In electronics manufacturing, efficiency and reliability begin long before a component is placed on a circuit board. The journey of a surface-mount device (SMD) from the supplier to the pick-and-place nozzle is critical. Loose handling can lead to misplaced components, damaged leads, and production delays. This is where specialized packaging becomes a fundamental part of the process. A waffle pack for SMD components provides a structured, secure, and automated-friendly solution for transporting and presenting delicate parts like QFNs, BGAs, connectors, and other sensitive ICs. Unlike tape-and-reel for high-volume, standardized parts, waffle packs excel at protecting low-to-medium volume, high-mix, or irregularly shaped devices. Manufacturers seeking consistent quality recognize the value of this reliable packaging method, with providers like Hiner-pack offering robust solutions tailored for modern assembly lines.

Why Loose Components Are a Problem for PCB Assembly

Feeding loose or improperly packaged SMD components into an automated assembly line creates several predictable issues. Vibrations during transport can cause parts to shift, tangle, or bump against each other. This movement risks damaging delicate pins and solder balls.

When operators or robots attempt to pick components from a disorganized pile, several problems arise:

- Increased Pick Errors: Vision systems may struggle to identify correct orientation, leading to mispicks.

- Mechanical Damage: Vacuum nozzles can crush components or apply uneven force if not properly aligned.

- Production Slowdowns: Technicians often must manually reorient or untangle parts, creating bottlenecks.

- ESD and Contamination Risk: Exposed components are more susceptible to electrostatic discharge and dust accumulation.

A dedicated waffle pack for SMD components directly addresses these challenges by providing order and physical protection at every stage.

Design and Functional Advantages of the SMD Waffle Pack

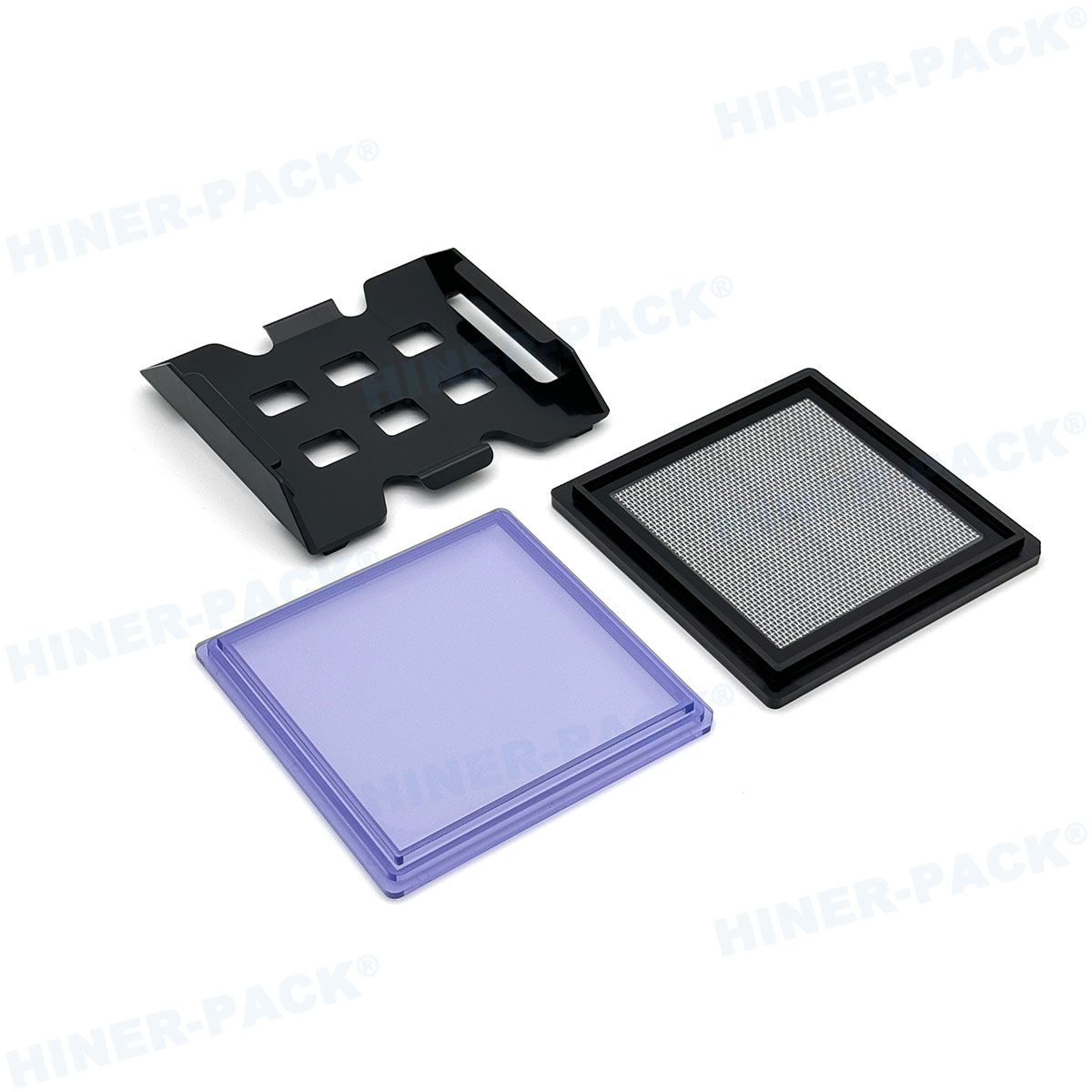

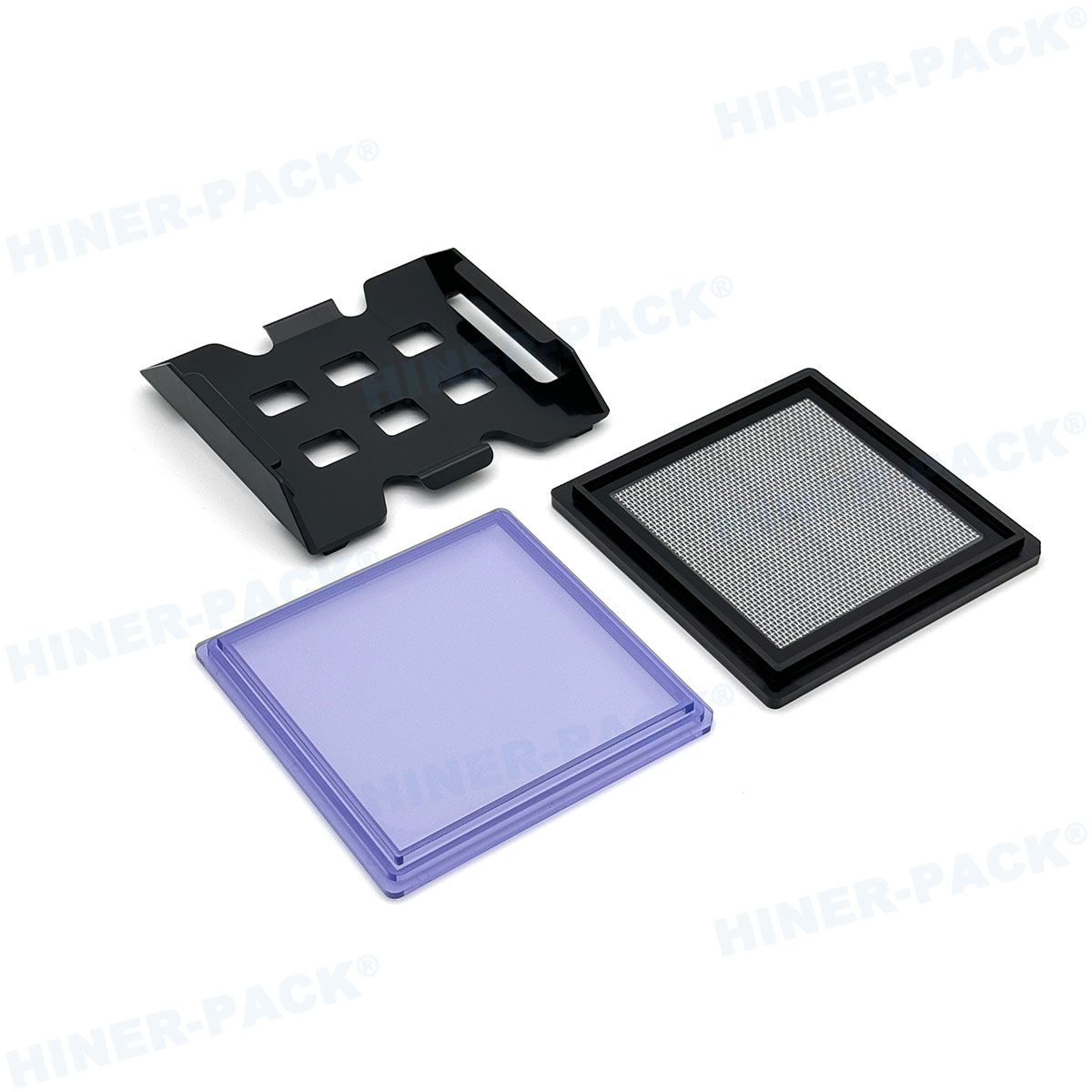

The design is elegantly simple and highly effective. A waffle pack is a rigid tray, typically made from conductive or dissipative polymer, featuring a grid of precisely molded cavities or pockets. Each cavity holds a single SMD component securely in place.

This design offers clear functional benefits:

- Secure Immobilization: Components cannot move, rotate, or collide during transit and handling.

- Guaranteed Orientation: Every part is presented in a known, repeatable position, which is essential for automated pick-and-place machines.

- Physical Protection: The cavity walls protect leads, pins, and solder balls from bending or shearing forces.

- ESD Protection: Conductive materials prevent static charge buildup that could damage sensitive semiconductors.

For assemblers working with complex BGA packages or fine-pitch QFNs, this level of protection is not a luxury—it is a necessity to maintain high first-pass yield rates.

Material Selection: Balancing Protection, Cleanliness, and Cost

The choice of material for a waffle pack for SMD components impacts performance, longevity, and total cost of ownership. The main options each serve specific needs.

- Anti-Static PVC: A common and cost-effective choice for many applications. It provides basic ESD protection and is suitable for components without extreme cleanliness requirements.

- Conductive Carbon-Filled PP or PE: Offers superior ESD protection by providing a conductive path to ground. This is often required for the most static-sensitive devices.

- Polycarbonate (PC) or ABS: Selected for higher temperature resistance and greater rigidity, which may be needed for certain processing or storage conditions.

- Static-Dissipative Materials: These polymers slowly bleed off static charge and are a strong middle-ground choice for many sensitive ICs.

Suppliers like Hiner-pack understand these nuances and can guide customers toward the right material based on their component type, automation setup, and factory environment. The goal is to prevent damage without introducing unnecessary cost or particle contamination.

Ensuring Compatibility with Automated Pick-and-Place Systems

The true value of a waffle pack is realized on the assembly floor. Modern pick-and-place machines are designed to interface with standardized tray systems. A well-designed waffle pack for SMD components follows these automation protocols.

Key compatibility features include:

- Standard External Dimensions: Packs conform to JEDEC or company-specific tray size standards (e.g., 140mm x 155mm, 175mm x 195mm) to fit universal tray feeders and machine loaders.

- Precise Cavity Geometry: Each pocket is dimensionally accurate to hold the component snugly without gripping it too tightly, allowing for smooth robotic pickup.

- Flatness and Rigidity: The tray must not warp, as this can cause misalignment in the feeder and lead to pick-up failures.

- Stackability: Many designs allow for secure stacking during storage and transport, optimizing space in the warehouse and on the production line.

This seamless integration allows manufacturers to run mixed setups—with tape, stick, and tray feeders simultaneously—maximizing line flexibility and uptime.

Best Practices for Using and Maintaining Waffle Packs

To get the longest service life and best performance from your trays, follow a few simple maintenance guidelines. Proper care protects your investment in both the packs and the valuable components they hold.

- Implement a Cleaning Schedule: Regularly clean packs with compressed air or approved cleaning solutions to remove dust and solder paste residue.

- Perform Visual Inspections: Before loading components, check cavities for cracks, warping, or accumulated debris that could affect placement.

- Handle with Care: Avoid dropping or stacking trays too high, as impact can crack cavities and compromise the secure fit.

- Establish a Retirement Cycle: Like any tool, waffle packs wear out. Track their usage and retire them when cavities become loose or damaged to prevent placement errors.

Choosing a Reliable Supplier for Your Packaging Needs

The quality of the waffle pack directly influences your assembly yield. Choosing a supplier is about more than just buying plastic trays. It is about securing a reliable component of your production process.

Look for a supplier that offers:

- Consistent Quality: Every tray should meet precise dimensional tolerances, batch after batch.

- Material Expertise: The ability to recommend the right polymer for your specific ESD and mechanical requirements.

- Customization Options: Willingness to create custom cavity layouts for unique or proprietary components.

- Industry Experience: A proven track record of supporting electronics manufacturers.

Companies like Hiner-pack have built their reputation on this foundation, providing durable and reliable tray solutions that assemblers trust to protect their critical SMD components from the warehouse to the board.

In the detailed world of PCB assembly, success hinges on controlling every variable. How a component is presented to the placement machine is a variable that can—and should—be fully controlled. Utilizing a dedicated waffle pack for SMD components brings order, safety, and reliability to the handling of delicate and high-value parts. It minimizes errors, prevents damage, and keeps automated lines running smoothly. For contract manufacturers and OEMs dealing with a diverse array of components, this packaging form is an indispensable tool for maintaining quality and efficiency. By sourcing well-designed trays from experienced partners like Hiner-pack, manufacturers can ensure their sensitive SMD components are perfectly positioned for a successful placement, every single time.

Frequently Asked Questions (FAQs)

Q1: When should I use a waffle pack instead of tape-and-reel or stick magazines?

A1: Waffle packs (trays) are ideal for large, heavy, irregularly shaped, or highly sensitive SMD components that tape-and-reel cannot accommodate. This includes large BGAs, QFNs, connectors, and LEDs with delicate lenses. They are also preferred for low-to-medium volume production runs where the cost of reeling is not justified.

Q2: Are waffle packs reusable, and how many times can they typically be used?

A2: Yes, high-quality waffle packs are designed for reuse. Their lifespan depends on the material, handling care, and the cleaning process. A well-maintained tray can often be used dozens of times. Regular inspection for wear, warping, or cavity damage is key to determining when to retire a pack.

Q3: How do I ensure the waffle pack material is compatible with my cleanroom or ESD requirements?

A3: Consult the manufacturer's data sheets for surface resistivity ratings (e.g., conductive, dissipative, anti-static). For cleanrooms, request information on particle shedding. Reputable suppliers like Hiner-pack can provide this documentation and recommend materials like static-dissipative polycarbonate for stringent environments.

Q4: Can I get custom-designed waffle packs for a proprietary component shape?

A4: Absolutely. Many suppliers offer custom molding services. You will typically need to provide the component drawing or a sample. The supplier will then design a cavity that securely holds your specific part. This is a common solution for protecting unique or newly developed components.

Q5: How should I store and organize empty waffle packs to save space and prevent damage?

A5: The best practice is to stack identical trays neatly in a dedicated rack or cupboard. Ensure the storage area is clean, dry, and away from direct sunlight or heat sources to prevent material warping. Many trays are designed with interlocking features for stable stacking.