optimizes overall equipment effectiveness.

Factors Influencing Wafer Carrier Price

Understanding the wafer carrier price is essential for budgeting and procurement decisions in semiconductor operations. The wafer carrier price can vary widely based on factors such as material quality, design complexity, and volume of purchase. For example, a standard 8 inch wafer carrier might be more affordable, while a Custom 8 inch wafer cassette or products from a high-end 200mm SMIF Pod manufacturer could command a premium due to specialized features. Additional costs may arise from certifications, shipping, and after-sales support. Market dynamics, such as raw material availability and demand fluctuations, also impact the wafer carrier price. To manage expenses, consider bulk purchasing or long-term contracts with suppliers. It's advisable to balance cost with quality, as cheaper options might lead to higher long-term costs from frequent replacements or contamination issues. By analyzing these factors, you can make informed decisions that align with your operational needs and financial constraints.

Common Questions About 8 Inch Wafer Carriers

In this section, we address frequently asked questions to provide clarity on 8 inch wafer carrier topics. These queries often arise from engineers, procurement managers, and technicians dealing with daily challenges.

What is the typical lifespan of an 8 inch wafer carrier?

The lifespan depends on usage conditions and maintenance. With proper care and regular wafer carrier cleaning service, a high-quality 200mm wafer carrier can last several years. However, exposure to harsh chemicals or physical stress may shorten it.

How do I choose between a standard and a Custom 8 inch wafer cassette?

Consider your specific process requirements. If you have unique equipment or need enhanced features, a Custom 8 inch wafer cassette is ideal. For standard applications, a generic 8 inch wafer carrier from a reputable 200mm SMIF Pod manufacturer may suffice.

What affects the wafer carrier price the most?

Material costs and customization are primary drivers. For instance, carriers made from premium materials or those requiring intricate designs from a 200mm SMIF Pod manufacturer will have a higher wafer carrier price. Volume discounts can mitigate this.

How often should I use a wafer carrier cleaning service?

This varies based on usage intensity and contamination levels. In high-volume fabs, monthly cleaning might be necessary, while lower-throughput environments could opt for quarterly services. Regular inspections help determine the optimal schedule.

Can I mix 200mm wafer carriers from different manufacturers?

It's not recommended, as dimensional variations could cause misalignment or damage. Stick to products from a single 200mm SMIF Pod manufacturer or ensure compatibility through rigorous testing.

What are the signs that a wafer carrier needs replacement?

Look for cracks, discoloration, or increased particle counts. If cleaning doesn't restore performance, it's time for a new 8 inch wafer carrier to avoid compromising wafer quality.

The 8 inch wafer carrier remains a fundamental component in semiconductor manufacturing, with its 200mm wafer carrier variant serving diverse industry needs. From selecting a reliable 200mm SMIF Pod manufacturer to leveraging a Custom 8 inch wafer cassette and maintaining hygiene through a wafer carrier cleaning service, each aspect contributes to operational excellence. By understanding the factors behind wafer carrier price and addressing common questions, you can optimize your processes for better efficiency and yield. As technology evolves, staying informed about these elements will ensure your facility remains competitive and resilient in the fast-paced world of semiconductor production.

This article has provided a detailed overview, but if you have further queries, consulting with industry experts or suppliers can offer additional insights tailored to your specific context.