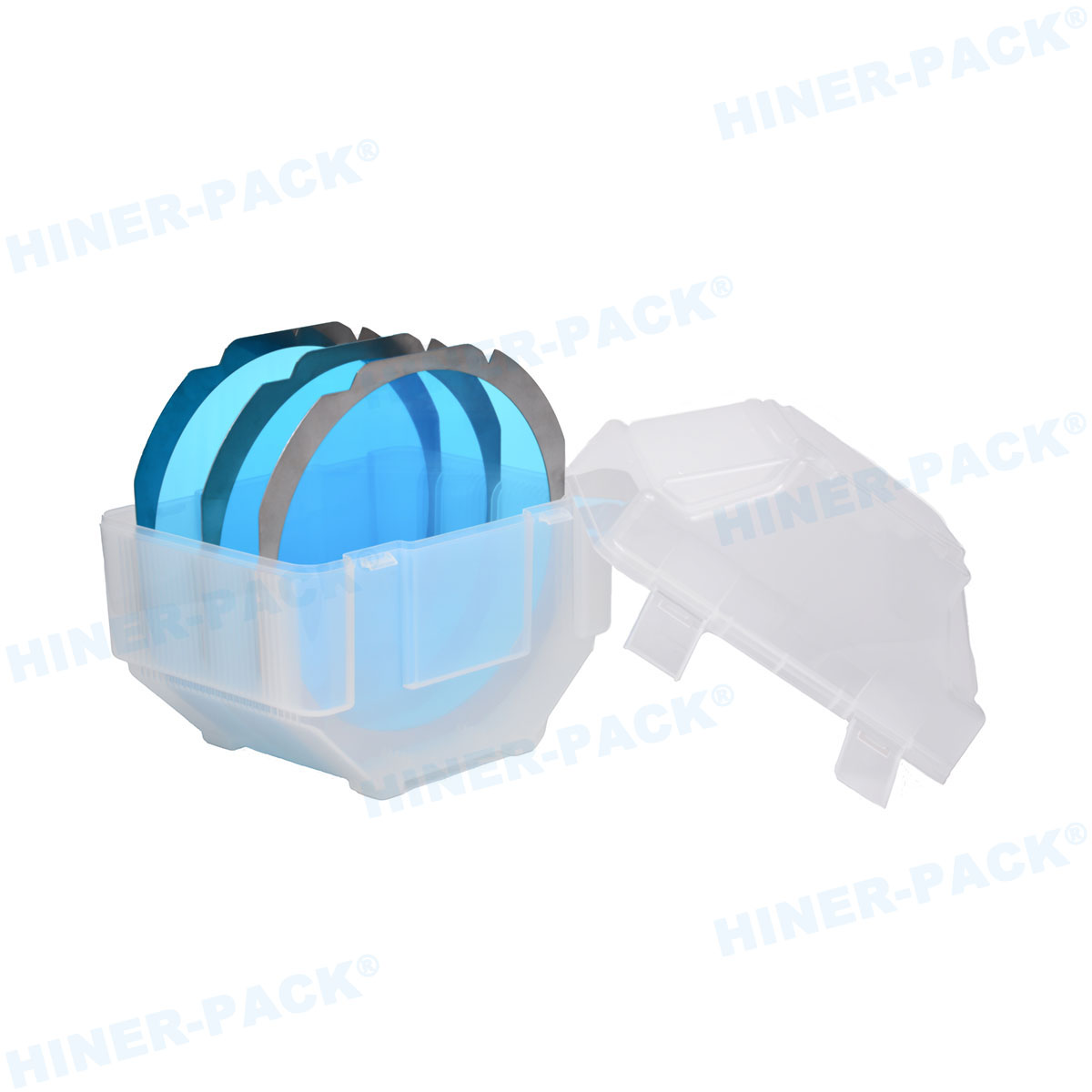

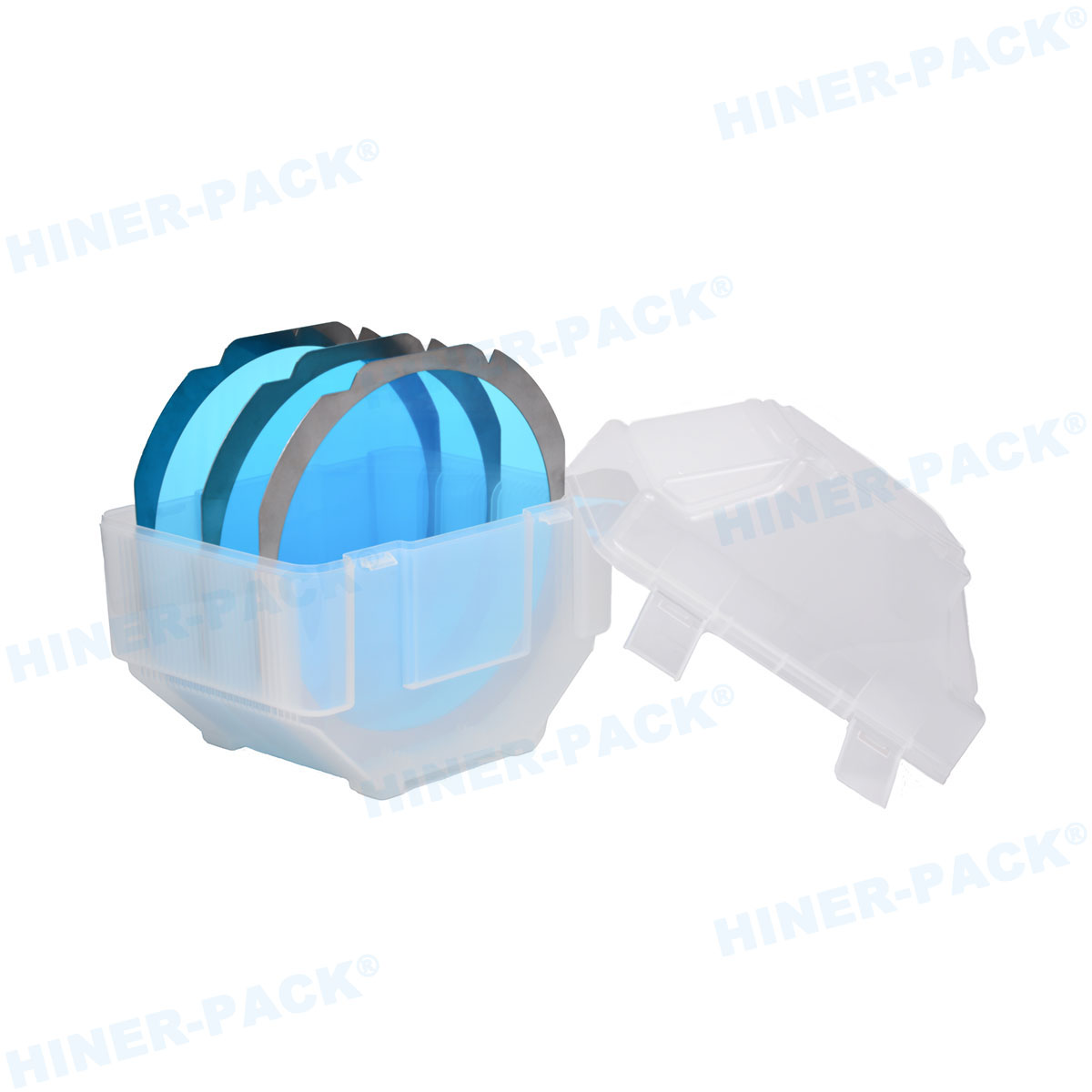

In the precise world of semiconductor manufacturing, every component matters. From the silicon wafer to the final packaged chip, protection and handling are non-negotiable. This is where JEDEC trays play a critical role. They are not just plastic containers; they are standardized carriers designed to safeguard delicate integrated circuits (ICs) during testing, handling, transport, and storage.

Selecting the right partner to produce these essential items is a strategic decision. The wrong tray can lead to damage, contamination, or handling failures, resulting in significant financial loss. This article outlines the crucial factors to evaluate when sourcing from JEDEC tray manufacturers.

Understanding the Role and Standards of JEDEC Trays

JEDEC trays are molded to specific outlines and cavity dimensions standardized by JEDEC (Joint Electron Device Engineering Council). These standards ensure interoperability across different automated handling equipment used in fabrication and assembly plants.

Trays must meet strict criteria for dimensional stability, electrostatic discharge (ESD) protection, and mechanical strength. They hold devices securely, preventing movement that could cause chipping or scratching. Reliable JEDEC tray manufacturers deeply understand these standards, including JESD30 for outline drawings and JEDEC-609 for packaging and shipping.

Material Selection and Engineering Expertise

The choice of material directly impacts performance. Common materials include carbon-filled PCT (Polycyclohexylenedimethylene Terephthalate) for high-temperature processes, anti-static PET, and advanced composites.

Top manufacturers like Hiner-pack invest in material science. They select resins that offer the right balance of stiffness, heat resistance (often above 150°C for lead-free soldering), and consistent ESD properties. The material must not outgas contaminants that could foul sensitive components.

Engineering expertise ensures the tray design accounts for warpage, stress points, and fluid dynamics during wash processes. The design must facilitate smooth automated pick-and-place operations.

Precision Tooling and Consistent Production

The heart of tray manufacturing is the mold. High-precision, stainless steel molds are essential. They guarantee that every cavity, every rail, and every stacking feature is identical across millions of units.

Consistency is king in semiconductor logistics. A slight variation in cavity depth or width can cause device misalignment. Leading JEDEC tray manufacturers operate in controlled environments. They maintain rigorous process controls to ensure dimensional tolerances are held batch after batch.

This level of precision prevents jams in high-speed automation equipment, a costly and disruptive event in a production line.

Comprehensive Quality Control and Testing

Quality cannot be inspected into a tray; it must be built in. However, exhaustive testing is the final gatekeeper. Reputable manufacturers implement a multi-layered QC protocol.

This includes Coordinate Measuring Machine (CMM) scans to verify every critical dimension. ESD surface resistance is tested regularly per ANSI/ESD S11.11. Mechanical tests check stackability, durability, and device retention force.

Additional tests might involve thermal cycling to simulate real-world conditions. Suppliers should provide certified test reports, giving customers full traceability and confidence.

Supply Chain Stability and Customization Support

The semiconductor industry runs on tight schedules. Delays in receiving trays can halt a packaging or test line. Therefore, evaluating a manufacturer's supply chain resilience is vital.

Look for manufacturers with control over their raw material sourcing and robust production planning. The ability to scale up quickly to meet demand spikes is a significant advantage.

Beyond standard offerings, many situations require customization. A skilled manufacturer can adapt designs for unique device shapes, add RFID tags, or modify trays for specific automation cells. Partners like Hiner-pack often work directly with OEMs to develop application-specific solutions.

Industry Reputation and Technical Collaboration

A manufacturer's reputation within the semiconductor ecosystem is a powerful indicator. Long-term relationships with major OSATs (Outsourced Semiconductor Assembly and Test providers) and IDMs (Integrated Device Manufacturers) signal reliability.

The best partnerships go beyond a buyer-supplier transaction. They involve technical collaboration. Good JEDEC tray manufacturers act as consultants, helping solve handling challenges, advising on new material technologies, and ensuring compliance with evolving industry standards.

Choosing a manufacturer for JEDEC trays is a decision that impacts yield, efficiency, and total cost of ownership. It requires looking beyond unit price to factors like material integrity, precision manufacturing, unwavering quality, and supply chain dependability.

By partnering with an experienced and technically proficient manufacturer, companies secure more than just a component. They gain a critical element of their production flow, one that protects their valuable devices from wafer to shipment. For industry leaders seeking this level of assurance, working with established JEDEC tray manufacturers like Hiner-pack provides the necessary foundation for success.

Frequently Asked Questions (FAQ)

Q1: What exactly is a JEDEC tray, and why is it important?

A1: A JEDEC tray is a standardized plastic carrier designed to hold and protect semiconductor devices (like IC chips) during manufacturing, testing, and shipping. Its importance lies in preventing physical damage, controlling electrostatic discharge, and ensuring compatibility with automated handling equipment across global supply chains.

Q2: Why shouldn't I just source the cheapest JEDEC trays available?

A2: The lowest-cost trays often compromise on material quality, precision, and consistency. This can lead to warping at high temperatures, poor ESD protection (damaging devices), or dimensional inaccuracies that cause jams in expensive automation equipment, resulting in far greater costs from downtime and yield loss.

Q3: How do I know if a JEDEC tray manufacturer has good quality control?

A3: Ask for their QC documentation. Reliable manufacturers will readily provide data from CMM measurements, ESD resistance tests (with values typically between 10^5 to 10^11 ohms), and mechanical testing. They should also have certifications like ISO 9001 and follow industry standards meticulously.

Q4: Can manufacturers create custom trays that aren't strictly JEDEC standard?

A4: Yes, many top manufacturers offer custom molding services. While based on JEDEC design principles for handling, trays can be adapted for unique device outlines, specific automation interfaces, or special requirements like embedded sensors. Companies like Hiner-pack frequently collaborate on such custom projects.

Q5: What are the key material properties I should ask about for high-temperature processes?

A5: For processes like lead-free solder reflow, focus on the Heat Deflection Temperature (HDT). Materials like carbon-filled PCT are common because they maintain dimensional stability well above the process temperature (often >220°C). Also, inquire about continuous use temperature and low outgassing properties to prevent contamination.