Reference Factors for Designing JEDEC TRAYs Compatible with MODULE Packaging

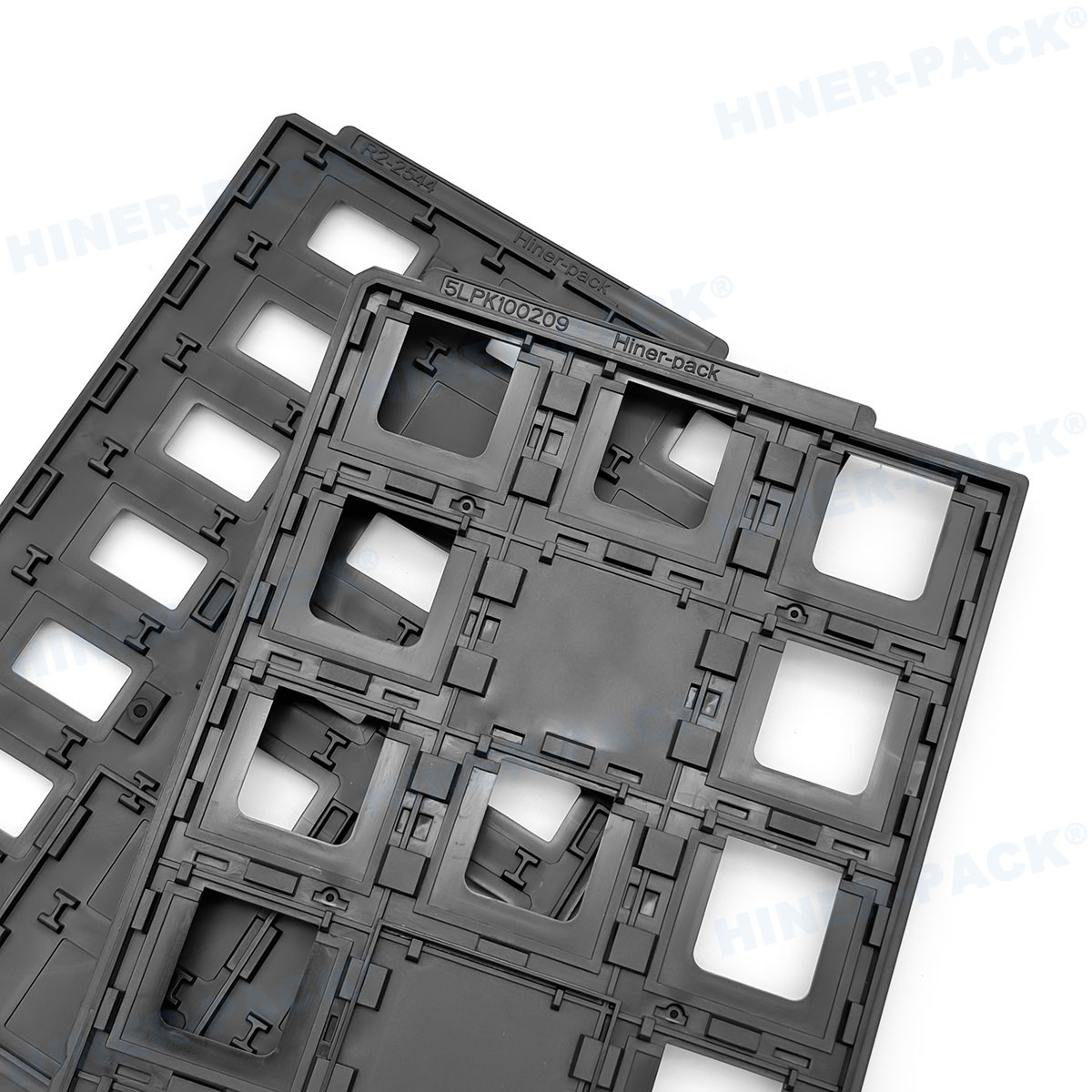

Absolutely avoid pressing or damaging pins, solder balls, or exposed connectors: The tray cavity should prevent any mechanical stress or friction on the electrical contact areas.

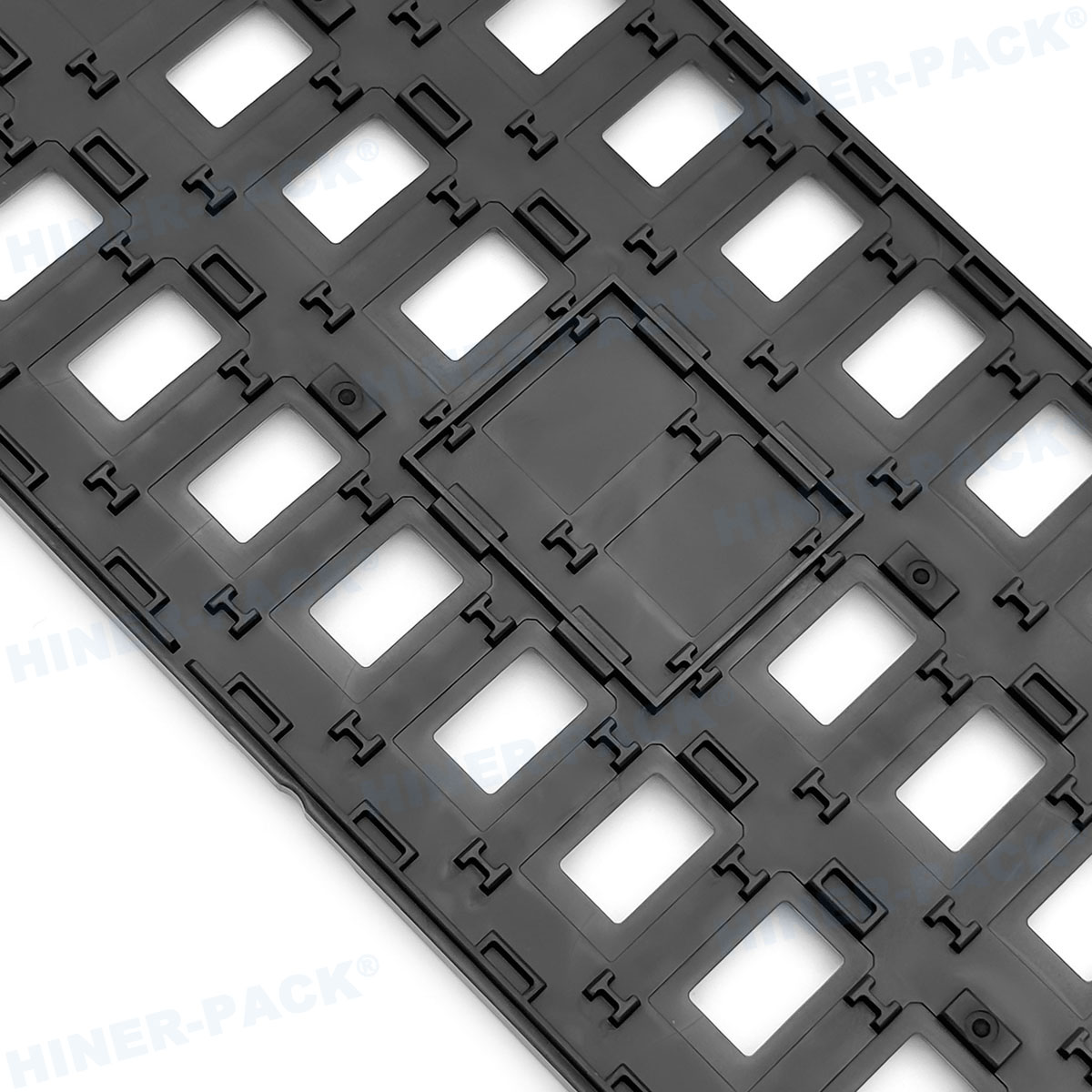

Provide stable multi-point support to the module body to prevent vibration, bending, or deformation during transportation, stacking, or automated handling.

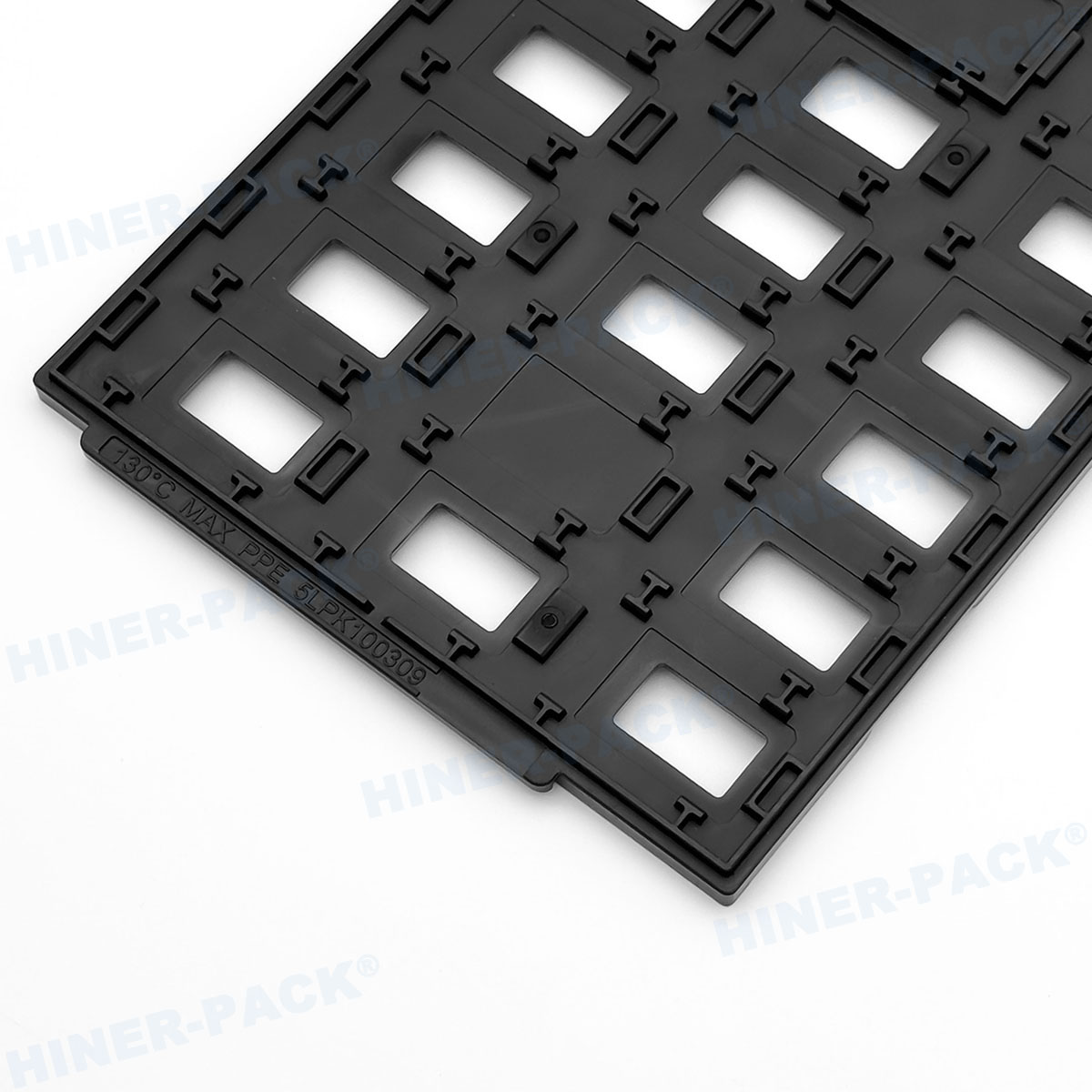

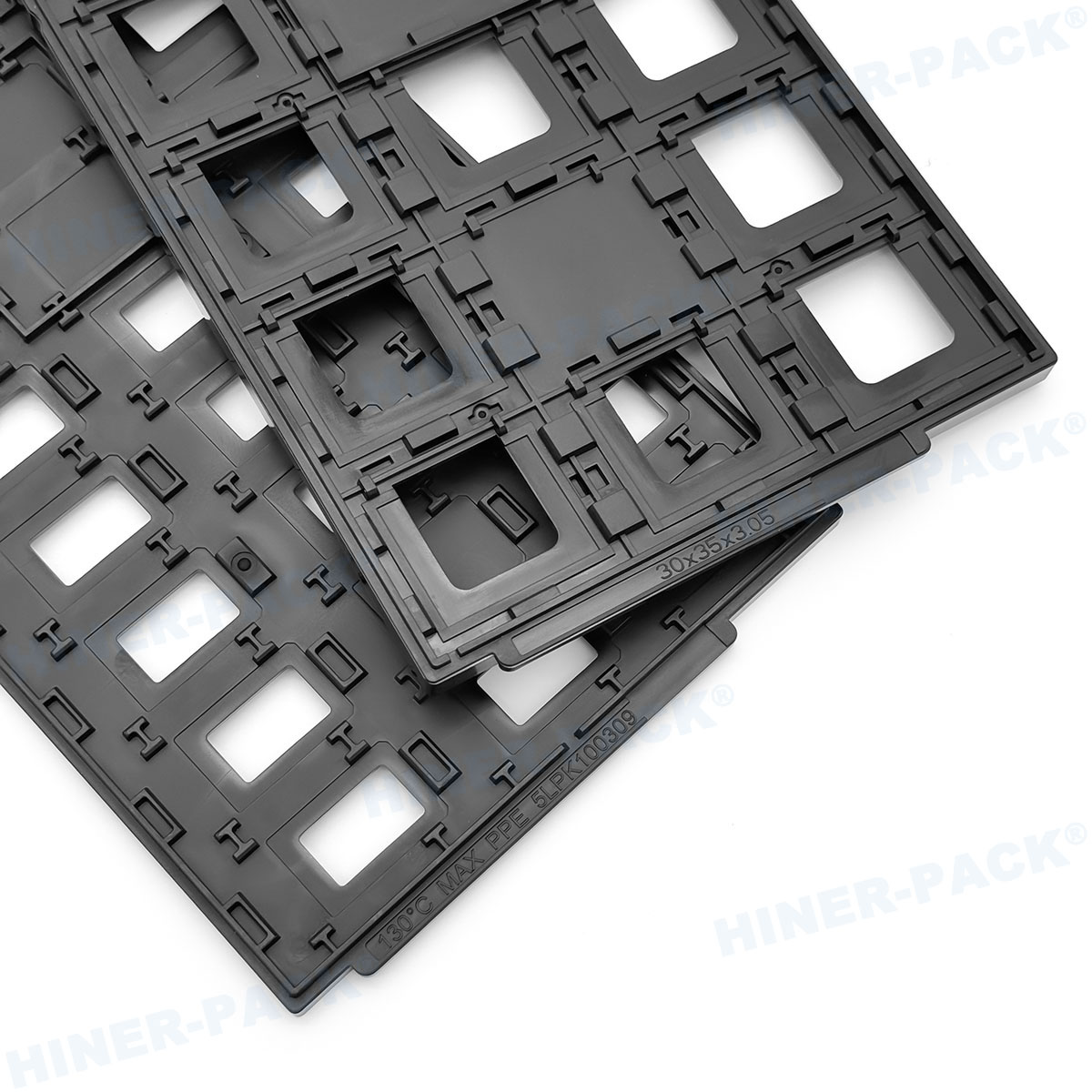

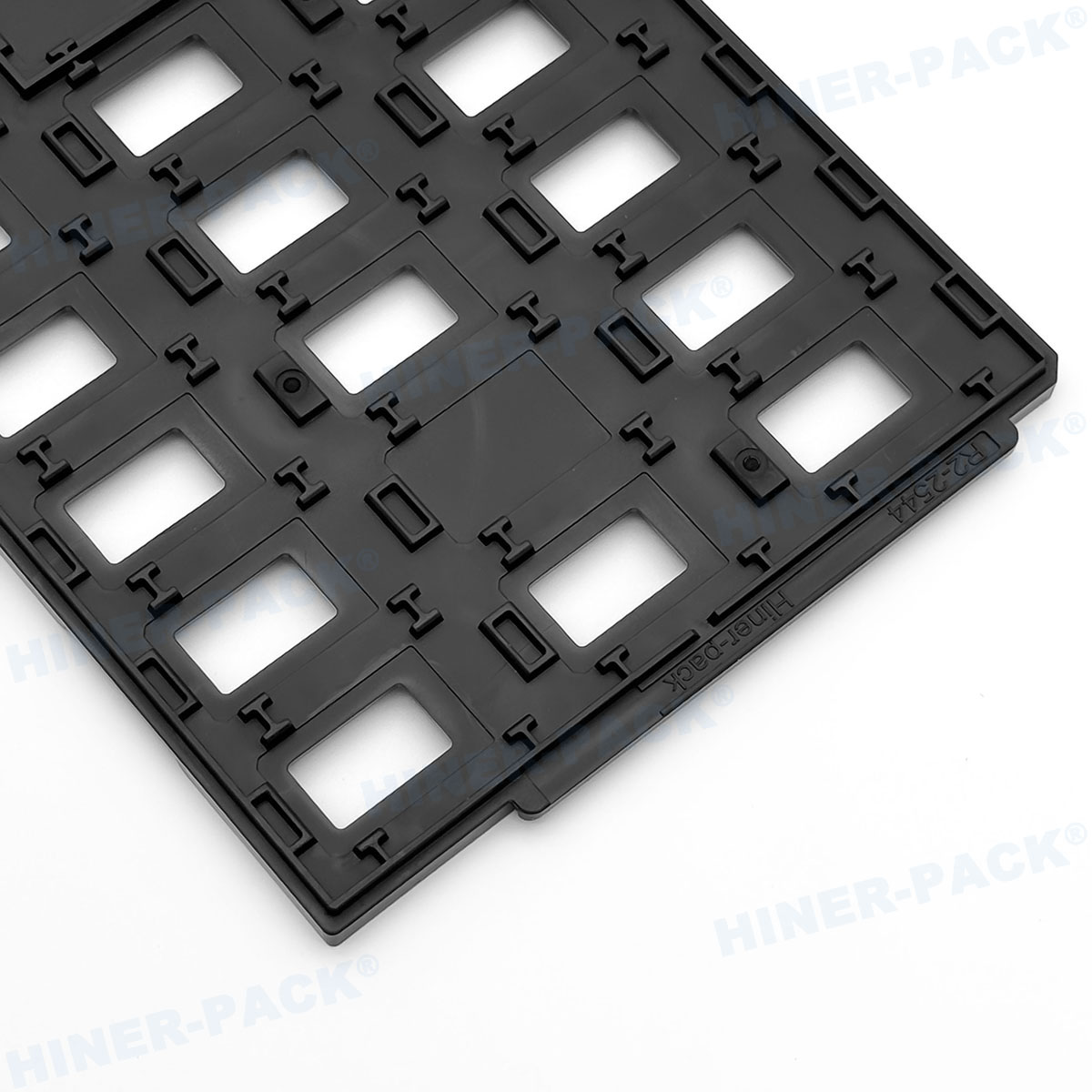

Ensure dimensional precision and flatness for compatibility with automated testing equipment, robotic arms, pick-and-place systems, and storage racks.

Tray material should meet ESD control requirements and withstand reflow oven, baking, or cleaning processes if required in module assembly lines.

Module (IC Module / System in Package Module):

Modules integrate multiple chips, passive components, or functional blocks into a single package, offering system-level performance in a compact footprint. They may adopt BGA, LGA, or castellated lead structures as external I/O interfaces. Module thickness and outline sizes vary widely depending on application, ranging from a few millimeters to large board-level packages. Their advantages include functional integration, miniaturization, and simplified PCB design, making them widely used in memory modules, RF front-end modules, power management modules, and AI/5G communication devices.