Transporting delicate semiconductor components is one of the most stressful parts of the manufacturing process. A single micro-crack can ruin a high-value die. This is where the gel pak gel box becomes an essential tool for engineers.

For decades, the industry has relied on this specific carrier technology to move fragile devices safely. Whether you are handling Gallium Arsenide (GaAs) wafers or fragile MEMS, the right packaging makes all the difference. Companies like Hiner-pack have recognized the critical need for these specialized carriers in the global supply chain, ensuring that chips arrive at their destination ready for wire bonding.

This article details how a gel pak gel box works, why it is the standard for the semiconductor industry, and how to select the right specifications for your production line.

What is a Gel Pak Gel Box?

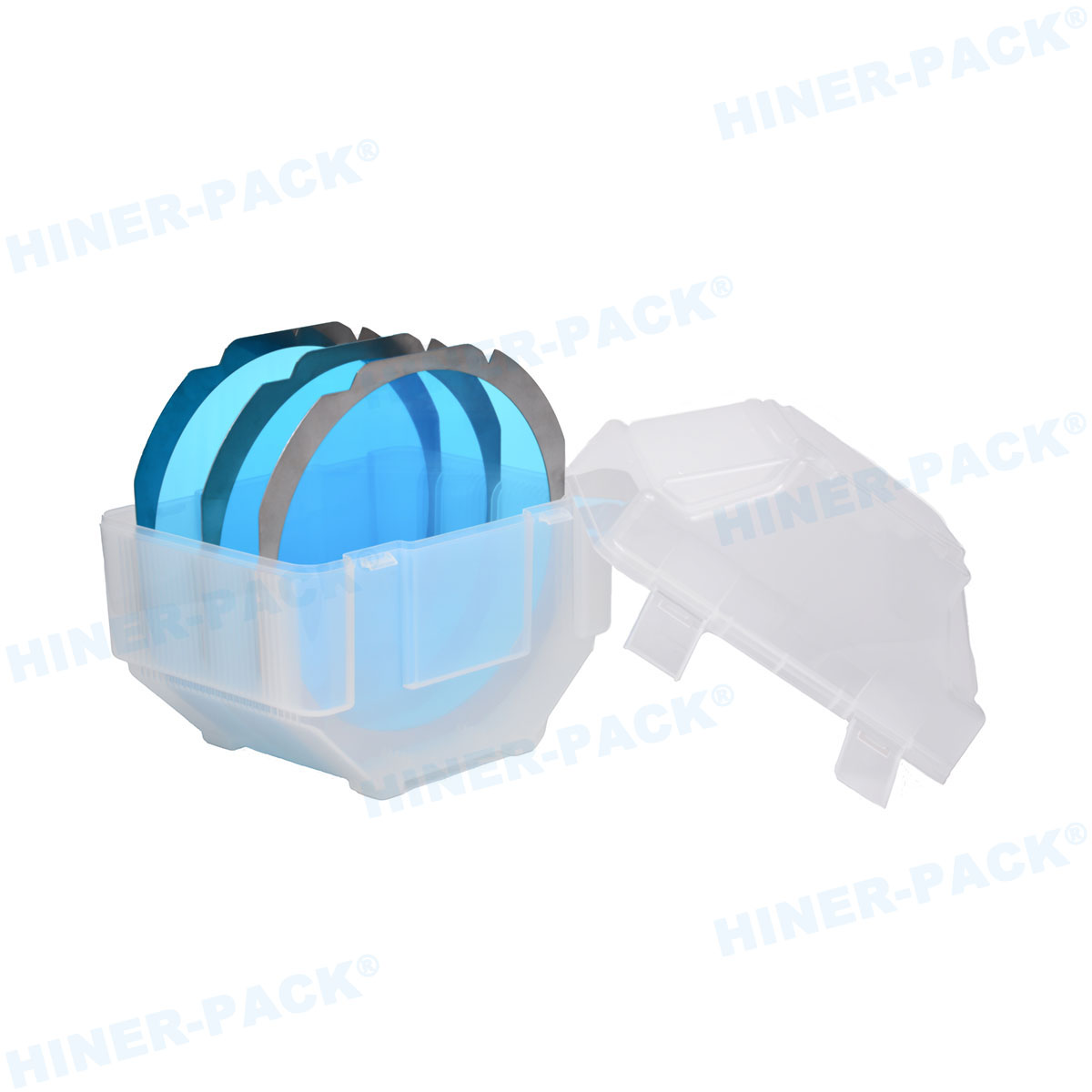

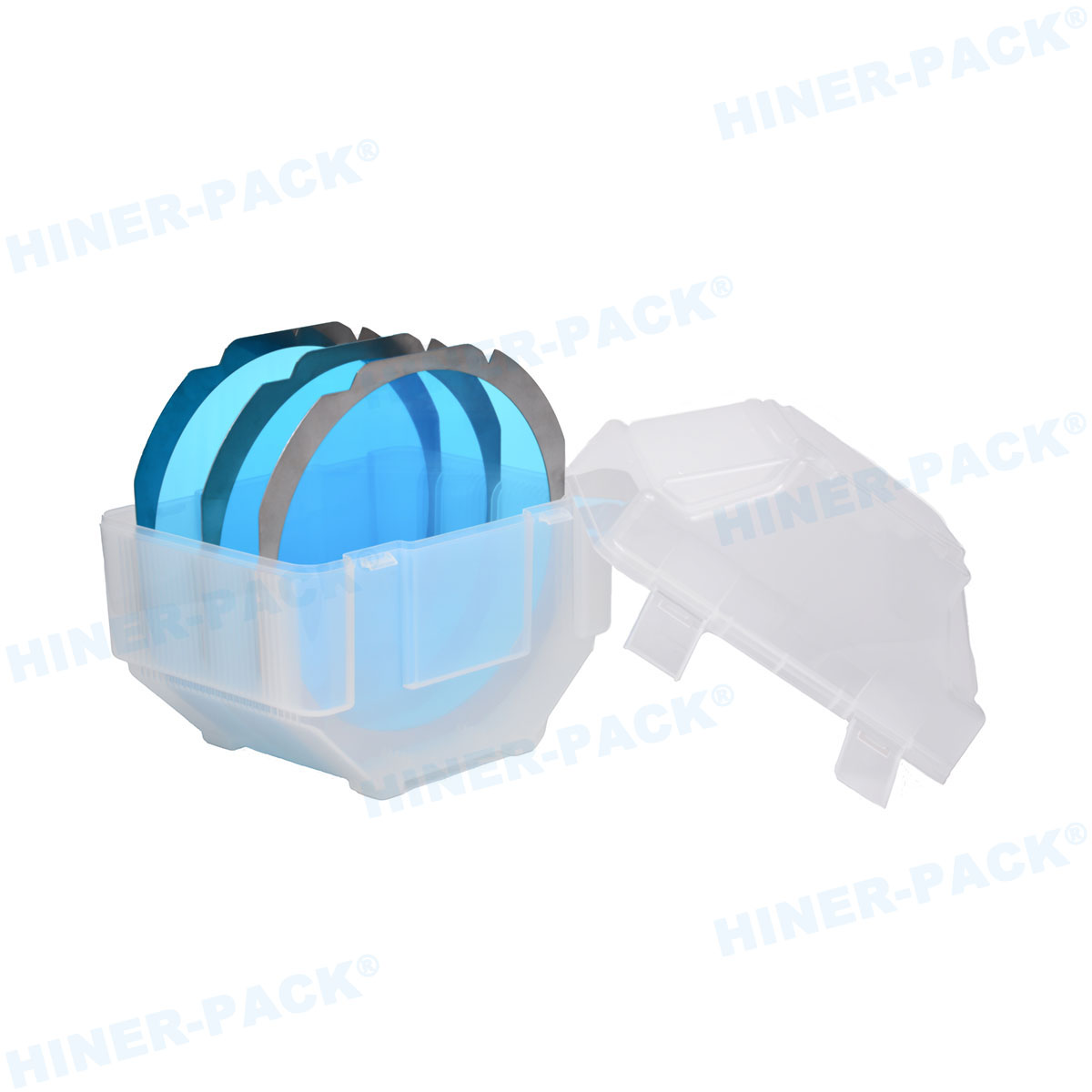

A gel pak gel box is a carrier tray designed with a proprietary gel material at the bottom. This gel relies on surface tension rather than adhesive glue to hold devices in place. The primary goal is to immobilize the component during shipping and handling while allowing for easy release when needed.

The key to this technology is the cross-linked polymer gel. It provides a secure hold that prevents the dies from shifting, even if the box is tilted or subjected to vibration. Unlike standard waffle packs, a gel pak gel box does not allow the die to rattle, which significantly reduces the risk of edge chipping.

The Mechanics of Adhesion

The holding force of a gel pak gel box comes from the tackiness of the elastomer. This tackiness is graded. You can order boxes with low, medium, or high retention levels depending on the mass and surface roughness of your device.

When a device is placed on the gel, the surface contact area creates a bond. For standard sticky gel boxes, you simply use tweezers to lift the device, breaking the surface tension. However, for thinner or more fragile dies, a specific Vacuum Release (VR) mechanism is required.

Vacuum Release vs. Standard Gel

There are two main categories when discussing gel pak gel box technology. The first is the standard "sticky" box. This is generally used for passive components or larger dies that can handle mechanical handling forces.

The second, and more advanced type, is the Vacuum Release (VR) tray. In a VR gel pak gel box, the gel membrane is placed over a mesh. When you apply a vacuum to the underside of the tray, the gel is pulled down through the mesh. This reduces the surface area contact with the die by over 95%. The bond is broken effectively, allowing the die to be lifted with zero force.

Applications in the Semiconductor Sector

The usage of a gel pak gel box is widespread across the international semiconductor landscape. It is not just for storage; it is an active part of the process flow.

Handling Thinned Wafers

As devices get smaller, wafers get thinner. Handling a wafer that has been back-grinded to 50 microns is extremely difficult. A gel pak gel box provides the planar support needed to transport these thinned dies without warping or cracking them.

Optoelectronics and Photonics

Optical devices often have sensitive surfaces that cannot be touched. A gel pak gel box allows the device to be held by its backside only. This prevents scratches on lenses or active optical areas.

Many photonics engineers specify a gel pak gel box for indium phosphide (InP) lasers. The material is brittle, and standard pockets usually cause damage during transit. The immobilization offered by the gel is the only safe solution.

Operating a Vacuum Release Gel Box

Using a Vacuum Release gel pak gel box requires specific equipment. It is not as simple as opening a lid. You must integrate the tray into a vacuum fixture.

The Vacuum Process

First, place the gel pak gel box on a porous vacuum chuck. Ensure the tray is aligned correctly with the vacuum holes. Once the tray is seated, turn on the vacuum source.

You will see the gel surface change texture slightly as it pulls against the mesh. This indicates that the gel pak gel box is in "release mode." The hold on the devices is now minimal.

Picking the Device

Once the vacuum is engaged, use a vacuum wand or soft-tip tweezers to pick the component. Because the gel pak gel box has released its hold, the component should lift effortlessly.

Do not attempt to pull a device off a VR gel pak gel box without applying the vacuum first. Doing so can damage the component or rip the gel membrane, rendering the tray useless.

Choosing the Right Retention Level

Not every gel pak gel box is built the same. Manufacturers offer different "tack" levels. Selecting the wrong level is a common mistake.

Low vs. High Retention

If you are shipping heavy ceramic substrates, a high-retention gel pak gel box is necessary. The heavy mass of the part means it creates more force during a drop, so the gel needs a stronger grip.

Conversely, for tiny, lightweight dies (like 200-micron LEDs), a low-retention gel pak gel box is preferred. If the retention is too high, even the vacuum release mechanism might struggle to let go of such a small, light part.

Mesh Size Considerations

For Vacuum Release trays, the mesh size matters. The mesh dictates how much support the die has. A finer mesh (high mesh count) is used for very small dies to prevent them from tilting into the holes of the mesh during the vacuum cycle.

When you consult with suppliers like Hiner-pack, they can help determine if you need a 16, 33, or 76 mesh count for your specific gel pak gel box.

Solutions for ESD Protection

Static electricity is the silent killer of semiconductors. A standard plastic box is an insulator and generates static charges. To combat this, the modern gel pak gel box is available in conductive or anti-static materials.

Conductive vs. Antistatic

A black, conductive gel pak gel box allows for electrostatic discharge (ESD) grounding. The shell and the gel itself are impregnated with conductive materials. This ensures that any charge built up during transport is dissipated safely.

For applications where you need to inspect the parts visually through the box, an anti-static clear gel pak gel box is used. These are treated to prevent charge buildup but allow optical inspection without opening the tray.

Storage and Maintenance of Gel Boxes

A gel pak gel box is reusable, but it has a lifespan. Dust and oils are the enemies of the gel surface.

Cleaning the Gel

If the tackiness of your gel pak gel box decreases, it is likely due to surface contamination. You can clean the gel using tape or a mild solvent recommended by the manufacturer. However, be careful not to use abrasive materials.

Most facilities treat a gel pak gel box as a consumable. After a certain number of cycles, the cross-linking in the gel may degrade, or the mesh may lose tension.

Temperature Constraints

Standard gel materials have a temperature range. If you expose a gel pak gel box to reflow oven temperatures, the gel will melt and ruin your devices. Always check the thermal rating. There are high-temperature versions available, but standard boxes are meant for room-temperature transport.

Solving Supply Chain Issues

The availability of these trays can be volatile. Sourcing a high-quality gel pak gel box often involves long lead times from major distributors.

This is where alternative high-quality providers step in. Hiner-pack has established itself as a reliable source for these specialized carriers. They offer compatible solutions that fit standard industry vacuum fixtures. By diversifying your supply of the gel pak gel box, you ensure your production line never stops due to a packaging shortage.

The gel pak gel box remains the gold standard for transporting fragile semiconductor devices. Its unique ability to immobilize parts without adhesive residue solves the biggest headaches in wafer handling. From Vacuum Release options to simple sticky trays, this technology ensures high yields and safe delivery.

Whether you are moving prototype MEMS or high-volume laser diodes, choosing the correct gel pak gel box specs—retention, mesh, and ESD properties—is vital. Remember to work with trusted partners like Hiner-pack to maintain a steady inventory of these critical components. protecting your chips means protecting your bottom line.

Frequently Asked Questions (FAQ)

Q1: What is the difference between a standard waffle pack and a gel pak gel box?

A1: A waffle pack relies on pockets to hold devices, allowing them to move slightly and rattle. A gel pak gel box uses a non-adhesive gel to immobilize the device completely, preventing any movement or edge damage during transport.

Q2: Can I reuse a gel pak gel box?

A2: Yes, a gel pak gel box is designed to be reusable. However, the lifespan depends on how clean the environment is. If the gel accumulates dust, it loses tackiness. It can often be cleaned with compatible adhesive tape to restore its holding force.

Q3: How do I know which retention level to choose for my gel pak gel box?

A3: Retention level depends on device size, weight, and surface roughness. Heavy or rough parts need High retention. Small, fragile, or smooth parts usually require Low or Medium retention. If you use a Vacuum Release gel pak gel box, you can generally use higher retention levels safely.

Q4: Is the gel material in a gel pak gel box conductive?

A4: It depends on the model. Standard clear gel is non-conductive. However, for ESD-sensitive devices, you should order a conductive gel pak gel box, which uses black, conductive gel and housing to dissipate static charges.

Q5: Will the gel leave a residue on the backside of my chip?

A5: No, a high-quality gel pak gel box uses a cross-linked polymer that relies on surface tension, not chemical adhesives. It is designed to be "residue-free," ensuring the backside of the die remains clean for die-attach processes.