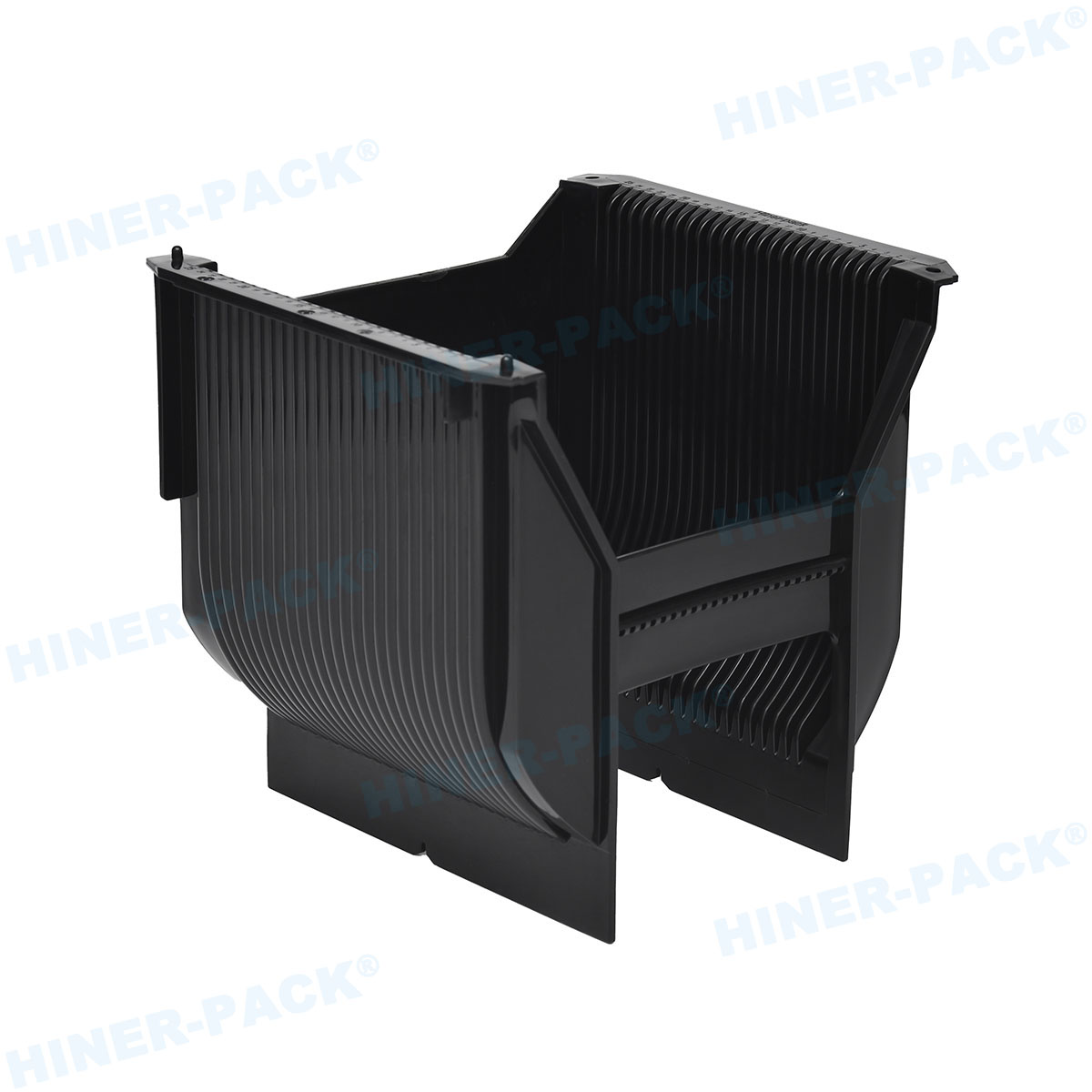

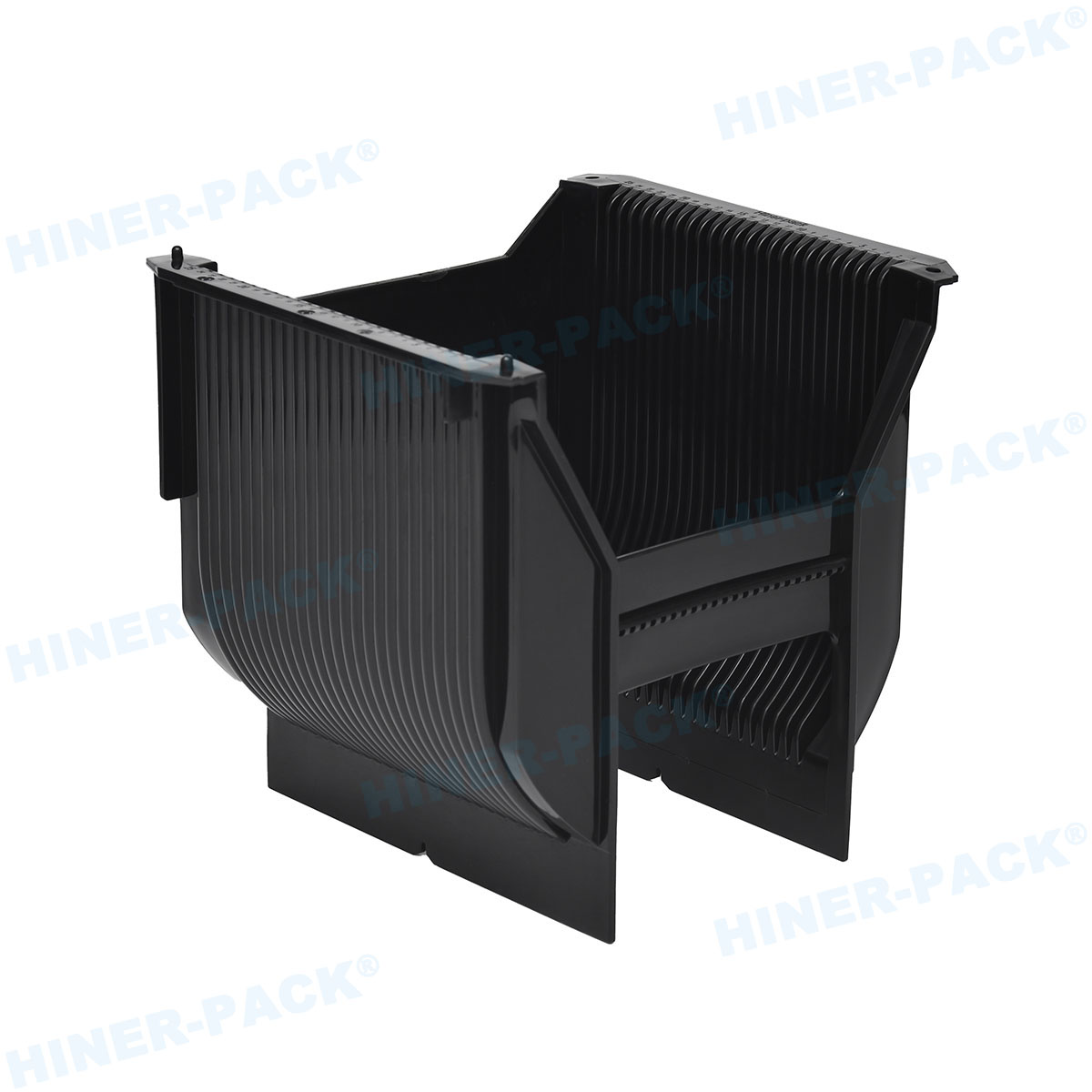

Cleanroom-Compatible Trays: Selection Guide for Semiconductor ManufacturingIn semiconductor and microelectronics production, controlling contamination is critical. Every component introduced into the cleanroom environment must meet stringent standards. **Cleanroom-compatible trays** are essential for safely handling, transporting, and storing sensitive items like wafers, masks, and critical parts. Selecting the right tray directly impacts yield, process integrity, and operational efficiency.

Understanding Cleanroom Compatibility

Cleanroom compatibility goes beyond basic cleanliness. It means a product is engineered to minimize particle generation, chemical outgassing, and electrostatic discharge (ESD) in controlled environments.

Key Standards and Classifications

Trays must align with the cleanroom's ISO classification. Common standards include:

ISO Class 1-5 for advanced semiconductor processes.

Federal Standard 209E and IEST-RP-CC004 guidelines.

SEMI standards for carrier and packaging specifications.

Manufacturers like **Hiner-pack** design trays to perform reliably within these strict parameters.

Why Material Choice is Critical for Trays

The material forms the foundation of a tray's performance. It must balance mechanical strength with ultra-clean properties.

Common High-Performance Materials

Static-Dissipative Polymers (PFA, PP, PC): Offer excellent chemical resistance and low particulate shedding. Ideal for wet process stations.

PEEK (Polyetheretherketone): Used for high-temperature applications. It exhibits exceptional purity and thermal stability.

Advanced Composites: Carbon-fiber reinforced materials provide strength and lightness for automated handling.

Each material is selected to ensure the long-term reliability of Cleanroom-compatible trays.

Essential Design Features of Quality Trays

A well-designed tray integrates multiple features to protect both the product and the cleanroom.

Contamination Control Design

Smooth, radiused edges to prevent particle trapping.

Minimalist structure to reduce surface area where contaminants can adhere.

Optimized drainage for quick drying after cleaning cycles.

Ergonomics and Automation Compatibility

Trays must interface seamlessly with equipment.

Precise dimensional tolerances for robotic pick-and-place systems.

Standard footprints compatible with SMIF pods and automation rails.

Lightweight yet rigid construction for manual handling safety.

Primary Applications in Semiconductor Fabs

These trays serve specialized roles throughout the manufacturing lifecycle.

Front-End Wafer Processing

Used for transporting batches of wafers between diffusion, etch, and deposition tools. Chemical resistance is paramount here.

Photomask and Reticle Handling

Mask carriers often use dedicated **Cleanroom-compatible trays** with secure latching mechanisms to protect critical patterning surfaces from damage and contamination.

Back-End Assembly and Test

In packaging and testing facilities, trays protect finished dies, ICs, and other components. ESD protection becomes a primary concern in these areas.

How to Select the Right Tray for Your Process

Choosing the correct tray requires a detailed assessment of your process needs.

Evaluation Criteria Checklist

Process Compatibility: Assess exposure to chemicals, temperatures, and UV light.

Cleanroom Class: Match the tray's particle generation data to your environment's class.

Physical Requirements: Consider load capacity, stackability, and dimensional specifications.

Compliance Needs: Verify certifications for ESD (e.g., ANSI/ESD S20.20) and relevant SEMI standards.

Partnering with an experienced supplier like **Hiner-pack** can streamline this selection process.

Maintenance and Validation for Long-Term Use

Proper care extends tray life and ensures ongoing compliance.

Cleaning and Inspection Protocols

Use DI water, mild solvents, or automated cleaning systems as recommended.

Implement regular inspection schedules for wear, cracks, or surface degradation.

Document cleaning cycles and particle count tests for quality audits.

Consistent maintenance preserves the integrity of your Cleanroom-compatible trays investment.

Conclusion

Selecting the appropriate **Cleanroom-compatible trays** is a technical decision with direct consequences for production yield and cost. By focusing on material science, precision design, and application-specific features, manufacturers can significantly mitigate contamination risks. Investing in high-quality trays from reputable sources is a fundamental step toward achieving process excellence in semiconductor fabrication.

Frequently Asked Questions (FAQs)

Q1: How often should Cleanroom-compatible trays be cleaned and validated?

A1: The frequency depends on the cleanroom class and process step. For ISO Class 3-5 areas, trays may require cleaning after every use or daily. Regular validation, such as particle count tests, should align with your facility's quality control schedule, often weekly or monthly.

Q2: Can these trays withstand autoclave or aggressive chemical cleaning?

A2: It depends on the material. Trays made from PFA or PEEK generally offer excellent resistance to harsh chemicals and high temperatures. Always check the manufacturer's specifications for maximum temperature and chemical compatibility before proceeding with aggressive cleaning methods.

Q3: What is the difference between conductive, dissipative, and insulating trays?

A3: Conductive materials (surface resistivity < 1 x 10^5 Ω/sq) allow charge to flow quickly. Dissipative materials (1 x 10^5 to 1 x 10^12 Ω/sq) allow a slower, controlled charge bleed-off. Insulating materials (> 1 x 10^12 Ω/sq) hold charge. For most ESD-sensitive components, dissipative **Cleanroom-compatible trays** are preferred as they safely neutralize charges without causing damage.

Q4: Are custom-designed trays available for unique components?

A4: Yes. Many suppliers, including **Hiner-pack**, offer custom design services. This includes creating trays with specific cavity sizes, profiles, material blends, or RFID tagging integration to fit unique parts and automation systems.

Q5: How do I properly dispose of or recycle old Cleanroom-compatible trays?

A5: Disposal should follow local environmental regulations. Some high-performance polymers can be recycled by specialized facilities. Contact the tray manufacturer for guidance; they often have take-back or recycling programs for end-of-life products to ensure proper material handling.