In the high-stakes world of semiconductor manufacturing, even the smallest static discharge can lead to catastrophic failures in delicate wafers. This is where anti-static waffle packs come into play. These specialized containers are designed to shield sensitive components from electrostatic discharge (ESD) during handling, storage, and transportation. For companies like Hiner-pack, producing reliable anti-static waffle packs is critical to ensuring yield rates and product integrity in the semiconductor industry. As wafer geometries shrink and sensitivity increases, the need for robust ESD protection has never been more pronounced. This article delves into key aspects of these packs, highlighting their importance and functionality.

How Anti-static Waffle Packs Prevent Electrostatic Damage

Anti-static waffle packs work by dissipating static charges that accumulate on surfaces. They are typically made from materials that have conductive or dissipative properties. This prevents the build-up of static electricity that could otherwise jump to a wafer.

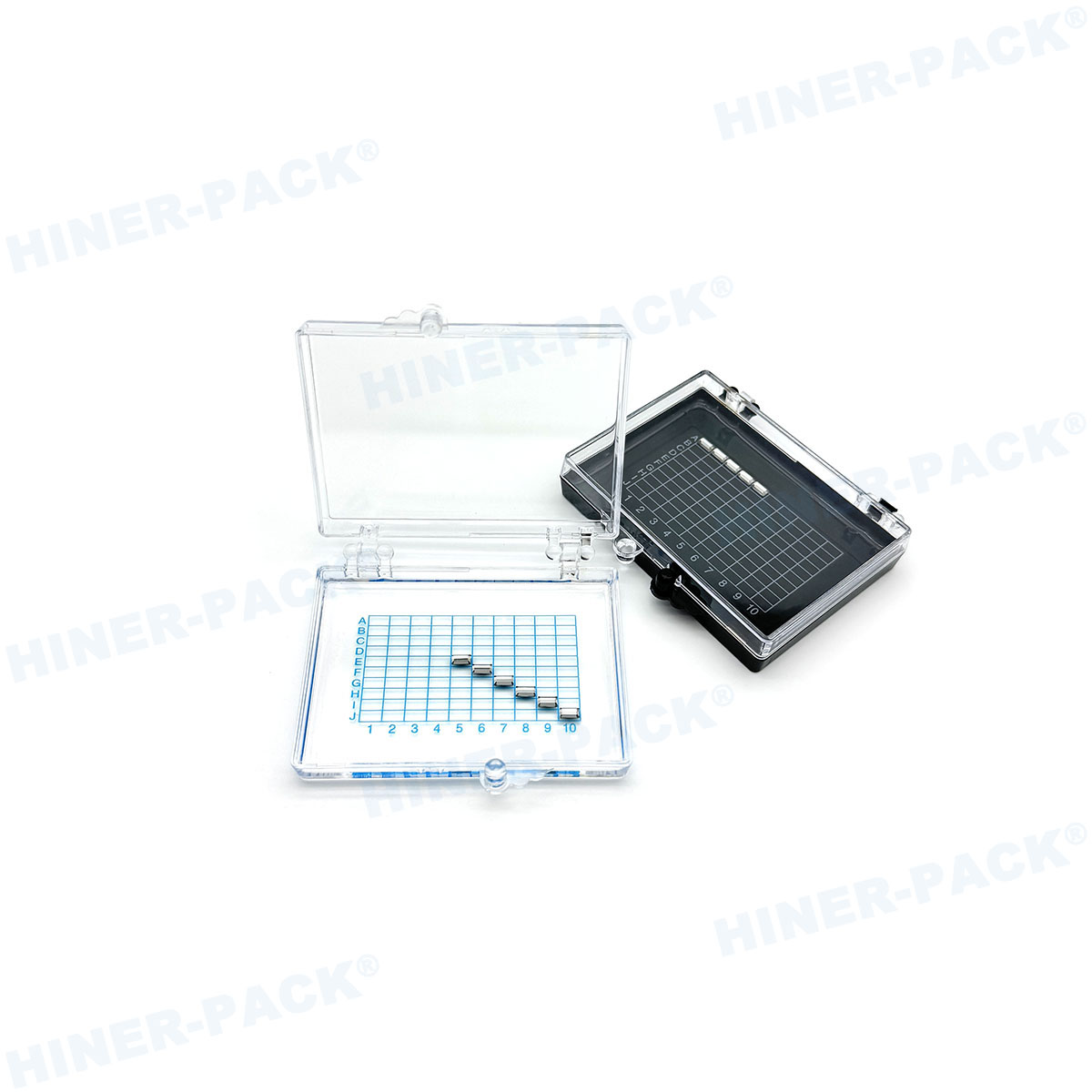

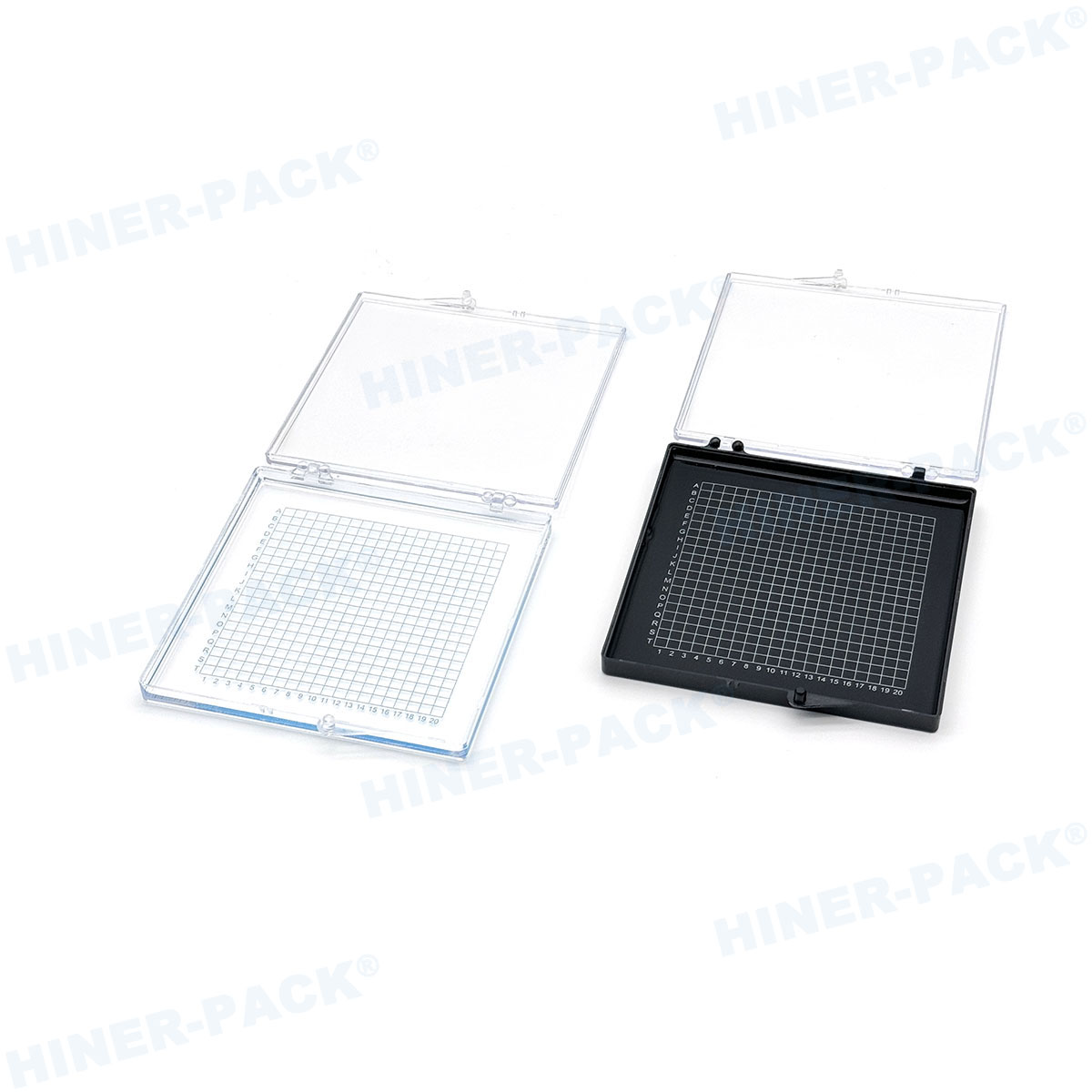

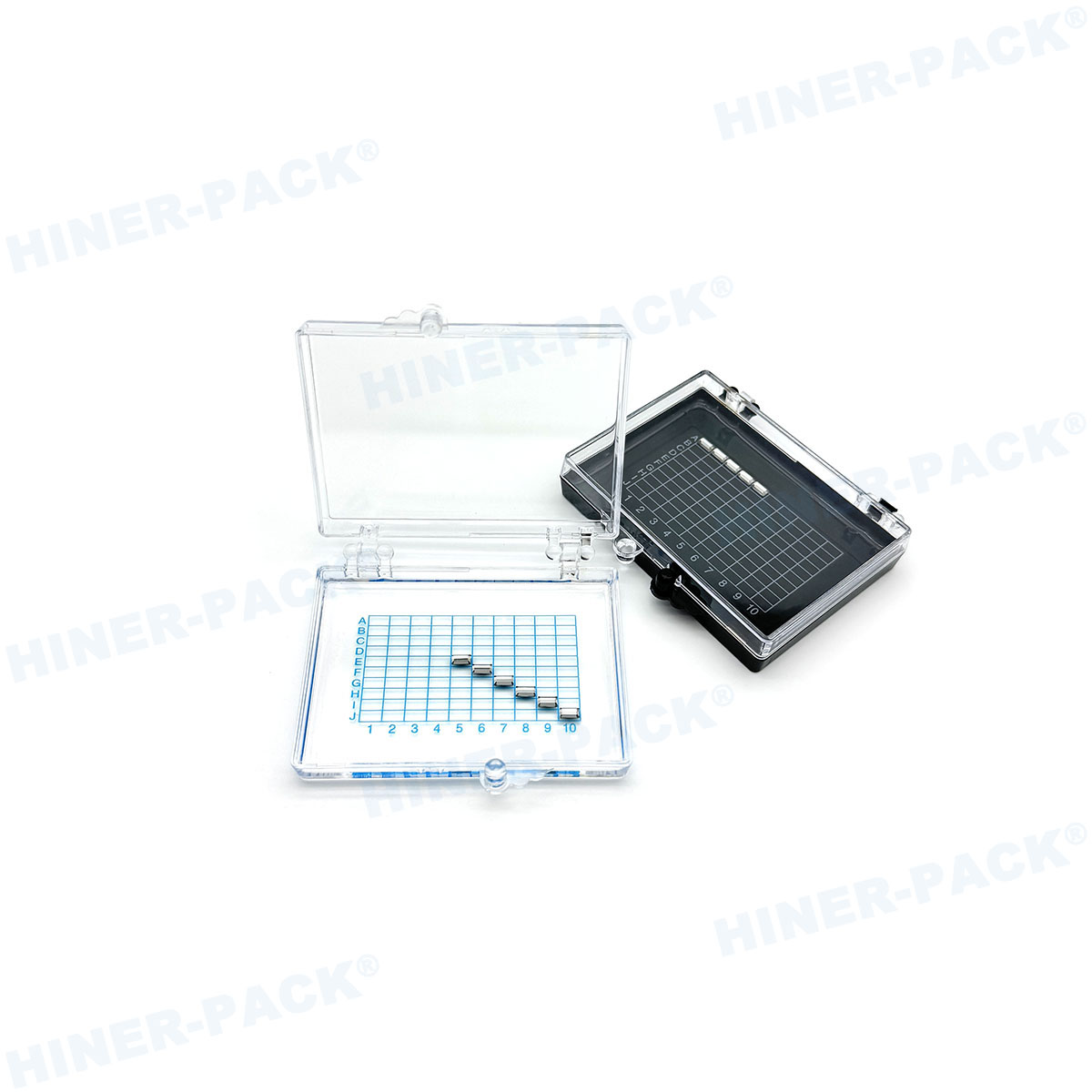

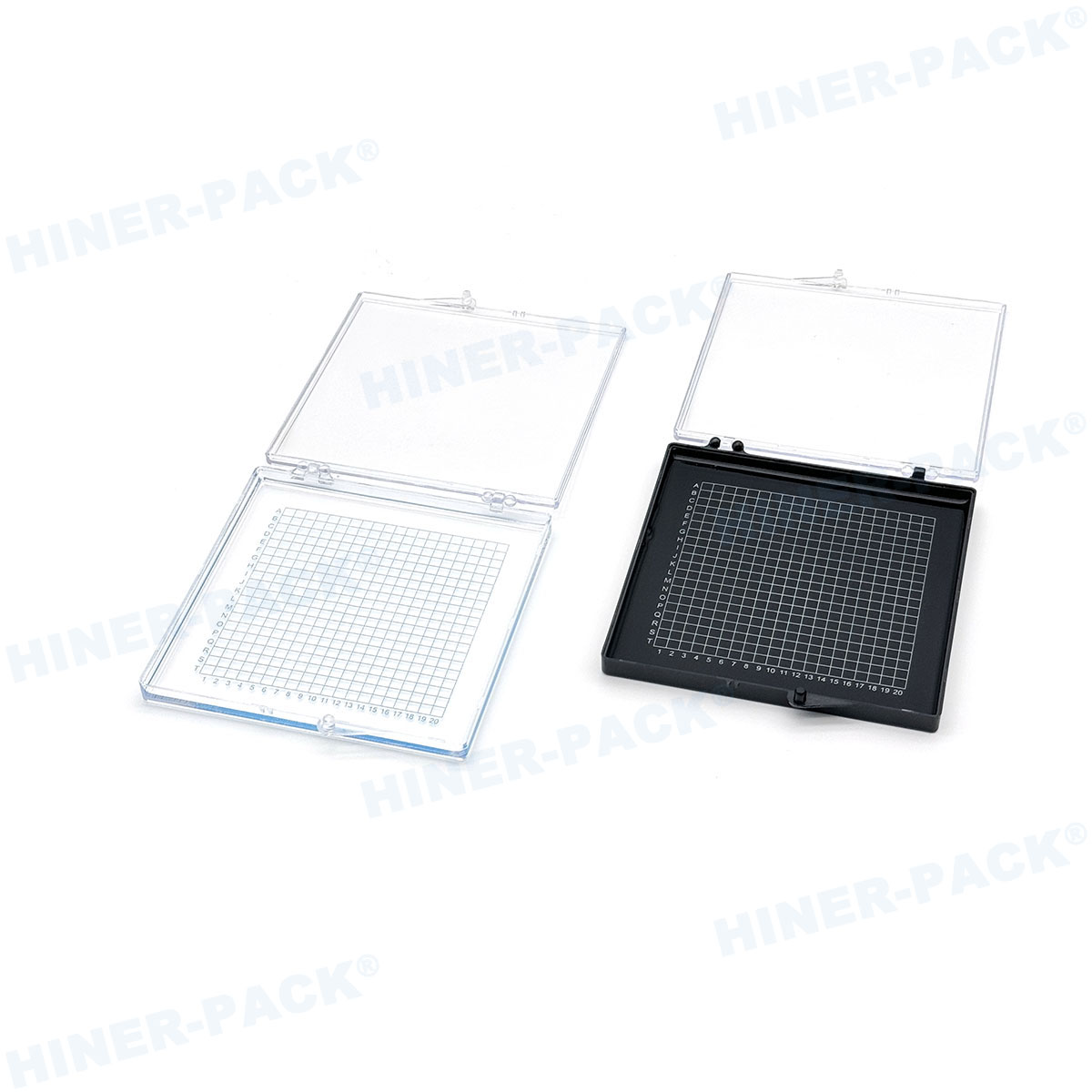

The design includes a waffle-like structure with cavities that cradle individual wafers. This minimizes movement and contact. By channeling static away from the wafers, these packs reduce the risk of ESD events.

In semiconductor labs, even human handling can generate static. Anti-static waffle packs act as a first line of defense. They ensure that wafers remain safe from invisible threats.

Hiner-pack emphasizes precision in this area. Their packs are engineered to meet industry standards for ESD protection. This helps manufacturers avoid costly rework or scrap.

Materials and Construction in Modern Anti-static Waffle Packs

High-quality anti-static waffle packs use materials like carbon-loaded polyethylene or polypropylene. These materials offer consistent static dissipation. They are also lightweight and durable.

The construction process involves molding the material into precise shapes. Each cavity must match wafer dimensions exactly. This prevents stress or damage during insertion and removal.

Cleanliness is paramount. Materials are often anti-dust and non-shedding. This maintains wafer purity in cleanroom settings. Hiner-pack selects materials that comply with semiconductor-grade requirements.

Regular testing ensures material performance over time. Factors like humidity and wear can affect anti-static properties. Robust packs maintain their efficacy through multiple uses.

Integration with Cleanroom Protocols in Semiconductor Facilities

Anti-static waffle packs are integral to cleanroom operations. They complement protocols that minimize contamination. Their smooth surfaces resist particle accumulation.

In cleanrooms, packs are often used alongside other ESD-safe tools. This creates a comprehensive protection system. Workers can handle wafers with confidence.

Hiner-pack designs packs that are easy to sterilize or clean. This supports stringent cleanliness standards. Compatibility with automated handling systems is also key.

The packs help maintain low particulate counts. This is crucial for advanced nodes in wafer fabrication. Even tiny contaminants can ruin a batch.

Economic Impact of Using Anti-static Waffle Packs in Production

Investing in anti-static waffle packs offers significant cost savings. ESD damage can lead to yield losses that impact profitability. Reliable packs reduce these risks.

Initial costs are offset by fewer defects and higher throughput. Manufacturers see improved return on investment. Hiner-pack focuses on durability to extend pack lifespan.

Downtime due to wafer damage is minimized. This keeps production lines running smoothly. The packs also reduce waste from faulty components.

In the long run, consistent quality from anti-static waffle packs enhances brand reputation. Customers trust products that are well-protected. This can lead to more business opportunities.

Hiner-pack's Approach to Anti-static Waffle Pack Innovation

Hiner-pack has developed a reputation for innovation in anti-static waffle packs. They incorporate advanced materials that enhance static dissipation. Their designs are tailored to specific wafer sizes and types.

The company conducts rigorous testing to ensure performance. This includes ESD resistance tests and durability checks. Hiner-pack collaborates with semiconductor firms to address emerging needs.

Customization options are available. Packs can be branded or adjusted for unique processes. This flexibility helps clients optimize their operations.

Hiner-pack also focuses on sustainability. They explore recyclable materials without compromising protection. This aligns with industry trends toward greener manufacturing.

Standards and Compliance for Anti-static Waffle Packs

Anti-static waffle packs must meet international standards like ANSI/ESD S20.20. These guidelines ensure consistent ESD protection. Compliance is verified through regular audits.

Materials are tested for surface resistance and charge decay. This data is provided to customers. Hiner-pack adheres to these standards to guarantee safety.

In the global semiconductor market, compliance facilitates trade. Packs that meet norms are accepted worldwide. This simplifies logistics for manufacturers.

Updates in standards drive innovation. Hiner-pack stays current with changes. This ensures their anti-static waffle packs remain effective.

Future Trends in Anti-static Packaging for Wafers

The semiconductor industry is evolving toward smaller and more sensitive wafers. Anti-static waffle packs will need to adapt. Materials with higher conductivity may emerge.

Integration with IoT for smart tracking could become common. Packs might include sensors to monitor ESD events. Hiner-pack is researching such advancements.

Sustainability will play a bigger role. Biodegradable or reusable packs might gain traction. Balancing eco-friendliness with protection will be key.

As automation increases, packs will need to interface seamlessly with robots. Design modifications for easier handling are likely. Hiner-pack is poised to lead in these areas.

Anti-static waffle packs are more than just containers; they are vital safeguards in semiconductor manufacturing. By preventing ESD damage, they protect investments and ensure quality. Companies like Hiner-pack continue to innovate, making these packs more effective and adaptable. As technology advances, the role of anti-static waffle packs will only grow in importance. Embracing best practices in their use can lead to smoother operations and better outcomes.

Frequently Asked Questions (FAQ)

Q1: What are anti-static waffle packs used for in the semiconductor industry?

A1: Anti-static waffle packs are used to store, transport, and handle semiconductor wafers safely. They prevent electrostatic discharge (ESD) that can damage delicate wafer components, ensuring higher yield rates and product reliability in manufacturing processes.

Q2: How do anti-static waffle packs differ from regular packaging?

A2: Unlike regular packaging, anti-static waffle packs are made from materials that dissipate static electricity, such as conductive plastics. They feature precise cavities to cradle wafers individually, minimizing movement and ESD risks, which is critical for sensitive semiconductor applications.

Q3: Can anti-static waffle packs be reused, and how should they be maintained?

A3: Yes, many anti-static waffle packs, like those from Hiner-pack, are designed for multiple uses. Maintenance involves regular cleaning with approved solvents to remove contaminants and testing for ESD performance to ensure they remain effective over time.

Q4: What standards should anti-static waffle packs comply with?

A4: They should comply with international standards such as ANSI/ESD S20.20 or IEC 61340, which set guidelines for ESD control. Compliance ensures consistent protection, and reputable brands like Hiner-pack provide certification details for verification.

Q5: How do I choose the right anti-static waffle pack for my wafer size?

A5: Select packs based on wafer diameter and thickness, ensuring a snug fit in the cavities. Consult with suppliers like Hiner-pack for custom options, and consider factors like material type, cleanroom compatibility, and handling requirements to match your specific needs.