Precise semiconductor packaging is not just about protection; it is about yield management. When moving fragile dies, Indium Phosphide (InP) wafers, or optical components, the dimensions of your carrier determine safety.

Engineers often search for standard Gel Pak tray sizes to ensure compatibility with automated pick-and-place equipment and storage systems. However, finding the exact correlation between active area, box dimensions, and retention levels can be confusing.

At Hiner-pack, we understand that a difference of a few millimeters can disrupt an automated line. This article breaks down the essential dimensions, retention mechanisms, and selecting the right carrier for your specific die application.

Why Tray Dimensions Matter in Process Engineering

The physical footprint of a gel carrier dictates how it fits into your workflow. If the tray is too large, it wastes shipping volume. If the active area is too small, you risk die collision during transport.

Most process engineers look for "Gel Pak tray sizes" as a reference point for industry standards. These usually fall into 2-inch, 4-inch, and JEDEC standard categories.

Hiner-pack manufactures high-precision gel sticky boxes and vacuum release trays that align with these global standards. Our goal is to ensure that whether you are handling 150-micron GaAs chips or heavy ceramic substrates, the tray size fits your existing fixtures.

The Standard 2-Inch Tray (VR-2 and AD-2 Equivalents)

The most ubiquitous size in the photonics and semiconductor industry is the 2-inch format. This is the workhorse for small to medium-batch production.

External Dimensions:Typically, the external carrier box measures approximately 2" x 2" (50.8mm x 50.8mm).

Active Area:The usable gel area is usually slightly smaller, often around 1.5" x 1.5" or 1.8" x 1.8", depending on whether the tray uses a vacuum release mechanism or a standard adhesive surface.

At Hiner-pack, we see high demand for this size because it fits standard hinge boxes. It allows for the safe transport of roughly 100 to 400 dies depending on the die size.

The 4-Inch Tray for High-Volume Transport

As production scales, the 2-inch tray becomes inefficient. The 4-inch format offers four times the surface area, making it ideal for larger wafers or high-quantity die shipments.

Key Specs:

External: 4" x 4" (101.6mm x 101.6mm).Compatibility: Fits standard 4-inch wafer rings and shipping jars.

When evaluating Gel Pak tray sizes, the 4-inch model is often required for automated die bonders that utilize larger stage inputs. Hiner-pack ensures that our 4-inch compatible trays maintain strict flatness. Warping in a tray of this size can cause vacuum leakage during the release process, leading to pick-up errors.

JEDEC Standard Trays (Matrix Trays)

For automated handling lines using standard tray feeders, the JEDEC format is non-negotiable.

Dimensions:These trays measure 12.79" x 5.35" (322.6mm x 136mm).

Unlike the smaller 2-inch or 4-inch hinged boxes, JEDEC trays from Hiner-pack are designed for high-speed SMT lines. The gel coating on these trays allows for the secure holding of non-standard components that cannot fit into pocket tape.

If you are transitioning from manual handling to full automation, moving to JEDEC-sized gel carriers is usually the necessary step.

Vacuum Release (VR) vs. Standard Gel Box Sizes

Size is not just length and width; it is also about depth and mechanism.

Vacuum Release (VR) Trays:These require a specific mesh geometry. The tray must sit on a vacuum chuck. If the external dimensions of the tray do not match the vacuum pedestal of your equipment, the release mechanism will fail.

Hiner-pack engineers trays where the vacuum port location aligns perfectly with industry-standard release stations. We ensure that our tray perimeters match the specifications often found when engineers look up Gel Pak tray sizes for VR applications.

Standard Gel Boxes (Non-Vacuum):These rely solely on surface tension. The critical dimension here is the clearance (gap) between the gel surface and the lid. If you are shipping tall components (like lensed optics), you must select a box with a deeper internal height to prevent the lid from crushing the component.

Retention Levels and Mesh Counts

While this article focuses on size, the "size" of the contact point matters too. This is defined by the mesh count in vacuum trays.

16 Mesh: Large holes, minimal contact. Good for very small devices.76 Mesh: Standard for most applications.195 Mesh: Tight weave for very small or thin devices.

When you select a tray size from Hiner-pack, you also select a retention level (Low, Medium, High). The retention force is calculated based on the backside area of your die. A large 4-inch tray holding heavy components will require a higher retention level than a 2-inch tray holding lightweight MEMS.

ESD Properties and Material sizing

The material composition affects the sizing tolerances.

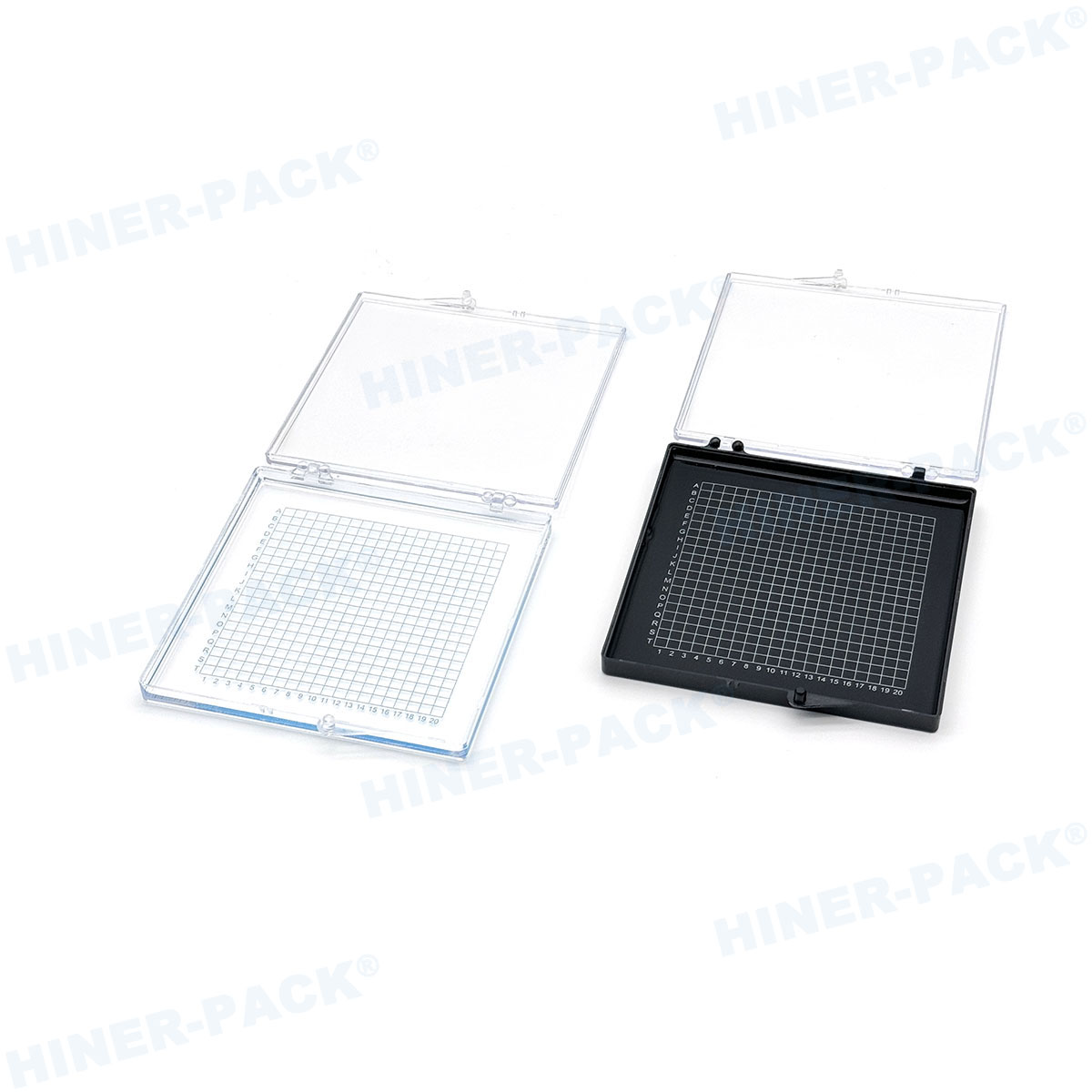

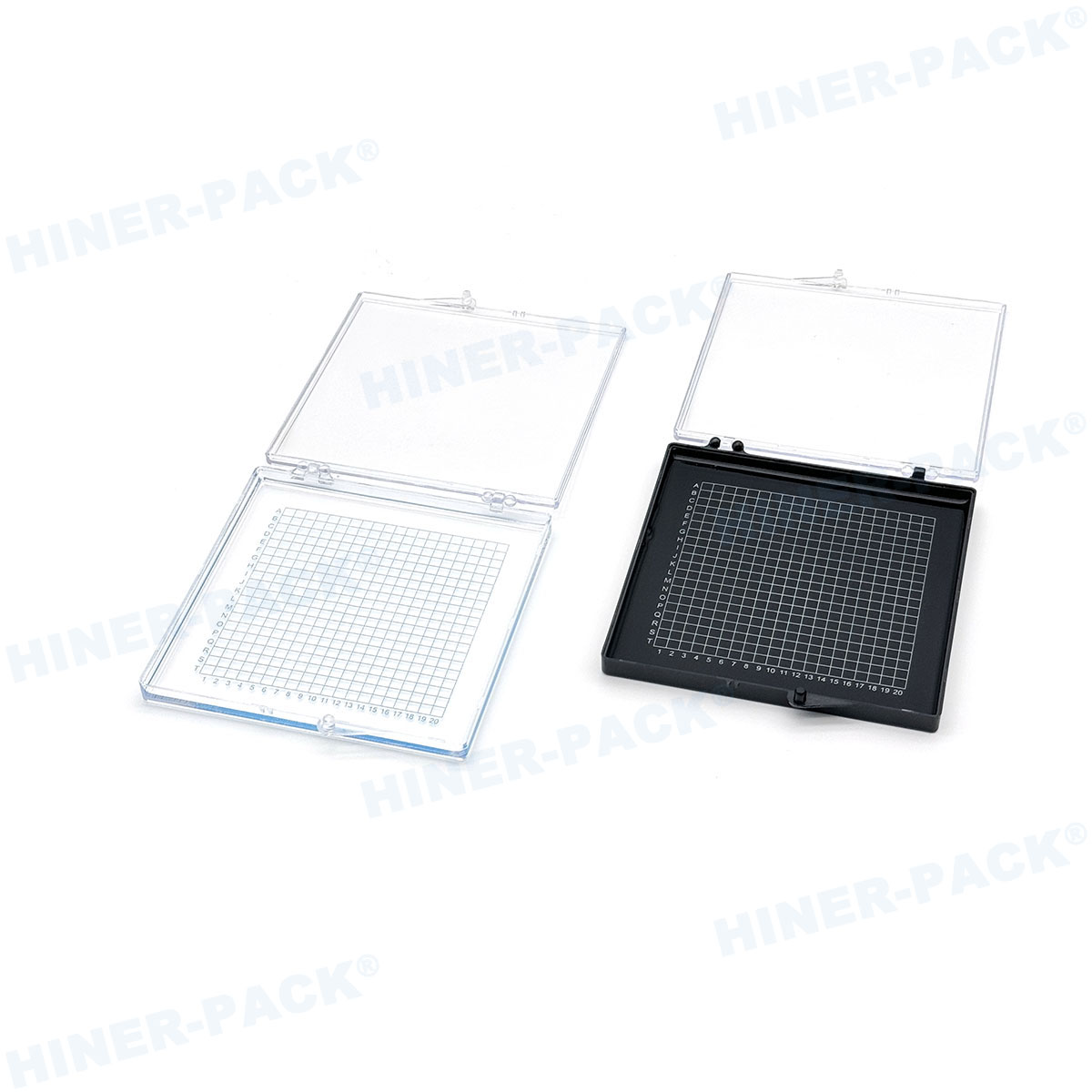

Conductive Black (ESD Safe):Carbon-loaded materials are used for static-sensitive devices. These materials are rigid.

Transparent (Non-ESD):Used for inspection.

Hiner-pack maintains tight dimensional tolerances on our conductive trays. Plastic shrinkage varies between conductive and non-conductive molds. We adjust our tooling to ensuring that a conductive 2-inch tray has the exact same external footprint as a transparent one, ensuring your machine fixtures do not need adjustment.

Custom Sizes at Hiner-pack

Sometimes, the standard list of Gel Pak tray sizes does not fit the application. You might have a long, narrow optical bar or a circular lens array.

Hiner-pack specializes in custom tooling. We can create gel carriers with specific active areas or print custom grids (laser marked or printed) onto the gel surface.

Grid sizes are crucial for manual operators. If a technician is manually picking dies, a 1mm x 1mm grid printed on the 2-inch tray helps them navigate the array. Standard off-the-shelf sizes often come with generic grids, but custom options allow for specific coordinate systems.

Selecting the Right Clip and Hinge Box

The gel tray usually sits inside a protective box. The fit between the tray and the box is vital.

If the tray is slightly smaller than the box interior, it will rattle during shipping. This vibration can cause dies to shift, even on the sticky gel.

Common Configurations:

Hinged Boxes: The gel is applied directly to the bottom of the box.Removable Trays: The gel tray is a separate plate held in place by a plastic clip.

When specifying your requirements, do not just look at the active area. Look at the total assembly height. Hiner-pack provides detailed datasheets showing the Z-height of our clip systems to ensure they fit in your magazines or shipping foam.

Shelf Life and Storage Dimensions

Gel trays have a shelf life. Over time, the tackiness can change. However, storage conditions depend on size.

Large JEDEC trays require flat storage to prevent warping. Smaller 2-inch trays can be stacked.

When planning your inventory, consider the physical volume. A box of 100 2-inch trays takes up significantly less warehouse space than 100 4-inch trays. It sounds obvious, but procurement often overlooks the storage footprint of packaging materials.

Comparing Hiner-pack to Market Standards

Our clients often come to us with a list of part numbers from other vendors, looking for compatible Gel Pak tray sizes.

We pride ourselves on offering:

Direct Dimensional Match: Our VR-2 and VR-4 compatible series fit existing vacuum fixtures.Cost Efficiency: Competitive pricing for high-volume consumables.Fast Lead Times: We stock standard sizes to avoid the long wait times common in the semiconductor supply chain.

We do not just sell a plastic box; we sell the assurance that your die reaches the wire bonder intact.

Selecting the correct carrier is a balance of die size, automation requirements, and shipping volume. While many start by searching for standard Gel Pak tray sizes, the final decision should be based on technical compatibility and supplier reliability.

Hiner-pack stands ready to support your backend processes with precision gel carriers, vacuum release trays, and custom solutions. Whether you need a standard 2-inch box for R&D or thousands of JEDEC trays for volume production, our specifications meet the rigorous demands of the international semiconductor market.

Protect your yield. Choose the right size. Trust Hiner-pack.

Frequently Asked Questions (FAQ)

Q1: What is the difference between Vacuum Release (VR) and standard Gel sticky boxes?

A1: Standard gel boxes rely entirely on the surface tension (tackiness) of the gel to hold the device. To remove the device, you must mechanically pluck it off, which works for robust parts. Vacuum Release (VR) trays have a mesh layer under the gel. When placed on a vacuum fixture, the air is pulled out, causing the gel membrane to conform to the mesh, reducing the surface contact area by over 90%. This allows very fragile or thin dies to be released with almost zero force, preventing breakage.

Q2: Can Hiner-pack trays fit on equipment designed for Gel-Pak® trays?

A2: Yes. Hiner-pack designs our trays to match the industry-standard external dimensions and vacuum port locations. If you have a pick-and-place machine or a manual vacuum release station set up for standard 2-inch or 4-inch VR trays, our products are designed to be drop-in compatible replacements without requiring tooling changes.

Q3: How do I determine the correct retention level (X4, X5, X8) for my device?

A3: Retention level depends on the mass of your device and the surface roughness.

Low Retention: For large, flat devices with a polished surface (high surface contact).Medium Retention: The standard for most bare dies and chips.High Retention: For heavy components, ceramic substrates, or parts with rough/textured surfaces that have less contact with the gel.Contact Hiner-pack technical support with your die dimensions and weight for a specific recommendation.

Q4: What are the temperature limits for these gel trays?

A4: Standard gel trays generally handle temperatures from -40°C up to 60°C for shipping and storage. High-temperature versions are available that can withstand up to 150°C or even higher for short durations (like wire bonding applications). Always check the specific datasheet for the tray material, as the plastic carrier (polystyrene vs. polycarbonate) and the gel chemistry differ by model.

Q5: Can the gel trays be cleaned and reused?

A5: In theory, yes, but in semiconductor production, it is risky. The gel surface can be cleaned with mild soap and water or specific adhesive rolls to remove dust. However, in high-reliability industries like aerospace or photonics, trays are typically treated as single-use consumables to guarantee zero cross-contamination and consistent retention force. Hiner-pack recommends using new trays for critical shipments to ensure yield safety.