Why JEDEC Trays Use PPE Material

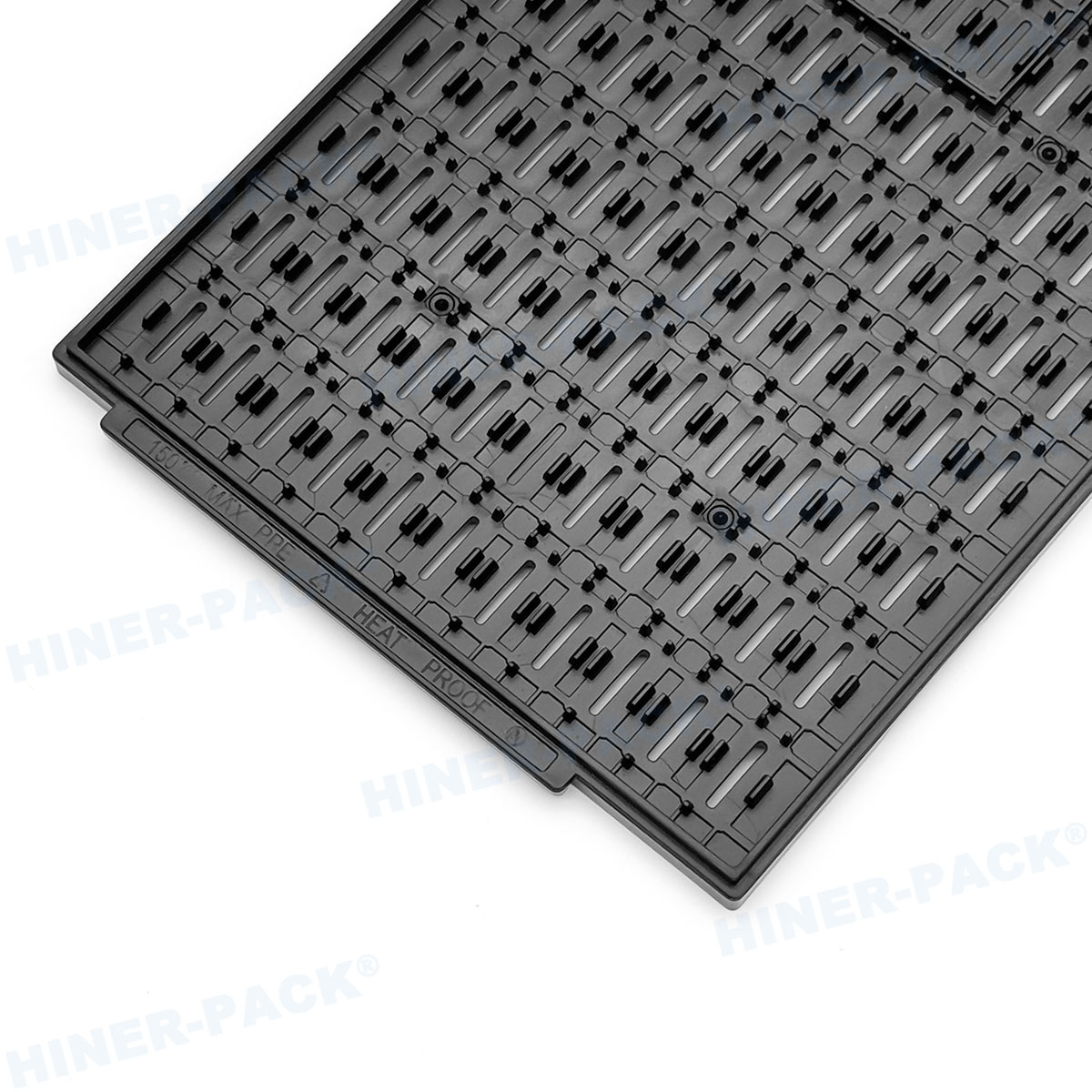

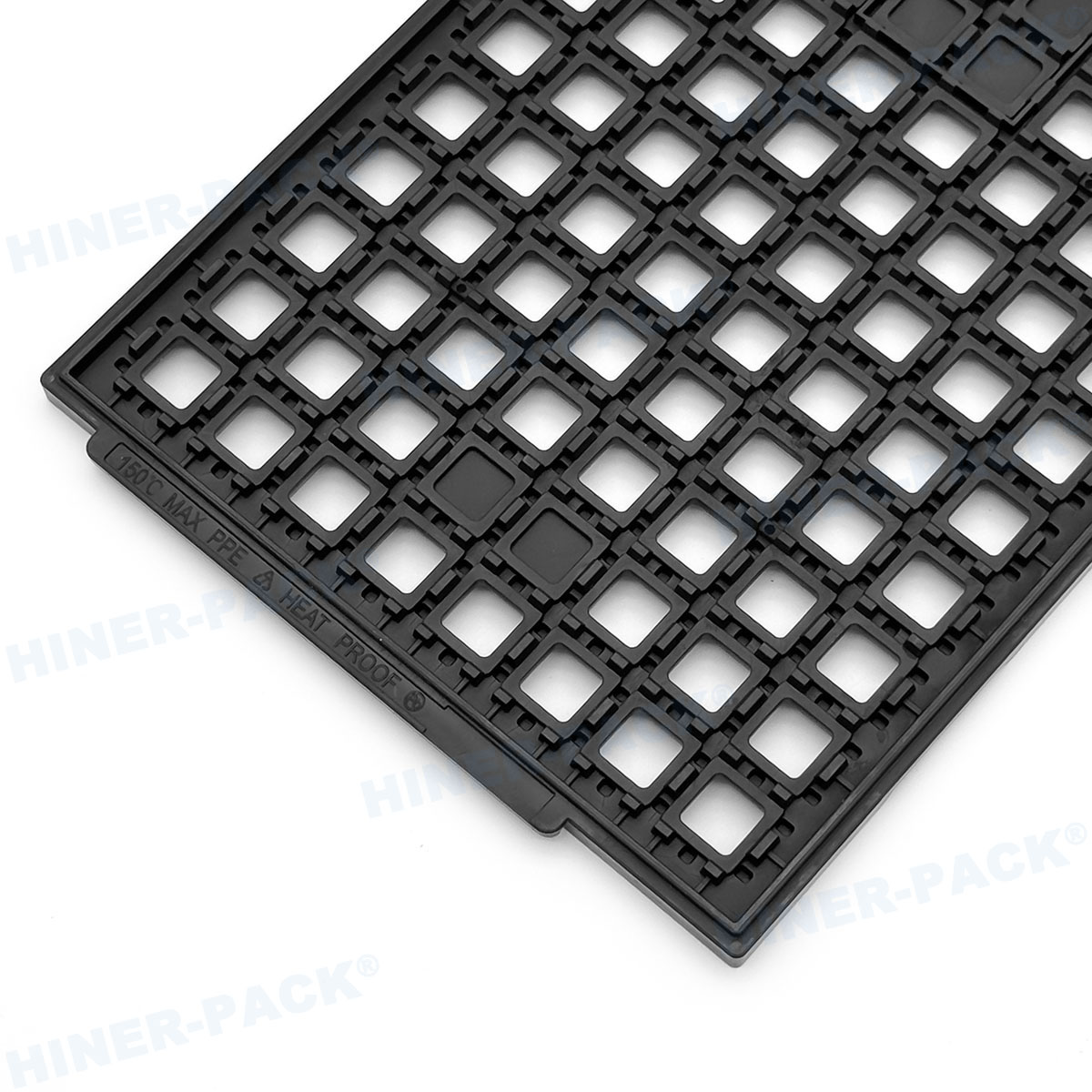

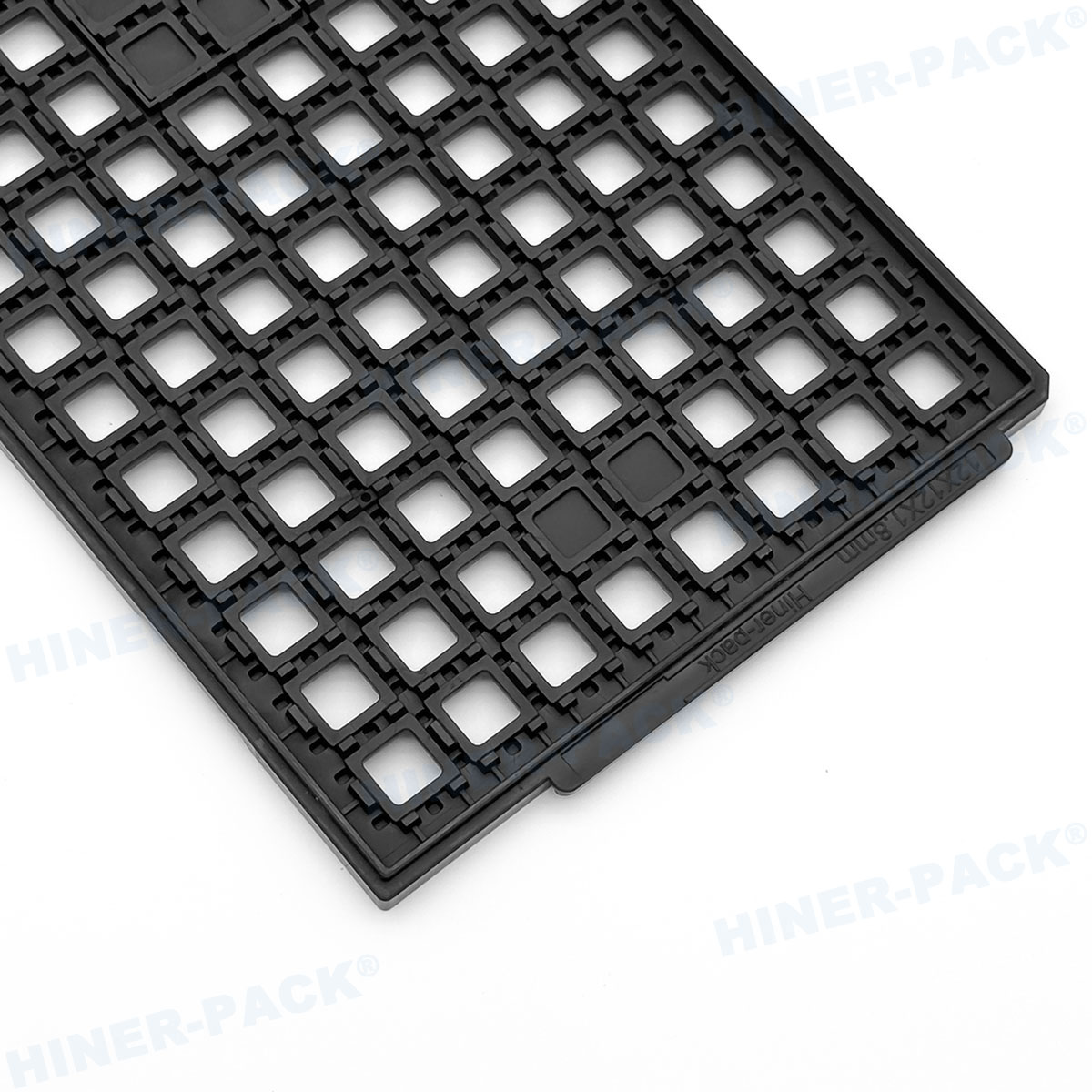

Dimensional Stability at High Temperatures

Trays must survive reflow soldering processes (MAX 150 °C) without warping.

PPE has excellent heat resistance and low thermal expansion, keeping the tray flat so chips don’t shift or get damaged.

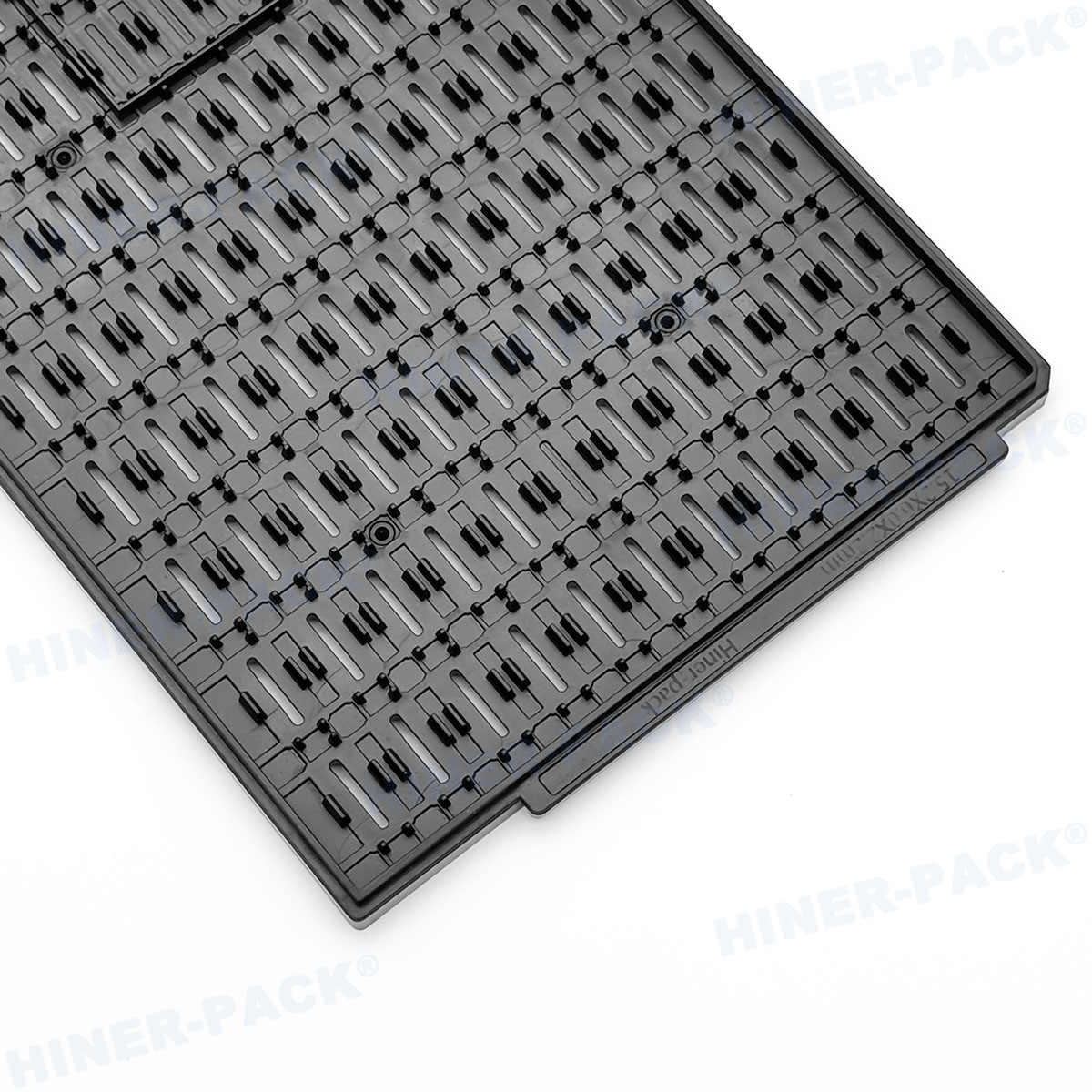

Low Moisture Absorption

PPE absorbs very little water compared to many plastics.

This prevents swelling or warping in humid environments and helps maintain tight dimensional tolerances required for automation.

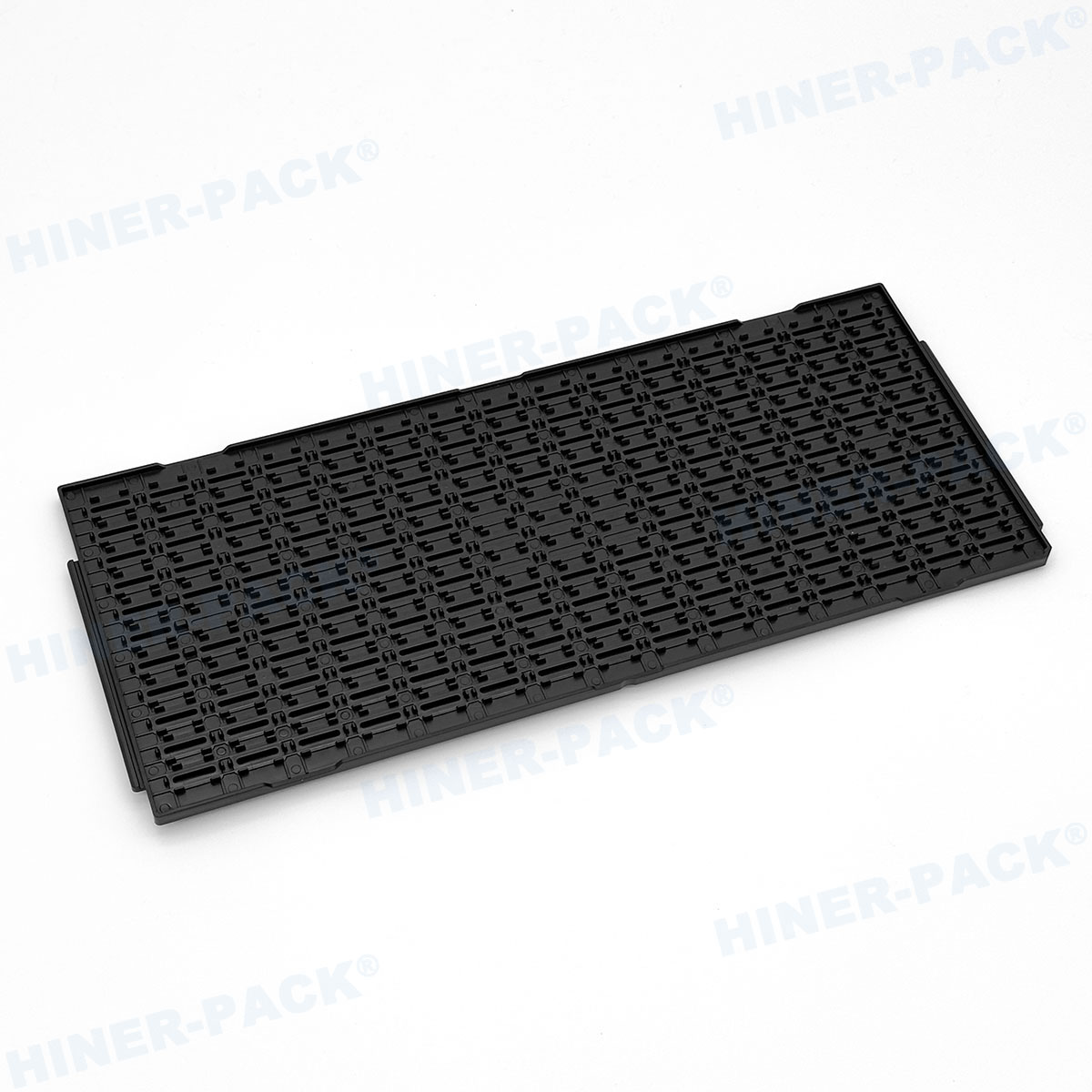

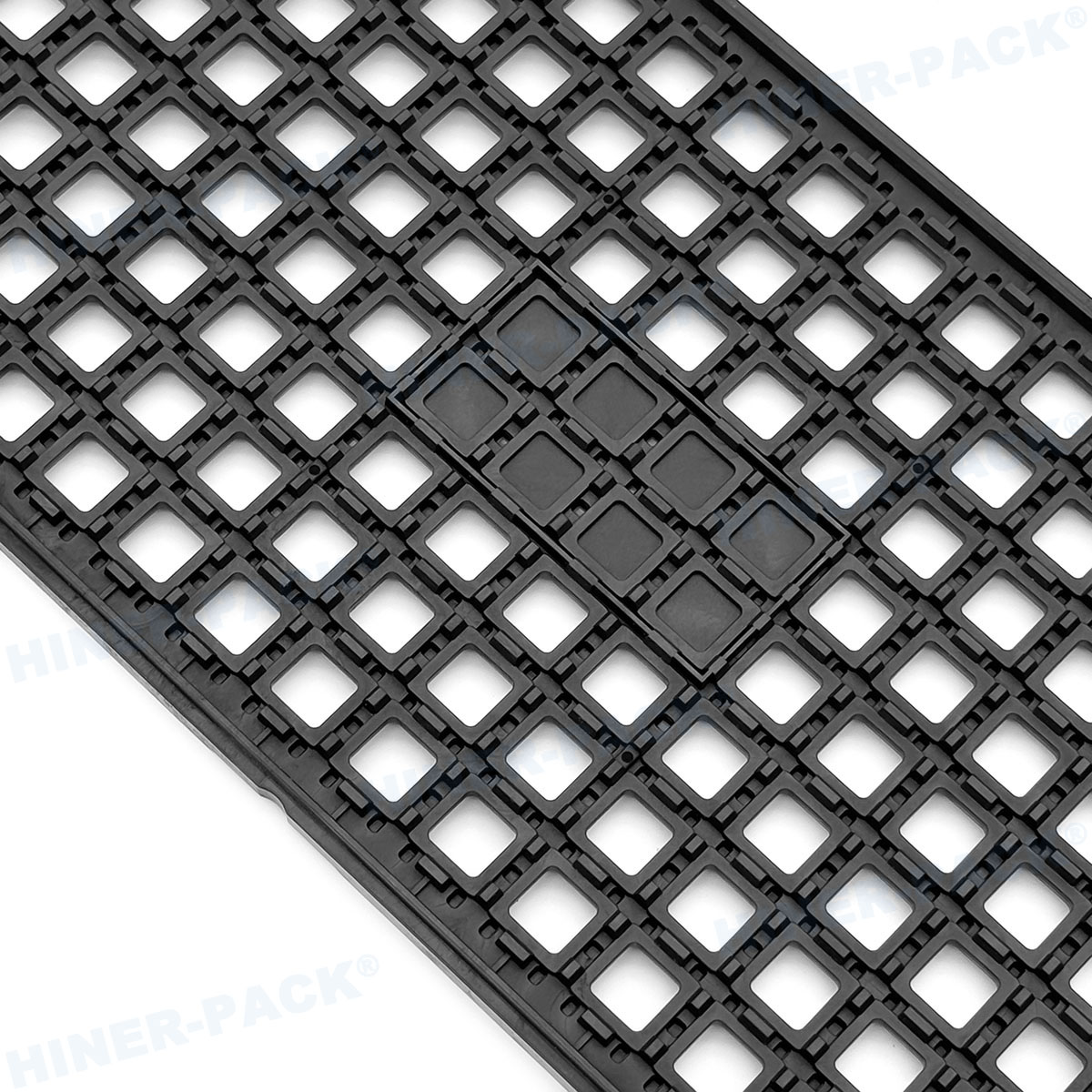

Good Mechanical Strength & Rigidity

PPE blends are stiff but not brittle.

They resist cracking under load, stacking, or robotic handling.

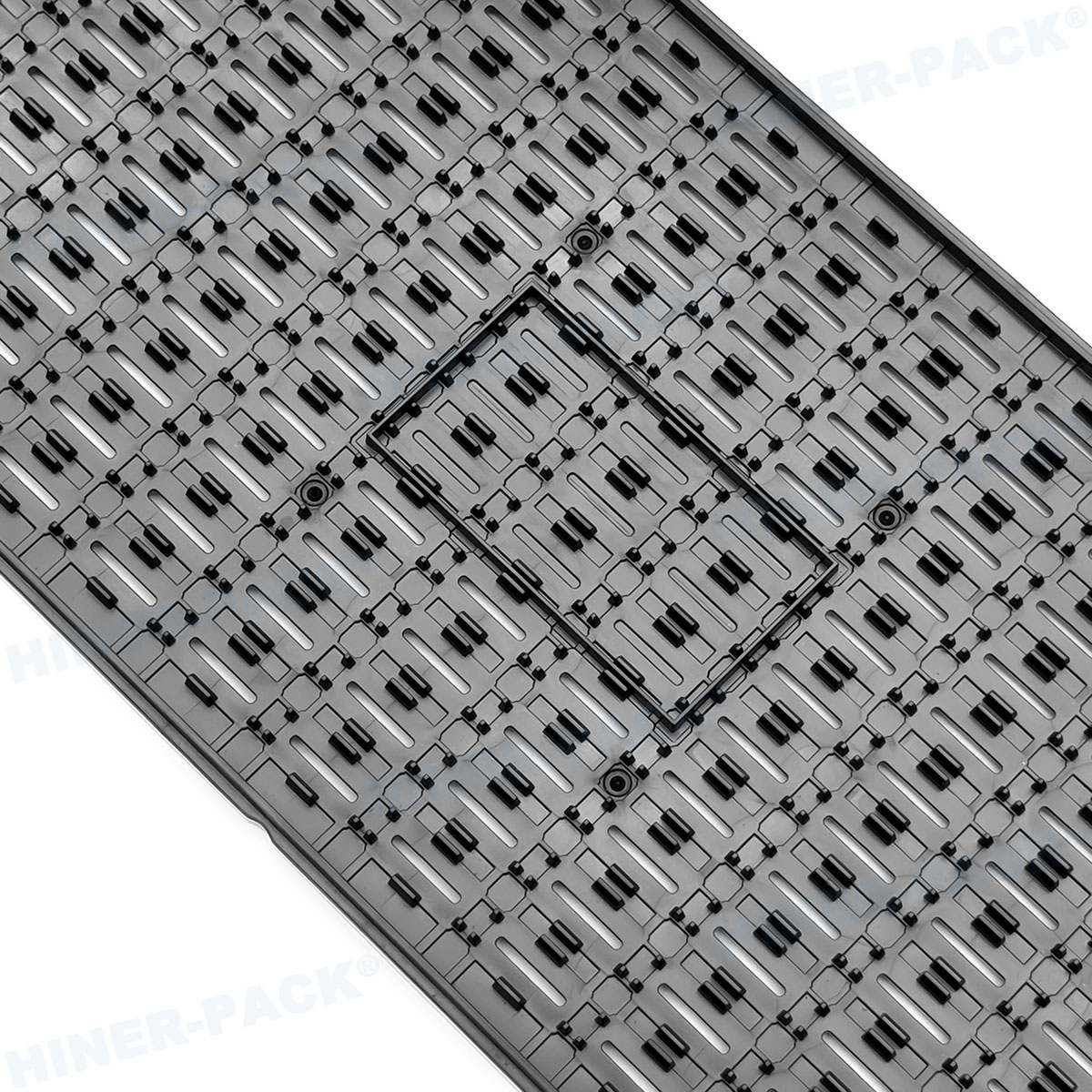

ESD (Electrostatic Discharge) Safety

JEDEC trays usually require antistatic or conductive grades to protect ICs.

PPE can be compounded with carbon or antistatic additives to achieve stable surface resistivity (10⁴–10¹¹ Ω/sq), making it suitable for semiconductor handling.

Chemical Resistance

Resistant to many solvents, flux residues, and cleaning chemicals used in electronics.

This extends tray lifespan even in tough environments.