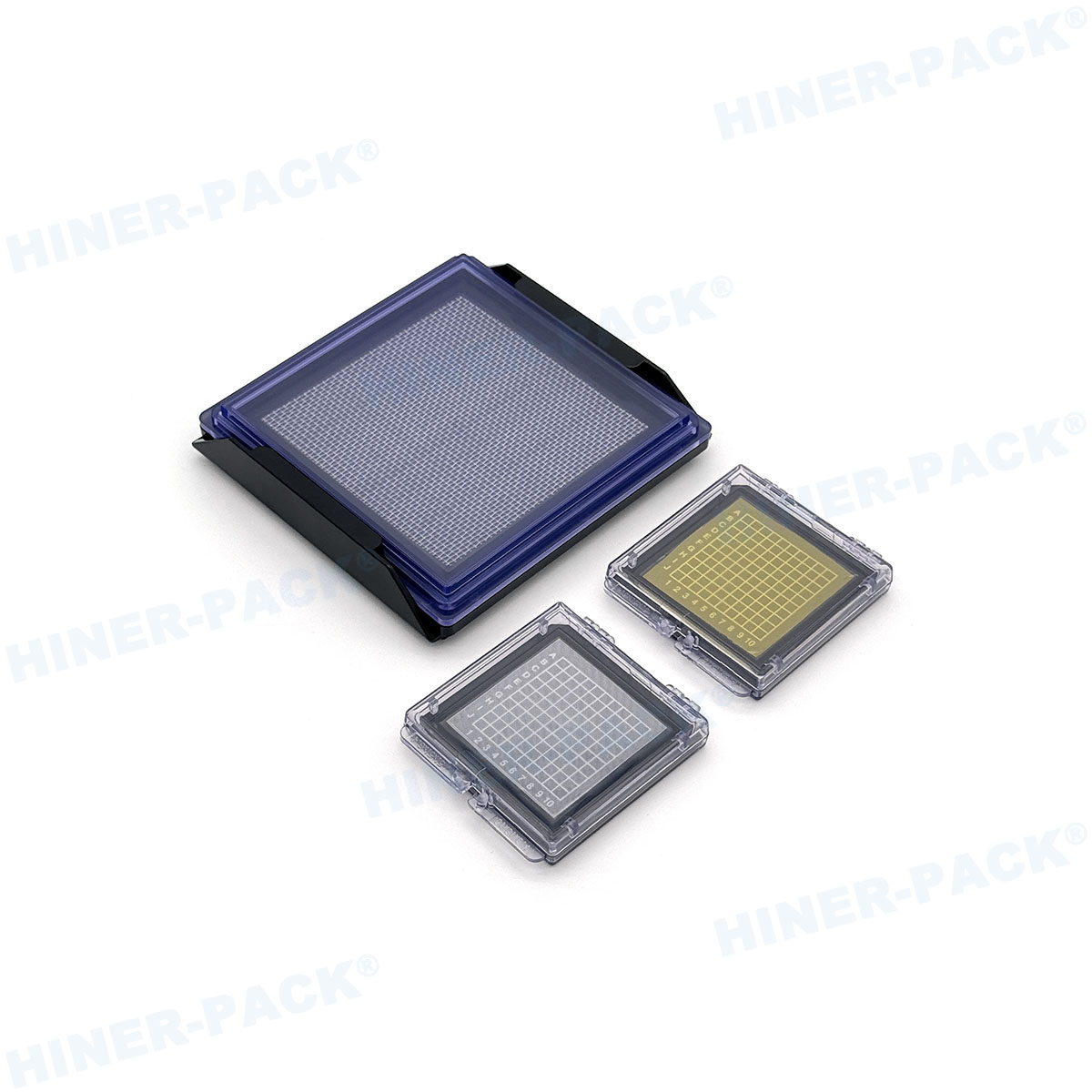

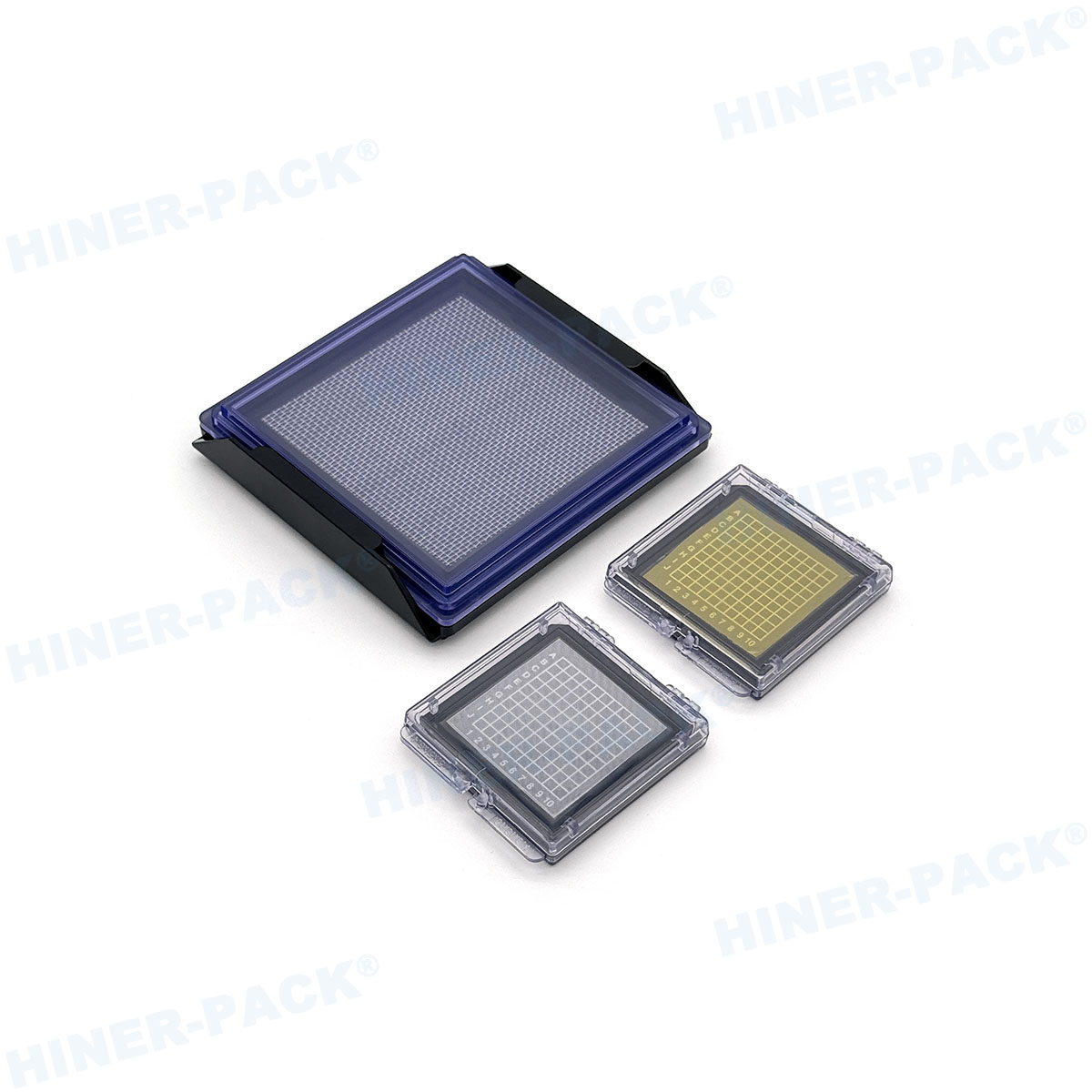

Choosing the right container for semiconductor wafers is not a matter of simple storage. It is a critical decision impacting yield, contamination control, and logistics efficiency. At the heart of this decision are the precise waffle pack dimensions. A miscalculation here can lead to wafer chipping, particle generation, or mishandling failures.

Hiner-pack understands that optimal waffle pack dimensions are engineered from a balance of international standards, material science, and practical handling requirements. This article breaks down the key dimensional considerations that engineers and procurement specialists must evaluate.

Material Impact on Dimensional Stability

Waffle packs, primarily made from advanced polymers like PFA, PP, or PC, are subject to thermal expansion. The specified waffle pack dimensions are measured at a standard room temperature (e.g., 23°C). Hiner-pack’s molding processes are calibrated to account for minimal shrinkage, ensuring that the final product’s critical dimensions, such as pocket pitch and depth, remain within the tight tolerances required for automation, even under minor temperature variations during transport or storage.

The Standardization Framework: SEMI Standards

The industry relies on SEMI standards for interoperability. Key standards like SEMI E1.2 for 200mm wafers and SEMI E1.9 for 300mm wafers define the primary outer waffle pack dimensions and crucial features. This includes the overall length, width, and height, as well as the location of kinematic coupling features for robotic handling. Adherence to these standards ensures that a Hiner-pack container will function correctly in standardized FOUPs, load ports, and factory automation systems globally.

Pocket Geometry: More Than Just a Size

The pocket that cradles the wafer is dimensionally complex. Its inner diameter is slightly larger than the wafer diameter to allow for non-contact seating, but the tolerance is often within ±0.2mm. The depth of the pocket is designed to support the wafer’s edge while maximizing vertical packing density. The taper angle of the pocket wall is critical for guiding the wafer in and out without scraping. Hiner-pack meticulously controls these sub-features to prevent mechanical stress on the wafer edge.

Wafer Gap and Pitch: Maximizing Capacity and Safety

The distance between adjacent wafer pockets, known as pitch, is a fundamental waffle pack dimension. A smaller pitch allows more wafers per pack, improving storage and transport density. However, it must provide sufficient gap to prevent wafers from touching during shock or vibration and to allow for safe robotic end-effector access. Hiner-pack optimizes this balance, offering designs that meet high-capacity needs without compromising physical safety margins.

Stackability and Overall Height

For efficient warehouse and cleanroom storage, waffle packs are designed to stack securely. The overall height and the design of interlocking features on the top and bottom lids are crucial waffle pack dimensions. A precise stacking height ensures stability in tall stacks and prevents undue pressure on the wafers inside the lower containers. Hiner-pack’s designs undergo rigorous testing to validate stackability under various environmental conditions.

Compatibility with Load Ports and Carriers

A waffle pack must interface seamlessly with larger systems. Its footprint dimensions must align with equipment load ports. The height, when combined with a lid, must fit within the specified zone of a Front-Opening Unified Pod (FOUP) or shipping container. Incompatibility here can halt a production line. Hiner-pack verifies that its product dimensions are compatible with mainstream carrier and tool specifications.

Lid Fit and Sealing Surfaces

The dimensions of the sealing flange and the corresponding lid are vital for containment. An imprecise fit can compromise the nitrogen purging environment or allow particle ingress. The flatness and parallelism of these sealing surfaces are as critical as their linear dimensions. Hiner-pack employs precision machining and molding to ensure a consistent, reliable seal that protects the wafer environment.

Handling Feature Dimensions

Features such as handles, alignment notches, and robotic flange geometries have defined dimensions. These are essential for ergonomic manual handling and repeatable robotic pickup. A misaligned robotic flange can cause a mispick, leading to wafer damage or tool downtime. Hiner-pack’s attention to these ancillary dimensions ensures smooth integration into both automated and manual workflows.

Custom Dimensions for Specialized Applications

While standards cover most needs, specialized applications—like MEMS, photomasks, or irregularly shaped substrates—require custom waffle pack dimensions. Hiner-pack works directly with clients to engineer solutions where pocket shape, pack footprint, or material thickness may deviate from the norm, always focusing on the primary goal of secure substrate protection.

In conclusion, waffle pack dimensions are a symphony of interrelated measurements. Each one, from the macro footprint to the micro-pitch, plays a role in protecting valuable semiconductor wafers. Partnering with a manufacturer like Hiner-pack, which prioritizes dimensional precision and holistic design, is essential for mitigating risk in the fab and throughout the supply chain.

Frequently Asked Questions (FAQ)

Q1: What is the single most critical waffle pack dimension for 300mm wafer automation?

A1: The location and geometry of the robotic handling flange, as defined by SEMI E1.9, are paramount. If these dimensions are out of spec, the automated material handling system (AMHS) may fail to pick or place the pack correctly, causing line stoppages.

Q2: How do waffle pack dimensions differ between 200mm and 300mm wafer packs?

A2: The core difference is in scale and some specific features. While both follow SEMI standards (E1.2 for 200mm, E1.9 for 300mm), the 300mm packs have more standardized and robust robotic handling features, a larger footprint, and are designed for exclusive use in fully automated FOUP-based systems, unlike some 200mm applications which may involve more manual handling.

Q3: Can incorrect waffle pack dimensions increase particle contamination?

A3: Absolutely. If pocket inner dimensions are too tight, they can scrape the wafer edge during loading/unloading, generating particles. If too loose, the wafer can move slightly, leading to micro-abrasion. Similarly, poorly fitting lids due to dimensional flaws compromise the sealed environment.

Q4: Why might a company choose a custom waffle pack dimension instead of a SEMI standard?

A4: Common reasons include: protecting non-standard substrate sizes (e.g., square dies, smaller R&D wafers), needing a unique pocket count to fit a specific process tool cassette, or requiring special material thickness/geometry for extreme environments (e.g., high temperature processes) that standard packs cannot withstand.

Q5: How does Hiner-pack ensure the long-term stability of its waffle pack dimensions?

A5: Hiner-pack uses high-precision, controlled-cavity molds and qualifies them rigorously. We perform ongoing quality audits, measuring critical dimensions against master samples. Furthermore, we select polymer materials with low creep and high dimensional stability under load to ensure packs do not warp or deform over time and use.