In the high-stakes world of semiconductor manufacturing, the safe transit of silicon wafers is not just a logistical step—it's a critical point of failure that can cost millions. With wafer sizes increasing and node sizes shrinking, the protective packaging is more vital than ever. The vertical wafer shipper has emerged as the industry-standard solution, but not all shippers are created equal. Choosing the wrong one can lead to catastrophic contamination, physical damage, and devastating yield loss. This article breaks down the seven essential factors your company must evaluate to ensure your wafers arrive in the same pristine condition they left the fab.

Why the Vertical Wafer Shipper Design is Non-Negotiable

Unlike traditional horizontal boxes, a vertical wafer shipper is engineered to hold wafers in a upright position during transport and storage. This design is fundamental to modern semiconductor logistics. It minimizes the surface contact area on the wafer, drastically reducing the risk of micro-scratches and particle generation. When wafers are laid flat, their entire surface area rests on a shelf, creating multiple points of potential contamination. The vertical wafer carrier eliminates this by cradling the wafer securely by its edges, the least critical part of the structure. This alignment is also crucial for compatibility with automated material handling systems (AMHS) in fabs, ensuring a seamless transition from transport to processing.

Beyond the Box: The Core Components of a Reliable Wafer Shipper

A vertical wafer shipping container is a system of integrated components, each playing a vital role.

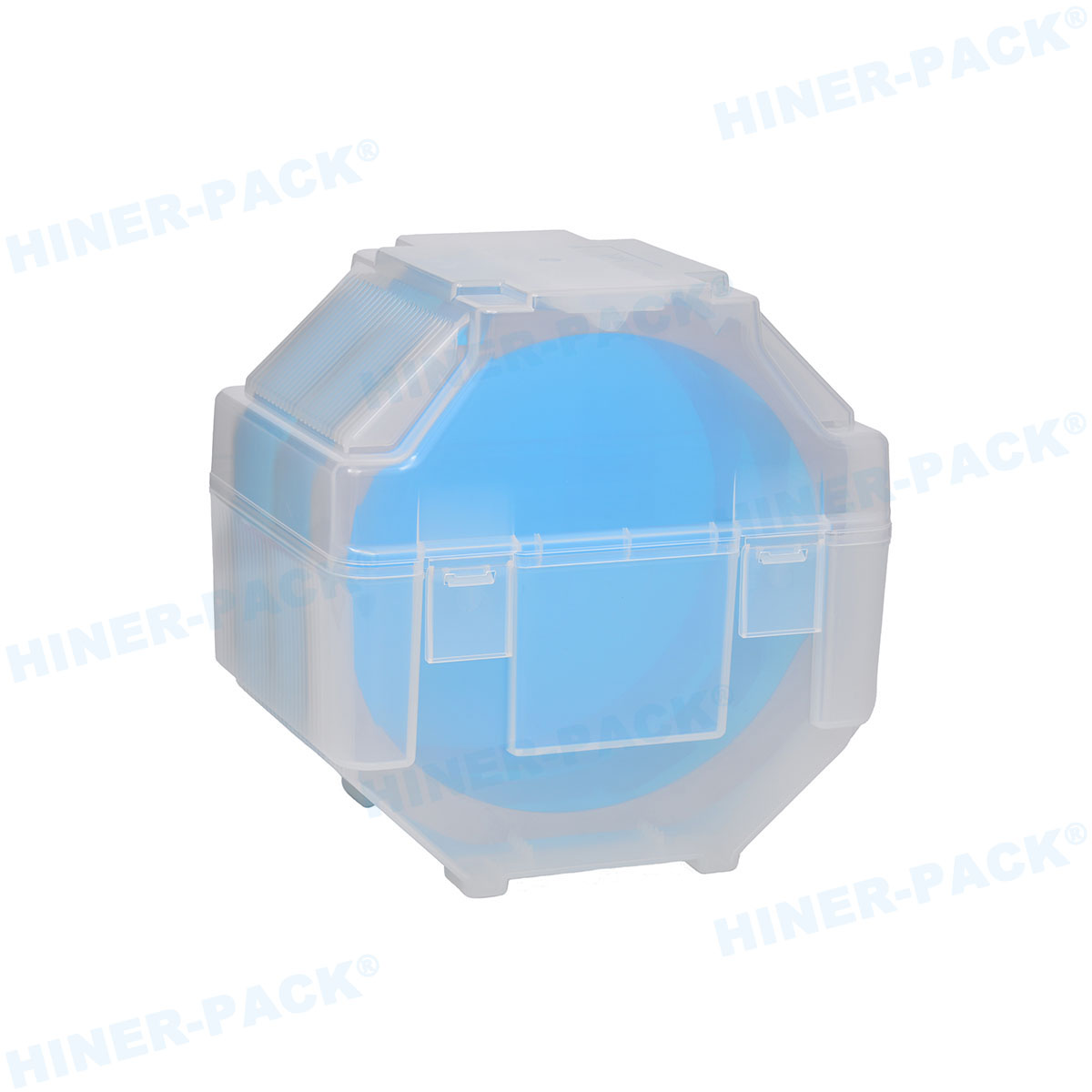

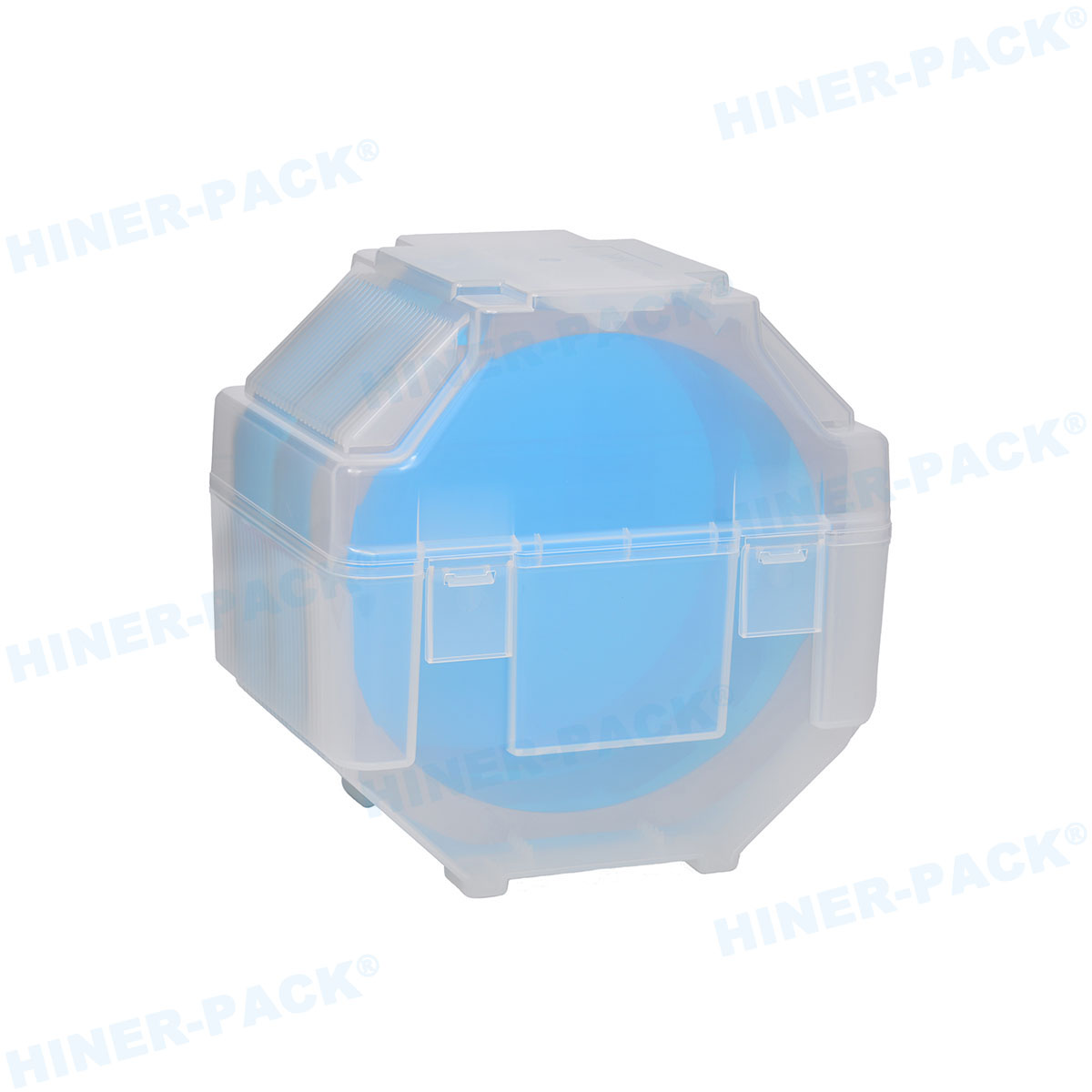

The Contamination-Free Shell: The outer shell, typically made from advanced, static-dissipative polymers, must be robust enough to withstand rough handling while being inherently clean. It should not outgas or shed particles. Companies like Hiner-pack utilize specialized composite materials that meet or exceed SEMI standards for purity and durability.

The Intelligent Cassette/Monorail System: Inside the shell, the mechanism that holds the wafers is the heart of the vertical wafer shipper. It’s often a monorail or cassette design with precisely molded pockets. These pockets are lined with ultra-clean, compliant materials that grip the wafer without applying stress, preventing movement and “wafer walk” during transit.

Mechanical Interface Precision: The entire unit must interface perfectly with standardized fab equipment. This includes precise dimensions for stacking and compatibility with load ports. A lack of precision here can lead to misalignment, jams, and automation failures.

The 7 Critical Selection Criteria for Your Next Vertical Wafer Shipper

When auditing potential suppliers for your vertical wafer shipper needs, use this checklist.

1. Mechanical Shock and Vibration Dampening

How much G-force can the container absorb? Reputable manufacturers will have independent test data showing performance under drop tests and vibration profiles that simulate air and road travel. The internal cushioning system must isolate the wafers from external impacts.

2. Particle and Outgassing Control

Ask for particle count data. A high-quality vertical wafer shipper will have certified data for particles greater than 0.3 microns. Furthermore, the materials must have low levels of outgassing to prevent airborne molecular contamination (AMC), which can degrade sensitive wafer surfaces.

3. Electrostatic Discharge (ESD) Protection

Static charge can attract particles and cause electrostatic discharge, damaging delicate circuits. Ensure the vertical wafer shipping container is made from materials with the correct surface resistivity and volume resistivity to safely dissipate charge, protecting wafers up to 450mm.

4. Sealing Integrity and Moisture Barrier

The door or lid seal is a critical component. It must create a hermetic barrier to prevent moisture ingress, which can lead to oxidation and haze. Look for designs with robust latching mechanisms and gaskets that have been validated through helium leak tests.

5. Thermal and Chemical Resistance

In certain processes, the wafer shipper box may be exposed to temperature variations or cleaning chemicals. The material should withstand these without warping, cracking, or degrading. Hiner-pack’s containers, for instance, are designed to maintain structural integrity across a wide temperature range.

6. Ergonomic and Automation-Friendly Design

While protecting wafers is paramount, the shipper must also be safe and easy for operators to handle. Features like ergonomic handles and lightweight designs reduce the risk of repetitive strain injuries. Simultaneously, the design must facilitate easy robotic handling without requiring complex adaptations.

7. Total Cost of Ownership (TCO), Not Just Unit Price

The cheapest vertical wafer shipper is often the most expensive in the long run. Calculate TCO by considering:

Durability and Reusability: How many trips can it reliably make?

Cleaning Costs: Is it easy to clean and re-certify?

Compatibility: Will it work with your existing equipment without causing downtime?

A supplier like Hiner-pack that focuses on long-term reliability often provides a lower TCO, even with a higher initial price.

Hiner-pack's Approach to Advanced Wafer Shipping Solutions

At Hiner-pack, we don't just manufacture containers; we engineer reliability. Our vertical wafer shipper product line is the result of close collaboration with leading semiconductor manufacturers. We understand that a failure in your supply chain is not an option. Our R&D focus is on pushing the boundaries of material science to create shippers that offer superior shock absorption, lower particle counts, and longer service life. We provide full traceability and validation documentation with every lot, giving you the peace of mind that your critical products are protected by the best wafer shipping solution on the market.

Applications: Where a High-Performance Vertical Wafer Shipper is Essential

The use of a robust vertical wafer carrier extends across the semiconductor ecosystem:

Fab-to-Fab Transfers: Shipping wafers between different manufacturing sites.

OSAT Logistics: Transporting wafers to Outsourced Assembly and Test facilities.

R&D and Pilot Lines: Moving sensitive prototype wafers and new materials.

Long-Term Archiving: Storing wafers for future use or reference, requiring exceptional sealing and material stability.

In the semiconductor industry, your wafers are your lifeblood. The choice of a vertical wafer shipper is a direct investment in protecting your yield, your reputation, and your bottom line. By moving beyond a simple price comparison and focusing on the seven critical engineering and performance factors outlined above, you can make an informed decision that safeguards your products from the fab to the final destination. Don't let your multi-million dollar investment be compromised by inadequate packaging.

Frequently Asked Questions (FAQs) About Vertical Wafer Shippers

Q1: How many times can a typical vertical wafer shipper be reused?

A1: The reuse cycle of a vertical wafer shipper depends heavily on the manufacturer's design, the material quality, and the rigor of the transport environment. A high-quality shipper from a brand like Hiner-pack can often withstand dozens of trips when properly handled, cleaned, and inspected between uses. It's crucial to follow the manufacturer's guidelines for requalification and to regularly check for signs of wear, especially on the internal cushions and door seals.

Q2: What is the main difference between a FOUP and a vertical wafer shipper?

A2: A FOUP (Front-Opening Unified Pod) is designed for internal use within a semiconductor fab, moving wafers between tools in a controlled cleanroom environment. A vertical wafer shipping container, while similar in its vertical orientation, is built for the harsh conditions of external transport. It has more robust structural integrity, superior shock and vibration dampening, and enhanced sealing to protect against temperature, pressure changes, and contamination outside the cleanroom.

Q3: How do I properly clean and decontaminate a vertical wafer shipper?

A3: Proper cleaning is essential for reuse. The process typically involves a combination of dry nitrogen purging to remove loose particles and a specialized chemical cleaning process, often using deionized water with specific surfactants, in a controlled environment. It is critical to use procedures and chemicals recommended by the vertical wafer shipper manufacturer, as using the wrong chemicals can damage the materials, leading to outgassing or particle shedding.

Q4: Are there standardized sizes for these shippers, such as for 300mm wafers?

A4: Yes, the semiconductor industry operates under strict standards set by organizations like SEMI. For 300mm wafers, the vertical wafer carrier dimensions, cassette interfaces, and load port specifications are highly standardized (e.g., SEMI E15.1, E47.1, E1.9). This ensures interoperability between different manufacturers' shippers and fab equipment. However, within these standard footprints, suppliers like Hiner-pack can differentiate through material composition, internal damping technology, and seal design.

Q5: What certifications or test data should I request from a potential supplier?

A5: You should always request validated test data for mechanical shock (e.g., MIL-STD tests), vibration, particle counts per SEMI standards, and outgassing. Certificates of Material Compliance stating that the materials meet SEMI and RoHS standards are also essential. A reputable supplier will be transparent with this data and may even offer to perform benchmark tests against your current wafer shipper box to demonstrate performance superiority.