Semiconductor manufacturing allows for zero margin of error. When dealing with 150mm fabrication processes, the equipment used to transport and hold substrates is just as critical as the chemistry involved. The choice of carrier material often dictates the success of wet etching and cleaning cycles.

Many fabs still struggle with particle generation and chemical leaching from inferior wafer boats. This is where the specific properties of a 6-inch Teflon Wafer Cassette become essential. Unlike standard plastics, high-grade fluoropolymers offer the resistance needed for aggressive acid baths and high-temperature stripping processes.

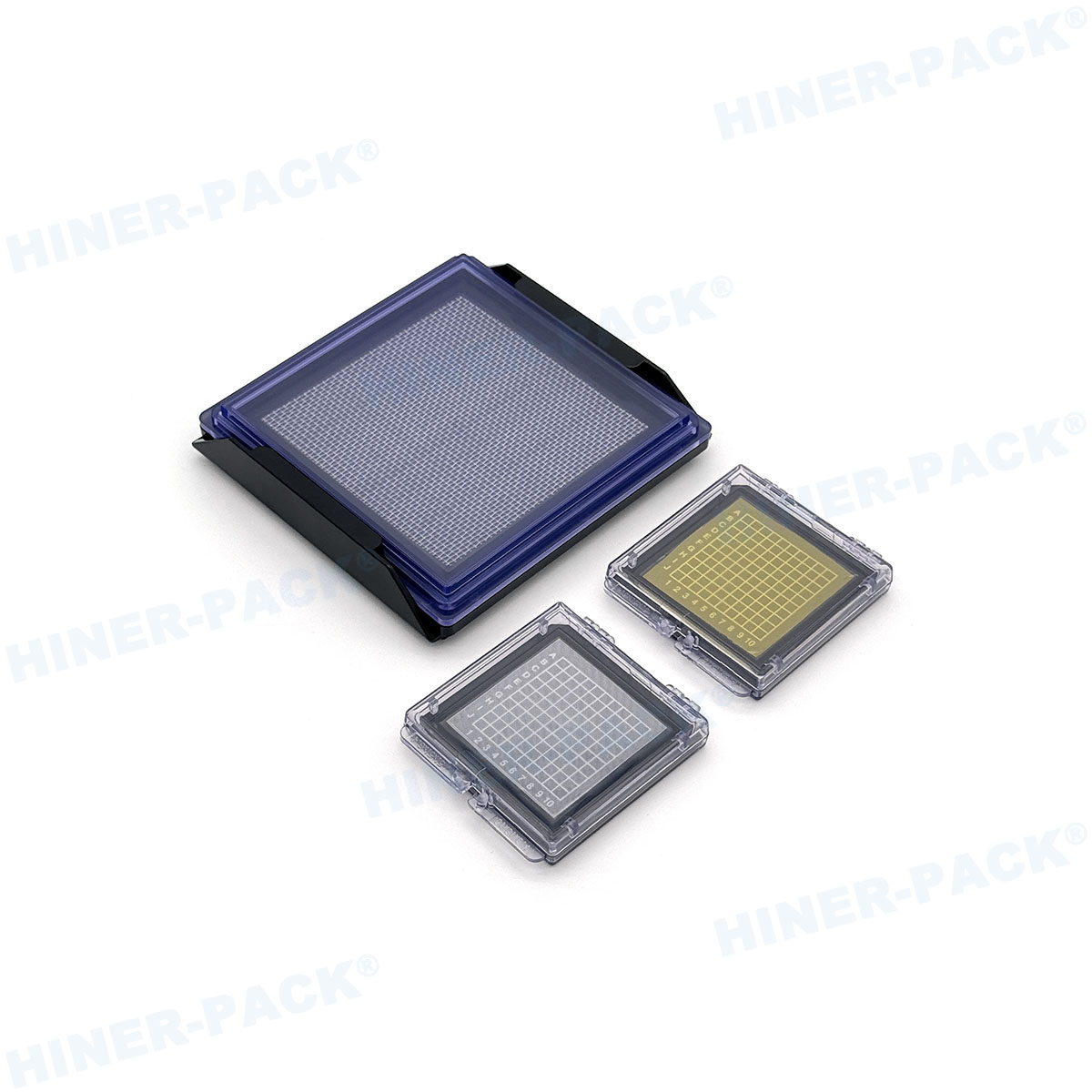

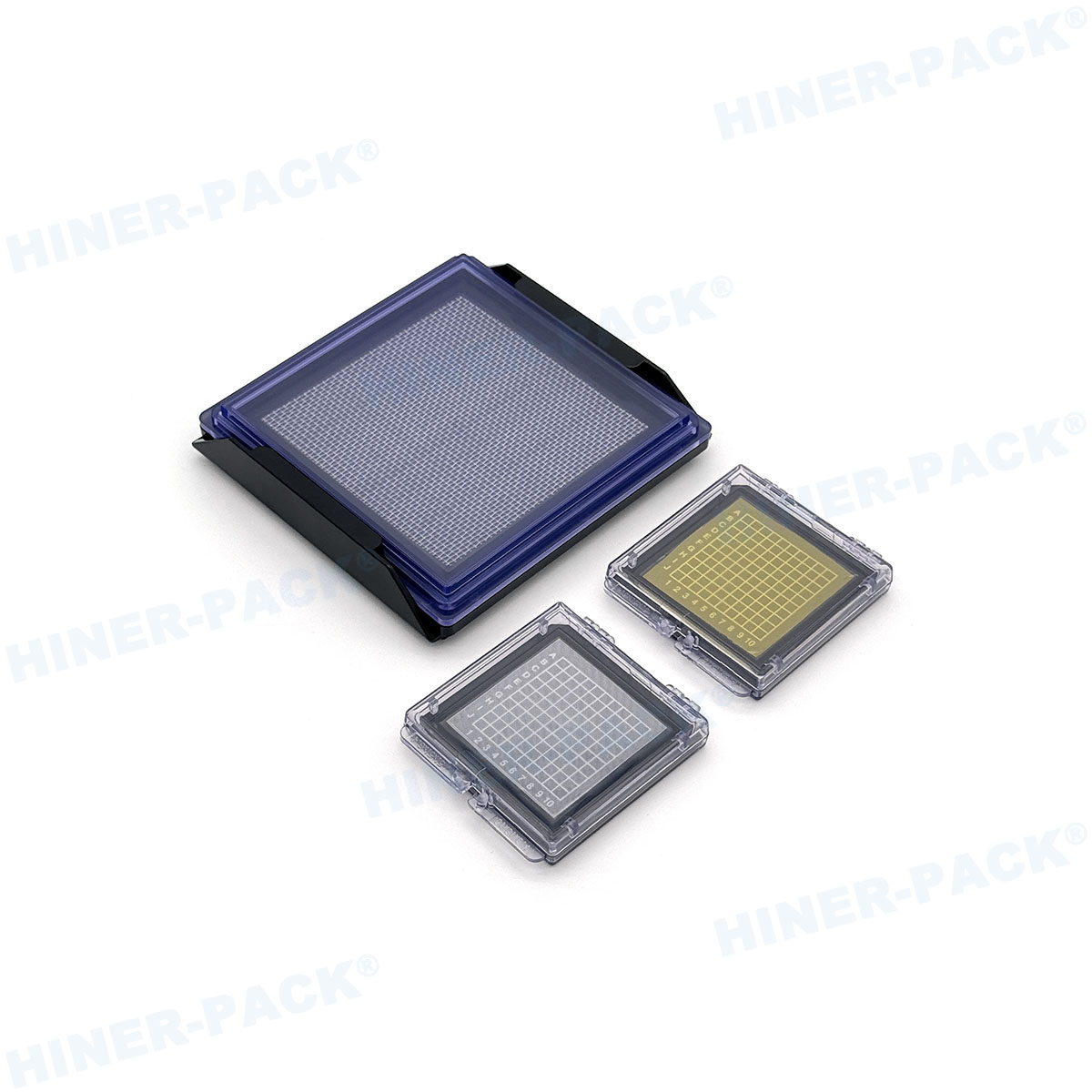

At Hiner-pack, we understand that yield improvement starts with the basics of material handling. This article looks at the technical reasons for choosing Teflon (PFA/PTFE) cassettes, how they withstand harsh fab environments, and why design precision matters for your production line.

The Material Science: Why PFA and PTFE Dominate

In the world of wet processing, material selection is the first line of defense against contamination. While Polypropylene (PP) or Polycarbonate (PC) might suffice for transport or storage, they fail in the process bath.

Teflon, specifically PFA (Perfluoroalkoxy) and PTFE (Polytetrafluoroethylene), provides a unique carbon-fluorine bond. This bond is one of the strongest in organic chemistry. It renders the surface almost entirely inert.

When you utilize a 6-inch Teflon Wafer Cassette, you are essentially using a container that chemically ignores the acids inside the tank. Whether you are running Hydrofluoric Acid (HF) to etch oxides or hot Sulfuric Acid for stripping photoresist, the cassette remains stable. It does not degrade, swell, or release ionic contaminants into the bath.

Minimizing Cross-Contamination in Wet Benches

Particle defects are the silent killers of wafer yields. As feature sizes shrink, even on established 6-inch lines, the tolerance for foreign material drops.

A major source of particles is the degradation of the wafer carrier itself. Lower-grade plastics can become brittle over time when exposed to UV light or harsh oxidizers. This brittleness leads to micro-cracking and shedding.

High-purity PFA cassettes manufactured by Hiner-pack are designed to resist this degradation. The surface finish is molded to be ultra-smooth. A smooth surface means there are fewer microscopic valleys where particles or bacteria can hide. This "non-stick" property also ensures that chemicals drain rapidly during the rinse cycle, reducing drag-out contamination between different process tanks.

Design Engineering for Automation Compatibility

Material is only half the battle. The physical geometry of the cassette must align perfectly with automated handling systems.

Modern fabs use robotic arms for transfer. If a cassette is warped or dimensionally inaccurate, the robot may mishandle the wafer, leading to scratches or breakage. A premium 6-inch Teflon Wafer Cassette maintains its dimensional stability even after repeated thermal cycling.

Key design features usually include:

Precise pitch spacing to ensure robot end-effectors can enter without touching wafers.Wash slots designed to maximize fluid flow across the wafer surface.Structural ribbing that prevents sagging when the cassette is fully loaded with 25 wafers.

Thermal Stability and Process Range

Wet benches often fluctuate wildly in temperature. A process might require a bath at 180°C followed immediately by a cold rinse.

Thermal shock can warp inferior plastics. Warping changes the pitch of the slots, potentially pinching the wafers. Teflon possesses a high melting point and excellent thermal stability.

A PFA-based carrier can handle continuous service temperatures up to 260°C. This covers virtually all wet chemical processes in silicon fabrication. By maintaining rigidity at high heat, the carrier ensures that wafers remain parallel and properly spaced, which is vital for uniform chemical exposure.

Hiner-pack’s Approach to Injection Molding

Creating a cassette that is both chemically pure and mechanically robust requires advanced manufacturing techniques. Machining Teflon is possible, but injection molding PFA is preferred for mass consistency.

Hiner-pack utilizes high-precision molds to create seamless cassette bodies. Molding reduces the stress points that often occur in welded or assembled carriers.

Furthermore, the raw material used in the molding process matters. We focus on using high-purity virgin resins. Recycled or low-grade PFA can contain trace metals like iron or copper. In a semiconductor bath, these metals can leach out and diffuse into the silicon crystal, altering its electrical properties. Virgin resin guarantees that the cassette is as pure as the water used in the rinse tank.

The Role of Surface Tension and Drying

Drying is the final and often most critical step in the wet process. Watermarks left on a wafer can cause open circuits or masking defects later on.

The hydrophobicity of the carrier plays a role here. A 6-inch Teflon Wafer Cassette is naturally hydrophobic. Water beads up and rolls off the surface instantly.

This characteristic assists Marangoni drying or spin-drying processes. Because the cassette does not hold water, it does not introduce humidity back into the environment once the drying cycle begins. Faster drying times lead to higher throughput for the fab.

Longevity and Cost of Ownership

Procurement teams often look at the initial price tag. Teflon carriers are significantly more expensive than Polypropylene alternatives. However, the calculation must change when viewing Total Cost of Ownership (TCO).

A PP cassette might survive a few months in an aggressive acid bath before it starts to discolor or crack. A PFA cassette can last for years.

Frequent replacement of cheap cassettes interrupts production. It requires requalification of the new carriers and adds to hazardous waste disposal costs. Investing in a durable 6-inch Teflon Wafer Cassette from a reputable supplier like Hiner-pack reduces these hidden costs. The longevity of the product amortizes the initial expense over thousands of successful process runs.

Electrostatic Discharge (ESD) Considerations

While standard PFA is an excellent electrical insulator, this can sometimes be a disadvantage. Static buildup attracts particles.

In areas where ESD is a major concern, fabs may opt for specialized versions of Teflon carriers that contain conductive fillers, such as high-purity carbon. These "ESD-safe" PFA cassettes allow static charge to dissipate safely to the ground.

It is crucial to balance the need for ESD protection with chemical purity. Some carbon fillers can introduce contamination. Hiner-pack engineers can help navigate these trade-offs, ensuring that the chosen cassette meets both the electrical and chemical requirements of the specific process node.

Cleaning and Reconditioning Protocols

Even the best cassette needs cleaning. Over time, organic residues or process byproducts can accumulate on the carrier.

Because Teflon is chemically robust, these cassettes can be aggressively cleaned. They can withstand prolonged soaks in Piranha solution (Sulfuric acid and Hydrogen Peroxide) to strip organics. They can also undergo ultrasonic cleaning without absorbing the sonic energy to the point of structural failure.

The ability to thoroughly clean and recondition a 6-inch Teflon Wafer Cassette extends its life cycle further. It allows fabs to maintain a "zero-particle" standard without constantly buying new consumables.

Supply Chain Security with Hiner-pack

The global semiconductor supply chain has faced disruptions recently. Relying on a single source or a supplier with limited inventory can halt production.

Hiner-pack emphasizes consistent supply and logistical support. We understand that a missing cassette can mean a stalled lot of wafers. By maintaining robust stock levels of standard 150mm carriers, we ensure that fabs can react quickly to ramp-ups in production demand.

Our quality control involves rigorous dimensional checks and surface composition analysis before any product ships. This ensures that when a box arrives at your dock, the cassettes are ready for the cleanroom immediately.

Future-Proofing 6-inch Lines

While the industry buzz often focuses on 300mm or the upcoming 450mm standards, 6-inch (150mm) lines remain vital. They are the workhorses for power electronics (IGBTs, MOSFETs), MEMS, and analog sensors.

These sectors are growing, not shrinking. As such, the requirements for 6-inch processing are becoming stricter. The "old" tech is being used to make advanced devices.

This evolution demands that 6-inch ancillary equipment, including wafer boats, meets modern standards of purity. Using legacy carriers on a line making advanced SiC (Silicon Carbide) or GaN (Gallium Nitride) power devices is a risk. Upgrading to a modern 6-inch Teflon Wafer Cassette is a simple step to bring a mature line up to current cleanliness standards.

The humble wafer cassette is a pivotal component in the semiconductor yield equation. It interacts with the wafer more than almost any other piece of equipment.

Choosing the right material is not just about chemical resistance; it is about particle control, thermal stability, and drying efficiency. PFA and PTFE offer the best balance of these properties for wet processing.

By selecting a high-quality 6-inch Teflon Wafer Cassette, fabs can reduce defect densities and extend the lifespan of their consumables. Hiner-pack remains committed to providing the industry with precision-molded solutions that stand up to the most rigorous chemical environments. In an industry where yield is king, investing in quality handling is investing in profitability.

FAQ: Common Questions About Wafer Cassettes

Q1: What is the maximum temperature a standard 6-inch Teflon Wafer Cassette can withstand?

A1: Generally, cassettes made from high-purity PFA can withstand continuous service temperatures up to 260°C (500°F). However, for mechanical stability under load (holding 25 wafers), it is often recommended to stay below 200°C to prevent any risk of slight warping over time.

Q2: Can I use PFA cassettes for transport and shipping, or are they only for process baths?

A2: While you technically can use them for shipping, it is not cost-effective. PFA cassettes are designed for chemical resistance and high heat. For shipping, less expensive materials like Polypropylene (PP) or Polycarbonate (PC) are standard, as they offer good impact protection at a fraction of the cost.

Q3: How do I distinguish between a PFA and a PTFE cassette?

A3: Visually, PFA (Perfluoroalkoxy) is usually translucent or semi-clear, allowing you to see the outline of the wafers inside. PTFE (Polytetrafluoroethylene) is typically opaque white. PFA is melt-processable (injection molded), which usually results in smoother surface finishes and tighter dimensional tolerances compared to machined PTFE.

Q4: Does Hiner-pack offer ESD-safe versions of Teflon cassettes?

A4: Yes. Standard PFA is an insulator and can hold a static charge. For applications sensitive to electrostatic discharge, we offer PFA blended with high-purity conductive carbon. This allows the static charge to dissipate safely, preventing damage to sensitive components on the wafer.

Q5: What is the best way to clean a Teflon cassette that has organic residue?

A5: Because PFA is chemically inert, you can use strong oxidizers. A Piranha solution (a mixture of Sulfuric Acid and Hydrogen Peroxide) is highly effective for removing organics. Always ensure a thorough DI water rinse and proper drying afterward to prevent chemical carryover.