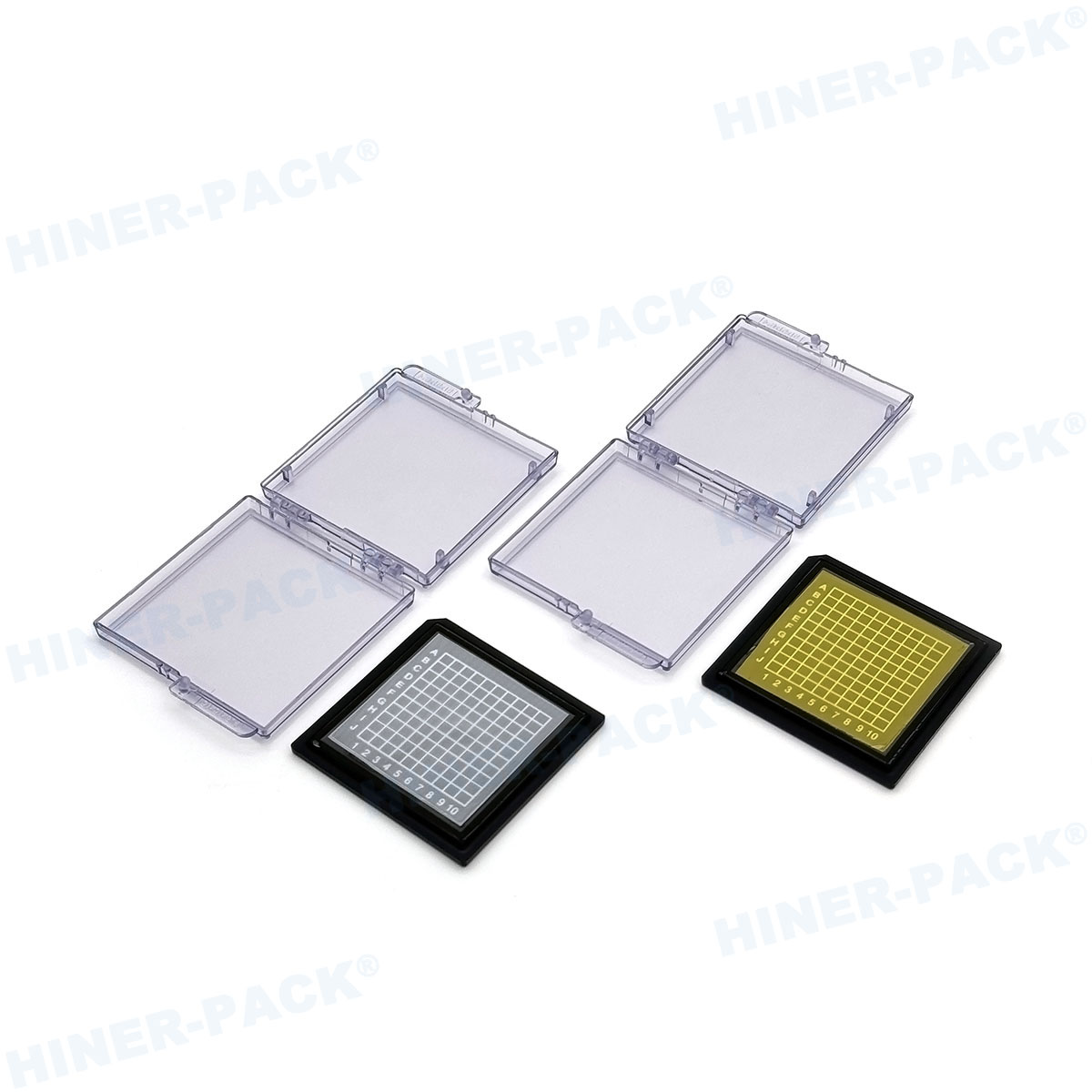

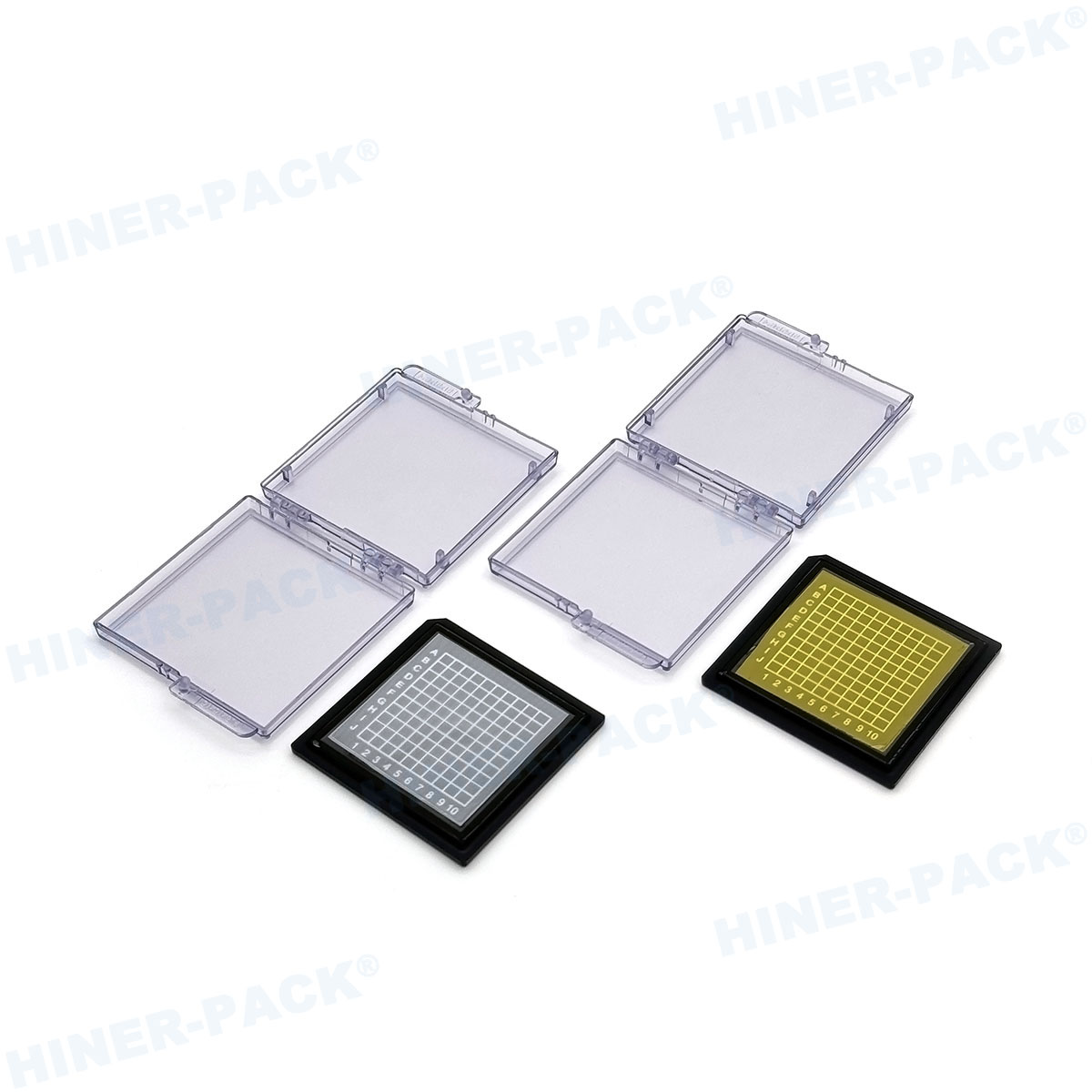

The IC packaging floor is a symphony of precision. After the delicate die is separated and tested, it must be protected, transported, and presented for its final assembly. Any mishandling in this phase translates directly into yield loss and cost. At the heart of this post-singulation workflow is a critical piece of infrastructure: JEDEC trays for IC packaging.

These are not mere containers. They are standardized, precision-molded substrates that secure individual integrated circuits through multiple process steps. From factory to assembly house, their uniformity and reliability underpin efficiency. This article breaks down why these trays are indispensable in packaging, examining their function, material science, and impact on the bottom line. We'll also look at how a specialist like Hiner-pack approaches their manufacture.

The Packaging Line: Where Trays Become Essential

The journey of a packaged IC—a QFN, BGA, or SOP—is physical and demanding. After mold and plating, units move through trim-and-form, electrical testing, laser marking, and visual inspection before shipping.

Bulk handling at this stage is not an option. Each unit needs a dedicated, secure location. JEDEC trays for IC packaging provide this organized matrix. They allow for safe transport between machines, enable batch processing, and present components correctly for automated final packing or direct placement.

Their standardized footprint is the common language that allows equipment from different manufacturers to work in concert.

Preventing Mechanical Damage and Warpage

One of the primary threats in packaging is physical stress. Pockets in a JEDEC tray are designed to cradle the IC body while exposing only the leads or bumps for contact. This prevents scratching and bending.

More critically, trays manage warpage. Polymer packages can warp due to thermal stress from molding. A non-compliant tray can exacerbate this by allowing uneven support during cooling or storage.

A true JEDEC compliant tray, with its specified flatness and precise pocket geometry, provides uniform, full-body support. This mitigates warpage and prevents "popcorning" or lead coplanarity issues that can ruin board-level soldering later.

ESD Protection: A Built-In Shield

The packaging environment is rife with electrostatic discharge risks. Moving belts, human handlers, and plastic surfaces can generate thousands of volts.

JEDEC standards categorize trays by their electrical properties. Conductive trays (surface resistance < 1 x 10^4 Ω/sq) create a Faraday cage, shielding components. Dissipative trays (1 x 10^5 to 1 x 10^11 Ω/sq) safely bleed away any charge.

Choosing the correct ESD-grade tray is a critical packaging decision. It is a primary defense against latent or catastrophic ESD failures that may only appear after the IC is on the end-user's board. Hiner-pack provides full material certification, so packaging managers know the level of protection built into every tray.

Enabling Seamless Automation and Tray-to-Tray Processing

Modern packaging is highly automated. Tray handlers, robotic pick-and-place arms, vision inspection systems, and stackers all interact with the carrier.

This is where JEDEC's mechanical specifications are non-negotiable. The exact location of stacking pins, anti-tilt lugs, and conveyor rail guides ensures that trays move smoothly through these systems.

A tray that deviates by even half a millimeter can cause a jam, stopping a line and costing thousands per hour. For processes like "tray-to-tray" testing or laser marking, this robotic compatibility is the foundation of throughput.

Material Matters: Withstanding the Packaging Environment

Packaging trays face specific stresses. They may be exposed to occasional high temperatures during testing or cleaning. They must resist chemicals from marking or cleaning processes. They endure constant mechanical cycling.

JEDEC-approved materials like PCTFE, PPS, or PEI are selected for this duty. For instance, trays used in a high-temp burn-in process must maintain dimensional stability. Hiner-pack engineers trays using these advanced polymers, balancing thermal performance, stiffness, and cost for the specific packaging stage.

Using an off-spec, commodity plastic tray risks tray warping under heat, contaminating components, or cracking after limited use.

The Supply Chain and Logistics Advantage

After final test, packaged ICs are shipped globally. Here, JEDEC trays for IC packaging deliver their final major benefit: universal compatibility.

A tray filled in a Malaysian packaging house will fit perfectly into the automated feeders at a contract manufacturer in Germany. This eliminates repacking, reduces handling damage, and simplifies inventory management.

Shipping boxes, dividers, and pallet patterns are also designed around the standard tray footprint. This end-to-end standardization, from process tool to shipping container, reduces complexity and cost across the entire supply chain.

Choosing a Supplier: More Than Just a Mold

Selecting a tray supplier for packaging applications requires technical diligence. Compliance should be a given, verified by data sheets and Certificates of Compliance.

Look for a partner with a deep understanding of packaging workflows. They should ask questions: Will these go through a laser marker? What is your wash process temperature? How many reflows do you anticipate?

A supplier like Hiner-pack brings value through this application knowledge. They can recommend the optimal material grade, advise on designs that ease automated unloading, and ensure their trays withstand the rigors of your specific packaging line. Consistency in high-volume production is also critical; every tray in a batch must perform identically.

In the intricate dance of IC packaging, consistency and protection are everything. JEDEC trays for IC packaging provide the foundational platform that makes high-volume, automated, and reliable packaging possible. They are a strategic component, directly influencing yield, line utilization, and total cost.

Investing in high-quality, fully compliant trays from a trusted manufacturer is not a purchasing decision; it is a process integrity decision. It ensures that the value created in fabrication and assembly is preserved all the way to the customer.

Frequently Asked Questions (FAQs)

Q1: Can we use the same JEDEC tray for both pre-cap and post-cap packaging steps?

A1: It depends on the thermal and cleanliness requirements. Pre-cap steps may involve higher heat or potential contamination. Often, a dedicated, high-temperature, clean-grade tray is used for initial steps, while a standard tray is used for post-mold, testing, and shipping. Consult your tray supplier for a process-specific recommendation.

Q2: How often should JEDEC trays in packaging be replaced?

A2: There's no fixed cycle count. Replacement should be based on inspection. Look for visible wear, cracking (especially at thin ribs or pins), permanent warpage, or contamination that cannot be cleaned. A rigorous packaging line should have a standard inspection and retirement procedure.

Q3: Are there JEDEC trays for panel-level packaging (PLP) or fan-out wafer-level packaging (FOWLP)?

A3: The standards primarily address singulated units. For panel or reconstituted wafer handling, specialized carriers are used. However, once singulated into individual packages from the panel, the components are always placed into standard JEDEC trays for IC packaging for subsequent handling and shipping.

Q4: What's the best way to clean trays that get contaminated during packaging?

A4: Manual wiping with IPA is common for spot cleaning. For batch cleaning, use a qualified aqueous or solvent-based cleaner in an automated washer. Crucially, verify that the tray material (e.g., PCTFE, PEEK) is chemically compatible with the cleaning agent and that the process temperature does not exceed the tray's HDT (Heat Deflection Temperature).

Q5: Our device has an unusual, non-rectangular shape. Can we still use a JEDEC tray?

A5: The outer tray dimensions and handling features must remain JEDEC-compliant to work with automation. However, the interior pocket geometry can often be customized to securely hold your specific package outline. Suppliers like Hiner-pack can design a compliant carrier with a custom pocket, giving you automation compatibility without sacrificing device security.