When you need to buy wafer shipping containers, the decision goes beyond simple procurement. Selecting the right container is critical for protecting valuable semiconductor wafers from contamination, physical damage, and static discharge during transport and storage. This guide outlines the essential factors to consider, ensuring your investment safeguards your critical assets effectively and efficiently.

Key Considerations Before You Buy Wafer Shipping Containers

Choosing the correct container requires a methodical approach. A mismatch can lead to costly wafer loss or production delays.

Understanding Wafer Container Types

The two primary categories are shipping containers and process carriers.

- Front-Opening Shipping Boxes (FOSB): These are the standard for secure inter-facility transport. They feature a robust, sealed design.

- Standard Mechanical Interface (SMIF) Pods: Used in automated fab environments, they provide a mini-environment for wafers.

- 300mm FOUPs (Front-Opening Unified Pods): The industry standard for 300mm wafer automated handling and shipping in closed environments.

When you aim to buy wafer shipping containers for secure logistics between sites, FOSBs are typically the focus.

Material and Construction Quality

The build material directly impacts performance and longevity.

- Static-Dissipative Materials: Essential for preventing electrostatic discharge (ESD) that can damage sensitive circuits.

- High-Purity Plastics: Materials like PFA, PP, or PC must have low outgassing properties to minimize molecular contamination.

- Structural Rigidity: The container must withstand stacking and rough handling without deforming.

- Seal Integrity: Gaskets and latches must ensure a particle-tight seal in closed positions.

Selecting the Right Specifications

Matching the container to your wafer process is non-negotiable.

Wafer Size and Capacity

Containers are designed for specific wafer diameters.

- Common sizes are 200mm and 300mm. Ensure the model you select matches your wafer size precisely.

- Standard capacities are 13 or 25 wafers. Confirm your required slot count.

Cleanroom Compatibility and Certification

Containers must meet stringent cleanliness standards.

- Look for containers certified for Class 1 or better cleanroom environments.

- Documentation should include particle count test reports.

- Containers from Hiner-pack are manufactured and certified in certified cleanrooms to ensure immediate usability.

Performance and Reliability Factors

Long-term performance protects your bottom line.

Durability and Lifespan

A quality container should endure thousands of cycles.

- Assess latch mechanism durability—it is the most frequently used component.

- Check for resistance to chemicals used in your cleaning processes.

- Containers should maintain dimensional stability over time and temperature variations.

Particle and Contamination Control

This is the primary function of the container.

- Inquire about the particle adders per cycle specification.

- Evaluate the design for ease of cleaning. Smooth, rounded interiors trap fewer particles.

- Consider containers with built-in RFID tags for tracking usage and cleaning history.

Cost and Supplier Evaluation

The total cost of ownership is more than the unit price.

Total Cost of Ownership (TCO)

When you buy wafer shipping containers, consider all cost factors.

- Initial Purchase Price: Obtain competitive quotes.

- Replacement Part Costs: Check prices for latches, gaskets, and shells.

- Cleaning and Maintenance Costs: Designs that are easy to clean reduce long-term expenses.

- Durability: A longer-lasting container has a lower cost per trip.

Choosing a Trusted Supplier

Your supplier is a key partner for quality and support.

- Industry Reputation: Choose established manufacturers like Hiner-pack with proven expertise.

- Technical Support: Ensure they provide clear specifications and material certifications.

- Consistent Supply Chain: They must reliably meet your volume and delivery timeline requirements.

- Customization Options: Some applications may require specific markings or slight design modifications.

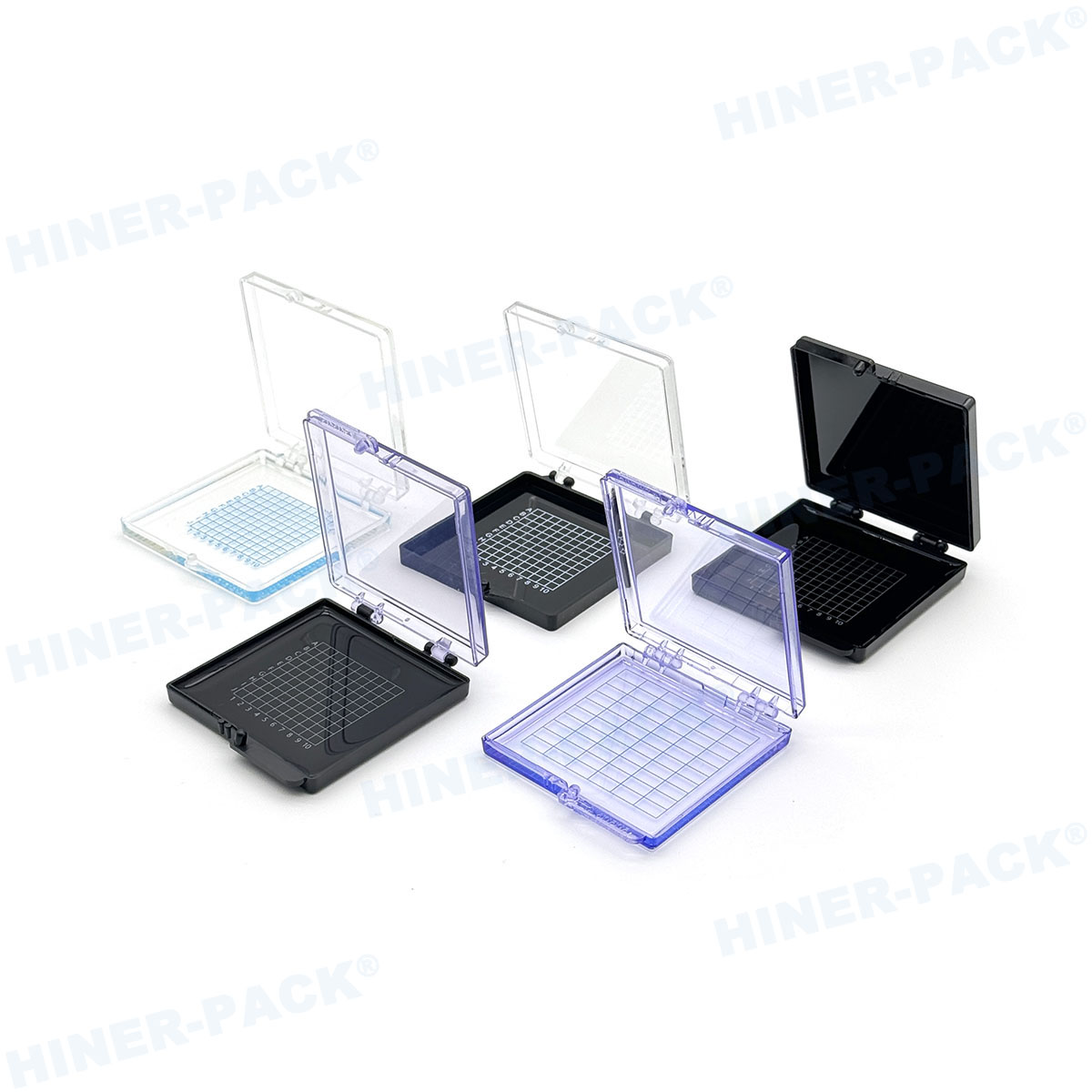

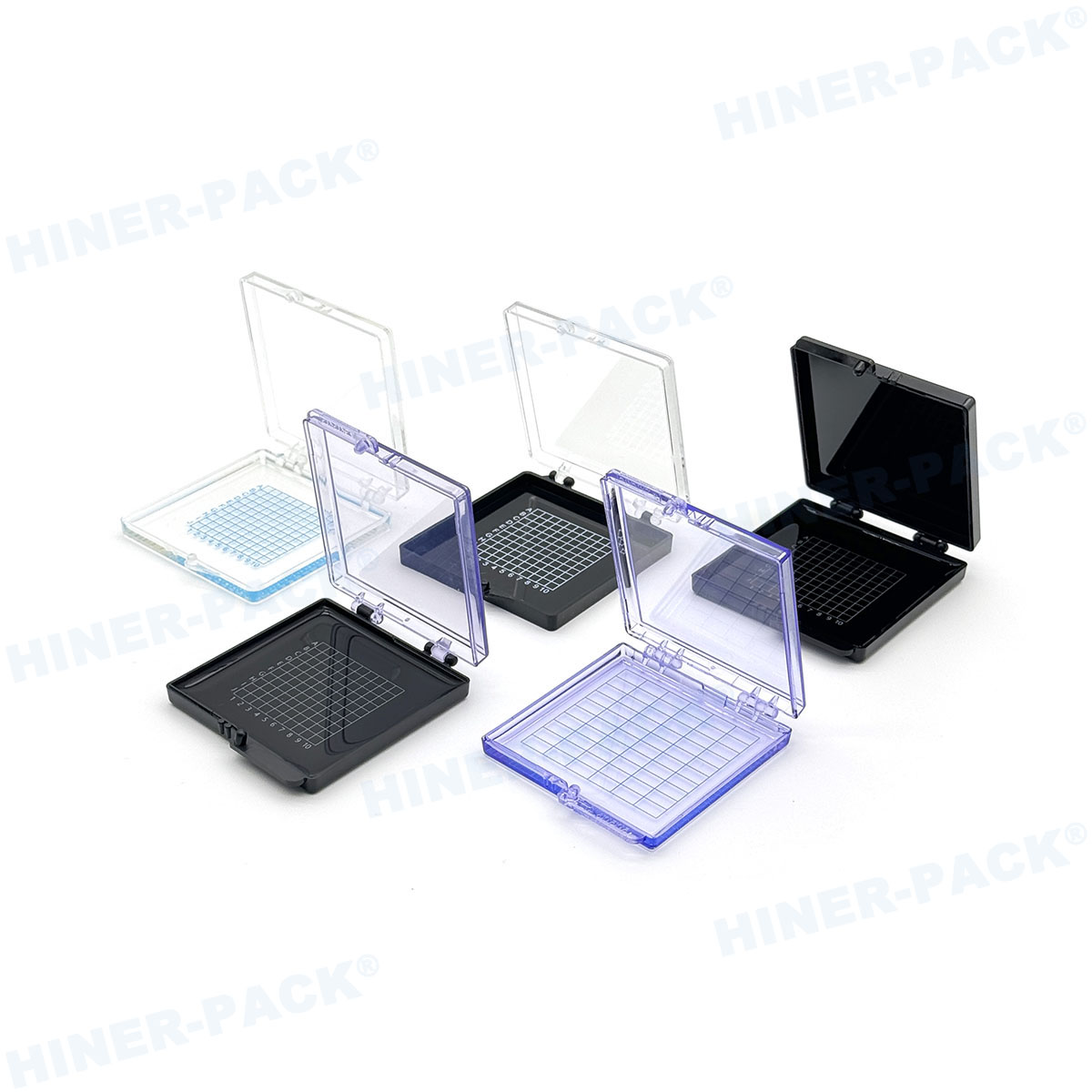

Why Choose Hiner-pack for Your Wafer Shipping Needs

For professionals looking to reliably buy wafer shipping containers, Hiner-pack offers engineered solutions. Our containers are designed with a focus on protecting your high-value wafers throughout the logistics chain.

We use certified, high-purity materials and precision molding techniques. Every container undergoes rigorous quality checks. Our goal is to provide a product that offers exceptional reliability, ensuring your wafers arrive in the same condition they were shipped.

Hiner-pack containers balance robust protection with cleanroom compliance. We understand the critical nature of semiconductor logistics. Partnering with us means investing in security for your most sensitive components.

Making an informed decision when you buy wafer shipping containers is a direct investment in yield protection and operational efficiency. By prioritizing material quality, exact specifications, cleanroom certification, and supplier reliability, you secure your production line against avoidable losses. Partnering with a dedicated manufacturer like Hiner-pack provides the confidence that your wafers are transported in containers built to meet the stringent demands of the semiconductor industry.

Frequently Asked Questions (FAQs)

Q1: How many times can a typical wafer shipping container be reused?

A1: A high-quality wafer shipping container from a reputable manufacturer like Hiner-pack is designed for thousands of cycles. The actual lifespan depends on handling, cleaning procedures, and environmental factors. Regular inspection of latches, seals, and interior surfaces is recommended.

Q2: How do I ensure the containers I buy meet my cleanroom Class standards?

A2: Always request and review the manufacturer's Certificate of Compliance (CoC) and particle count test data. Reputable suppliers will provide documentation showing the container's performance in standardized tests, verifying its suitability for Class 1, ISO 4, or other specified environments.

Q3: Can I use the same container for 200mm and 300mm wafers?

A3: No. Wafer shipping containers are precision-engineered for a specific wafer diameter. Using an incorrect size will not provide proper support, leading to a high risk of wafer breakage, slippage, and contamination. Always match the container to your exact wafer size.

Q4: What is the lead time typically when I need to buy wafer shipping containers?

A4: Lead times vary by supplier and order volume. Standard models from suppliers with good inventory, like Hiner-pack, may have shorter lead times. For large or customized orders, plan ahead and discuss timelines with your supplier during the quotation process.

Q5: Besides the container itself, what other items should I consider purchasing?

A5: It is advisable to also source compatible accessories. These include:

- Protective outer shipping cases for extra physical security.

- Replacement gaskets, latch kits, and other spare parts for maintenance.

- Dedicated cleaning tools and validated cleaning protocols.

- RFID tags or barcode labels for asset tracking and management.