The semiconductor industry is defined by its pursuit of the microscopic. As manufacturers push the boundaries of what is possible on a silicon substrate, the physical protection of these components during transport becomes just as vital as the lithography process itself. For many specialized facilities, particularly those handling thinned wafers or specific dicing frames, the 135/123 mm Vacuum-Formed Hoop Ring Single Wafer Shipper has become a critical piece of the logistical puzzle. Hiner-pack understands that when a wafer is mounted on a hoop ring, it requires a unique housing that accounts for the added dimensions of the frame while maintaining a contamination-free environment.

Transporting a wafer is never a simple task. Beyond the risk of physical breakage, there are invisible threats like electrostatic discharge (ESD) and chemical outgassing. Hiner-pack has focused its engineering efforts on creating a container that addresses these variables simultaneously. The 135/123 mm sizing is specifically engineered to accommodate standard industry hoop rings, ensuring that the wafer remains suspended and secure, even when subjected to the rigors of international shipping.

The Specifics of the 135/123 mm Geometry

In the world of wafer frames and hoop rings, dimensions are everything. The 135 mm measurement typically refers to the outer diameter of the carrier’s seating area, while the 123 mm dimension relates to the internal support structure that interfaces with the hoop ring itself. This tiered design is intentional. It allows the hoop ring to sit snugly within the shipper without the active surface of the wafer ever touching the plastic walls.

Hiner-pack utilizes precision molds to ensure these tolerances are kept within microns. A shipper that is even slightly too loose can allow the hoop ring to vibrate during transit. This vibration can lead to "micro-chatter," where the edges of the wafer or the dicing tape begin to degrade. By providing a perfect fit, the 135/123 mm Vacuum-Formed Hoop Ring Single Wafer Shipper eliminates this movement, preserving the integrity of the die.

Furthermore, the "single wafer" configuration is preferred for high-value R&D projects or small-batch custom chips. Unlike mass-carrying cassettes, a single-wafer shipper allows for individual tracking and specialized handling. This is particularly important for outsourced assembly and test (OSAT) providers who receive wafers from various sources and must keep them strictly segregated.

Advantages of the 135/123 mm Vacuum-Formed Hoop Ring Single Wafer Shipper in Production

One might wonder why vacuum forming is the preferred method for these carriers rather than traditional injection molding. Vacuum forming allows for the use of thinner, more flexible materials that act as a natural shock absorber. When a shipping box is dropped or jostled, a rigid injection-molded part transfers that energy directly to the wafer. In contrast, the 135/123 mm Vacuum-Formed Hoop Ring Single Wafer Shipper produced by Hiner-pack has a degree of structural "give" that dissipates mechanical energy before it reaches the silicon.

The vacuum forming process also results in a very smooth surface finish. In a cleanroom environment, every ridge or bump on a plastic surface is a potential site for particle accumulation. Hiner-pack’s forming techniques ensure that the interior of the shipper is as smooth as possible, reducing the surface area where dust or micro-particles can hide.

Additionally, the lightweight nature of these shippers reduces shipping costs. In an industry where air freight is the standard for high-speed delivery, every gram counts. Hiner-pack designs these containers to be as light as possible without sacrificing the structural rigidity needed to protect the contents from being crushed under the weight of other packages.

Material Science: Managing ESD and Outgassing

Semiconductors are incredibly sensitive to static electricity. A single discharge can melt the tiny traces on a chip, rendering the entire wafer useless. To combat this, Hiner-pack uses advanced conductive or static-dissipative polymers in the construction of the 135/123 mm Vacuum-Formed Hoop Ring Single Wafer Shipper. These materials are engineered to bleed off static charges at a controlled rate, preventing the buildup of high-voltage potential.

The material selection also focuses on the chemical purity of the plastic. Many low-grade plastics release volatile organic compounds (VOCs) over time—a process known as outgassing. If these gases settle on a wafer, they can cause oxidation or interfere with subsequent manufacturing steps like wire bonding. Hiner-pack selects electronic-grade materials that have been tested for low outgassing, ensuring that the atmosphere inside the shipper remains as pure as the cleanroom where the wafer was made.

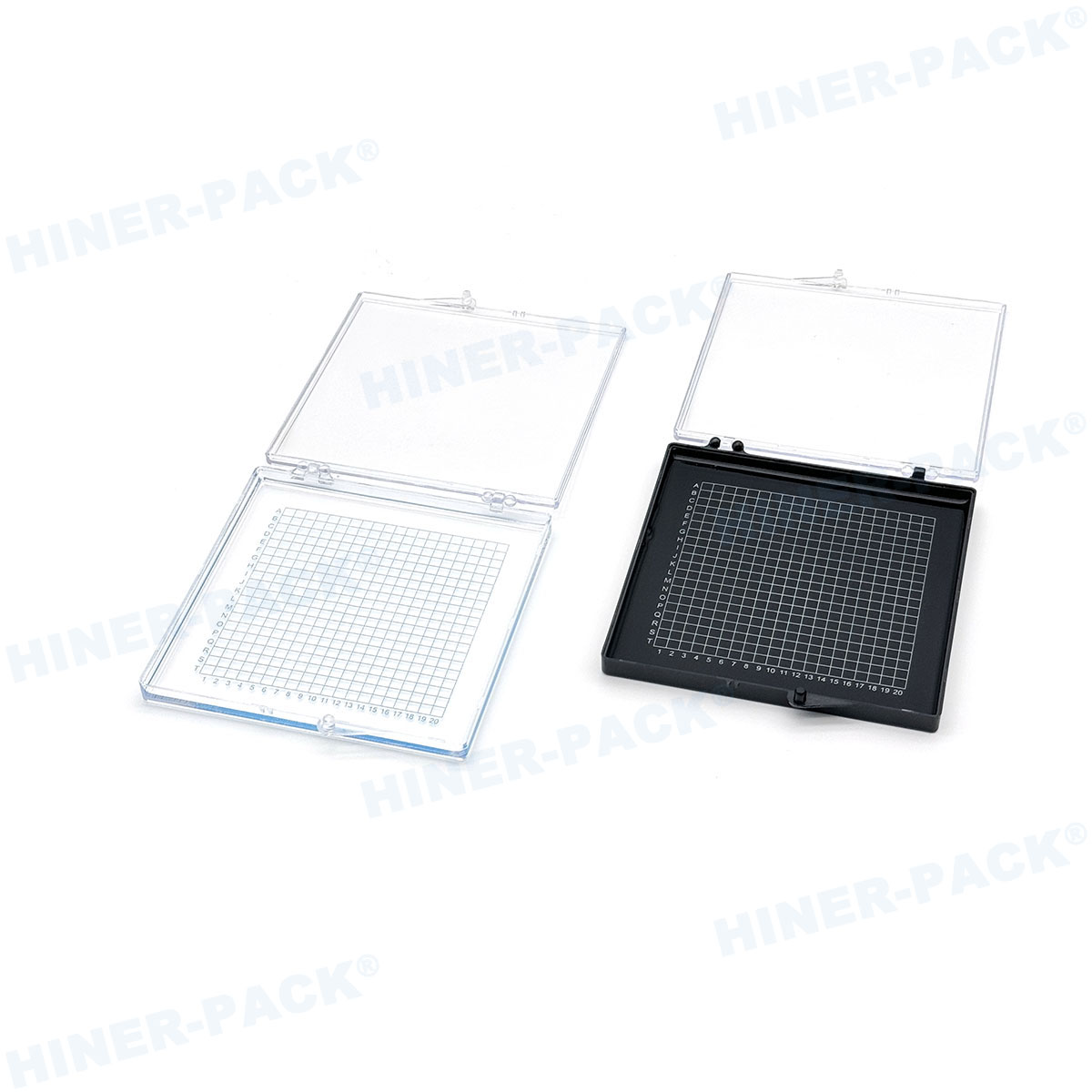

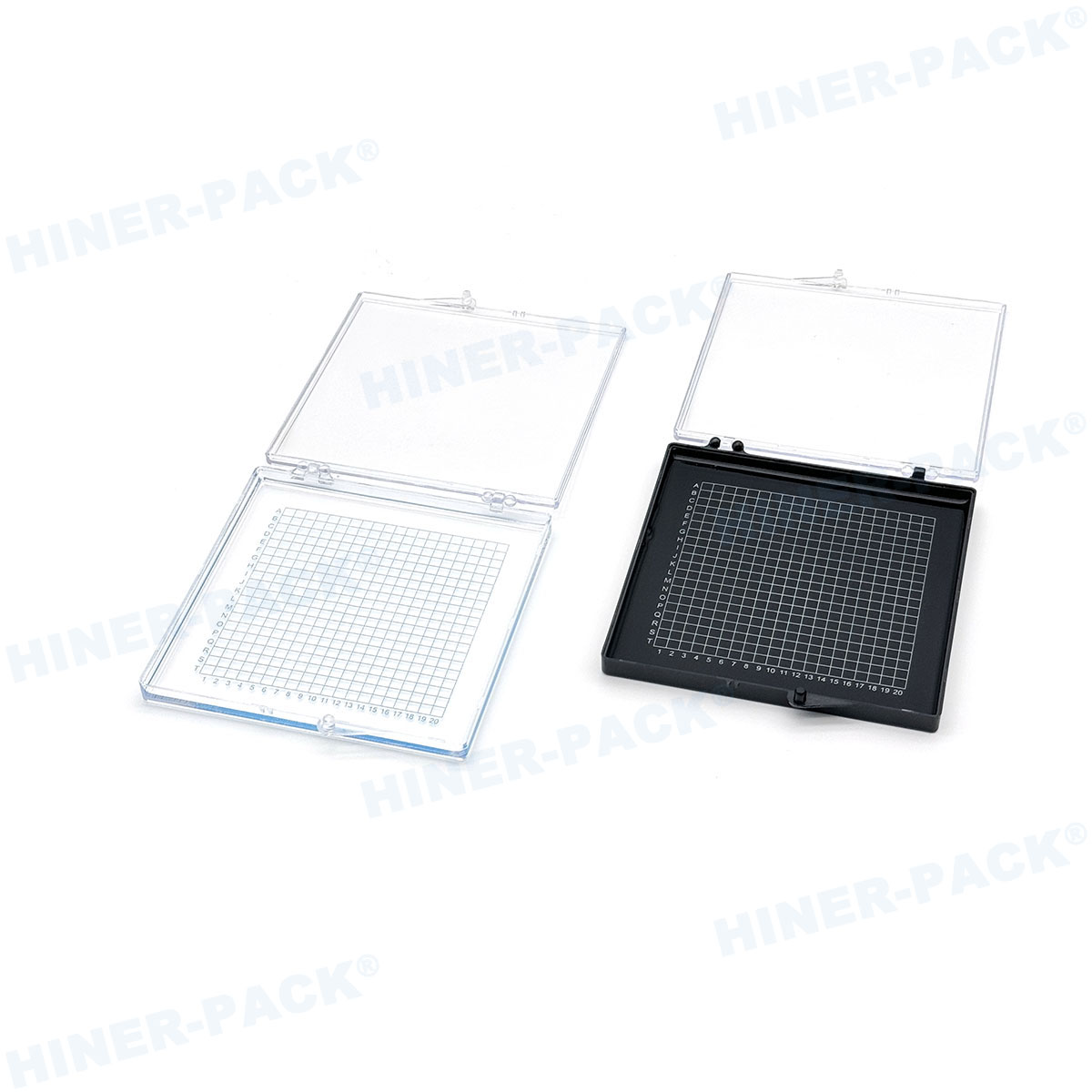

Color choice is also more than aesthetic. Black conductive shippers are the industry standard for maximum ESD protection, while clear or natural anti-static shippers are often used when visual inspection of the wafer or the frame’s barcode is required without opening the package. Hiner-pack provides options for both, depending on the specific workflow requirements of the client.

Structural Integrity and Cleanroom Compatibility

Every 135/123 mm Vacuum-Formed Hoop Ring Single Wafer Shipper undergoes a rigorous cleaning process before it leaves the Hiner-pack facility. It is not enough to design a good shipper; it must also be free of contaminants from the moment it is opened by the customer. Our shippers are washed and packaged in a controlled environment to ensure they meet the stringent particle counts required by modern fabs.

The structural design includes reinforced ribs and interlocking features. These allow multiple shippers to be stacked on top of one another without sliding or putting pressure on the wafer inside. For facilities that manage thousands of wafers, this stackability is essential for efficient storage in nitrogen-purged cabinets or cleanroom shelving.

Hiner-pack also pays attention to the "opening experience." The shippers are designed with ergonomic grip points, making it easy for technicians wearing bulky cleanroom gloves to open the container without jerky movements. A smooth opening process is vital to ensure the wafer isn’t accidentally launched or tilted during access.

The Role of Hoop Rings in the Dicing Process

To appreciate why this specific shipper is necessary, one must understand the dicing process. After a wafer is fabricated, it is often thinned and then mounted onto a dicing tape which is held in place by a metal or plastic hoop ring. This frame allows robotic arms to handle the wafer without touching the silicon.

Because the hoop ring is wider than the wafer itself, standard wafer carriers won't work. The 135/123 mm Vacuum-Formed Hoop Ring Single Wafer Shipper provides the specific clearance needed for these frames. This is especially common for 4-inch and 5-inch wafer processes that have transitioned to thinned substrates for power electronics or MEMS devices.

Hiner-pack has worked closely with dicing equipment manufacturers to ensure that our shipper dimensions align with the most common frame standards. This collaboration ensures that when a wafer finishes the dicing process, it can move directly into a Hiner-pack shipper and then to the customer without any compatibility issues.

Sustainable Practices in Semiconductor Packaging

Environmental responsibility is becoming a major focus for tech companies worldwide. Hiner-pack is committed to reducing the environmental impact of its products. While the primary mission is protection, the materials used in the 135/123 mm Vacuum-Formed Hoop Ring Single Wafer Shipper are selected with recyclability in mind.

Many of our shippers are designed for reuse. In a closed-loop system, where wafers are sent from a fab to an assembly house and back, these shippers can be cleaned and re-entered into the supply chain many times. This not only reduces waste but also provides a significant cost savings over time for the manufacturer.

Even the production process is optimized to reduce scrap plastic. Vacuum forming is a highly efficient process, and Hiner-pack recycles the "skeletal" remains of the plastic sheets used during forming to create new raw materials for non-critical applications. This circular approach helps our partners meet their own corporate sustainability goals.

Logistics and Global Supply Chain Reliability

In the fast-paced world of semiconductors, delays can cost millions. Having a reliable supplier for packaging materials is just as important as having a reliable supplier for silicon ingots. Hiner-pack maintains a robust supply chain to ensure that the 135/123 mm Vacuum-Formed Hoop Ring Single Wafer Shipper is available when our customers need it.

We understand that global shipping involves many variables—humidity changes in cargo holds, pressure changes in aircraft, and the rough handling of local couriers. Our shippers are tested against these environmental stresses to ensure that no matter how the package is handled, the wafer remains in its original, pristine condition.

The trust that international semiconductor leaders place in Hiner-pack is built on years of consistent performance. By focusing on the niche requirements of hoop ring transport, we provide a specialized solution that generic packaging companies simply cannot match.

The safety of a semiconductor wafer is a reflection of the quality of its packaging. Choosing a high-performance carrier like the 135/123 mm Vacuum-Formed Hoop Ring Single Wafer Shipper is an investment in the final yield of the product. Hiner-pack continues to innovate in this space, refining designs and materials to keep pace with the ever-evolving demands of the electronics industry.

Whether you are a startup working on the next generation of sensors or an established fab scaling up production, the way you move your wafers matters. With Hiner-pack, you are choosing a partner dedicated to precision, cleanliness, and the total protection of your technological assets. The 135/123 mm Vacuum-Formed Hoop Ring Single Wafer Shipper remains a cornerstone of our product line, embodying our commitment to excellence in every millimeter.

Frequently Asked Questions (FAQ)

Q1: What specific hoop ring sizes are compatible with the 135/123 mm shipper?

A1: This shipper is designed for standard industry hoop rings where the outer diameter is approximately 135 mm and the inner support ring is around 123 mm. It is most commonly used for wafers that have been mounted for dicing or thinning processes.

Q2: Does Hiner-pack provide certificates of compliance for cleanroom use?

A2: Yes, Hiner-pack can provide documentation regarding the material properties, ESD surface resistivity, and cleanliness levels of the 135/123 mm Vacuum-Formed Hoop Ring Single Wafer Shipper to ensure they meet your facility's internal quality standards.

Q3: Is the material used in these shippers transparent or opaque?

A3: We offer both options. Our conductive black material is opaque and provides the highest level of ESD shielding. We also offer clear anti-static materials that allow for visual inspection and barcode scanning without opening the container.

Q4: How does vacuum forming compare to injection molding for this specific shipper?

A4: Vacuum forming allows for a more flexible, shock-absorbent structure which is ideal for protecting fragile wafers during transit. It also allows Hiner-pack to offer more competitive pricing for specialized sizes compared to the high tooling costs of injection molding.

Q5: Can these shippers be customized with a company logo or specific tracking labels?

A5: Yes, Hiner-pack offers customization options for large orders, including embossed logos and dedicated areas for adhesive tracking labels or RFID tags to streamline your inventory management.

Q6: What is the lead time for a standard order of these shippers?

A6: For standard configurations of the 135/123 mm Vacuum-Formed Hoop Ring Single Wafer Shipper, Hiner-pack maintains a consistent stock for rapid dispatch. For custom material requirements, our team can provide a specific timeline based on your production needs.