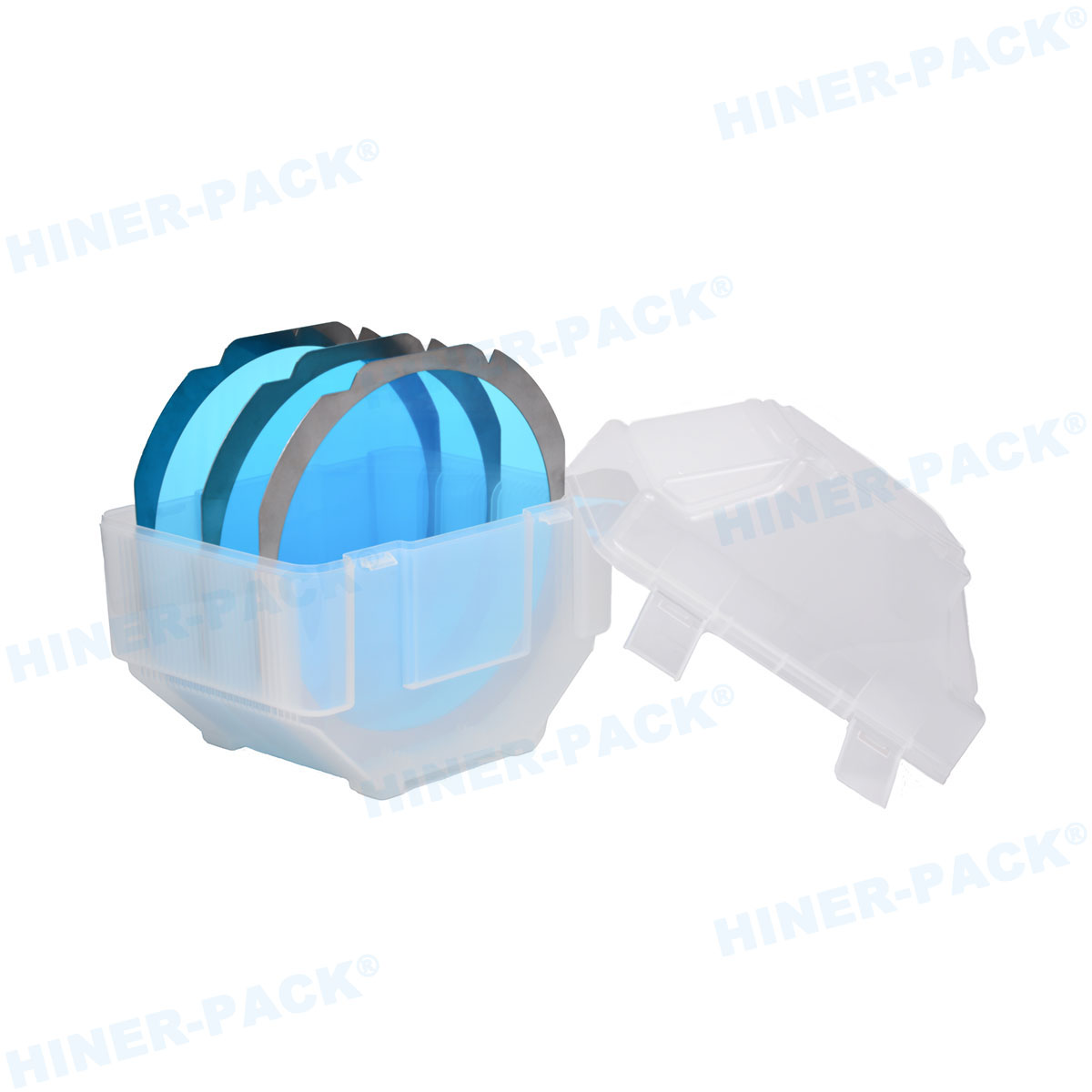

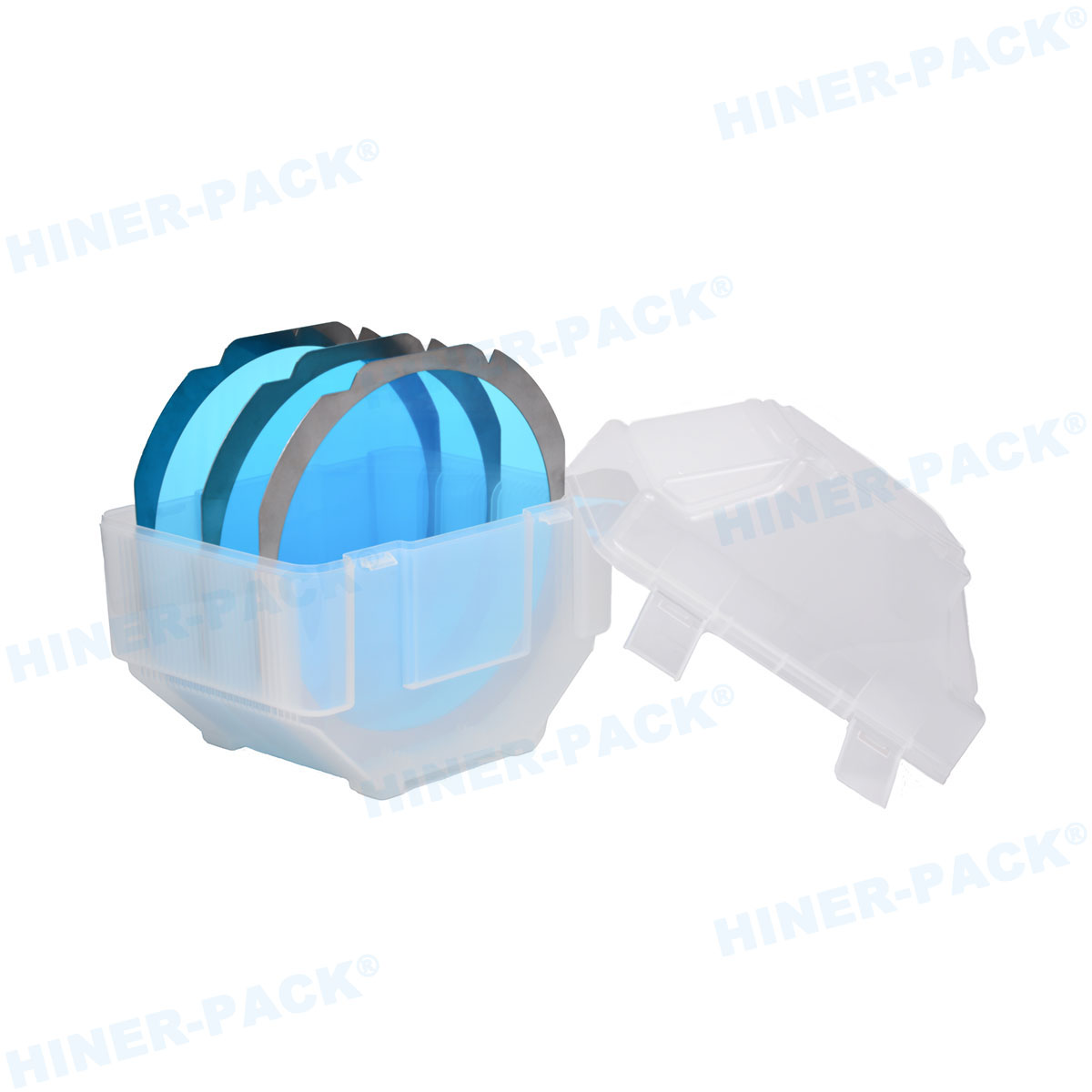

In the precise world of semiconductor manufacturing, every component must ensure purity, protection, and efficiency. Among these critical components, the 4-inch Wafer Cassette remains a fundamental workhorse. It is the primary container for handling and transporting 4-inch (100mm) silicon wafers through various process stages.

While larger wafer diameters dominate advanced logic production, the 4-inch wafer is still vital. It is extensively used in research & development, MEMS devices, power semiconductors, and optoelectronics. For these applications, the reliability of the wafer cassette is non-negotiable. A single particle-generating or misaligning cassette can ruin an entire batch of valuable substrates.

This article details the importance, design, and selection criteria for these essential carriers.

Why the 4-inch Wafer Cassette is Still Critical Today

The transition to 200mm and 300mm wafers is well-documented. However, dismissing the 4-inch format would be a significant error. Many mature and specialized technologies are perfectly suited to this diameter.

Fab lines for sensors, diodes, and specialized analog chips often run on 4-inch wafers. Their equipment base is stable and cost-effective. In R&D labs, 4-inch wafers allow for rapid prototyping and experimentation with new materials or processes at a lower cost.

For all these processes, the 4-inch Wafer Cassette provides the first and last line of defense. It ensures wafers are kept separated, organized, and safe from mechanical damage and environmental contaminants during storage and intra-fab movement.

Key Design and Material Specifications

Not all cassettes are created equal. Their design directly impacts yield and operational smoothness.

- Material Purity: High-purity polypropylene (PP) or perfluoroalkoxy (PFA) are standards. These materials minimize outgassing and resist degradation from chemicals and high temperatures. Hiner-pack cassettes, for instance, use specially formulated polymers to meet stringent Class 1 cleanroom requirements.

- Precision Slot Geometry: Each slot must be molded to exacting tolerances. This prevents wafer wobble, which can cause misalignment in automated equipment, and eliminates scraping that generates particles.

- Structural Rigidity: The cassette must not warp or flex during handling or under load. Warpage can cause robots to mispick wafers, leading to crashes. Reinforced designs are essential for automation.

- Ergonomic and Automation Features: Proper handles, robotic flange compatibility, and clear visual markings are mandatory. These features enable safe manual handling and reliable integration with automated material handling systems (AMHS).

Applications Beyond Standard Silicon Processing

The use of 4-inch Wafer Cassette units extends beyond traditional IC fabrication.

In compound semiconductor fabs (GaAs, GaN), these cassettes must withstand different chemistries. In solar cell production for specialized applications, they handle brittle substrates. The MEMS industry relies on them for delicate micro-structures that are highly sensitive to particulate contamination.

In each case, the cassette is adapted. Modifications might include custom slot counts, materials for high-temperature stability, or conductive materials for electrostatic discharge (ESD) protection.

Selecting the Right Supplier: More Than Just a Plastic Box

Choosing a cassette supplier is a technical decision. Consistency in manufacturing is paramount. Every batch of cassettes must have identical mechanical and chemical properties.

A trusted brand like Hiner-pack focuses on this consistency. Their manufacturing process is controlled to eliminate mold flash and particulate shedding. Furthermore, they offer traceability and lot control, which is crucial for high-reliability fabs.

Total Cost of Ownership (TCO) is also key. A cheaper cassette that sheds particles or breaks quickly leads to massive downstream yield loss and tool downtime. Investing in high-quality carriers from the start prevents these costly failures.

Maintenance and Best Practices for Longevity

Even the best cassette requires proper care. A defined maintenance and inspection protocol is necessary.

Cassettes should be regularly cleaned in dedicated wafer-cleaning tools or via manual processes with appropriate solvents. They must be inspected for cracks, wear on slot edges, and any signs of deformation.

Implementing a cassette tracking and retirement system is a best practice. This ensures carriers are removed from circulation after a certain number of process cycles or at the first sign of wear.

The 4-inch Wafer Cassette is a testament to the fact that in semiconductor manufacturing, foundational elements never lose their importance. As long as 4-inch wafers are used in fabs and labs worldwide, the demand for precise, reliable, and clean carriers will continue. Selecting a high-performance cassette is a direct investment in process stability, yield protection, and overall fab efficiency. Partners like Hiner-pack provide the engineered solutions that this critical task demands.

Frequently Asked Questions (FAQs)

Q1: Are 4-inch wafer cassettes compatible with all 4-inch wafer tools?

A1: Most are designed to SEMI standards, ensuring broad compatibility. However, always verify the exact flange and kinematic coupling design required by your specific loadports. Some older or specialized equipment may need adapters or custom cassettes.

Q2: How many wafers does a standard 4-inch wafer cassette hold?

A2: The standard capacity is 25 wafers. However, cassettes are available in other common capacities, such as 13-waffle packs or smaller batches for specific process tools.

Q3: Can PFA and PP cassettes be used interchangeably?

A3: Not always. PFA offers superior chemical and temperature resistance but is more expensive. PP is standard for most applications. The choice depends on your process chemistry (e.g., aggressive acid use requires PFA) and your cleanroom budget.

Q4: How often should 4-inch wafer cassettes be cleaned and inspected?

A4: The frequency depends on usage. A good practice is to inspect before each use for visible damage. Formal cleaning should follow a scheduled protocol—for example, after every 10 process cycles or immediately if contamination is suspected. High-priority processes require more frequent cleaning.

Q5: Does Hiner-pack offer ESD-safe versions of their 4-inch cassettes?

A5: Yes. For processes sensitive to electrostatic discharge, which can damage sensitive devices, Hiner-pack and other suppliers offer cassettes made with static-dissipative or conductive materials. These help safely drain charge and prevent static-related defects.