In the fast-paced world of semiconductor manufacturing, precision and protection are paramount. Imagine a scenario where delicate silicon wafers, worth thousands of dollars, are being transported across a cleanroom. Any mishap could lead to catastrophic losses. This is where the wafer cassette carrier comes into play—a unsung hero in the electronics industry. These specialized containers are designed to safeguard wafers during storage, transport, and processing, ensuring minimal contamination and damage. As the demand for smaller, more powerful chips grows, understanding the intricacies of the wafer cassette carrier becomes essential for engineers, technicians, and industry newcomers alike. In this article, we'll dive into seven critical aspects that highlight its importance, from design to future innovations, providing a comprehensive look at why this component is indispensable in modern fabrication facilities.

What is a Wafer Cassette Carrier?

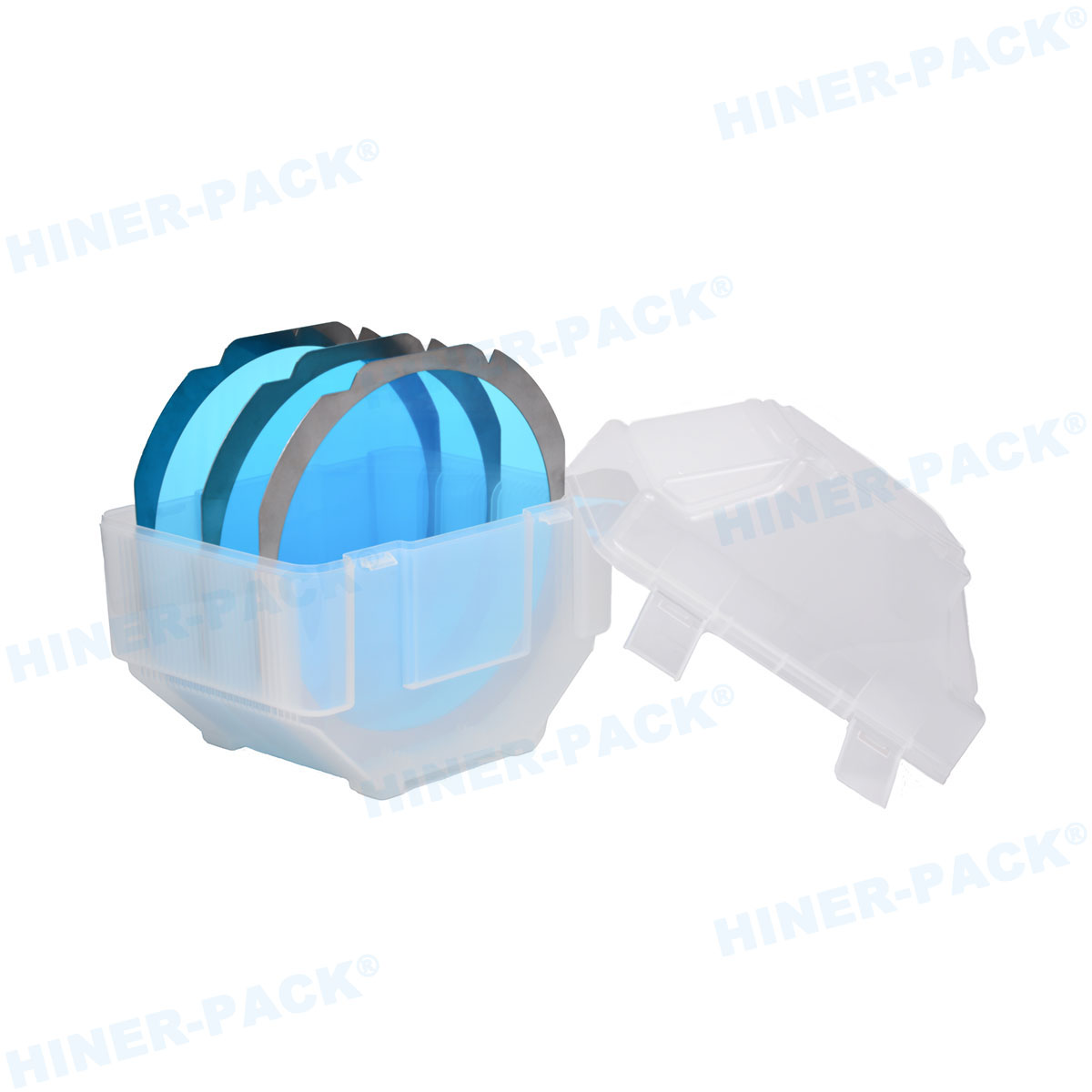

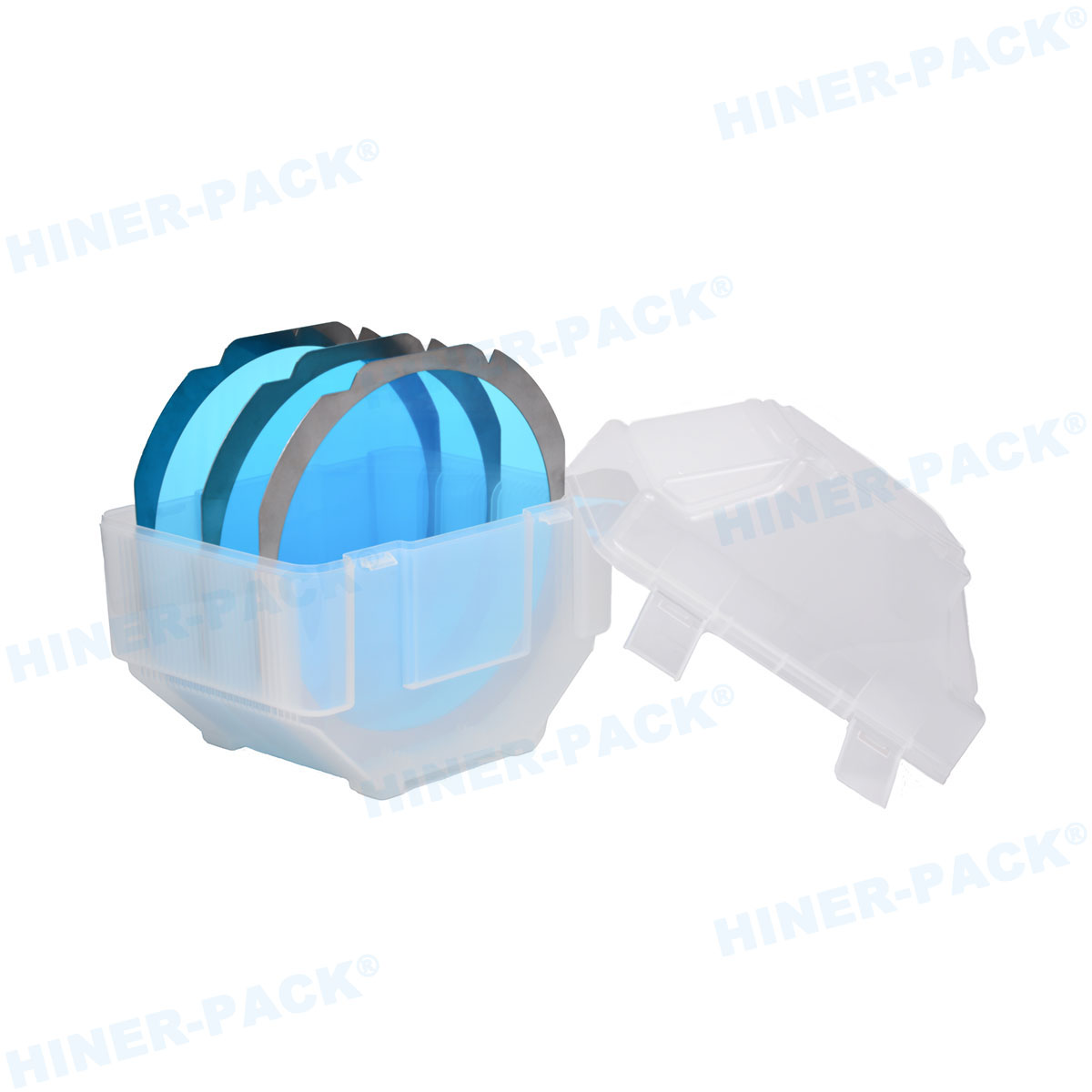

A wafer cassette carrier is a protective enclosure used in the semiconductor industry to hold and transport silicon wafers securely. Typically, it consists of a rigid frame that houses a cassette—a tray-like structure with slots to hold multiple wafers in place. The primary purpose of the wafer cassette carrier is to shield wafers from environmental hazards such as dust, moisture, physical shock, and electrostatic discharge. These carriers are engineered to meet stringent cleanroom standards, often featuring materials that minimize particle generation. In essence, the wafer cassette carrier acts as a mobile safe for wafers, enabling seamless movement between different stages of production, from lithography to etching. Without it, the risk of wafer damage would skyrocket, leading to yield losses and increased costs. The design of a wafer cassette carrier often includes handles, locking mechanisms, and compatibility with automated systems, making it a versatile tool in high-volume manufacturing environments.

Design and Materials of Wafer Cassette Carriers

The design of a wafer cassette carrier is a marvel of engineering, focusing on durability, cleanliness, and ergonomics. Most carriers are constructed from high-purity plastics like polycarbonate or PEEK (polyetheretherketone), which offer excellent chemical resistance and low outgassing properties. These materials are chosen to prevent contamination that could arise from shedding particles or reacting with wafer surfaces. The internal structure of the wafer cassette carrier includes precisely spaced slots to hold wafers without causing stress or scratches, often incorporating soft linings or coatings to cushion against vibrations. Externally, features like sealed lids, gaskets, and HEPA-filter compatible vents are common to maintain a controlled environment. Additionally, the wafer cassette carrier may include RFID tags or barcodes for tracking purposes, integrating with factory automation systems. The weight and size are optimized for manual handling and robotic arms, ensuring that operators can move them efficiently without compromising safety. This thoughtful design not only extends the lifespan of the carrier but also enhances overall production throughput by reducing downtime due to wafer mishandling.

Functions and Applications in Semiconductor Manufacturing

The wafer cassette carrier serves multiple critical functions in semiconductor manufacturing, primarily centered around protection and logistics. One key role is contamination control; by enclosing wafers in a sealed environment, the carrier prevents airborne particles from settling on sensitive surfaces, which is crucial for maintaining high yields in processes like photolithography. Another function is physical protection—the wafer cassette carrier absorbs shocks and prevents wafers from shifting during transport, whether by humans or automated guided vehicles. In terms of applications, the wafer cassette carrier is used across various stages, including wafer sorting, chemical mechanical planarization, and deposition. It also facilitates batch processing by allowing multiple wafers to be moved together, streamlining workflow in fabs. Moreover, the wafer cassette carrier supports interoperability with standard equipment like load ports and stockers, ensuring compatibility in diverse manufacturing setups. As chip geometries shrink to nanometers, the precision offered by these carriers becomes even more vital, underscoring their role in enabling advanced technologies like 5G and IoT devices.

Types of Wafer Cassette Carriers

There are several types of wafer cassette carriers tailored to different needs in the semiconductor industry. Standard carriers are designed for general-purpose use, accommodating common wafer sizes such as 200mm or 300mm diameters. Then, there are specialized versions like front-opening unified pods (FOUPs), which are advanced wafer cassette carrier units used in 300mm wafer processing; these provide a mini-environment to keep wafers isolated from external conditions. Another type is the rear-opening unified pod (RUP), which offers similar benefits but with different access mechanisms for specific tool interfaces. Additionally, some wafer cassette carrier models are built for high-temperature applications, using materials that can withstand thermal cycling without degrading. For research and development settings, smaller or customizable carriers might be employed to handle non-standard wafer sizes or experimental materials. Each type of wafer cassette carrier is optimized for particular scenarios, whether it's mass production, prototyping, or harsh environment operations, highlighting the adaptability of this essential component to evolving industry demands.

Maintenance and Cleaning Procedures

Proper maintenance of a wafer cassette carrier is crucial to ensure its longevity and performance. Regular cleaning is necessary to remove contaminants like residues, particles, or static charges that accumulate over time. Typically, this involves disassembling the carrier and using ultra-pure water, isopropyl alcohol, or specialized cleaning solutions in a controlled environment to avoid introducing new impurities. For a wafer cassette carrier, automated cleaning systems are often employed in fabs to maintain consistency, with processes including ultrasonic baths or spray rinses. Inspection steps follow, where technicians check for cracks, wear, or deformation that could compromise wafer safety. Additionally, preventive maintenance schedules might include replacing seals, gaskets, or filters to uphold the integrity of the enclosure. It's also important to handle the wafer cassette carrier with cleanroom-compatible gloves and tools to prevent human-induced contamination. By adhering to these procedures, companies can extend the life of their carriers and reduce the risk of wafer defects, ultimately saving costs and improving product quality.

Benefits of Using Wafer Cassette Carriers

The benefits of using a wafer cassette carrier are manifold, directly impacting efficiency, cost, and yield in semiconductor manufacturing. Firstly, they provide superior protection against physical and environmental damage, which minimizes wafer breakage and contamination-related losses. This leads to higher production yields and lower scrap rates, translating into significant financial savings. Secondly, the wafer cassette carrier enhances operational efficiency by enabling smooth, automated material handling; this reduces manual intervention and speeds up cycle times. Another advantage is scalability—carriers are designed to integrate with existing fab infrastructure, supporting high-volume production without major retooling. Furthermore, the use of a wafer cassette carrier promotes safety for both personnel and products by reducing exposure to hazardous materials or electrostatic discharge. From a quality assurance perspective, these carriers help maintain traceability through embedded identifiers, aiding in defect tracking and process optimization. Overall, the wafer cassette carrier is a cost-effective solution that boosts reliability and supports the industry's push toward smaller, more complex chip designs.

Future Trends in Wafer Cassette Carrier Technology

The future of wafer cassette carrier technology is shaped by trends like miniaturization, automation, and sustainability. As wafers grow larger—such as the shift to 450mm—carriers will need to evolve with stronger, lighter materials to handle increased weight without sacrificing protection. Smart wafer cassette carrier designs are emerging, incorporating IoT sensors to monitor internal conditions like temperature, humidity, and shock in real-time, enabling predictive maintenance and data-driven decisions. Additionally, there's a push toward eco-friendly materials and processes, with carriers being made from recyclable polymers to reduce environmental impact. Automation will further integrate the wafer cassette carrier with robotics and AI, allowing for fully autonomous transport and storage systems in "lights-out" fabs. Another trend is customization for advanced packaging techniques, where carriers must accommodate heterogeneous integration and 3D stacking. These innovations promise to make the wafer cassette carrier even more integral to next-generation semiconductor manufacturing, driving progress in areas like AI and quantum computing.

In summary, the wafer cassette carrier is a foundational element in semiconductor production, offering protection, efficiency, and adaptability across various applications. By understanding its design, functions, types, maintenance, benefits, and future directions, professionals can better appreciate its role in enabling technological advancements. As the industry continues to evolve, the wafer cassette carrier will remain a key player in ensuring that wafers move safely from one process to the next, underpinning the devices that power our digital world.

Frequently Asked Questions (FAQ)

Q1: What is the primary purpose of a wafer cassette carrier?

A1: The primary purpose of a wafer cassette carrier is to protect silicon wafers from contamination, physical damage, and environmental factors during storage, transport, and processing in semiconductor manufacturing. It ensures wafers remain clean and intact, thereby maintaining high production yields.

Q2: How often should a wafer cassette carrier be cleaned?

A2: A wafer cassette carrier should be cleaned regularly, typically after each use or according to a scheduled maintenance plan based on the fab's contamination controls. This frequency can vary depending on the environment and usage intensity, but it often involves daily or weekly cleaning to prevent particle buildup.

Q3: Can wafer cassette carriers be used for different wafer sizes?

A3: Yes, wafer cassette carriers are available in various sizes to accommodate different wafer diameters, such as 150mm, 200mm, and 300mm. However, each carrier is usually designed for a specific size to ensure proper fit and protection, so it's important to select the correct type for your application.

Q4: What materials are commonly used in manufacturing wafer cassette carriers?

A4: Common materials for wafer cassette carriers include high-purity plastics like polycarbonate, PEEK, and other advanced polymers. These materials are chosen for their low particle generation, chemical resistance, and durability, which help maintain cleanroom standards and protect wafers.

Q5: How do wafer cassette carriers integrate with automated systems?

A5: Wafer cassette carriers integrate with automated systems through features like standardized dimensions, RFID tags, and barcodes, allowing robotic arms and automated guided vehicles to identify, pick, and transport them seamlessly. This integration supports efficient material handling in modern semiconductor fabs, reducing manual labor and errors.