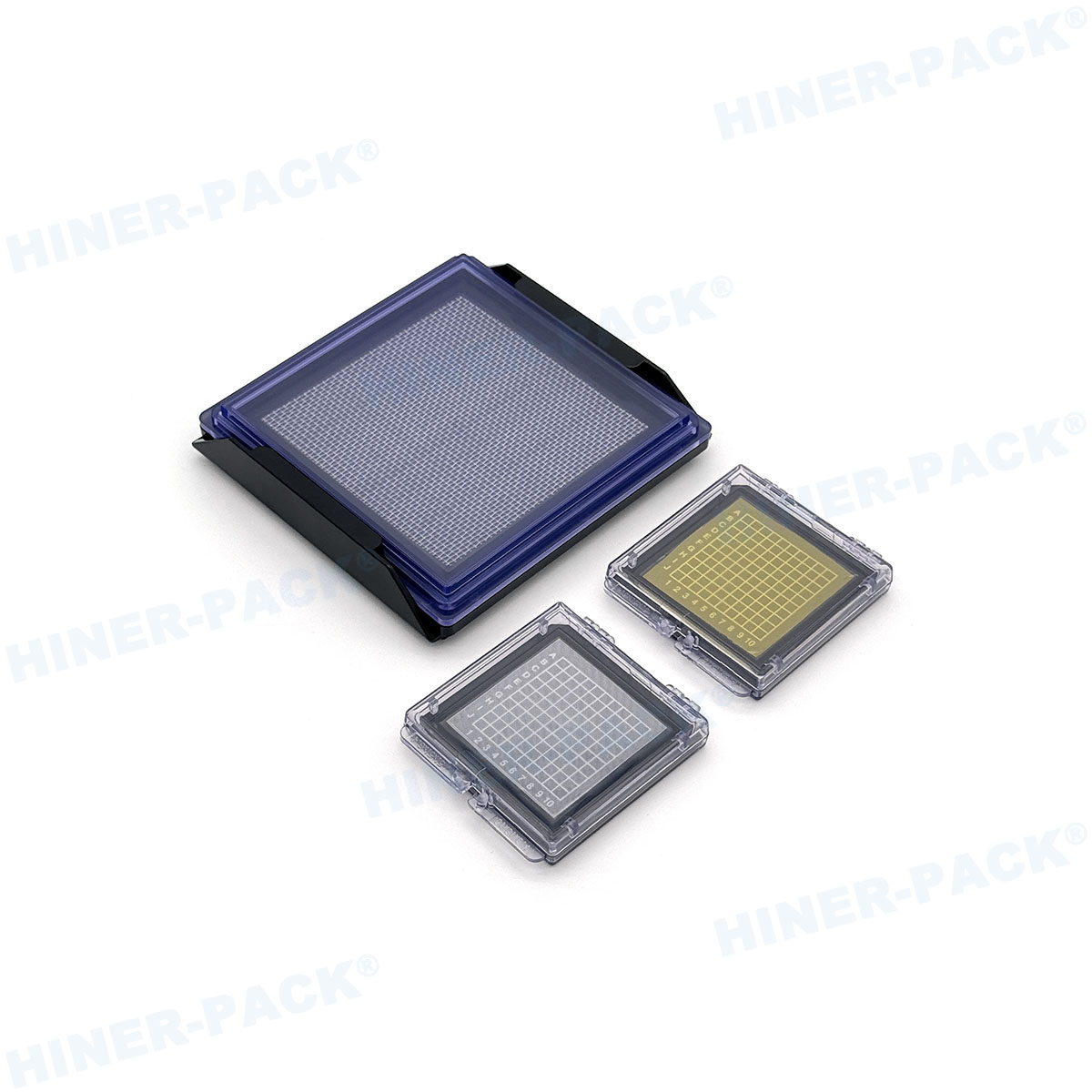

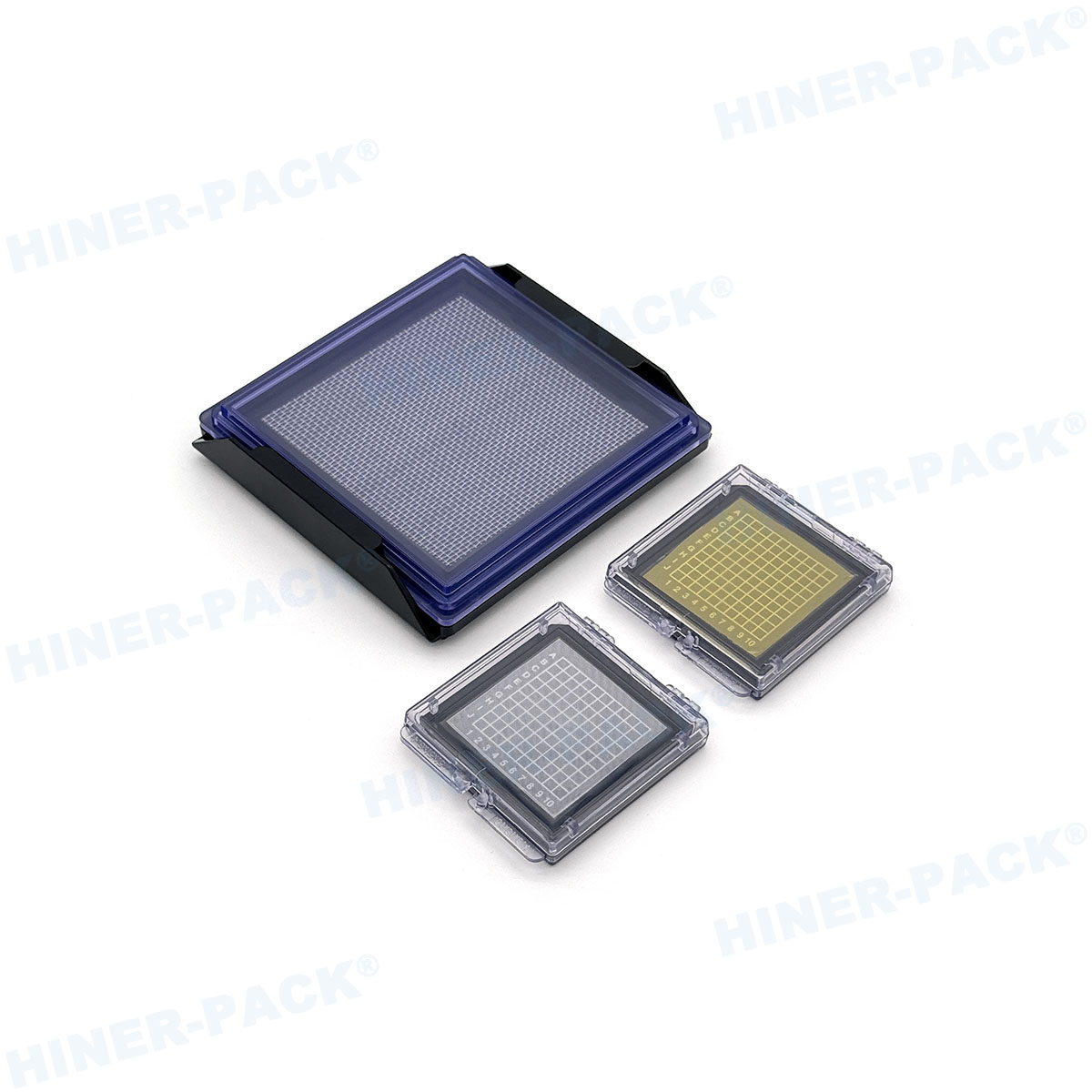

Every engineer in the semiconductor field knows the frustration of opening a shipping container to find damaged components. You spend weeks designing a chip and thousands of dollars fabricating the wafer, only to lose yield during the "last mile" of transport. This is where the packaging choice becomes critical. While traditional waffle packs have been the standard for decades, the gel storage box is quickly becoming the preferred method for handling high-value, fragile dies.

A gel storage box offers a completely different approach to device retention compared to pocket-style trays. Instead of relying on a physical barrier or a lid to keep parts in place, these boxes utilize a tacky, cross-linked polymer material. This surface tension holds the device firmly on the bottom of the container.

Whether you are working with Gallium Arsenide (GaAs), Indium Phosphide (InP), or ultra-thin silicon MEMS, understanding how to use a gel storage box correctly can save your company significant money. In this post, we will look at the technical advantages, selection criteria, and best practices for using this packaging technology, with insights from industry suppliers like Hiner-pack.

The Mechanics of a Gel Storage Box

To understand why this packaging works, you have to look at the physics. A standard waffle pack relies on a "pocket." The die sits inside a square indentation. If the pack is shaken, the die moves. It hits the walls of the pocket. For a robust silicon transistor, this is fine. For a brittle laser diode or a lens, this movement causes chipping.

A gel storage box eliminates all relative motion. Once a component touches the gel surface, it stays exactly where you placed it. The bond is strictly surface tension. There is no glue residue left on the chip when you remove it.

This "residue-free" characteristic is vital. Manufacturers like Hiner-pack spend years perfecting the chemical formula of the gel to ensure it provides strong adhesion during transport but releases cleanly during pick-and-place operations.

Why Retention Levels Matter

One of the most confusing aspects for new users is the "retention level" or "tackiness." You cannot use the same gel storage box for every device. The physics of adhesion depends on the surface area and roughness of your specific chip.

Low Retention (L)

Low retention boxes are essential for large, flat devices. If you have a polished glass filter or a large die (10mm x 10mm), the contact area is huge. If you put this on high-tack gel, you will never get it off. You might actually snap the component trying to pry it loose. A low-retention gel storage box allows these large parts to be removed easily.

Medium Retention (M)

This is the standard for the industry. It works well for typical integrated circuits and diced chips ranging from 1mm to 5mm in size. Most Hiner-pack starter kits will include medium retention boxes as they cover about 60% of standard applications.

High Retention (H)

Small components have very little surface area touching the gel. A 200-micron ceramic capacitor or a tiny beam-lead diode doesn't have enough contact area to stick to low-tack gel. If the box is dropped, these parts will fly off. A high-retention gel storage box increases the chemical grip to keep these tiny parts secure.

The Vacuum Release Difference

There is a specialized version of the gel storage box known as a Vacuum Release (VR) tray. This is often used for extremely fragile or thinned wafers.

In a standard box, you pull the die off the gel mechanically. In a VR gel storage box, the gel is mounted on a mesh. When you place the box on a vacuum chuck, the air is sucked out from beneath the gel membrane. The gel shape changes, reducing the surface contact with the die to almost zero.

The die is then sitting loosely, allowing a pickup tool to lift it without any stress. This is the premium end of the market, and Hiner-pack supplies these for critical applications where even micro-newtons of force could damage the product.

Handling Procedures: Loading the Box

Using a gel storage box requires a steady hand and clean tools. The loading process is straightforward but prone to human error.

First, ensure the environment is clean. Dust is the enemy of the gel storage box. If dust lands on the gel, that spot loses its stickiness. It creates a "dead zone."

When placing a die, use a vacuum pen. Lower the die until it just kisses the surface of the gel. You do not need to press down. The gravity of the chip combined with the surface tension of the gel storage box is sufficient. Pressing down hard can embed the sharp edges of the die into the soft polymer, making it harder to remove later.

Handling Procedures: Unloading the Box

Removing a die from a gel storage box is where most accidents happen.

Do not use metal tweezers to pry the chip up. This will scratch the gel and likely chip the die. You should use a vacuum pickup tool with a soft tip (rubber or PEEK).

For a standard gel storage box, you cannot simply yank the die straight up. You are fighting the surface tension directly. The trick is to twist the die slightly (if geometry allows) or peel it from one corner. This breaks the vacuum seal between the die and the gel.

If you are using high-tack boxes from Hiner-pack, they often recommend specific pickup speeds to allow the gel time to release its grip slowly rather than snapping back.

Comparing Costs: Waffle Pack vs. Gel Box

A common objection from procurement departments is price. A waffle pack costs cents. A gel storage box costs dollars.

However, you must look at the Total Cost of Ownership.

Waffle Pack: Low unit cost, but requires a new mold for every different chip size. High risk of breakage for brittle materials.Gel Storage Box: Higher unit cost, but universal. One box fits any chip size. Zero breakage during normal transport.

If you are shipping engineering samples or low-volume production runs, the gel storage box is cheaper because you don't need custom tooling. If you are shipping millions of robust plastic-packaged chips, waffle packs are better. But for bare die, the gel box is the clear economic winner when yield is factored in.

Technical Specifications to Look For

When sourcing a gel storage box, check the datasheet for these three things:

ESD Properties: The box should be static dissipative or conductive. Standard Hiner-pack boxes use conductive black plastic or antistatic clear coatings to prevent electrostatic discharge from frying your sensitive chips.Outgassing: Cheap gels release volatile chemicals over time. These chemicals can deposit on laser facets or wire bond pads. A high-quality gel storage box uses stable polymers with low outgassing.Flatness: The gel layer must be perfectly flat. If it is wavy, the die won't sit flat, leading to issues with automated pick-and-place machines.

Application Areas

The gel storage box has found a home in several high-tech sectors.

Optoelectronics: Lenses, mirrors, and filters are easily scratched. The soft gel surface prevents scratches that would occur on hard plastic trays.

Thinned Die: Wafers ground down to 50 microns are flexible. A rigid pocket tray can cause them to warp or crack. The gel storage box supports the entire back surface of the die, keeping it flat.

Prototyping: In R&D labs, chip sizes change every week. You cannot order custom trays for every iteration. The gel storage box serves as a universal carrier for the lab.

Storage and Shelf Life

A gel storage box is a consumable item. It does not last forever.

The gel properties are sensitive to UV light. Store your boxes in a dark cabinet or opaque bags. Direct sunlight can cause the cross-links in the polymer to break down, turning the gel into a gooey mess or drying it out completely.

Standard shelf life for a Hiner-pack box is typically 2 years from the date of manufacture, assuming it is kept in a climate-controlled warehouse. High temperatures (above 40°C) can accelerate degradation.

Branding and Quality Assurance

Not all boxes are created equal. We have seen generic boxes where the gel delaminates from the plastic base. When you pick up the die, the gel comes with it.

Brands like Hiner-pack focus on the interface between the plastic and the gel. They use specific surface treatments on the plastic casing to ensure the gel stays anchored to the box, not your device. Consistency is also key. You need the "Medium" retention level to be exactly the same in January as it is in December. Hiner-pack utilizes strict process controls to maintain this consistency.

Common Mistakes to Avoid

Touching the Gel: The oils from your fingers will ruin the gel storage box immediately.Overcrowding: Putting chips too close together makes it hard for the pickup tool to grab one without bumping the neighbor.Wrong Tack: Putting a rough ceramic heater on a low-tack box. It will slide around and damage other parts.Cleaning with Solvents: Never use Acetone or IPA on the gel unless the manufacturer says so. It usually dissolves the surface.

Final Thoughts on Safe Transport

The semiconductor supply chain is long and hazardous. Your package will be thrown onto trucks, flown in planes, and handled by customs officers. The only thing protecting your years of research is the box.

The gel storage box provides the necessary isolation from shock and vibration. It simplifies inventory because one box size fits many devices. While it requires better handling techniques than a simple tray, the payoff in yield is undeniable.

By choosing a reliable partner like Hiner-pack and selecting the correct retention level for your specific die, you can ensure that your technology arrives in the customer's hands exactly as it left your cleanroom.

Common Questions (FAQ)

Q1: How do I know which retention level to order for my gel storage box?

A1: The general rule is based on surface texture and size. Large, smooth devices need Low Retention. Small or rough devices need High Retention. If you are unsure, Medium Retention is the industry standard and works for about 60-70% of applications. It is often best to ask Hiner-pack for a sample kit to test with your specific parts.

Q2: Can I reuse a gel storage box multiple times?

A2: Yes, a gel storage box is reusable. However, its lifespan is determined by cleanliness. Each time you open it, dust can settle on the gel. Once the surface is covered in dust, it loses tackiness. In a cleanroom environment, a box can be reused for months. In a dirty warehouse, it might only be good for a single trip.

Q3: How should I clean the gel if it gets dirty?

A3: Do not use cloth or paper wipes, as they leave fibers. The best way to clean a gel storage box is using "Scotch" style adhesive tape. Gently press the tape onto the gel and peel it off. The dust and debris will stick to the tape, leaving the gel surface clean. Do not use water or alcohol unless specified by the datasheet.

Q4: Is the gel storage box safe for static-sensitive components?

A4: Yes. Most industrial gel storage box options come in ESD-safe versions. The black boxes are typically conductive (Carbon loaded), and the clear boxes are treated with antistatic compounds. This ensures that the triboelectric charge generated during peeling is dissipated safely.

Q5: What is the temperature range for a standard gel storage box?

A5: Standard boxes are designed for shipping conditions, usually -10°C to +60°C. You should not put a standard gel storage box in a reflow oven or a cryostat. Extreme heat will melt the gel, and extreme cold can make the gel brittle, causing it to lose adhesion.