In semiconductor assembly, precision is measured in microns and speed in milliseconds. The die bonder is the heart of this process, placing individual chips onto substrates. But what feeds the heart? For critical riveting or thermosonic bonding processes, the wafer riveting magazine is the unsung hero. It’s the precise, reliable feeder that ensures your bonder operates at peak efficiency without hiccups.

Choosing the wrong magazine leads to mis-picks, damaged die, and costly downtime. Understanding this component is essential for any production manager or process engineer focused on yield and throughput. This article details the function, selection, and innovation behind the wafer riveting magazine.

What Exactly is a Wafer Riveting Magazine?

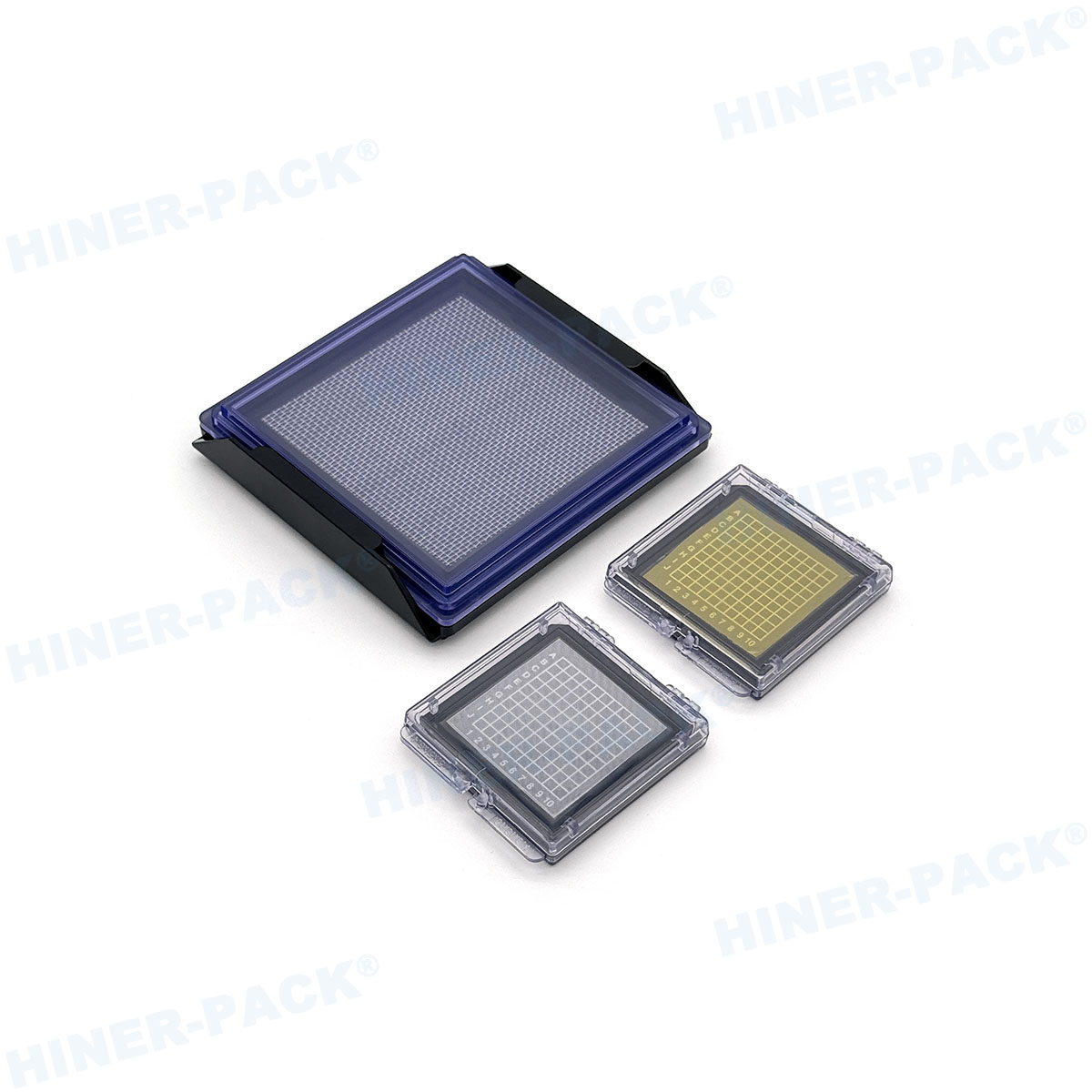

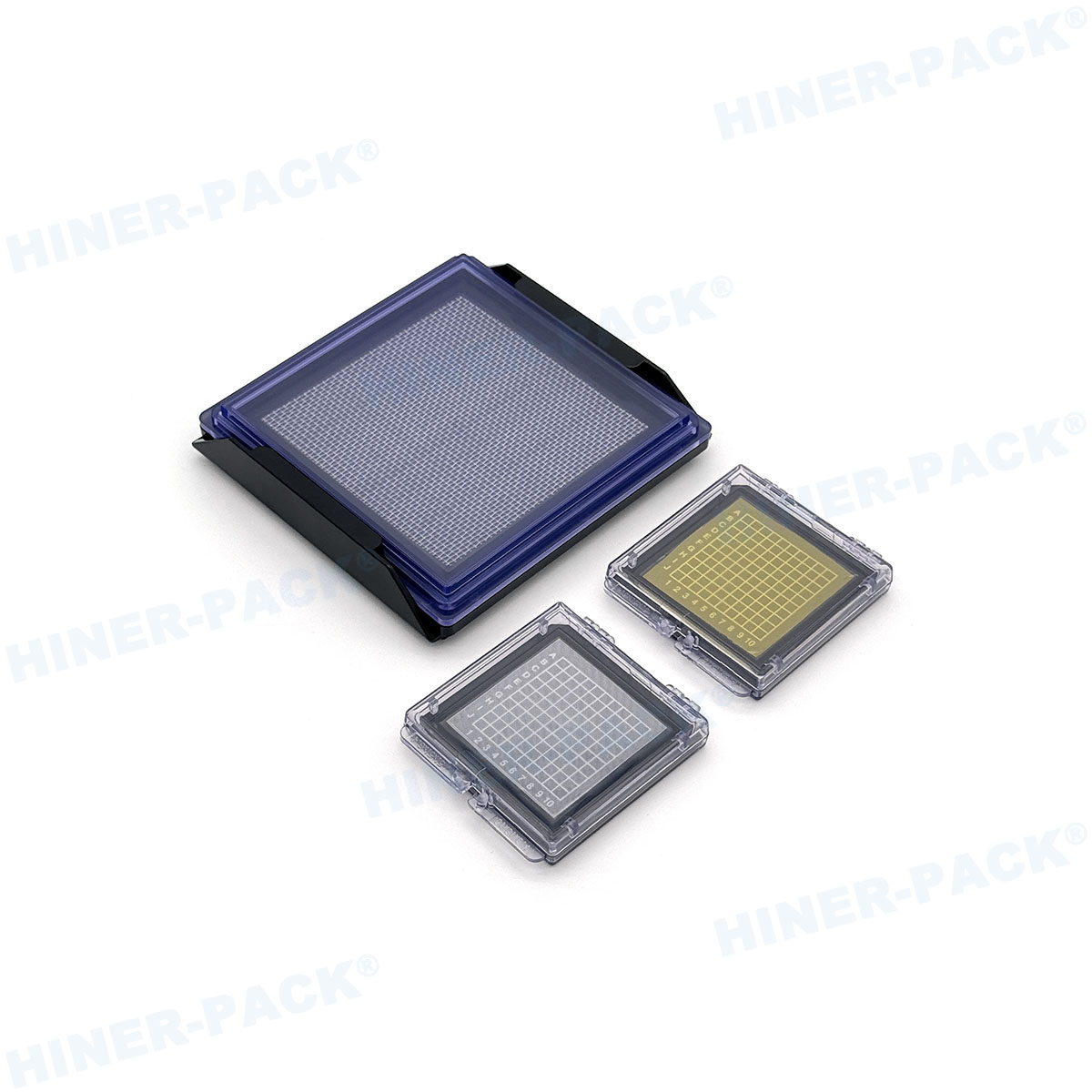

A wafer riveting magazine is a specialized carrier and interface unit. It securely holds a wafer frame (a diced wafer on a film frame) and presents it to the bonder’s pickup mechanism with exceptional accuracy and stability.

Think of it as a high-precision stage. During bonding, the bond head moves at high speed, picking up die with a collet. Any vibration or shift in the wafer frame causes misalignment. The magazine’s job is to eliminate this movement entirely.

It is a critical consumable in the backend assembly line. Its performance directly impacts placement accuracy, machine uptime, and ultimately, production yield.

Core Function and Technical Demands

The wafer riveting magazine must meet stringent mechanical and compatibility requirements.

Rigid Clamping: It employs a secure, often tool-less, clamping system to lock the wafer frame in place. This prevents any lateral shift or "frame creep" during the violent acceleration and deceleration of the bond head.

Precision Flatness: The mounting surface must be machined to extreme flatness. Any warp introduces Z-height variation, leading to inconsistent pick force and potential die crack.

Material Science: It's typically made from advanced engineering plastics or anodized aluminum. Materials must be static-dissipative, chemically resistant to cleaning solvents, and dimensionally stable across varying cleanroom temperatures.

Equipment Compatibility: A wafer riveting magazine is not universal. It is designed for specific bonder platforms from companies like ASM Pacific Technology, Besi, or Kulicke & Soffa. Using the correct magazine is non-negotiable.

Application and Selection Guide

Selecting the right magazine is a straightforward but vital decision.

Identify Your Bonder Model: This is the first and most critical step. You must know the exact make and model of your die bonder. A magazine for an ASM ADAT is entirely different from one for a Besi 8800.

Consider Your Wafer Format: Match the magazine to your standard wafer frame size, commonly 6-inch or 8-inch. Some applications may use irregular or rectangular formats.

Process-Specific Features: For thermosonic bonding riveting magazine applications, where heat and ultrasonic energy are applied, magazines with enhanced thermal stability are preferred. Discuss your specific process with your supplier.

Volume Assessment: High-volume fabs will prioritize durability and long-term consistency. Prototype or R&D lines might value flexibility. Hiner-pack offers robust standard designs and custom wafer riveting magazine solutions for both scenarios.

The Customization Question: Do you handle ultra-thin wafers or use a non-standard film frame thickness? Standard magazines might not suffice. This is where exploring a custom wafer riveting magazine with Hiner-pack becomes essential to solve unique process challenges.

Understanding Price and Value

The price of a wafer riveting magazine reflects its precision engineering and material quality.

Cost Drivers: The primary cost factors are the bonder compatibility (more complex interfaces cost more), the material grade (high-performance PEEK vs. standard PPS), and the level of customization.

Avoiding False Economy: A cheaper, off-spec magazine can seem like a savings. In reality, it leads to increased downtime, higher die loss, and potential damage to the bonder’s expensive pickup mechanism. The total cost of ownership favors a high-quality magazine.

Investment in Stability: Purchasing a reliable wafer riveting magazine from a trusted manufacturer like Hiner-pack is an investment in process stability. It is a key component in eliminating a major variable from your production line.

Semi-Custom Options: For common bonders with slight process tweaks, Hiner-pack provides optimized standard designs. These offer performance enhancements over basic OEM versions without the full cost of a bespoke custom magazine.

Technical Innovations from Hiner-pack

Beyond basic manufacture, innovation in magazine design solves real production pains.

Advanced Clamping Mechanisms: We design clamps that distribute hold-down pressure more evenly, preventing frame bowing, especially critical for thin wafers on sticky tape.

Integrated RFID Tags: For smart fabs, we can embed RFID chips into the wafer riveting magazine. This allows for automatic tool tracking, wear monitoring, and process data logging.

Weight-Optimized Designs: Reducing mass without sacrificing rigidity minimizes the kinetic energy transferred to the machine during high-speed indexing. This can contribute to longer bonder service life.

Surface Engineering: Proprietary coatings and surface treatments can further reduce particle generation and improve release properties, keeping the magazine cleaner for longer.

Commercial Services and Partnership

A leading supplier does more than sell a product; they provide support.

Rapid Prototyping: Hiner-pack can quickly produce prototype wafer riveting magazines for process validation or new equipment trials, accelerating your time-to-market.

Material Consultation: Our engineers can advise on the optimal material choice for your specific application, whether it involves high-temperature processes, aggressive chemistries, or extreme cleanliness requirements.

Inventory Management: For high-volume manufacturers, we establish blanket orders and scheduled deliveries. This ensures you never face a production stop due to a missing or worn-out magazine.

Performance Validation: We can provide test data and work with you to validate that a new magazine design meets or exceeds your requirements for flatness, clamping force, and particulate performance.

In the drive for higher yields and lower cost per unit, every component matters. The wafer riveting magazine is a small but fundamental piece of the die bonding puzzle. It directly influences machine availability, placement accuracy, and process repeatability.

Choosing a high-quality magazine, and partnering with a specialized engineer like Hiner-pack for standard or custom wafer riveting magazine needs, is a strategic decision for operational excellence. It’s about ensuring your capital-intensive bonder can run at its designed capability, hour after hour, day after day.

Frequently Asked Questions (FAQ)

Q1: What is the typical operational lifespan of a wafer riveting magazine?

A1: With proper handling and cleaning, a high-quality wafer riveting magazine from Hiner-pack can last for tens of thousands of production cycles. Lifespan depends heavily on the abrasiveness of the wafer frames used and the cleaning procedures. Regular inspection for wear on clamping surfaces is recommended.

Q2: Can you create a magazine for an older or discontinued bonder model?

A2: Yes, this is a common request. Hiner-pack specializes in reverse-engineering and manufacturing custom wafer riveting magazine solutions for legacy equipment. This can extend the service life of older bonders when OEM parts are no longer available.

Q3: How should I properly clean and maintain my magazines?

A3: Use approved, non-abrasive cleanroom wipes and solvents (like IPA). Avoid aggressive scraping. Ultrasonic cleaning can be effective for some models but consult Hiner-pack first, as it may affect integrated sensors or specific materials. Establish a regular cleaning schedule based on your usage.

Q4: My current magazines cause slight frame bowing. Is there a solution?

A4: This is often a clamping force distribution issue. Hiner-pack can analyze your current magazine and wafer frame setup. A custom wafer riveting magazine design with a modified clamp footprint or a different pressure profile can typically solve this problem and improve yield.

Q5: Do you offer a quick-turnaround service for prototype magazines?

A5: Absolutely. Hiner-pack operates a dedicated rapid prototyping service. We can often produce a functional prototype wafer riveting magazine for testing and validation within a matter of weeks, depending on the complexity of the design and interface requirements.