In the semiconductor backend process, the difference between high yield and a rejected lot often comes down to packaging. After dicing and testing, bare dies are incredibly vulnerable. They need a transport system that protects them from physical shock, electrostatic discharge (ESD), and contamination.

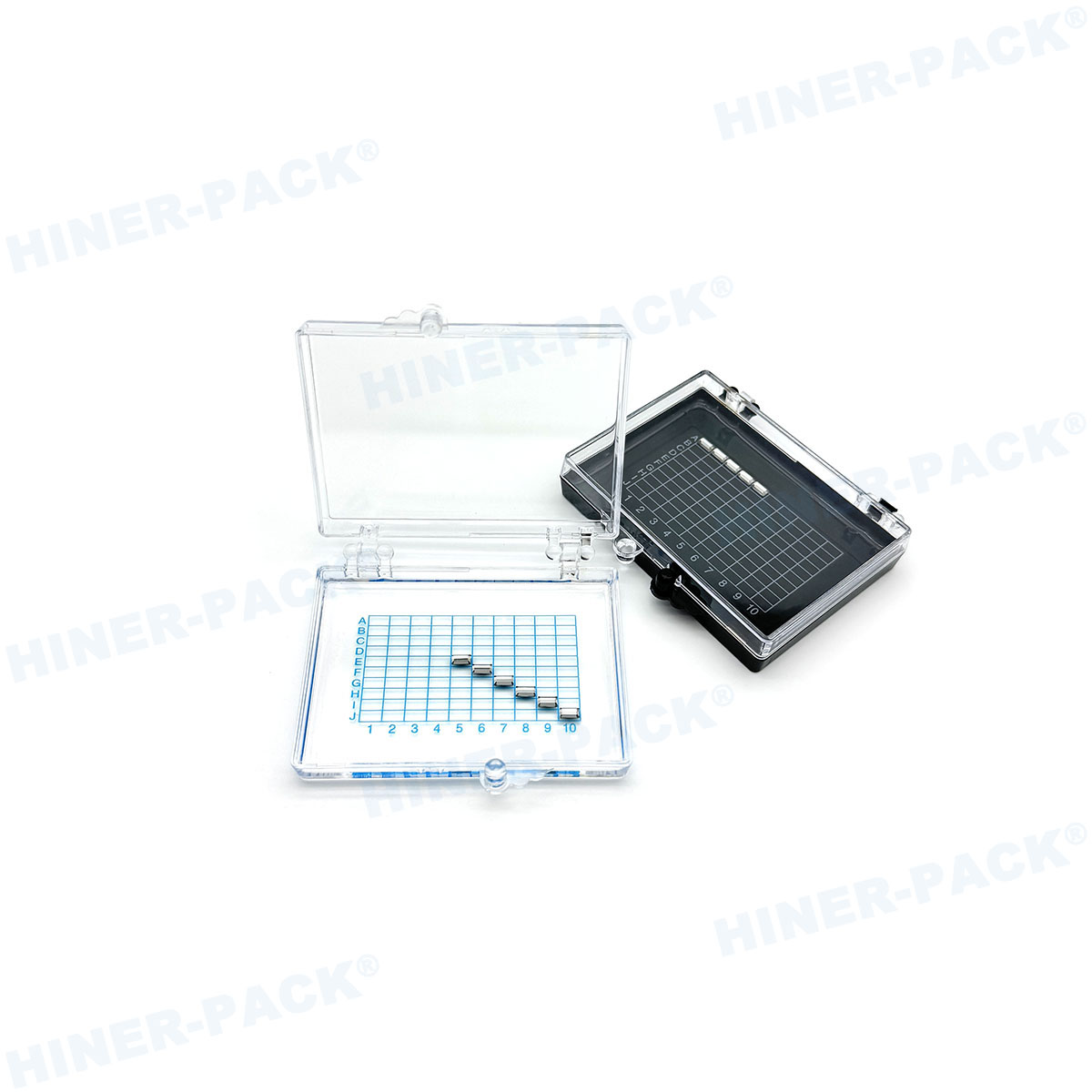

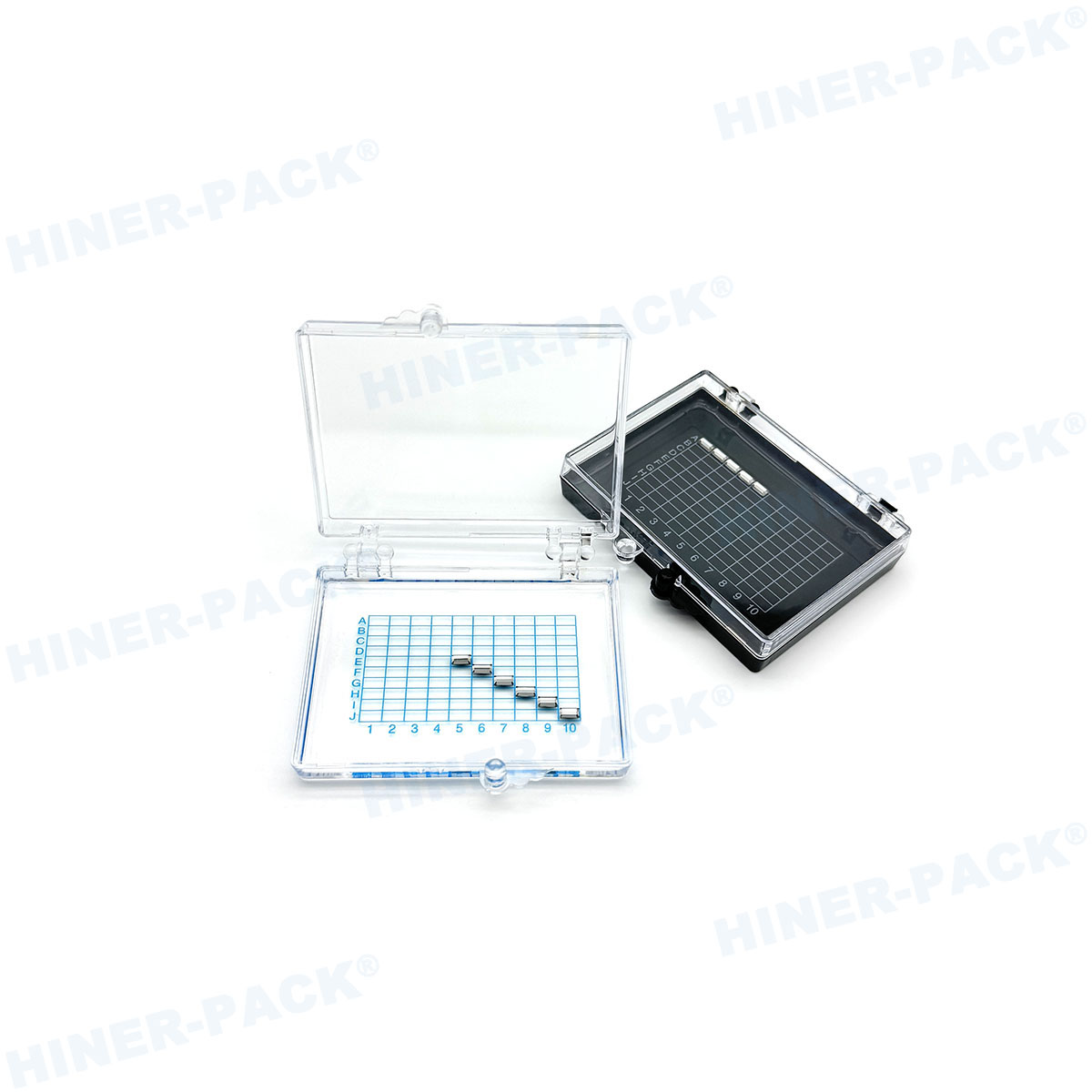

For decades, engineers have relied on Plastic waffle packs as the industry standard for handling bare die, optical components, and chip scale packages (CSP). While they look simple—just a plastic tray with a grid of pockets—the engineering behind them is complex.

At Hiner-pack, we see packaging as a critical component of your manufacturing line. If a tray is slightly warped or the pocket dimension is off by a few microns, it can jam a pick-and-place machine. This article breaks down the technical specifications, material choices, and best practices for selecting the right carrier for your devices.

The Role of Plastic Waffle Packs in Yield Management

Moving silicon or compound semiconductor materials requires precision. Unlike tape and reel, which is great for mass volume of robust parts, trays offer a rigid environment. They allow for inspection without removing the component.

Plastic waffle packs are designed to hold individual components in a fixed array (matrix). This isolation prevents dies from colliding with each other during shipping. The "waffle" grid structure provides structural integrity to the tray, ensuring it remains flat.

Flatness is vital. If a tray bows in the center, the vision system on a wire bonder might fail to recognize the die location. This leads to machine downtime. Hiner-pack manufactures trays with strict flatness tolerances to ensure seamless integration with automated handling systems.

1. Material Selection: ESD vs. Non-ESD

The first specification to define is the material. This decision depends on the sensitivity of your device.

Conductive Black (ESD Safe):Most semiconductor applications require ESD protection. Conductive materials, usually Carbon Powder loaded ABS or HIPS, allow static electricity to dissipate safely. This prevents sudden shocks that could blow the gate oxide on a sensitive chip.

Antistatic (Clear or Tinted):Some coated plastics resist static buildup but are not fully conductive. These are often used when visual inspection through the bottom of the tray is necessary.

Non-ESD (Standard):For passive mechanical parts or ceramics where static is not a concern, standard plastics are used. However, Hiner-pack advises most electronic clients to stick to ESD-safe materials to avoid any potential risks.

2. Temperature Resistance and Baking

Do you need to bake your components while they are in the tray? This is a common requirement to remove moisture before soldering.

Standard ABS trays generally cannot withstand high temperatures. If you put a standard Plastic waffle packs tray in an oven at 125°C, it will warp or melt.

For baking applications, you need high-performance engineering plastics like Polysulfone (PSU) or MPPO. These materials are more expensive but maintain their dimensional stability at elevated temperatures. Always check the datasheet for the "Heat Deflection Temperature" before placing a tray in an oven.

3. Pocket Dimensions and Tolerances

The "pocket" is where the die sits. Sizing this correctly is an art.

If the pocket is too tight, the die will get stuck. You will struggle to pick it out. If the pocket is too loose, the die will rotate.

The Rotation Problem:Automated pickers expect the die to be straight. If a square die rotates 45 degrees in a loose pocket, the vacuum nozzle might miss it, or worse, crash into the silicon.

At Hiner-pack, we recommend a specific clearance formula based on the die thickness and X/Y dimensions. The goal is to allow just enough room for easy loading but restrict movement enough to keep the die oriented correctly.

4. Understanding Die Migration

One of the biggest fears with Plastic waffle packs is die migration. This happens when a component jumps out of its pocket and lands in a neighboring pocket or on top of another die.

This usually occurs during rough shipping. To prevent this, the system relies on a lid and a clip.

The gap between the top of your die and the bottom of the lid must be minimal. However, you cannot have the lid touching the delicate surface of the die (especially for MEMS or lensed parts).

Process engineers must calculate the Z-height stack-up carefully. The tray depth plus the die thickness must work in harmony with the lid design to trap the part effectively without crushing it.

5. The Importance of Tyvek and Interleaf Paper

To solve the migration and protection issue, accessories are often used.

Tyvek Paper:Placed between the tray and the lid, Tyvek is distinct because it is non-linting and anti-static. It acts as a soft buffer. If a die bounces up, it hits the soft paper instead of the hard plastic lid.

Static Dissipative Foam:Sometimes placed under the lid to apply gentle downward pressure.

Hiner-pack supplies these consumables along with the trays. Using the right interleaf prevents the "rattle" effect during transport.

6. Automation and Pocket Design

Modern assembly lines use computer vision. The camera looks at the tray to find the die.

The color and texture of the Plastic waffle packs matter here. A high-gloss black tray might reflect light, confusing the camera. A matte finish is often preferred for better contrast.

Furthermore, the shape of the pocket floor matters. Some pockets have relief holes or specific textures to minimize the contact area between the die and the plastic. This reduces surface tension (stiction), making it easier for the vacuum nozzle to lift the part.

7. Custom Tooling vs. Standard Sizes

The industry has several standard sizes, often referred to as "2-inch" or "4-inch" trays based on the outer dimensions. JEDEC standard trays are larger and common in PCB assembly.

However, chip sizes vary wildly. Using a "close enough" standard tray is risky.

Hiner-pack offers custom tooling services. We create a mold specifically for your die dimensions. While there is an upfront tooling cost, the long-term savings in yield are massive. A custom pocket ensures zero rotation and perfect protection.

For low-volume runs, standard molds are acceptable. But for high-volume production, a custom-fitted tray is an investment in quality control.

8. Cleaning and Reusability

A common question we get is about reuse. Can you wash and reuse these trays?

Technically, yes. High-end trays made from durable materials can be washed. However, washing introduces risks.

If the washing process leaves any residue, that residue ends up on your chip. Also, mechanical scrubbing can scratch the ESD coating on some trays, reducing their protective properties.

For critical applications, Hiner-pack suggests treating trays as single-use consumables. The cost of a fresh tray is far lower than the cost of a contaminated sensor or processor.

9. Clips and External Packaging

The tray does not travel alone. It is usually stacked. A stack of 5 or 10 trays is secured with a clip.

The tension of the clip is important. Too tight, and it cracks the tray edges. Too loose, and the trays slide apart.

We design clips that provide consistent pressure. We also ensure that the external packaging—the bags and boxes—are ESD safe. Putting a conductive tray inside a standard pink poly bag is a good practice to create a Faraday cage effect for shipping.

The Hiner-pack Advantage in Supply Chain

Finding a reliable supplier is as important as the spec itself. The semiconductor supply chain is volatile. Lead times for plastics can fluctuate.

Hiner-pack maintains a robust inventory of standard molds and raw materials. We understand that you cannot stop a fab line because you ran out of plastic trays.

We also focus on batch-to-batch consistency. Our quality control measures the surface resistivity and dimensional accuracy of every lot. You need to know that the tray you buy today is identical to the one you bought six months ago. Automation hates variation, and so do we.

Cost Considerations

Price is always a factor. Standard black conductive ABS trays are the most cost-effective solution for general electronics.

High-temperature trays or custom-designed solutions naturally cost more. However, when calculating cost, you must factor in yield loss.

If a cheap tray causes 1% of your dies to chip or crack, that cost far exceeds the price difference of a premium tray. Investing in high-quality Plastic waffle packs is essentially an insurance policy for your product.

Comparison with Gel and Tape

Why choose a waffle pack over other methods?

vs. Gel Packs:Gel is great for very fragile or non-standard shapes. However, gel packs rely on surface tackiness. Over time, that tackiness can change. Waffle packs rely on simple mechanical containment, which is more stable long-term.

vs. Tape and Reel:Tape is the king of speed for SMT components. But you cannot easily inspect parts in tape. You also need a specific quantity to make reeling worth it. Waffle packs offer flexibility for smaller batches and high-mix, low-volume production.

Final Thoughts on Selection

Choosing the right packaging is a sequence of technical decisions. You start with the die size, determine the ESD requirement, check the temperature needs, and then look at automation compatibility.

It is easy to overlook packaging until the last minute. But as we have discussed, the wrong choice can lead to migration, damage, and machine errors.

Hiner-pack is here to guide you through this process. We don't just sell plastic; we provide a safe harbor for your technology. From standard off-the-shelf options to fully custom molds, we ensure your devices arrive ready for action.

When you are ready to secure your yield, look at your current Plastic waffle packs strategy. Is it optimized? If not, it is time to talk to the experts.

Frequently Asked Questions (FAQ)

Q1: What is the difference between "Conductive" and "Antistatic" waffle packs?

A1: The difference lies in surface resistance. Conductive trays (usually black) have a low resistance (typically

Q1: The difference lies in surface resistance. Conductive trays (usually black) have a low resistance (ypically to ohms),allowing charges to flowinstantly to ground. This is ideal for very sensitive components.Antistatic trays (often pink or clear) have a higher resistance (to ohms) and rely onchemical coatingsto prevent the generation of static charges, but they don't drain charge as quickly. Hiner-pack recommends conductive blacktrays for most active semiconductor devices.

Q2: How do I know if my die fits in a standard waffle pack pocket?

A2: You need to check the "pocket size" and the "pocket depth." A good rule of thumb is that the pocket should be at least 0.1mm to 0.2mm larger than your die in both X and Y dimensions to allow for loading. However, it shouldn't be so large that the die can rotate more than 10 degrees. The depth should be sufficient so the die is fully seated, but not so deep that it flips over.

Q3: Can I bake my chips inside the Hiner-pack trays?

A3: It depends on the material you order. Standard ABS trays will warp at temperatures above 60°C. If you need to perform a bake-out (e.g., at 125°C or 150°C) to remove moisture, you must specify high-temperature materials like Polysulfone (PSU) or MPPO when ordering. Always consult the material datasheet before placing plastic trays in an oven.

Q4: Why do I need Tyvek paper with my waffle packs?

A4: Tyvek paper acts as a cushion and a gap filler. Even with a lid, there might be a small gap between the top of the die and the lid. If the box is dropped, the die hits the lid. Tyvek is soft, non-linting, and antistatic, so it absorbs the impact and prevents the die from scratching against the hard plastic lid. It also helps prevent dies from migrating into neighboring pockets.

Q5: Does Hiner-pack offer custom grid sizes for non-standard dies?

A5: Yes. While we stock hundreds of standard die sizes, many modern chips have unique aspect ratios. We can design and manufacture custom tooling (molds) to create Plastic waffle packs with pockets that match your exact device dimensions. This is the best way to ensure zero component damage during shipping.