In the hyper-controlled, multi-billion-dollar environment of a wafer fabrication fab, the smallest particle can lead to catastrophic yield loss. While massive investments are made in lithography scanners and etching tools, the humble carrier boxes for wafer fabrication fab are often an afterthought. This is a costly oversight. These boxes, also known as FOUPs (Front-Opening Unified Pods), FOSBs (Front-Opening Shipping Boxes), and cassettes, are the primary guardians of wafer integrity during transport, storage, and processing. Choosing the wrong one is like using a cardboard box to move a priceless painting. This article dives into the five critical factors that semiconductor manufacturers must consider to protect their most valuable asset—the wafers.

For companies like Hiner-pack, which specializes in high-purity packaging solutions, understanding these nuances is the foundation of their product design.

Why the Right Wafer Carrier Box is Non-Negotiable

Before we delve into the selection criteria, it's essential to grasp the stakes. A modern wafer fabrication fab processes silicon wafers that will become hundreds of chips, each worth thousands of dollars. A single scratch, a minute particle contamination, or static discharge from an inadequately protected carrier can render an entire wafer useless. The role of carrier boxes for wafer fabrication fab extends beyond mere containment; they are active components in the contamination control strategy. They maintain a mini-environment of ultra-clean, particle-free air or inert gas around the wafers, shielding them from the cleanroom's ambient atmosphere during critical moves.

Factor 1: Material Matters – PFA, PC, PEEK, or Beyond?

The material of your carrier boxes for wafer fabrication fab directly impacts performance, longevity, and contamination risk.

High-Purity Plastics (PFA, PP): Materials like Perfluoroalkoxy (PFA) are industry standards for high-temperature processes. They offer excellent chemical resistance, minimal outgassing, and outstanding purity, making them ideal for the harsh chemistries inside a fab. Polypropylene (PP) is a cost-effective alternative for less aggressive environments or shipping.

Engineering Plastics (PC, PEEK): Polycarbonate (PC) offers high impact strength and clarity but may not withstand all process chemicals. Polyether ether ketone (PEEK) is a premium material known for its incredible thermal stability and mechanical properties, used in the most demanding applications.

Composite and Specialty Materials: For specific needs, such as static control or maximum rigidity, carbon-filled composites or specialized static-dissipative polymers are used.

The choice isn't just about the base polymer. The manufacturing process of the box itself must prevent the introduction of contaminants. Suppliers like Hiner-pack employ advanced molding techniques to ensure a smooth, non-particle-shedding interior surface.

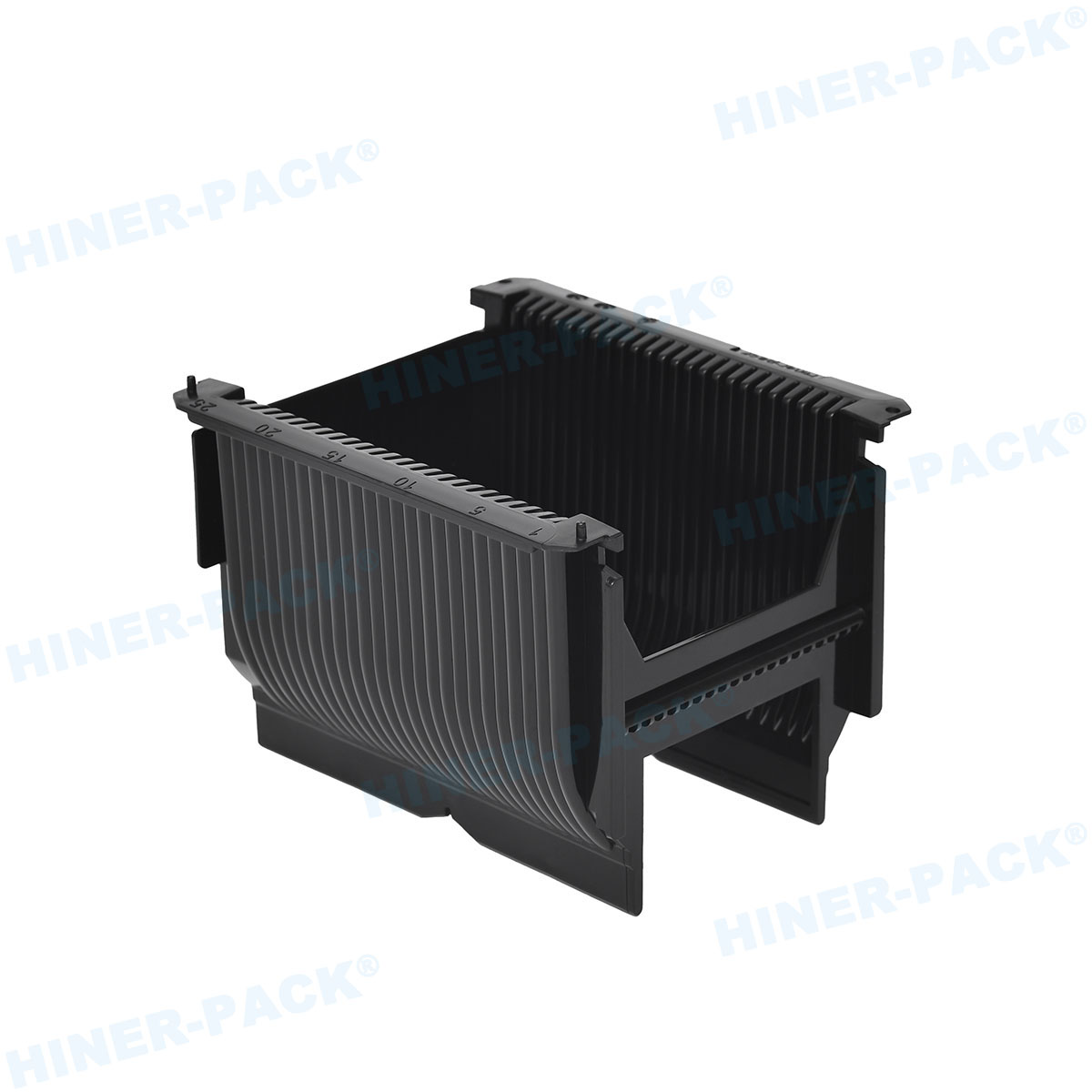

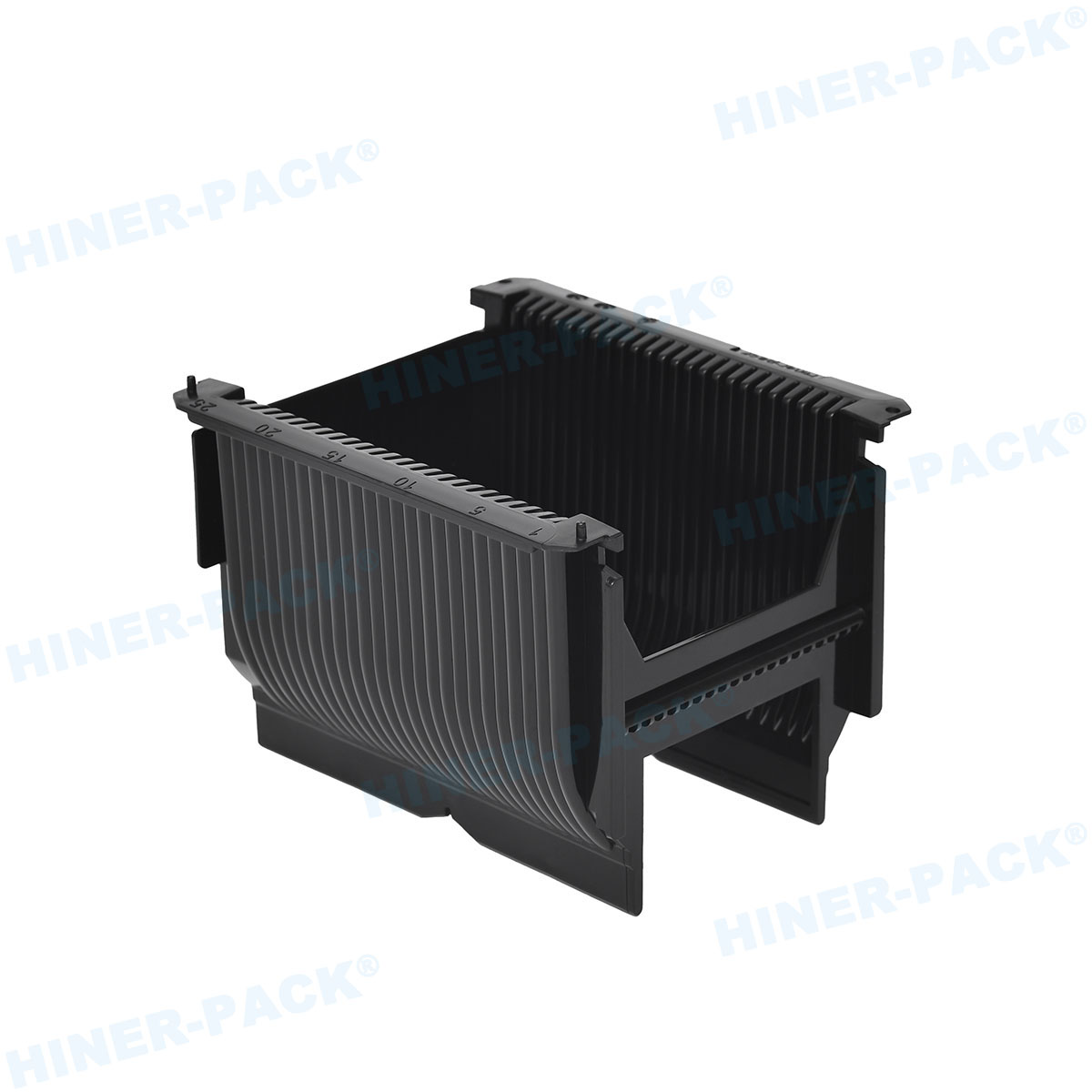

Factor 2: The Duel of Design – FOUP vs. FOSB vs. Cassette

Not all carrier boxes for wafer fabrication fab are created equal. Their design is tailored to specific functions within the production lifecycle.

FOUP (Front-Opening Unified Pod): This is the workhorse inside the fab. It's designed to interface directly with the process tools in an automated 300mm fab. Its front-opening door ensures a sealed transition between the pod and the equipment, maintaining the wafer's protected environment. The precision of the kinematic coupling and door mechanism is paramount.

FOSB (Front-Opening Shipping Box): Similar in appearance to a FOUP, the FOSB is built for inter-facility transport. It is generally more robust, with enhanced structural integrity to withstand the rigors of shipping. While it may interface with some automation, its primary role is to be a secure, sealed vessel for long-distance travel.

Wafer Cassettes: These are simpler, open structures that hold wafers in place, typically used within a single tool or for manual handling in smaller fabs (e.g., for 150mm wafers). They offer no sealed protection from the environment.

Selecting the wrong type—for instance, using a cassette where a FOUP is required—is a fundamental failure in contamination control.

Factor 3: Capacity and Wafer Size – 200mm, 300mm, and the 450mm Future

The semiconductor industry's evolution is marked by increasing wafer sizes. The carrier boxes for wafer fabrication fab must keep pace.

300mm Dominance: The current mainstream high-volume manufacturing standard is 300mm. FOUPs for this size are highly standardized in their external dimensions for automation compatibility but can vary in the number of wafers they hold (e.g., 13 or 25).

200mm Legacy and Specialty: A vast number of fabs, especially those producing analog, power, and MEMS devices, still operate on 200mm wafers. The ecosystem here often uses SMIF pods or open cassettes.

The Niche of Larger Formats: While 450mm wafer adoption has stalled, the principle remains: the carrier must be precisely engineered to handle the weight and fragility of larger wafers without sagging or inducing stress. The internal supports must be perfectly contoured to prevent micro-scratches.

Factor 4: Sealing and Purge Performance – The Invisible Shield

Perhaps the most critical functional aspect of a sealed carrier boxes for wafer fabrication fab is its ability to isolate the wafers. This is achieved through two key features:

The Gasket: The door seal, or gasket, must create a perfect, reliable hermetic seal every time the door is closed. Materials like high-grade elastomers are used, and their integrity over thousands of open-close cycles is vital.

Purge Connections: To create an inert environment, boxes are equipped with purge ports. These allow nitrogen or clean dry air to be pumped in, displacing oxygen and moisture that could cause oxidation or other wafer defects. The efficiency of the purge—how quickly and completely the internal atmosphere can be replaced—is a key performance metric for advanced carrier boxes for wafer fabrication fab.

Factor 5: Automation Compatibility and RFID Integration

A modern fab is a "lights-out" factory. Every piece of hardware must communicate with the Manufacturing Execution System (MES). This is where the "brains" of the carrier boxes for wafer fabrication fab come into play.

Kinematic Coupling: This is the standardized "mounting point" on the bottom of a FOUP/FOSB. It allows automated guided vehicles (AGVs) and overhead hoist transports (OHTs) to pick up and position the pod with micron-level precision. Any wear or inaccuracy here can lead to misloading and production downtime.

RFID Tags: Most advanced pods come with integrated Radio-Frequency Identification (RFID) tags. This tag contains a unique identifier for the pod and, crucially, data about the wafers inside—their process history, recipe requirements, and destination. This allows for full traceability and automated routing.

Brands that focus on the future, such as Hiner-pack, design their carrier solutions with this seamless integration in mind, ensuring compatibility with a wide range of fab automation systems.

Frequently Asked Questions (FAQ)

Q1: What is the typical lifespan of a wafer carrier box like a FOUP, and what are the main factors that lead to its replacement?

A1: The lifespan of a FOUP can vary from 5 to 10 years with proper maintenance. The primary reasons for replacement are wear and tear on the door mechanism and gasket, degradation of the kinematic coupling from repeated robotic handling, and cosmetic or structural damage from impacts. Over time, plastic can also become brittle or discolored, though this doesn't always immediately affect function.

Q2: How often should carrier boxes for wafer fabrication fab be cleaned, and what methods are recommended?

A2: Cleaning frequency depends on the specific processes the box is exposed to but typically occurs every time wafers are unloaded or on a fixed schedule (e.g., every 10 cycles). Recommended methods include DI water rinses, chemical cleaning with specific solvents for residue removal, and specialized dry ice or laser cleaning for stubborn particles. Automated cleaning stations are common in high-volume fabs.

Q3: Can we use a FOSB as a direct replacement for a FOUP in our automated fab line?

A3: Generally, no. While they look similar, FOSBs are often built to slightly different mechanical tolerances and may be heavier to withstand shipping. Using a FOSB in a high-speed FOUP-based automation system can cause misalignment, jams, and damage to both the pod and the expensive process tool. Always use the pod type specified for your fab's automation protocol.

Q4: What are AMC (Airborne Molecular Contamination) specifications, and why are they important for wafer carriers?

A4: AMCs are gaseous contaminants like acids, bases, or condensables that can deposit on wafer surfaces, causing defects. Carrier boxes must be made of materials that do not outgas these molecules and should act as a barrier to external AMC. Specifications define the maximum allowable levels of specific AMC classes that a pod can emit or allow to penetrate, which is critical for processes sensitive to molecular contamination.

Q5: How does the cost of a high-quality carrier box justify itself in the overall fab economics?

A5: While a premium FOUP from a trusted supplier may have a higher upfront cost than a generic alternative, its value is proven through drastically reduced yield loss. A single particle-induced defect can scrap a wafer worth tens of thousands of dollars. High-quality boxes minimize this risk through superior materials, precision manufacturing, and reliable sealing. This ROI, combined with longer service life and less unplanned downtime, makes them a far more economical choice in the long run.