Customer Overview and Project Background

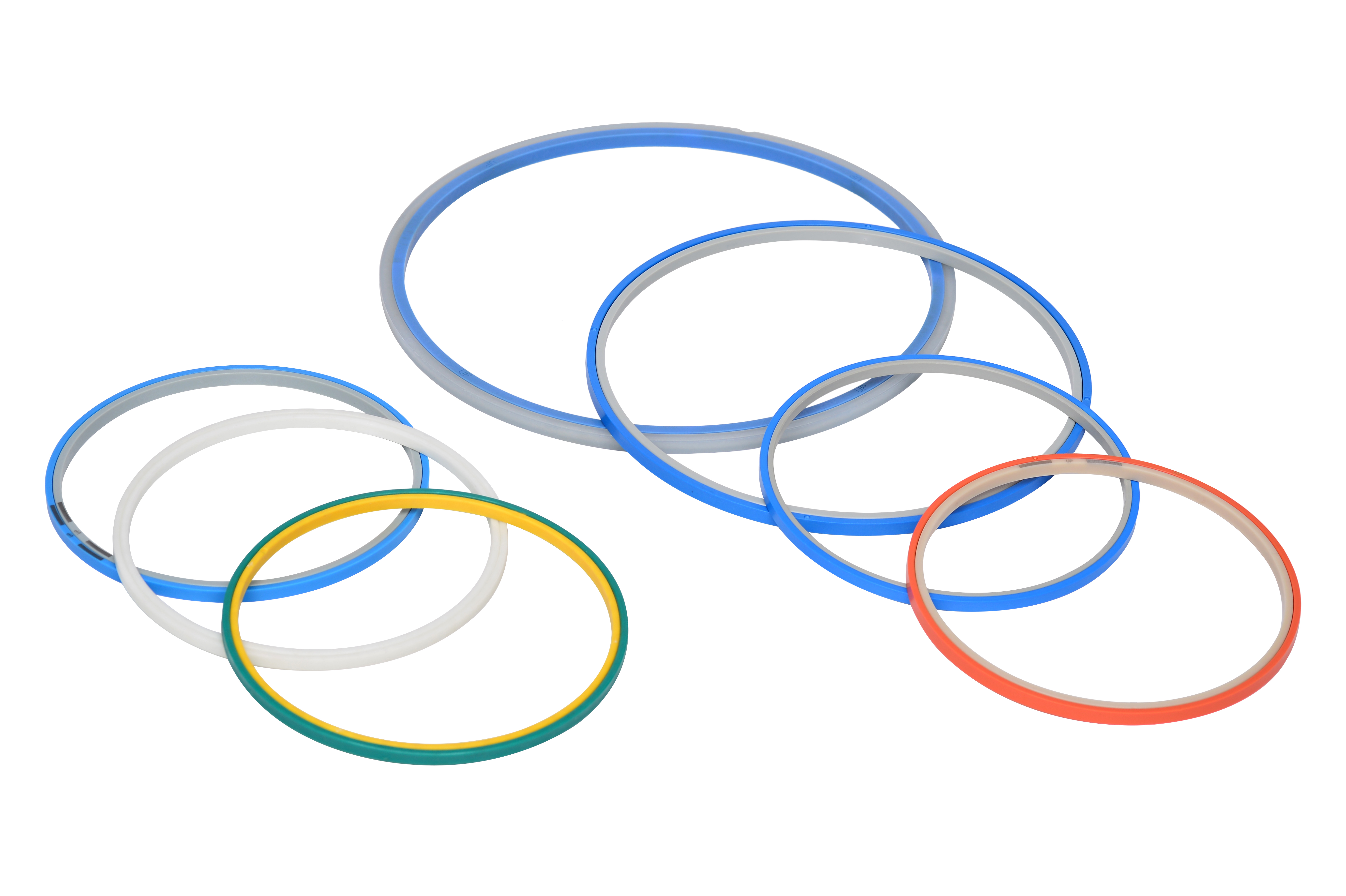

G Company, a semiconductor materials and chip R&D enterprise with a solid background, procured a batch of 6-inch wafer expansion rings from our company in May 2025 for wafer expansion development and wafer transportation testing. No issues were reported during the testing phase, but abnormal film breakage (UV Dicing Film/Blue Dicing Film) occurred during subsequent mass production. G Company reported this issue to us and requested a solution within one week.

Solution

Upon receiving feedback from the customer, our company immediately convened an emergency meeting to discuss solutions. Relevant personnel from the engineering and quality departments conducted a comprehensive diagnostic investigation into the causes of the product abnormalities. They examined everything from the material batches to machine parameter settings and external temperature and humidity conditions during actual production on that day, but no issues were identified. Subsequently, a consistency retest was performed on the inventory products from the abnormal batch proposed by the customer. After testing, it was confirmed that the dimensions of the retained samples from the same batch complied with the drawing tolerances, and no significant differences were found. To identify the cause of the product abnormalities, quality department personnel tested and recorded the tightness and fit of the products using a torque meter, comparing the data with a control group of high-quality products from the same batch.

Implementation Process

•Installation and debugging of the torque meter and fixtures

•Connecting the inner and outer rings of the wafer expansion ring to the torque meter for tightness testing and recording the values

•Testing the fit between the inner and outer rings and recording the values

•Comparing and analyzing the data with that of high-quality products and marking abnormal products

•Randomly selecting a new batch of products and repeating steps 1-4 to compare actual usage conditions

Implementation Results

Through data analysis of positive and negative tests on two batches of products, it was determined that the abnormal film breakage was caused by excessive tightness in the fit between the inner and outer rings. Due to excessive surface tension during the pressing process, uneven fiber dispersion led to high friction in localized areas on the surface, posing a risk of film breakage. Based on this conclusion, we modified the fiber ratio of the original material while maintaining the existing material basis and conducted sample verification again. Ultimately, the film breakage rate of the products significantly decreased, meeting normal standards and allowing for mass production.

Customer Feedback

"I am amazed by Hiner-Pack's rigorous attitude towards product quality and its high sense of responsibility towards customers. Their practical actions have proven to me that choosing Hiner-Pack was an extremely wise decision. At the same time, this timely and efficient after-sales response has eliminated all my concerns, allowing our company to focus wholeheartedly on product development."

Project Value Summary

From demand communication to solution implementation, the project team fully matched the customer's needs in terms of response speed, professionalism, and flexibility. The efficient problem-solving process allowed the customer to experience our professional service capabilities, significantly enhancing their trust in us. This cooperation model centered on "solving the customer's actual pain points" laid a solid foundation for subsequent in-depth cooperation and expanded business scenarios, serving as an important practical endorsement of our service capabilities.