Customer Overview and Project Background

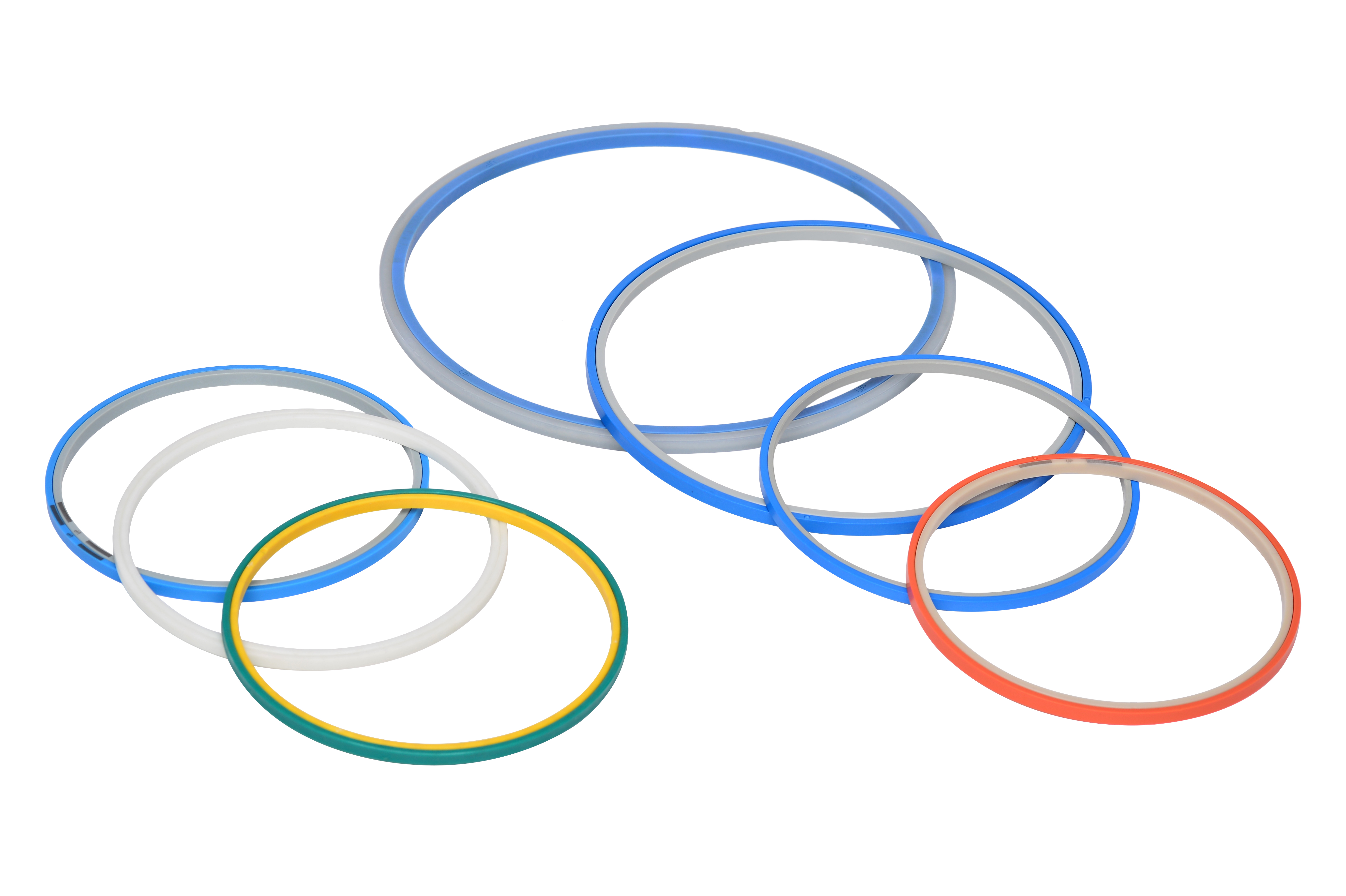

H Company is a semiconductor R&D enterprise that has maintained a good cooperative relationship with our company for the past five years. In March 2024, H Company planned to purchase a batch of 8-inch vertical frame boxes from our company for product storage and transportation. However, during the testing phase, abnormal breakage of the accessory fasteners of the wafer frame transportation box was discovered. The relevant person in charge at H Company expressed the hope that our company could quickly identify the cause and resolve the issue.

Solution

Since this product had not exhibited any abnormal quality issues in the past and had been mass-produced and exported domestically and internationally, all relevant departments in the factory attached great importance to this matter. An emergency meeting was convened in the afternoon to investigate the abnormal cause, listing all potential factors that could trigger the problem. A profound analysis and discussion were conducted on this issue to facilitate subsequent verification one by one. The relevant factors are as follows:

1.Raw Materials

•Whether the raw materials were confused

•Whether other impurities were mixed into the raw materials during the production process

•Errors in the raw material ratio

2.Machinery

•Misalignment of the mold structure

•Machine changes

•Incorrect preset parameters

3.Personnel

•Production not carried out according to regulations

•Failure to strictly enforce inspection standards

•Failure to meet the sampling inspection quantity requirements

Implementation Process

1.Investigation of Raw Material Factors

•The product material records and remaining materials for this batch were reviewed, and no errors in material usage or ratio were found.

•The fracture location of the product was examined with a magnifying glass, and no impurities were found at the fracture site, thus ruling out the possibility of material mixing.

2.Investigation of Machinery Factors

•The dimensions of the mold bending position were verified, confirming that they conformed to the 3D drawing design. The product bending area was smooth, posing no risk.

•All machine preset parameters were correct, ruling out relevant risks.

•It was found that there was a risk due to the inconsistency between the trial mold machine and the mass production machine (Risk 1). The dedicated machine only produces PP materials, while non-dedicated machines produce both PP and PPE materials.

3.Investigation of Personnel Factors

•Relevant personnel carried out production and inspection according to regulations.

•The sampling inspection quantity met the requirements.

4.Verification of Risk 1

A: Samples were tested using a mass production machine for PP materials. After cooling for 24 hours, the sample fasteners showed no breakage in drop tests and could be bent back and forth 20 times without breakage.

B: Samples were tested again using a machine for PPE materials without cleaning. After cooling for 24 hours, the sample fasteners broke directly after being bent back and forth twice.

C: Samples were tested again after cleaning the mass production machine. After cooling for 24 hours, the sample fasteners showed no breakage in drop tests and could be bent back and forth 20 times without breakage.

Implementation Results

Through systematic review, testing, and verification, the cause of the abnormal breakage of the fasteners was successfully identified. After eliminating this risk, trial mold production was resumed, and a comprehensive inspection of the products was conducted. The defective product rate was reduced to a normal level, and no abnormalities occurred during subsequent use.

Customer Feedback

"No product can be guaranteed to be perfect. When choosing a supplier, manufacturers should not only examine the other party's ability to prevent issues beforehand but also their ability to control them afterward. This is why I firmly chose Hiner-Pack. Fortunately, we have never disappointed each other."

Project Value Summary

As our long-term partner, this project focused on quickly responding to and resolving issues encountered by the customer during product use. Through cross-departmental collaboration and in-depth technical investigations, we not only quickly identified the inducing factors but also took precautions against potential risks, further enhancing the stability and safety of the products. This efficient and professional service not only helped the customer avoid losses from business interruptions but also solidified our long-term, mutually trusting cooperative relationship, laying a solid foundation for future deeper cooperation and joint innovation.