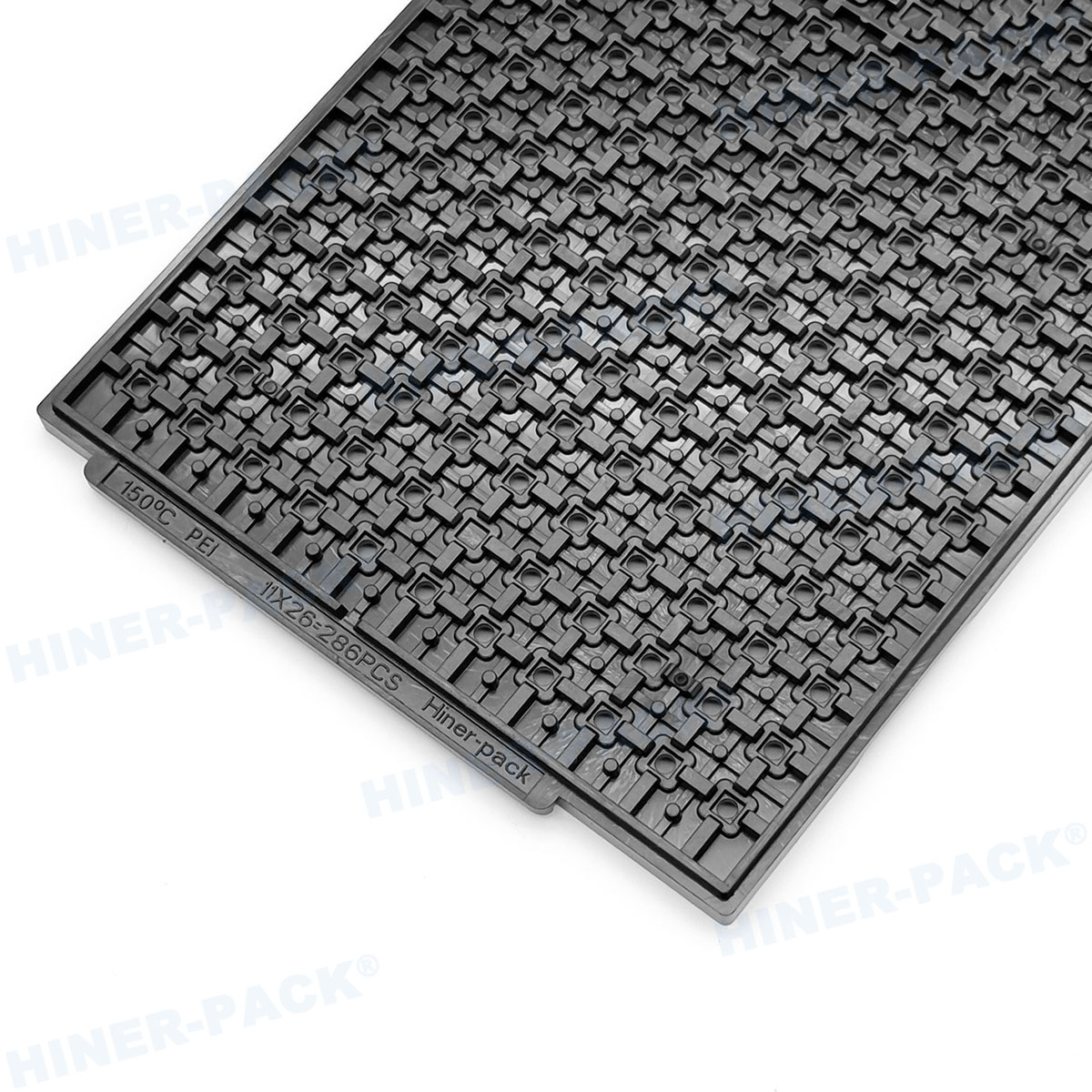

Why JEDEC Trays Use PEI Material

Very High Heat Resistance

PEI has a glass transition temperature (Tg) ≈ 215 °C.

Withstands high-temperature reflow (≥150~180 °C), IC baking, and multiple heating cycles without warping.

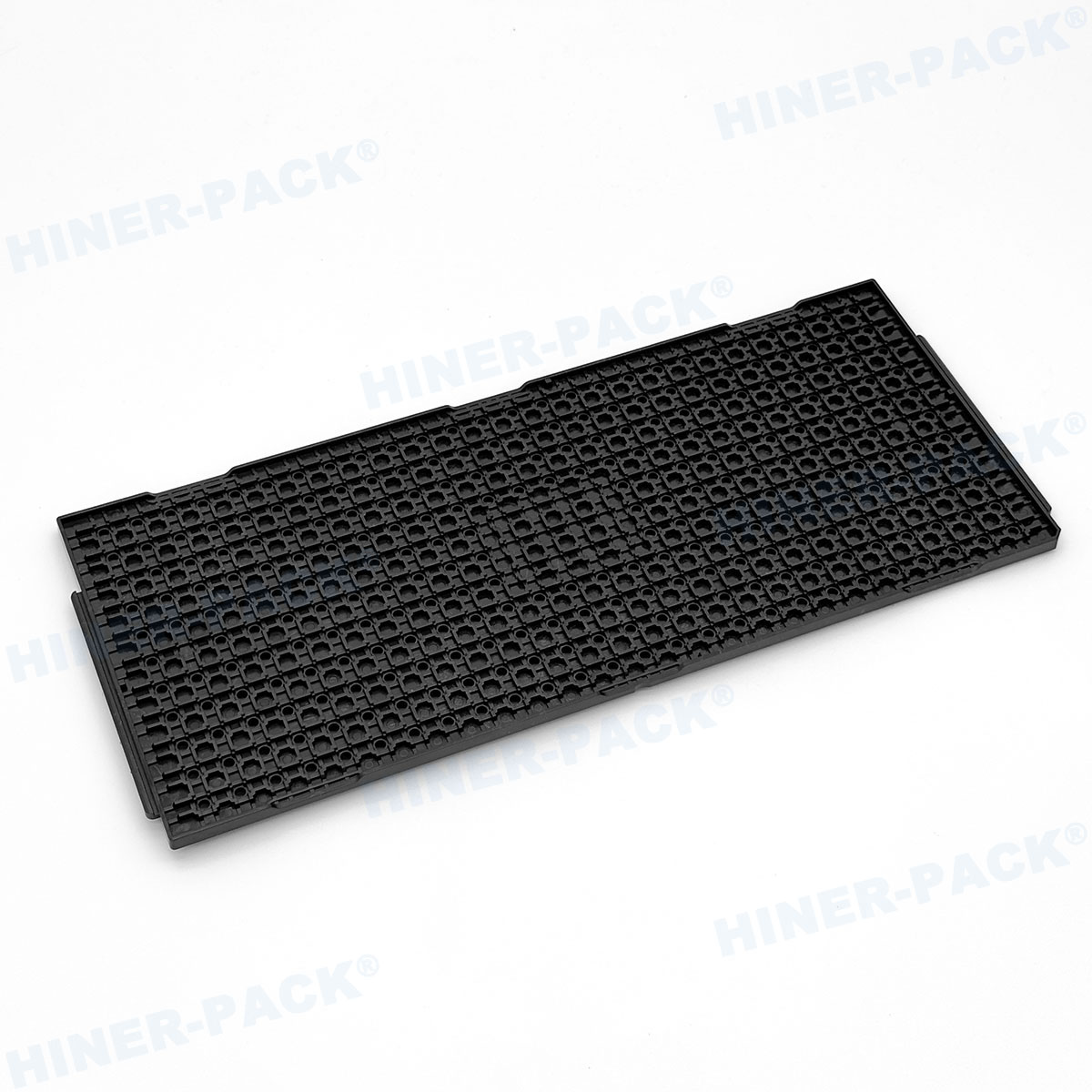

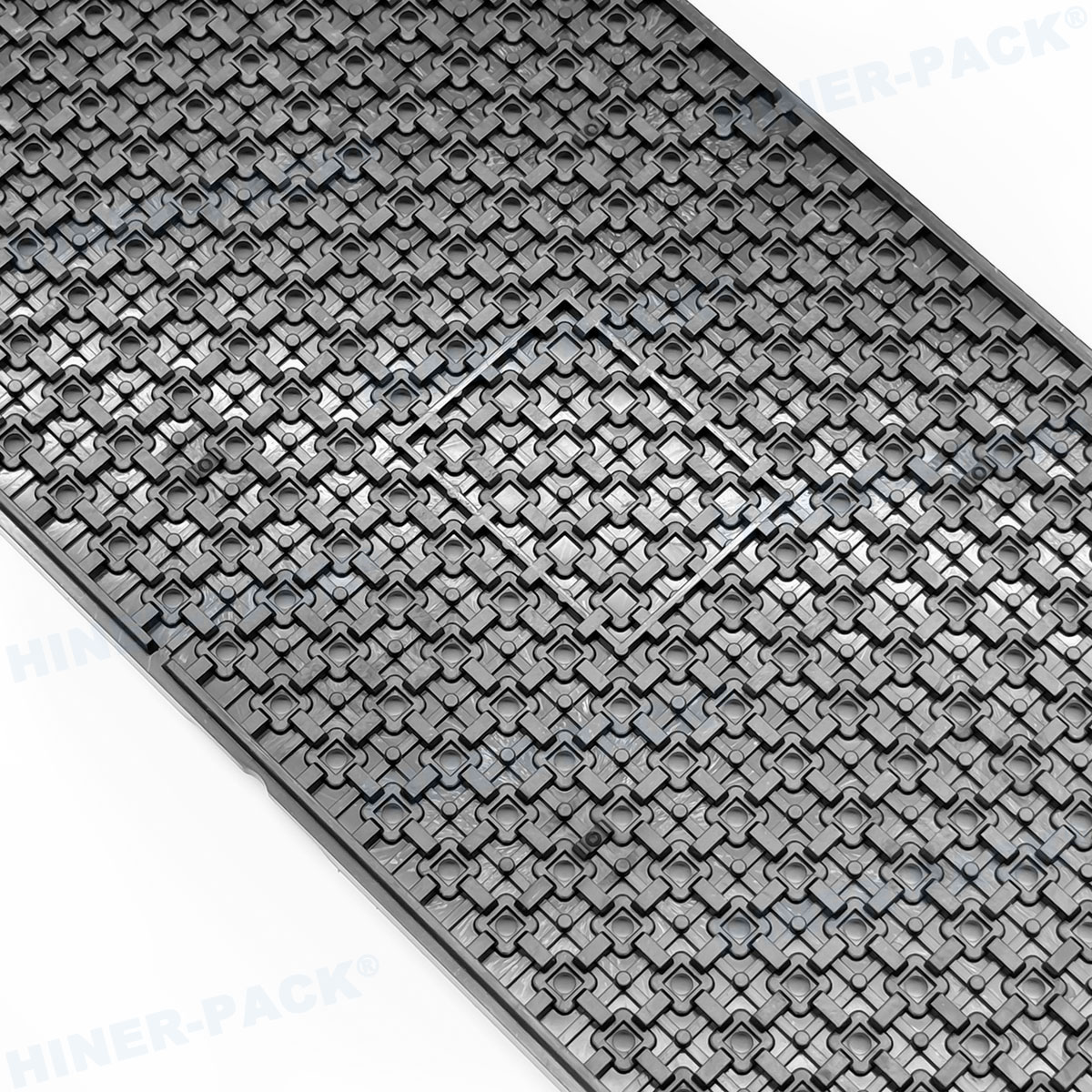

Dimensional Stability

Extremely low creep and shrinkage.

Maintains tight tolerances in cavity size and tray flatness, critical for automation and stacking.

Low Moisture Absorption

Better than many other engineering plastics, keeping dimensional accuracy even in humid environments.

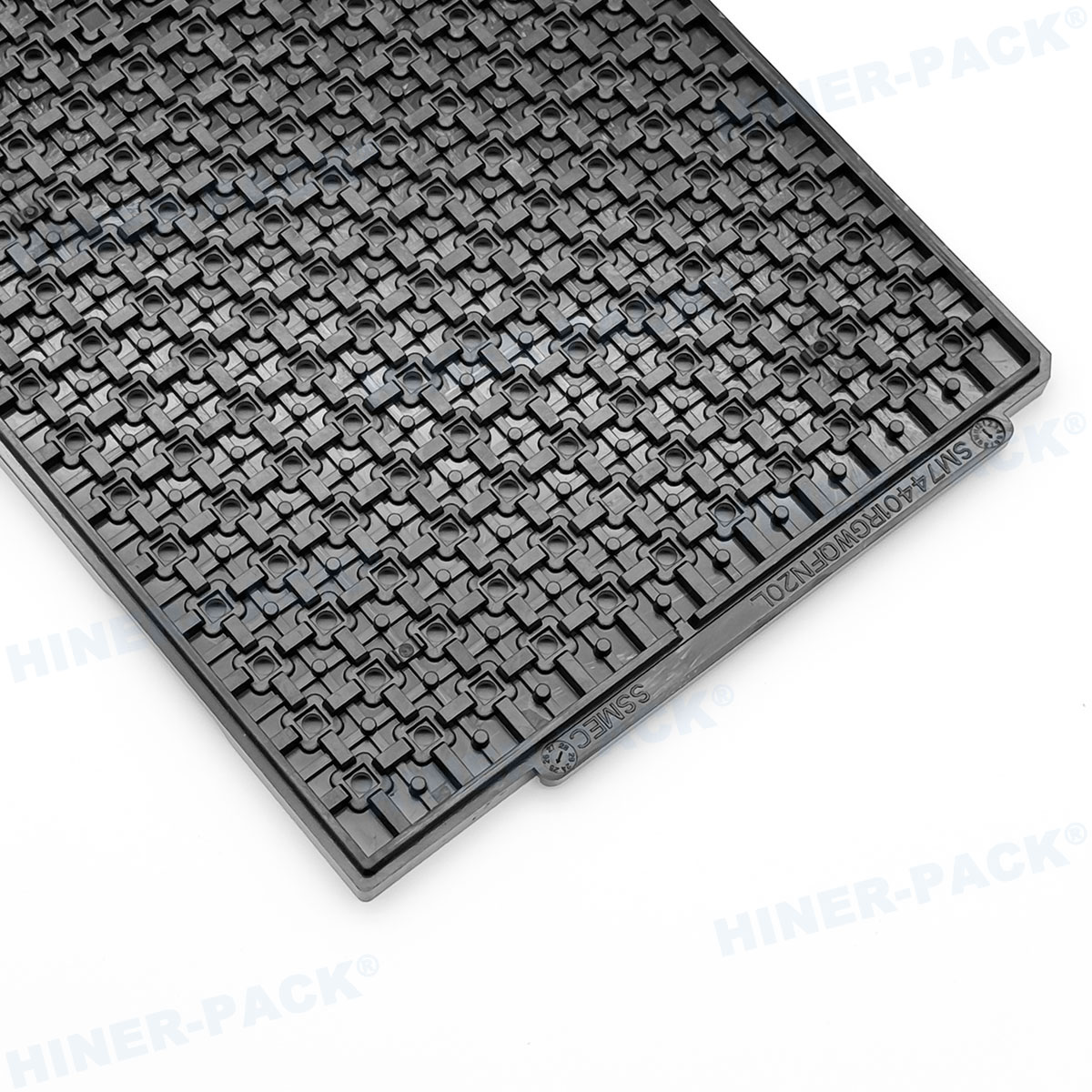

ESD Control

PEI can be compounded with carbon fiber, carbon black, or conductive fillers to achieve static-dissipative or conductive grades.

Ensures safe handling of sensitive ICs.

High Mechanical Strength

Resists cracking, abrasion, and mechanical stress from repeated robotic handling and stacking.

Long Service Life

Because of its thermal stability + toughness, PEI trays can be reused many more times

This makes them attractive when durability and reusability matter more than initial cost.

Why Not Always PEI?

Cost: PEI is much more expensive than MPPO.

Processing: Higher molding temperature requirements (340–400 °C), more challenging to mold than other raw material.

Over-spec in some cases: For many IC packages, MPPO or PPE already provides enough heat resistance, so PEI is only used when the extra performance is necessary.