How to Choose Semiconductor Packaging Suppliers: A Guide for OEMsThe semiconductor supply chain is complex and specialized. Selecting the right semiconductor packaging suppliers is a critical decision for any OEM. These partners provide the essential materials and components needed to protect delicate silicon wafers and dies throughout manufacturing and shipping. This choice directly impacts product yield, reliability, and time-to-market.

The Role of Semiconductor Packaging Suppliers

Packaging suppliers provide more than just containers. They are integral to protecting semiconductor integrity from the fab to the end customer. Their offerings ensure physical safety, environmental control, and logistical efficiency.

Reliable semiconductor packaging suppliers deliver solutions that meet stringent industry standards. They support a wide range of processes, from wafer-level handling to final device shipment.

Core Products and Components

Suppliers offer a variety of specialized products. These items are designed for different stages of the semiconductor lifecycle.

Wafer Cassettes and Carriers: Used for transporting wafers within and between fabrication facilities.

Trays and Matrix Trays: Secure individual dies after dicing to prevent damage and contamination.

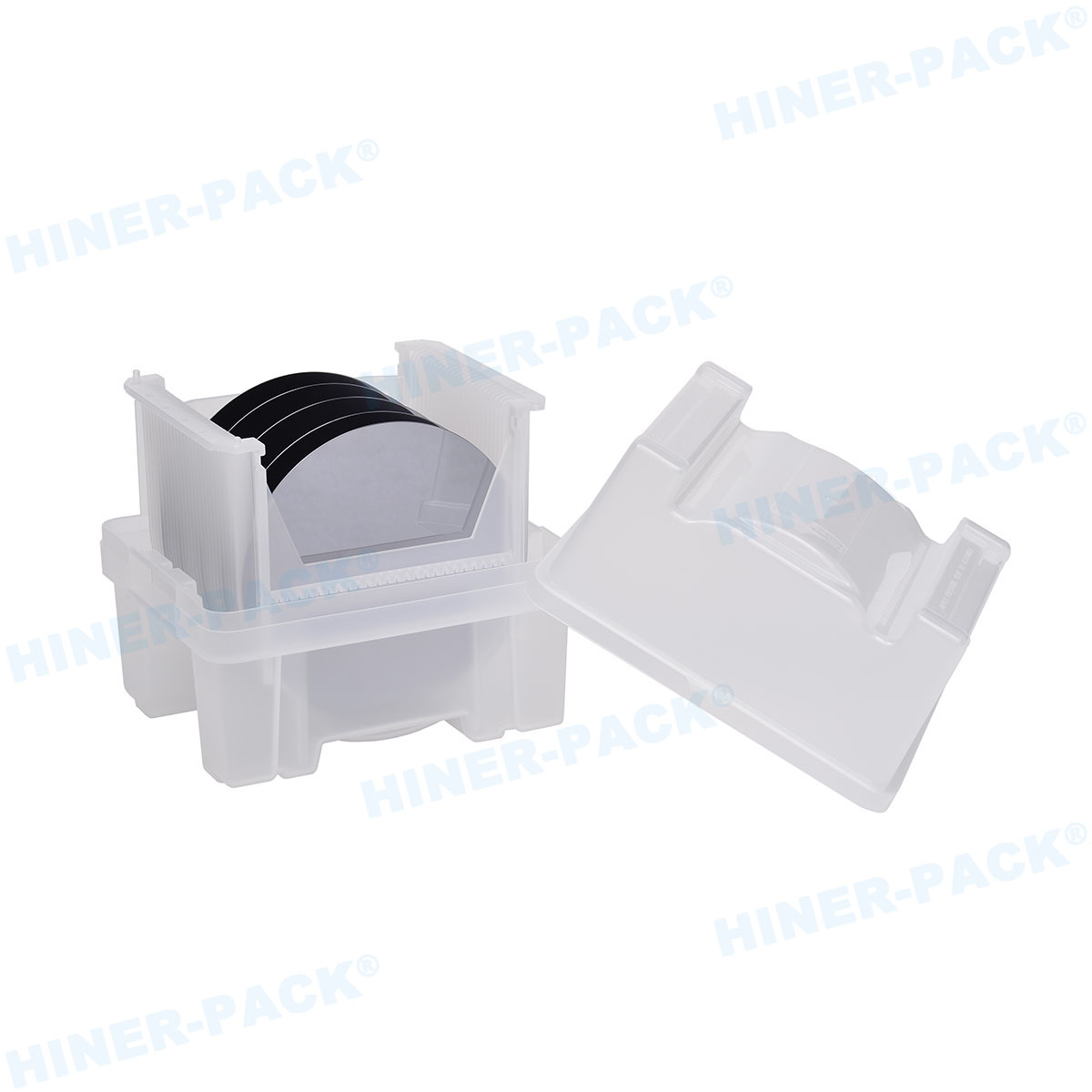

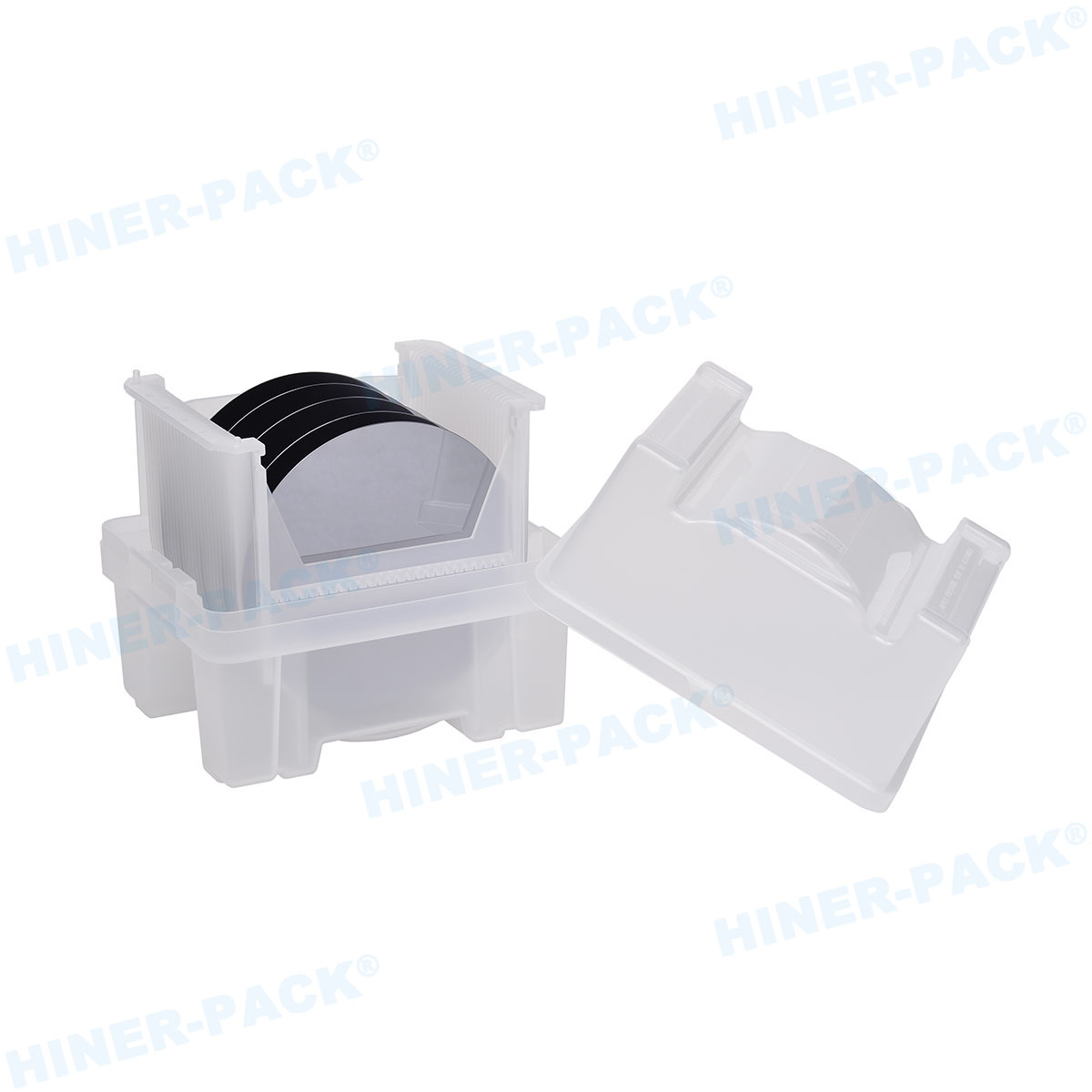

Shipping Boxes and Tote Containers: Provide bulk transport and storage for packaged units or wafers.

ESD-Safe and Cleanroom Materials: Essential for preventing electrostatic discharge and particulate contamination.

Custom Foam Inserts and Dividers: Offer cushioning and organization for sensitive components.

Value-Added Services

Leading suppliers go beyond manufacturing. They provide services that add significant value to their clients' operations.

Custom design and engineering for unique form factors.

Just-in-time (JIT) delivery and inventory management programs.

Technical support for material selection and process integration.

Validation and testing to ensure compliance with client specifications.

Key Criteria for Selecting a Supplier

Choosing a partner requires careful evaluation. Consider these factors to ensure a successful and long-term partnership.

Quality and Certification Standards

Adherence to international standards is non-negotiable. It guarantees product consistency and reliability.

SEMI Standards: Compliance with SEMI guidelines for dimensions, materials, and performance is fundamental.

ISO Certifications: ISO 9001 for quality management and ISO 14001 for environmental management are key indicators.

Material Purity: Suppliers must document material composition to prevent outgassing or ionic contamination.

Consistent Manufacturing: Processes must deliver defect-free products batch after batch.

Technical Capability and Innovation

The ability to innovate and solve technical challenges is crucial. Packaging requirements evolve with new semiconductor technologies.

Suppliers must demonstrate expertise in material science and engineering. They should be proactive in developing solutions for larger wafers, thinner dies, and advanced node devices.

A strong R&D department is a positive sign. It shows commitment to future-ready solutions.

Supply Chain Reliability and Scalability

A robust and transparent supply chain is essential for business continuity. Suppliers must demonstrate resilience.

Geographic Presence: Multiple manufacturing or distribution points can mitigate regional disruptions.

Capacity Planning: Ability to scale production up or down to match market demand.

Raw Material Sourcing: Stable relationships with material providers to avoid shortages.

Lead Time Consistency: Predictable delivery schedules that support your production planning.

Different Types of Packaging Suppliers

Not all semiconductor packaging suppliers are the same. The market includes specialists and broad-line providers.

Specialized Material and Component Providers

These companies focus on a specific range of products. They often possess deep expertise in particular materials, such as high-purity plastics or conductive compounds.

Companies like Hiner-pack fall into this category, specializing in wafer and component shipping solutions. They offer deep knowledge in protective packaging for the most sensitive stages of transit.

Full-Service Packaging Partners

These larger suppliers offer a comprehensive portfolio. They may provide everything from front-end wafer carriers to back-end IC tubes and final shipping systems.

They act as one-stop shops for high-volume manufacturers. This can simplify logistics but may offer less specialization in niche areas.

The Importance of Partnership and Collaboration

The best relationships are strategic partnerships, not simple buyer-seller transactions. Collaborative suppliers become extensions of your engineering team.

Early Engagement in Design

Involving a packaging supplier early in a new product design can yield significant benefits. They can advise on design-for-manufacturability (DFM) for packaging.

Recommend cost-effective materials that meet performance needs.

Suggest design modifications to improve handling or stacking.

Help avoid costly redesigns or qualification failures later in the process.

Continuous Improvement and Support

A good partner works with you on ongoing improvements. They provide data and analysis to help reduce total cost of ownership.

This includes initiatives to increase container reuse cycles, reduce particulate generation, or optimize packing density. Their technical support should be responsive and knowledgeable.

Future Trends Impacting Packaging Suppliers

The industry is constantly changing. Forward-thinking suppliers are adapting to several key trends.

Advanced and Heterogeneous Integration

Technologies like 2.5D and 3D integration create new packaging challenges. Suppliers must develop solutions for handling and transporting these complex, often fragile, assemblies.

Sustainability and Circular Economy

Environmental responsibility is a growing priority. There is increased demand for sustainable practices from semiconductor packaging suppliers.

Development of recyclable and bio-based materials.

Design for refurbishment and extended reuse of durable containers.

Programs to take back end-of-life packaging for responsible processing.

Automation and Industry 4.0

Smart factories require smart packaging. Suppliers are integrating features for seamless automation.

This includes standardized geometries for robotic handling, embedded RFID tags for tracking, and data-rich labels for inventory systems. Packaging is becoming an active part of the digital production flow.

Conclusion

Selecting the right semiconductor packaging supplier is a strategic decision with long-term implications. By thoroughly evaluating potential partners on quality, capability, reliability, and their collaborative approach, OEMs can build a resilient and efficient supply chain.

As technologies evolve, partnering with innovative and responsive semiconductor packaging suppliers will be key to maintaining a competitive edge. Companies that specialize, like Hiner-pack, provide the focused expertise necessary to solve specific, critical challenges in wafer and component protection.

Frequently Asked Questions (FAQ)

Q1: What is the main difference between a semiconductor packaging supplier and an OSAT company?

A1: An OSAT (Outsourced Semiconductor Assembly and Test) company performs the actual physical assembly, bonding, and testing of the semiconductor device. A packaging supplier provides the specialized materials, containers, and components (like trays, carriers, boxes) used to handle, ship, and protect wafers and dies throughout the manufacturing and assembly process.

Q2: Why is compliance with SEMI standards so important for these suppliers?

A2: SEMI standards ensure interoperability, safety, and reliability. They define precise dimensions, material properties, and performance criteria. Compliance means a supplier's products will work correctly with automated equipment from different manufacturers and will safely protect sensitive semiconductors, reducing the risk of costly line stoppages or product damage.

Q3: Can a single supplier typically provide all packaging needs for a complex semiconductor product?

A3: Often, no. A complex product may require different specialized suppliers for front-end wafer carriers, die trays, and final shipping solutions. While full-service partners exist, many OEMs work with a mix of specialists, like Hiner-pack for transport solutions, to get the best expertise for each specific need.

Q4: How are sustainability concerns changing the packaging supplier industry?

A4: Sustainability is driving innovation. Suppliers are now developing reusable/returnable container programs, investing in recyclable or renewable materials, and designing for longer product life cycles. This shift reduces waste and total cost of ownership while meeting the environmental goals of semiconductor manufacturers.

Q5: What should I look for during an audit of a potential packaging supplier?

A5: Focus on their quality control labs and process documentation. Check their material certification records, inspect their manufacturing floor for cleanliness and organization, review their change control procedures, and assess their capacity planning and raw material inventory. A transparent and well-documented operation is a strong indicator of reliability.