The relentless drive for efficiency in semiconductor manufacturing touches every component, no matter how seemingly simple. The humble wafer box is a prime example. For decades, the primary focus was on brute-force durability. Today, a new critical metric has emerged: weight.

The shift towards lightweight wafer boxes is not a trivial trend. It is a direct response to the demands of modern, highly automated fabs where every gram matters for throughput, ergonomics, and cost.

This move is fueled by the increasing mass of silicon wafers. A single 300mm wafer is substantial. A box carrying 25 of them is heavy. Traditional boxes made this a significant physical burden for operators and a mechanical one for robotics.

The Weight Equation: More Than Just a Number

Why does the mass of a wafer box matter so much? The impact is felt across the fab.

In Automated Material Handling Systems (AMHS), robotic arms and overhead hoists transport thousands of carriers daily. Every gram saved reduces the energy required for acceleration and deceleration. This lowers operational costs and reduces mechanical wear on the entire system.

For human operators, lightweight wafer boxes are a matter of safety and ergonomics. Repetitive lifting of heavy carriers leads to fatigue and increases the risk of drops or musculoskeletal injuries. A lighter box makes the workplace safer.

Furthermore, in logistics and shipping, weight translates directly into cost. Transporting wafers between fabs or to customers is cheaper and has a lower carbon footprint with lighter packaging.

The Core Conflict: Lightweight vs. Protective Strength

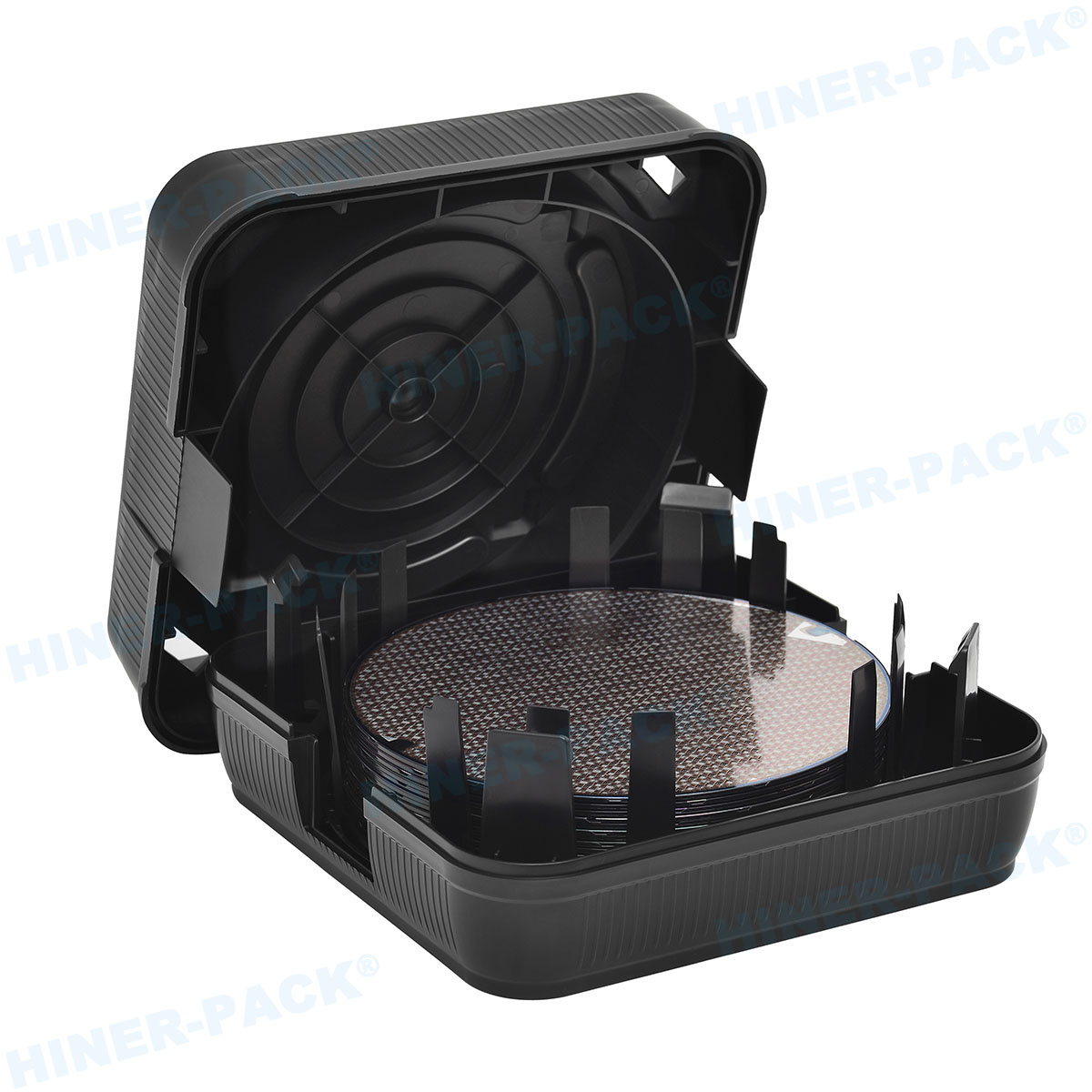

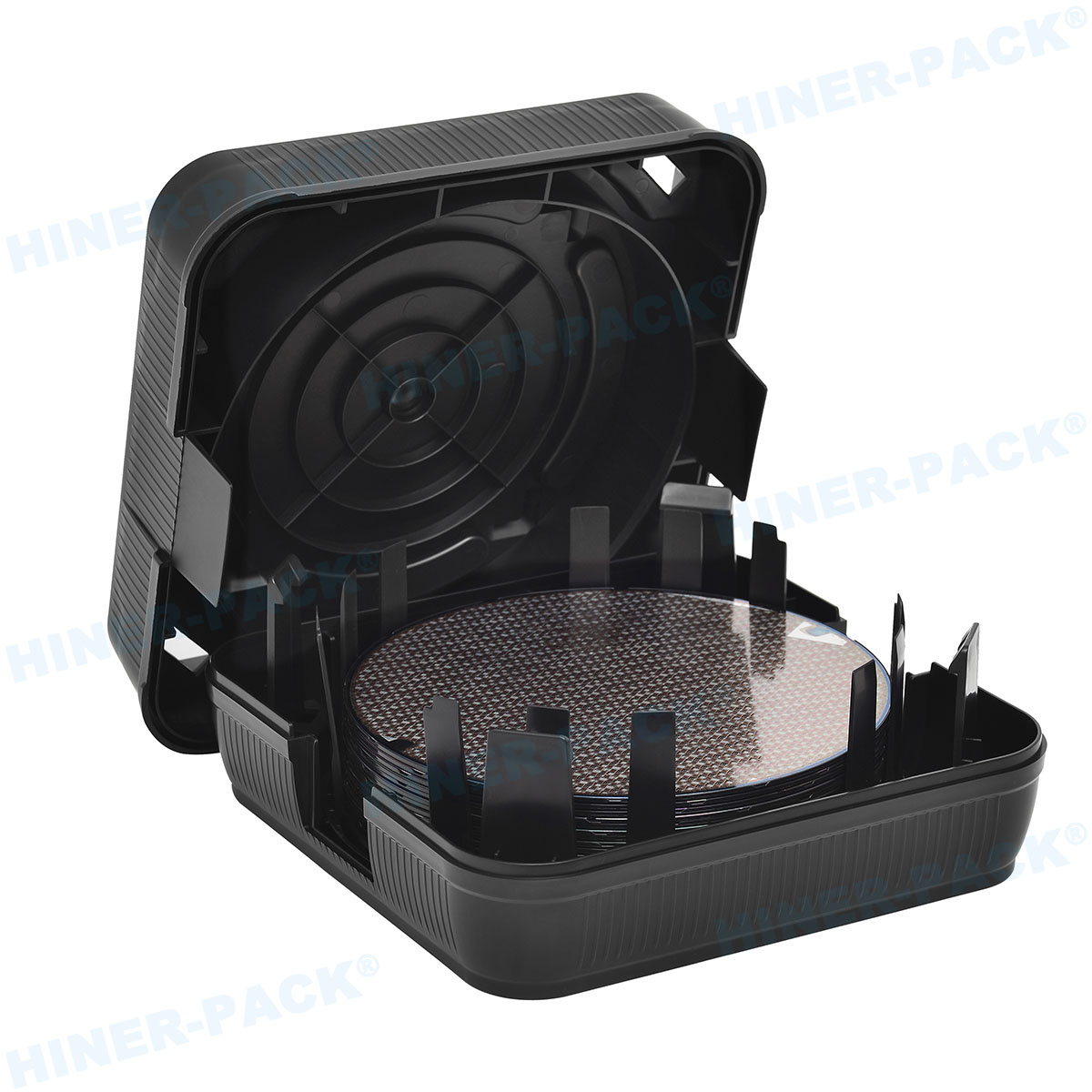

The central engineering challenge is unmistakable. How do you remove material to save weight without compromising the box's primary function: protecting multi-million dollar wafer lots?

A box that is light but fragile is worthless. A box that is strong but prohibitively heavy is inefficient. The ideal lightweight wafer box exists at the perfect intersection of minimal mass and maximal protection.

This requires a fundamental rethink of material selection and structural design. It's no longer just about picking a polymer and molding it. It's about advanced engineering.

Materials Making Lightweight Boxes Possible

The quest for the optimal lightweight wafer boxes has narrowed down to a few key material choices.

Advanced PPS Composites:

Standard Polyphenylene Sulfide (PPS) is a good material. But by formulating it with specific reinforcing agents, manufacturers can create a composite that offers a superior strength-to-weight ratio. This allows for thinner wall sections without sacrificing rigidity or chemical resistance.

PEEK for High-Performance Applications:

Polyether Ether Ketone (PEEK) remains the gold standard for performance. Its innate high strength means less material is needed to achieve the same structural integrity as other plastics. A PEEK-based lightweight wafer box often represents the peak of performance, offering minimal particle generation and excellent durability at a low mass.

Carbon Fiber Reinforced Polymers:

For the most demanding weight-saving applications, carbon fiber reinforcement is being explored. This creates an exceptionally stiff and light structure, crucial for the largest wafers on the horizon. The challenge lies in cost and ensuring no conductive fibers can pose a contamination risk.

Companies like Hiner-pack invest heavily in developing and testing these advanced material formulations to hit the precise balance their clients need.

Where Lightweight Boxes Deliver the Biggest Impact

The value of a lightweight wafer box is universal, but it's critical in specific areas.

High-Speed AMHS: In fabs with extensive robotic transport, the cumulative energy savings and reduced system wear are immense.

Metrology and Inspection Stations: These tools often require manual loading and unloading by engineers. Reducing operator fatigue here minimizes handling errors.

Inter-Bay Transfer: Moving carriers between different cleanroom bays or buildings is faster and safer with lighter boxes.

Global Supply Chain: Every shipment of finished wafers or blank substrates becomes more cost-effective. This is a direct bottom-line benefit.

Selecting the Right Lightweight Wafer Box: A 5-Point Checklist

Choosing a box isn't just about picking the lightest one on the catalog. Use this checklist to guide your decision.

Verify the Structural Load Rating: What is the maximum weight of wafers the box is certified to hold? Ensure there is a significant safety margin.

Request Particle Performance Data: A lighter design must not come at the cost of higher particle generation. Ask for test results from independent labs.

Check Chemical Compatibility: Ensure the material retains its properties and does not degrade when exposed to your standard cleanroom chemicals.

Evaluate the Latching Mechanism: A light box needs a secure, easy-to-use latch that won't fail under vibration or impact. It should also be designed for low particle generation.

Assess the Total Cost of Ownership (TCO): Factor in potential savings from reduced AMHS energy, lower shipping costs, and longer system lifespan, not just the unit price.

Understanding the Cost: Why Lightweight Doesn't Mean Cheap

There is a common misconception that a lightweight wafer box should cost less because it uses less material. The opposite is often true.

The cost is in the advanced material science and the precision engineering required to make it work. The raw materials—high-purity PPS composites or PEEK—are more expensive per kilogram than standard grades.

Furthermore, the molding process for thin-walled, high-strength designs is more complex. It requires higher-precision tools and stricter process control to prevent warping or internal stresses.

You are not paying for less plastic. You are paying for smarter, more advanced engineering. The return on investment comes from operational savings, not a lower purchase price.

The Engineering Behind the Weight Reduction

Creating a reliable lightweight wafer box is an exercise in structural optimization.

Engineers use techniques like Finite Element Analysis (FEA) to simulate stress points across the box's structure. This allows them to strategically reinforce high-stress areas like corners, latch points, and the bottom shelf, while safely removing material from low-stress zones.

The design of the wafer pockets is also optimized. Ribs and contact points are meticulously shaped to use the minimum material necessary to securely cradle the wafer and dissipate kinetic energy from impacts.

This is where experienced suppliers like Hiner-pack excel, applying deep domain knowledge to create designs that are both featherlight and fortress-strong.

The Future of Wafer Handling is Lighter

The trajectory of semiconductor manufacturing is clear: everything must become smarter, more efficient, and more integrated. Wafer packaging is no exception.

The adoption of lightweight wafer boxes is a logical and necessary step in this evolution. It represents a move from passive containers to actively optimized fab components. By reducing mass, we enhance automation, protect our workforce, and cut costs across the entire supply chain.

The goal is no longer just to protect wafers, but to do so in the most intelligent and efficient way possible.

Frequently Asked Questions (FAQs)

Q1: Can lightweight wafer boxes be just as durable as standard-weight boxes?

A1: Yes, when properly engineered. The durability comes from the material's advanced properties (like high strength-to-weight ratio) and intelligent structural design, not simply from bulk. A well-designed lightweight box can meet or exceed the performance of a heavier, less-optimized design.

Q2: Are there any risks of electrostatic discharge (ESD) with lightweight materials?

A2: This is a critical consideration. Reputable manufacturers ensure their lightweight wafer boxes are made with static-dissipative or conductive composites. This is a fundamental part of the material specification, not an afterthought, to protect sensitive wafers from ESD damage.

Q3: How much weight can typically be saved by switching to a lightweight design?

A3: Weight reduction depends on the starting point and the target application. Savings can range from 15% to over 30% compared to a standard carrier of the same size and material class. For a 300mm wafer box, this can translate to a kilogram or more of saved weight per carrier.

Q4: Is the cleaning process different for lightweight wafer boxes?

A4: Generally, no. They are designed to withstand the same standard cleanroom cleaning procedures as traditional boxes, including DI water rinses and chemical baths. Always refer to the manufacturer's guidelines, as the maximum temperature tolerance may vary with thinner wall sections.

Q5: We have older AMHS equipment. Are lightweight boxes compatible?

A5: In most cases, yes. The key is dimensional compliance. A lightweight wafer box from a quality supplier will conform to the same SEMI mechanical standards (e.g., SEMI E1.9) as a standard box, ensuring interoperability. The reduced mass is typically a benefit, not a compatibility issue, for the robotics.