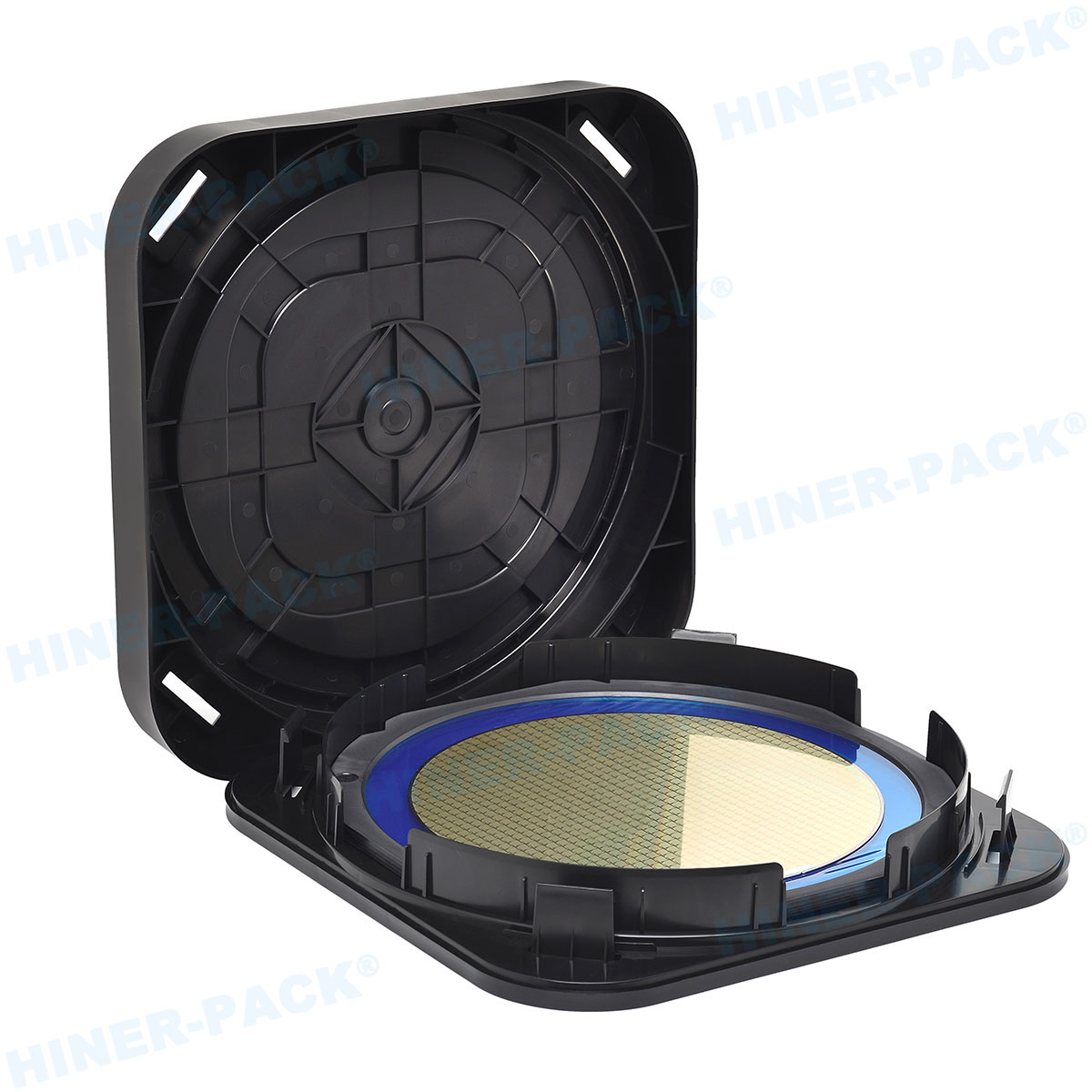

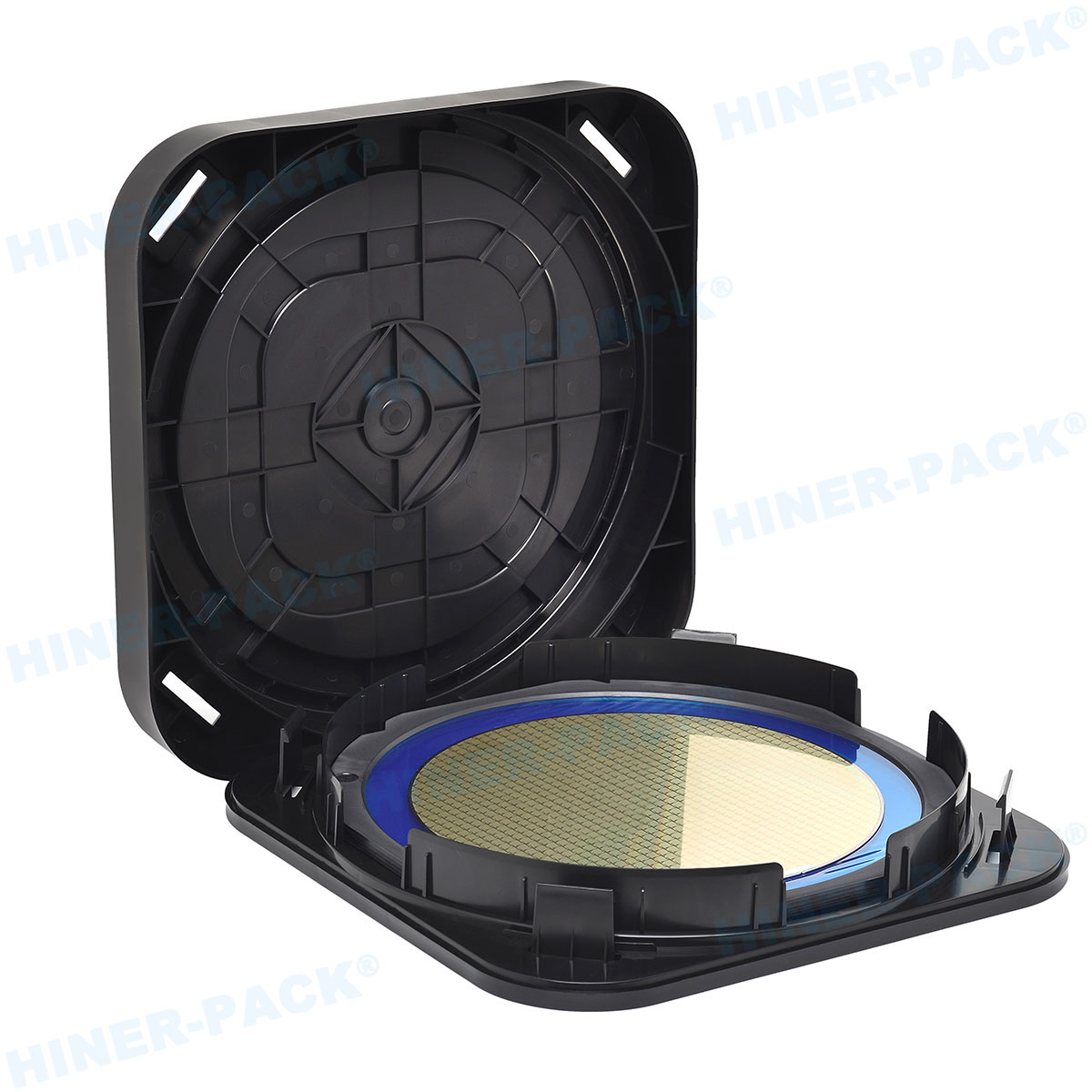

In semiconductor manufacturing, the transition to larger wafer diameters is a story of efficiency. Yet, the 150mm, or 6-inch wafer cassette, remains a cornerstone in many fab lines worldwide. It represents a critical balance between historical investment and modern performance.

This format is deeply entrenched in the production of numerous essential devices. From power semiconductors and advanced MEMS to robust optoelectronics and a vast array of analog chips, the 6-inch platform offers a proven, cost-effective foundation. For these production lines, the carrier is not just a container; it is a vital piece of process infrastructure.

The reliability of this component directly influences yield. A poorly designed or contaminated carrier can introduce defects, cause misprocessing, or lead to costly robotic handling errors. Understanding its role is key to maintaining a smooth and profitable operation.

The Enduring Role of the 6-Inch Platform

Why does the 150mm format persist? The answer lies in its optimal position on the cost-performance curve. The equipment for this diameter is fully depreciated, highly reliable, and well-understood by process engineers.

For many device types, scaling to larger wafers does not provide a compelling economic advantage. The materials used, such as silicon carbide (SiC) or gallium arsenide (GaAs) for power and RF devices, are expensive. Sticking with a 6-inch wafer cassette minimizes material cost while leveraging mature, high-yield process tools.

This makes the format a sustained workhorse. Its ongoing relevance ensures that the demand for high-quality, compatible carriers remains strong.

Design and Material Considerations for Reliability

Not every cassette is suitable for a high-tech fab. Specific design elements are non-negotiable.

Material selection is the first priority. High-purity, low-particulate polypropylene is the standard. For harsh chemical environments or high-temperature processes, PFA (perfluoroalkoxy alkane) cassettes are necessary. These materials must not outgas or degrade over time.

Precision molding is equally critical. Each slot must hold a wafer securely without any lateral movement. This prevents chipping and particle generation. The slots must also provide minimal, consistent contact points to reduce backside contamination.

Structural integrity prevents warpage. A cassette that bends under the weight of 25 wafers will cause misalignment at the load port. This can halt production. Reinforced sidewalls and a rigid bottom plate are essential features.

Ensuring Compatibility with Automated Systems

Modern fabs, even those running 6-inch lines, utilize a high degree of automation. The 6-inch wafer cassette must interface flawlessly with these systems.

This requires precise standardization. The cassette must meet specific SEMI (Semiconductor Equipment and Materials International) dimensional standards. Key features include the robotic handling flange, kinematic coupling pins, and the bottom notch for orientation.

These standards allow automated material handling systems (AMHS) and equipment robots to reliably pick, place, and transfer cassettes without human intervention. Inconsistencies here lead to machine faults and unscheduled downtime.

Brands like Hiner-pack engineer their carriers to these exact specifications. This guarantees smooth integration into automated workflows, protecting your investment in fab robotics.

Cleaning, Maintenance, and Contamination Control

A cassette is a reusable asset. Its lifecycle management directly impacts wafer purity. A rigorous cleaning and inspection regimen is mandatory.

Particulate contamination is the primary enemy. Cassettes must be cleaned regularly in dedicated wet benches or cleaning tools. The cleaning chemistry must be compatible with the cassette material to avoid damage.

Visual and tactile inspection should occur after every cleaning cycle. Technicians look for signs of wear, such as glossy streaks in the slots, cracks, or any deformation. Worn cassettes become particle generators and must be decommissioned.

Many fabs implement a tracking system. This logs the number of process runs for each carrier, ensuring they are retired after a defined service life. This proactive approach is cheaper than dealing with yield loss.

Selecting a Supplier: Quality Over Price

Choosing a source for these critical components is a strategic decision. The lowest upfront cost often leads to the highest total cost of ownership.

Consistency is paramount. Every 6-inch wafer cassette from a batch must be identical. Variations in dimensions or material quality introduce risk. A reputable supplier will have stringent quality control at every stage of manufacturing.

Technical support is another factor. A good supplier understands the application challenges. They can advise on material selection for specific processes, such as SiC wafer handling or high-temperature diffusion steps.

Hiner-pack has built a reputation on this depth of support. They provide not just a product, but a guarantee of performance and consistency that fabs can depend on for years.

While industry headlines focus on the latest nodes and largest wafers, the 6-inch wafer cassette continues to enable a vital segment of the semiconductor industry. Its role is foundational.

Selecting and maintaining these carriers with care is a direct contribution to line stability and product yield. In a business where a single particle can spell failure, the humble cassette demands and deserves precise attention. Partnering with a dedicated manufacturer ensures this critical link in your process chain remains strong.

Frequently Asked Questions (FAQs)

Q1: What is the standard wafer capacity for a 6-inch cassette?

A1: The most common capacity is 25 wafers. This aligns with historical lot sizes and is widely supported by furnace boats and process tool loadports. Other capacities, like 13 slots, are also available for specific applications.

Q2: Can we use the same cassette for both silicon and compound semiconductor (e.g., GaAs) wafers?

A2: It is not recommended without evaluation. Compound semiconductor wafers can be more brittle. Furthermore, cross-contamination of materials must be avoided. Dedicated cassettes, sometimes with specialized slot designs, are best practice for different substrate materials.

Q3: How do we know if a cassette is compatible with our older equipment?

A3: Check the equipment manual for the required SEMI standard (e.g., SEMI E1.2). Then, verify with your supplier, like Hiner-pack, that their cassette model meets that exact specification. Providing the manufacturer and model of your tool is the safest way to confirm.

Q4: What are the clear signs that a cassette needs to be replaced?

A4: Visible cracks or chips are immediate disqualifiers. Look for wear marks inside the wafer slots—a polished or grooved appearance indicates particle generation. Any warpage that prevents smooth loading onto a tool's load port also means the cassette should be retired.

Q5: Does Hiner-pack offer conductive or static-dissipative 6-inch cassettes for ESD-sensitive devices?

A5: Yes. For processes where electrostatic discharge (ESD) is a concern, Hiner-pack supplies cassettes made from carbon-loaded or other static-dissipative polymers. These materials safely control charge build-up, protecting sensitive devices from potential damage during handling.