Semiconductor manufacturing is an unforgiving industry. A single particle of dust or a minor vibration during transport can ruin a batch of high-value wafers. While the primary shipping container—often a canister or a cassette—gets the most attention, the internal components are just as critical. These additional layers of protection are known collectively as wafer shipper accessories.

At Hiner-pack, we see these accessories not as optional add-ons, but as vital insurance policies. They bridge the gap between a standard plastic box and a high-yield logistics solution. Whether you are moving raw silicon, glass, or fully processed compound semiconductors, the right combination of separators, cushions, and rings ensures the product arrives intact.

This article details the specific components used inside shippers, their functions, and how they contribute to maintaining wafer integrity across the supply chain.

The Role of Wafer Shipper Accessories in Surface Protection

The primary enemy of a polished wafer is friction. When wafers are stacked in a coin-style horizontal shipper, they physically touch each other. Without intervention, this contact leads to surface scratching and particle generation.

Interleaf separators are the most common wafer shipper accessories used to combat this. Typically made from Tyvek or specialized low-lint paper, these discs sit between each wafer. They provide a soft, non-abrasive barrier that prevents direct silicon-to-silicon contact.

Tyvek is generally preferred over standard paper in cleanroom environments. It resists tearing and does not generate lint, which is crucial for maintaining ISO class standards. Using the wrong type of separator can introduce contaminants that are difficult to remove during subsequent cleaning steps.

Managing Movement with Cushions and Spacers

A wafer shipper is rarely filled to its exact capacity every single time. If a canister is designed for 25 wafers but you are only shipping 10, there is a significant gap at the top of the stack.

Leaving this gap empty is dangerous. It allows the wafers to bounce vertically during transit, potentially cracking the edges or shattering the stack entirely. This is where cushions and spacers come into play.

Foam cushions are placed at the top and bottom of the stack to absorb shock. They act as springs, keeping the wafers under slight compression so they do not rotate or rattle. Spacers, often made of rigid plastic or thick foam, are used to fill the void of missing wafers. Ensuring the stack is tight is a fundamental rule of wafer logistics.

ESD Control Through Specialized Materials

Electrostatic discharge (ESD) can destroy the microscopic circuitry on a processed wafer in nanoseconds. While the outer shipper box is usually made of conductive or static-dissipative material, the internal wafer shipper accessories must also support this protection.

Pink anti-static foam and conductive black foam are industry standards. They ensure that no static charge builds up between the wafer and the cushioning material. If standard polyethylene foam were used, the friction from the foam rubbing against the wafer could generate a charge.

Hiner-pack emphasizes the use of conductive accessories to ensure a continuous path to ground. This protects the sensitive oxide layers on the devices from "zapping" during the unpacking process.

Security Clips and Secondary Locks

The lid of a wafer jar or canister is designed to screw on or snap shut. However, air pressure changes in a cargo hold or rough handling by couriers can sometimes cause lids to loosen.

To prevent accidental opening, many logistics managers utilize secondary security clips or tamper-evident tape. These plastic clips snap over the closure mechanism, physically preventing the lid from rotating.

These small tools provide a visual indicator of security. If the clip is broken or missing upon arrival, the receiving engineer knows immediately that the package may have been compromised. Including these simple items in your shipping protocol adds a necessary layer of accountability.

Choosing the Right Wafer Shipper Accessories for Your Workflow

Selection depends heavily on the wafer type. A rugged sapphire wafer might tolerate a simple paper separator, while a fragile thinned silicon wafer requires a highly specialized, ultra-smooth Tyvek interleaf and softer foam density.

Thickness is also a factor. Standard spacers are designed for standard thickness wafers. If you are shipping TAIKO wafers or ultra-thin dies, you may need custom-thickness spacers to ensure the stack height is calculated correctly. A mismatch here can lead to crushing (if the stack is too high) or rattling (if the stack is too low).

Hiner-pack engineers often advise clients to calculate the total stack height—including all interleaves—before selecting the final top cushion. This precision prevents stress fractures during the lid-closing process.

Maintaining Cleanroom Standards

Accessories must be as clean as the wafers they protect. Bringing dirty cardboard or non-cleanroom-rated foam into a fab is a major violation of protocol.

High-quality accessories are manufactured, cleaned, and vacuum-sealed in a cleanroom environment. When you open a pack of separators or cushions, they should be ready for immediate use without further cleaning.

Reusing accessories is a topic of debate. While cost-saving, reusing separators or foam carries a high risk of cross-contamination. Particles embedded in a foam cushion from a previous shipment can transfer to the next batch. For high-yield processes, single-use accessories are the industry best practice.

The safety of a semiconductor shipment relies on more than just the outer container. It is the internal system of wafer shipper accessories—the separators, cushions, and spacers—that truly secures the product.

By reducing friction, absorbing shock, and managing static electricity, these components preserve the value of the wafers. Whether you are an engineer at a foundry or a logistics manager at an assembly plant, paying attention to these small details prevents costly yield losses.

Hiner-pack continues to supply high-reliability packaging solutions that prioritize cleanliness and physical protection. Investing in quality accessories is investing in the reputation of your final product.

Frequently Asked Questions

Q1: What is the difference between Tyvek and paper separators?

A1: Tyvek is a synthetic material made from flash-spun high-density polyethylene fibers. It is cleaner, stronger, and generates significantly fewer particles than standard paper. Paper separators are cheaper but are more prone to tearing and releasing fibers, which can contaminate the wafer surface. Tyvek is the standard for high-purity semiconductor shipping.

Q2: Can I reuse foam cushions and spacers?

A2: It is generally not recommended to reuse foam cushions for high-value wafer shipments. Foam can degrade over time, losing its "spring" and ability to absorb shock. Furthermore, foam is porous and can trap particles or chemical residues that are difficult to clean. Reusing them increases the risk of contamination and physical damage.

Q3: How do I know which size cushion to use?

A3: The cushion size must match the diameter of the wafer (e.g., 150mm, 200mm, 300mm) to ensure even pressure distribution. The thickness of the cushion depends on the remaining space in the canister. You should aim for a stack height that is slightly taller than the canister rim, so the lid compresses the foam slightly to lock the wafers in place without crushing them.

Q4: Are all wafer shipper accessories ESD safe?

A4: No, not all accessories are ESD safe by default. You must specifically request antistatic (pink) or conductive (black) materials if your devices are sensitive to electrostatic discharge. Standard white foam or clear plastics are often insulative and can generate static charges that damage active circuits.

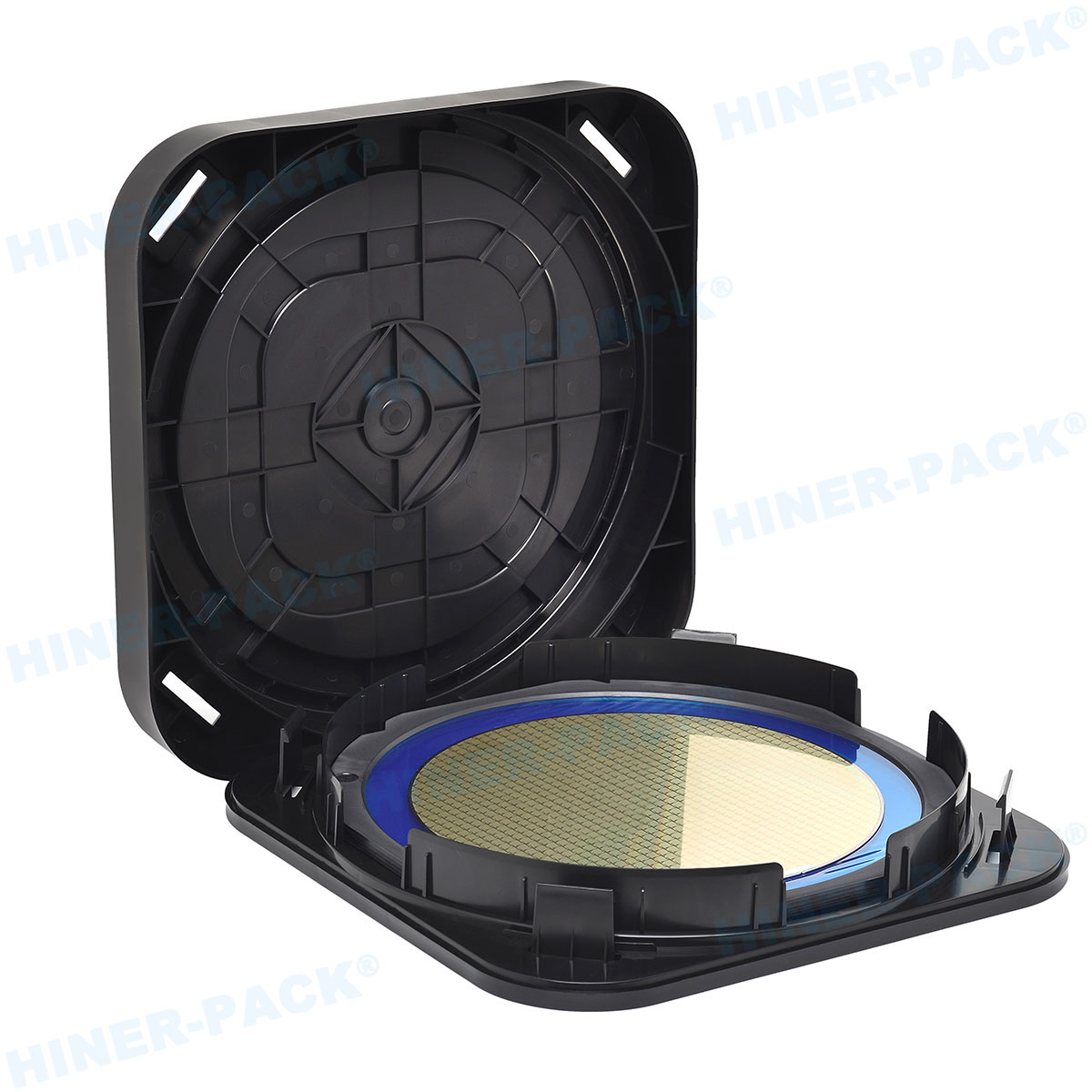

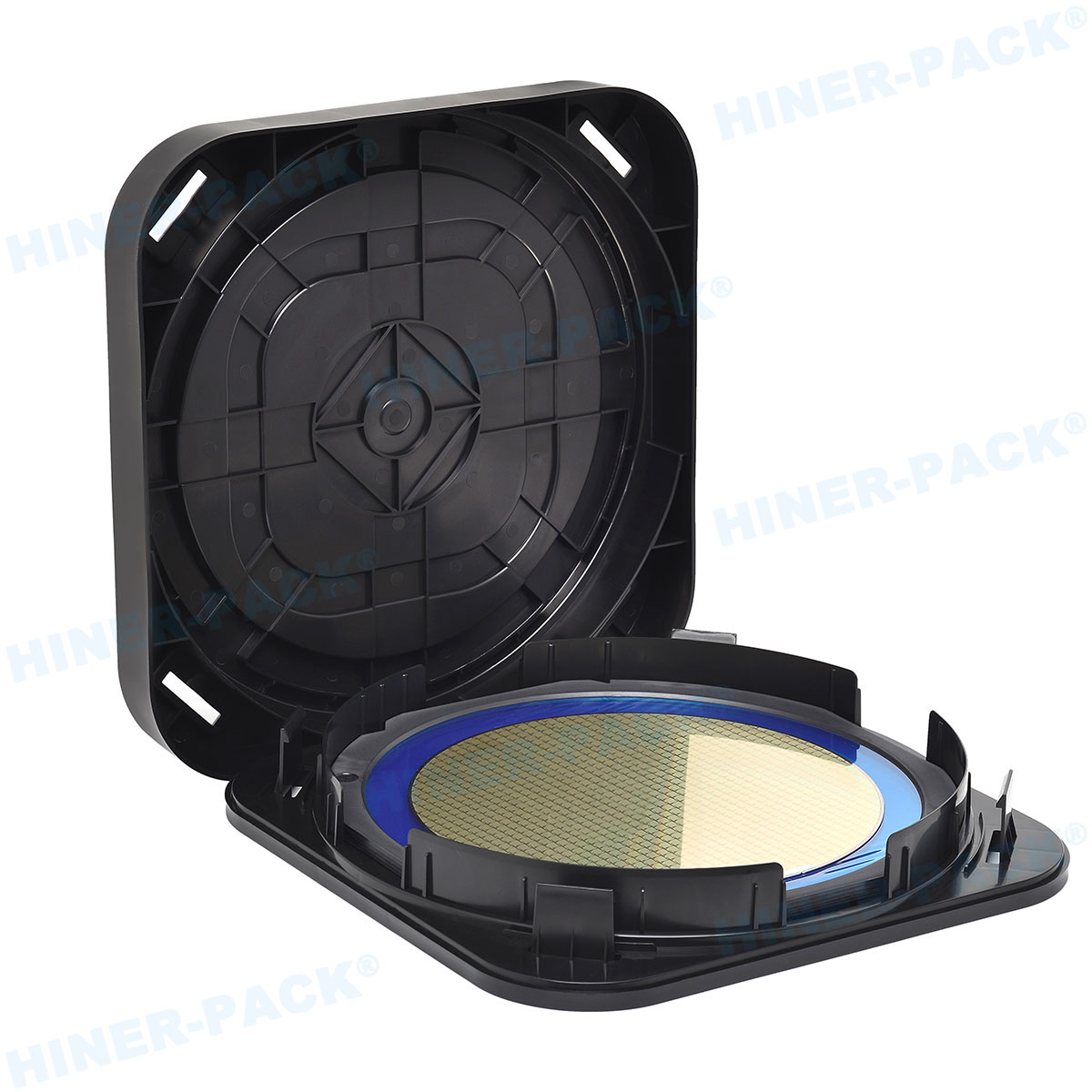

Q5: What are "wafer rings" in the context of shipping?

A5: Wafer rings (or film frames) are used to hold a wafer that has been mounted on dicing tape. While they are sometimes considered accessories, they are often part of a specific frame shipper system. They keep the wafer flat and suspended during the dicing and transport process, preventing the diced chips from colliding.