In the high-stakes world of semiconductor manufacturing, contamination and physical damage are the enemies of yield. Protecting delicate wafers during transport, storage, and handling is not just a step in the process; it's a fundamental requirement. This is where the specialized role of Gel Pak membrane boxes becomes non-negotiable.

While many containers claim to offer protection, the unique design of Gel Pak membrane boxes provides a level of security specifically engineered for the semiconductor and photomask industry.

What Are Gel Pak Membrane Boxes?

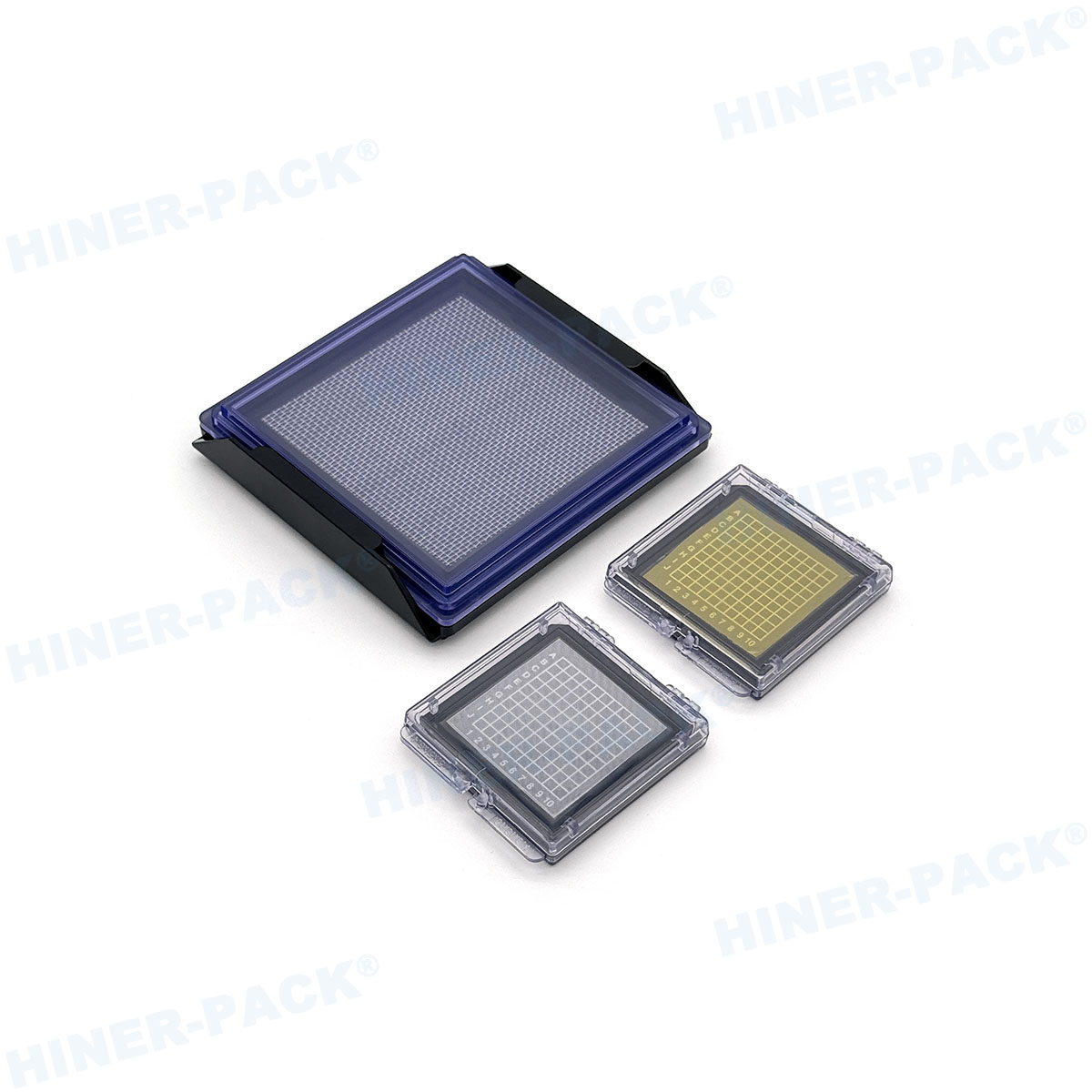

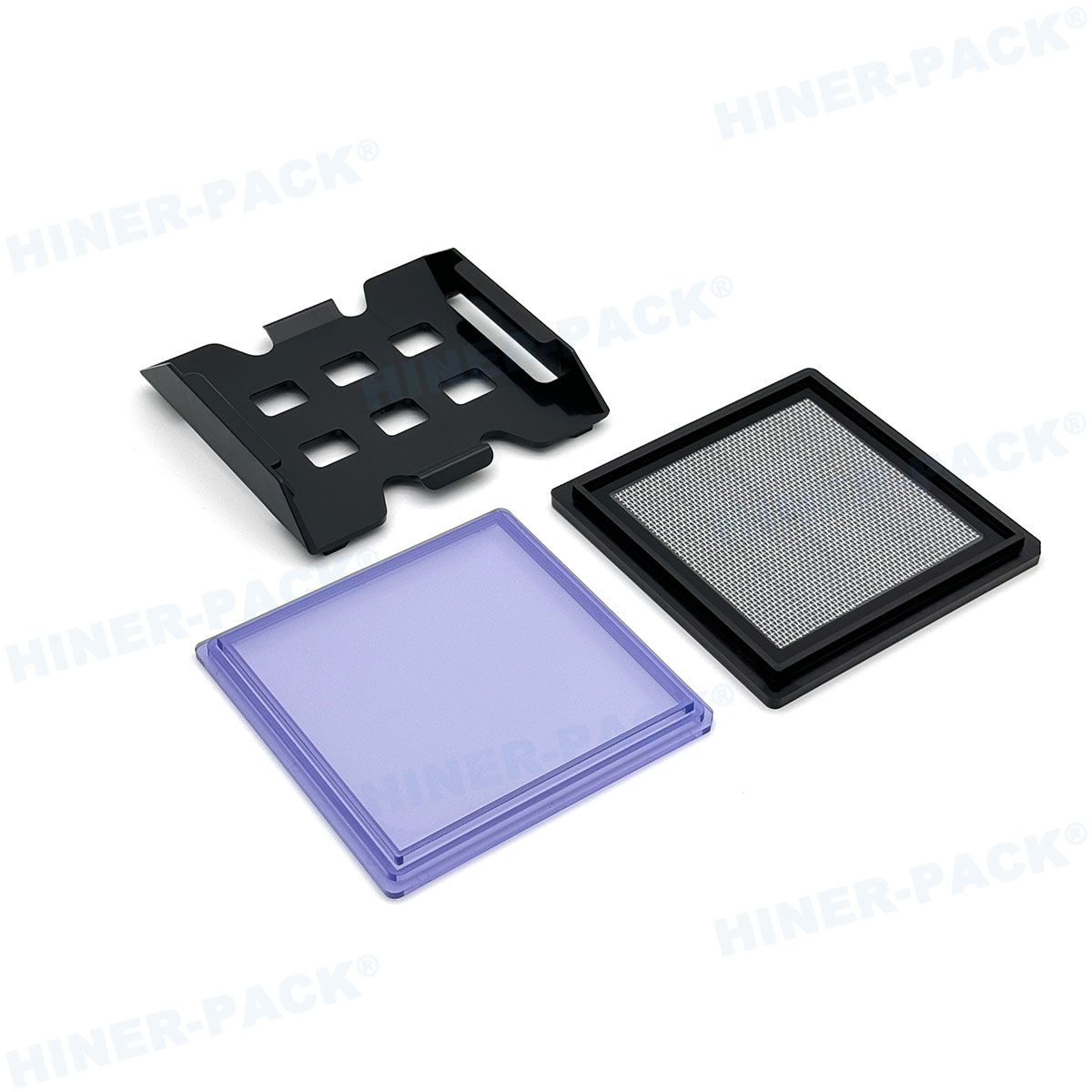

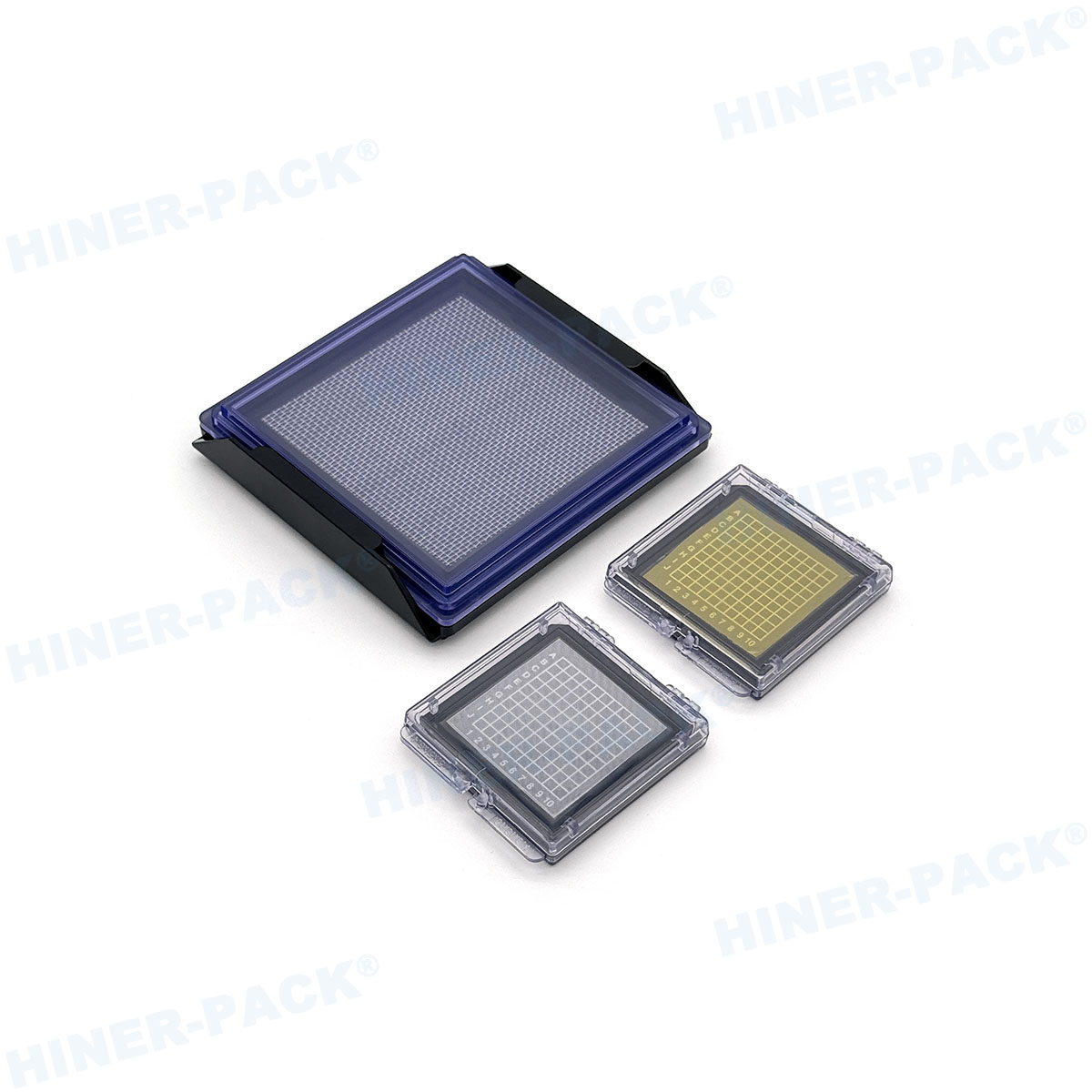

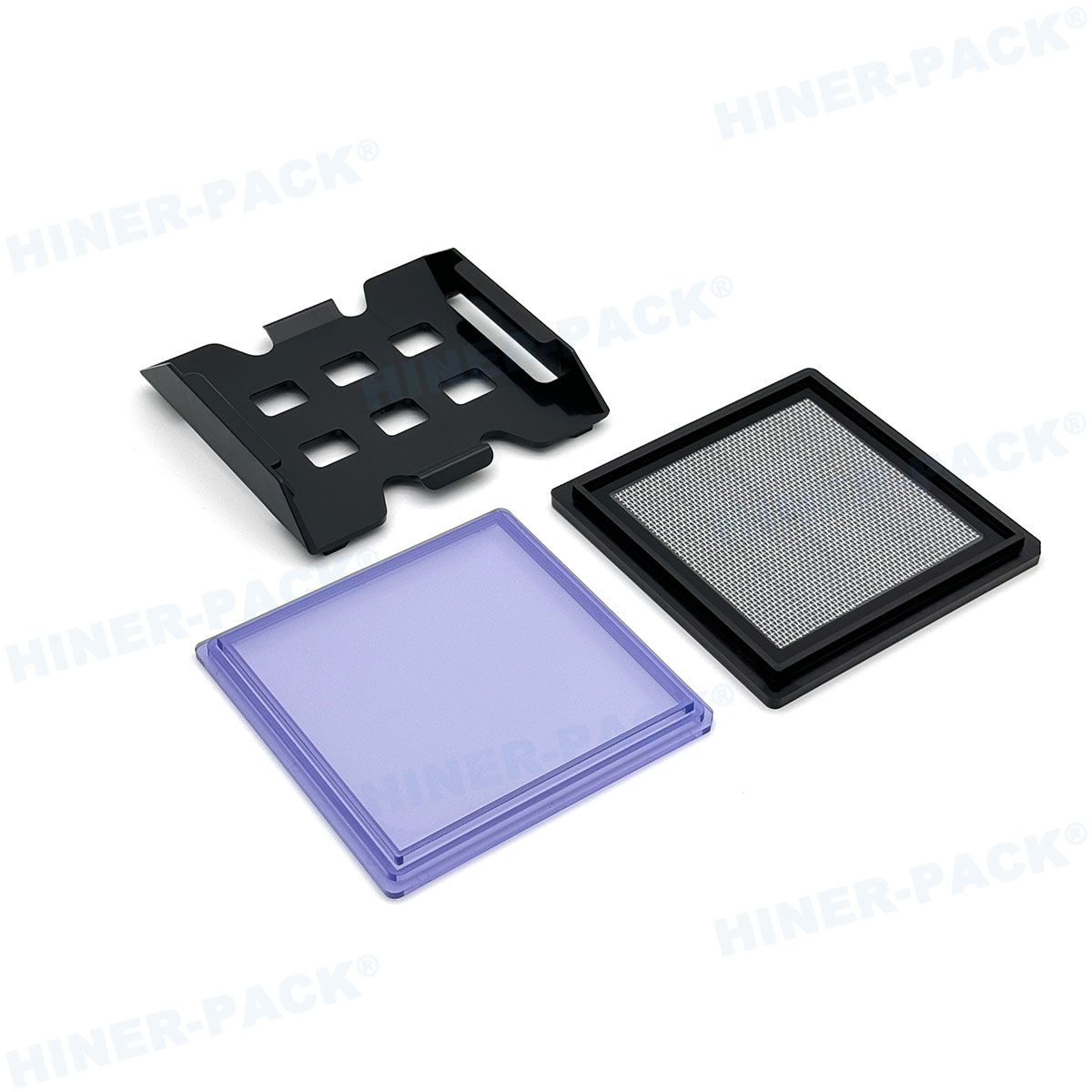

A Gel Pak membrane box is a type of wafer shipping container. Its defining feature is an integrated, pressure-sensitive, antistatic adhesive membrane—the "Gel Pak"—sealed within a rigid, conductive or static-dissipative plastic casing.

The wafer is placed onto this low-outgassing, non-corrosive adhesive gel. A protective liner is then peeled off a clear, antistatic polymer film (the membrane), which is pressed down over the wafer. This action gently bonds the wafer to the gel, holding it securely in place without any lateral movement.

The sealed box then protects against particles, physical shock, and electrostatic discharge (ESD).

Why Standard Containers Fall Short for Wafers

Standard wafer carriers or simple boxes lack active retention. Wafers can "rattle" inside during transit. This movement generates damaging particles through abrasion. It also risks edge chipping and breakage, especially for thinner wafers.

Furthermore, without a proper ESD-safe environment, static buildup can attract particulate contamination or cause electrostatic damage to sensitive circuits. The Gel Pak membrane box design directly addresses these failure points.

The Anatomy of a Superior Gel Pak Membrane Box

Understanding the components explains why this solution is so effective.

- Rigid, Engineered Polymer Shell: Made from materials like static-dissipative polycarbonate or PEEK. It provides structural strength, crush resistance, and a controlled internal environment.

- Antistatic Gel Layer: This is not a conventional adhesive. It is a soft, compliant, and clean gel formulated to hold the wafer without transferring residues. Its natural tackiness provides consistent, gentle holding power.

- Protective Release Liner: A removable layer that keeps the gel clean and uncontaminated until the moment of use.

- Antistatic Membrane Film: A clear, durable polymer film that forms the primary barrier. Once applied over the wafer and gel, it creates a sealed pouch, immobilizing the wafer.

- Secure Latching Mechanism: Ensures the box remains hermetically sealed during its journey, preventing accidental opening and environmental exposure.

1. Unmatched Wafer Immobilization

The core benefit. The combination of gel and membrane eliminates all internal movement. This prevents micro-scratches, edge damage, and breakage caused by vibration and shock during air or road freight. Your wafers arrive exactly as they were packed.

2. Superior Particle Control

By securing the wafer and creating a sealed environment, Gel Pak boxes drastically reduce the generation and circulation of particles inside the container. The materials themselves are certified for low outgassing and are manufactured in cleanroom environments to ensure ultra-low levels of extractables.

3. Essential ESD Protection

Every component, from the shell to the membrane, is designed to be conductive or dissipative. This creates a Faraday cage effect, shielding the wafer from external static fields and safely draining any internal charges. This is critical for protecting advanced nodes from ESD damage.

4. Process Compatibility and Cleanliness

High-quality Gel Pak membrane boxes are designed for use in cleanrooms. The gel is formulated for clean release, leaving minimal to no residue on the wafer backside. This compatibility with downstream processes prevents contamination issues in fabrication or metrology steps.

5. Durability and Reusability

While often used for one-way shipping, the robust construction of the boxes allows for careful inspection and reuse in many internal logistics scenarios. This can provide significant cost savings for intra-facility transfers.

How to Select the Right Gel Pak Membrane Box

Not all gel pak boxes are created equal. Specify based on your needs:

- Wafer Size: Standard sizes (150mm, 200mm, 300mm, 450mm) are available. Ensure a precise fit.

- Material Specifications: Look for compliance with SEMI standards (e.g., SEMI E1.9 for physical dimensions). Confirm the surface resistivity (e.g., 10^4 to 10^11 Ω/sq for dissipative range).

- Gel Adhesion Level: Some gels offer standard hold, while others provide extra-strong adhesion for high-vibration transport or vertically oriented shipping.

- Lid Design: Opt for secure, tool-less latches and clear labeling areas for logistics tracking.

For maximum protection of high-value semiconductor wafers, reticles, and other sensitive substrates, the investment in certified, high-performance Gel Pak membrane boxes is a direct investment in yield preservation and risk mitigation.

Frequently Asked Questions (FAQs) About Gel Pak Membrane Boxes

Q1: Can the gel from a Gel Pak membrane box damage my wafers?

A1: No, when you use boxes designed for semiconductor use. The specialized gel is formulated to be non-corrosive, low-outgassing, and to release cleanly. It leaves minimal to no residue, making it compatible with sensitive semiconductor processes. Always source boxes from suppliers specifying cleanroom-grade materials.

Q2: How many times can I reuse a Gel Pak membrane box?

A2: Reusability depends on the condition of the box and the gel. Inspect the box shell for cracks, the latches for function, and the gel for contamination or loss of tackiness. For internal, controlled-environment transfers, boxes can often be reused multiple times. For critical inter-fab or international shipping, single use is recommended to guarantee performance.

Q3: Are these boxes suitable for shipping fragile, thin wafers?

A3: Yes, they are often the preferred method. The gentle, uniform pressure of the gel and membrane holds thin wafers securely across their entire backside, distributing stress and preventing flexing or breakage that can occur in rigid, point-contact carriers.

Q4: What is the temperature range for Gel Pak membrane boxes?

A4: Standard boxes typically have an operational range from approximately -20°C to +60°C. The gel's holding power can diminish at very high temperatures. For extreme environment shipping, consult with the manufacturer for specifications on specialized gels designed for a wider temperature tolerance.

Q5: How do I properly unpack a wafer from a Gel Pak membrane box?

A5: Open the box's latches on a clean, stable surface. Gently peel back the antistatic membrane film starting from a designated corner. Once the membrane is fully removed, you can carefully lift the wafer from the gel layer. If needed, a slight twisting motion can help release it. Always follow the supplier's recommended unpacking procedure.