The global semiconductor industry operates on a scale of precision that is often difficult to visualize. As circuits shrink and wafer substrates become thinner, the challenge of transporting these delicate components becomes a primary concern for fabrication plants (fabs) and assembly houses. Within this high-stakes environment, the 152/141 mm Vacuum-Formed Hoop Ring Single Wafer Shipper has emerged as a specialized solution designed to bridge the gap between manufacturing excellence and logistical safety. Hiner-pack has been at the forefront of developing these transport solutions, ensuring that every wafer arrives at its destination without a single microscopic defect.

Protecting a wafer isn't just about preventing it from breaking. It is about maintaining a pristine environment free from ionic contamination, outgassing, and electrostatic discharge (ESD). When dealing with specialized hoop ring configurations, the dimensions must be exact. The 152/141 mm specification refers to the precise fit required for wafers mounted on specific frames, often used in dicing or back-grinding processes. Hiner-pack understands that even a millimeter of play within the shipper can lead to vibration damage, making the vacuum-formed precision of these containers an industry necessity.

The Engineering Behind the 152/141 mm Vacuum-Formed Hoop Ring Single Wafer Shipper

To understand why this specific shipper is so effective, one must look at the vacuum-forming process itself. Unlike injection molding, which can sometimes create rigid, high-stress plastic parts, vacuum forming allows for the creation of thin-walled yet structurally sound pockets. This process ensures that the 152/141 mm Vacuum-Formed Hoop Ring Single Wafer Shipper provides a snug "nest" for the wafer.

The hoop ring design is particularly important. In many semiconductor workflows, wafers are not transported as bare silicon. They are often mounted on a metal or plastic ring to facilitate automated handling by robotic arms. The 152/141 mm dimensioning is tailored to these rings, providing a secure perimeter that prevents the wafer surface from ever coming into contact with the shipper’s internal walls. Hiner-pack utilizes advanced polymers during the forming process to ensure that the shipper remains rigid under pressure but flexible enough to absorb mechanical shocks during air or ground transit.

Material selection is another pillar of this engineering feat. Most of these shippers are manufactured using conductive or dissipative materials. In a cleanroom environment, static electricity is a silent killer of integrated circuits. By using specialized plastics, Hiner-pack ensures that any static charge is safely bled off, rather than discharging through the sensitive gates of the microchips on the wafer.

Critical Dimensions and the Importance of the Hoop Ring Fit

In the world of semiconductor packaging, "close enough" is never good enough. The distinction between the 152 mm outer dimension and the 141 mm inner support is what defines the stability of the 152/141 mm Vacuum-Formed Hoop Ring Single Wafer Shipper. This specific geometry is designed to support the hoop ring at its strongest points, ensuring that the tension of the dicing tape—if present—remains constant.

If a shipper is too large, the hoop ring can shift, potentially causing the wafer to delaminate or crack. If it is too small, the pressure applied to the edges of the ring can distort the wafer's flatness. Hiner-pack focuses on these micro-tolerances to ensure that the fit is seamless. This level of detail is why international semiconductor manufacturers rely on these shippers for high-value components used in automotive sensors, medical devices, and aerospace communication arrays.

Furthermore, the "single wafer" aspect of the design is a strategic choice for high-value or low-volume batches. While mass-production cassettes are common for front-end processing, single-wafer shippers are the preferred method for shipping samples, R&D prototypes, or wafers that have completed the thinning process. They offer individualized protection that a bulk carrier simply cannot match.

Contamination Control and Cleanroom Standards

One of the biggest threats to semiconductor yield is particle contamination. A single dust mote can ruin an entire batch of dies. Consequently, the 152/141 mm Vacuum-Formed Hoop Ring Single Wafer Shipper must be produced and packaged in a controlled environment. Hiner-pack maintains rigorous cleanroom standards during the manufacturing of these shippers to ensure they are "out-of-the-box" ready for fab use.

The vacuum-forming process used by Hiner-pack is optimized to minimize the release of Volatile Organic Compounds (VOCs). Outgassing is a phenomenon where plastics release gasses over time, which can then condense on the wafer surface and cause chemical contamination. By selecting high-purity, medical-grade or electronic-grade polymers, Hiner-pack effectively eliminates this risk, maintaining the chemical integrity of the wafer’s top layers.

The interior surface finish of the shipper is also polished to a high degree. This reduces friction and prevents the shedding of plastic micro-particles when the hoop ring is inserted or removed. In the international semiconductor field, these minor details are what separate a standard packaging supplier from a critical high-tech partner.

ESD Protection and Static Dissipative Features

Electrostatic Discharge (ESD) is perhaps the most well-known enemy of the semiconductor. When a wafer is moved, friction can generate thousands of volts of static electricity. Without a proper path to ground, this energy can arc. The 152/141 mm Vacuum-Formed Hoop Ring Single Wafer Shipper is specifically engineered to combat this through its material composition.

Hiner-pack typically utilizes Black Conductive Polypropylene or clear anti-static materials depending on the customer's visibility requirements. Conductive shippers provide a "Faraday Cage" effect, shielding the wafer from external electromagnetic interference and static fields. This is essential during air transport, where changes in cabin pressure and friction can increase the risk of static buildup.

The surface resistivity of these shippers is carefully monitored during production. It must fall within the narrow range that allows for controlled dissipation. If the material is too conductive, a sudden spark could occur; if it is too resistive, the charge will stay on the surface too long. Hiner-pack’s expertise in material science ensures that every 152/141 mm Vacuum-Formed Hoop Ring Single Wafer Shipper meets the international ESD Association standards.

Ergonomics and Automation Compatibility

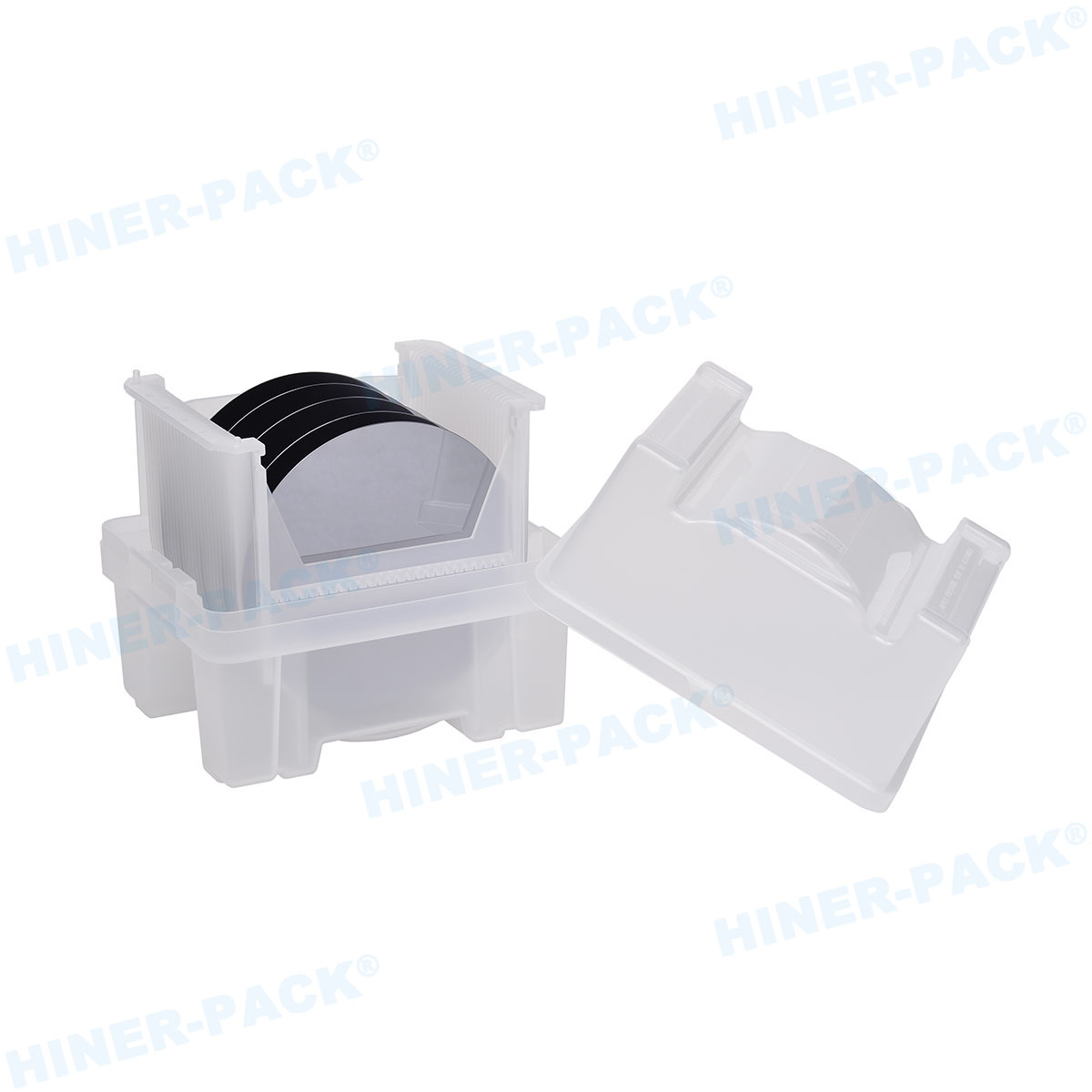

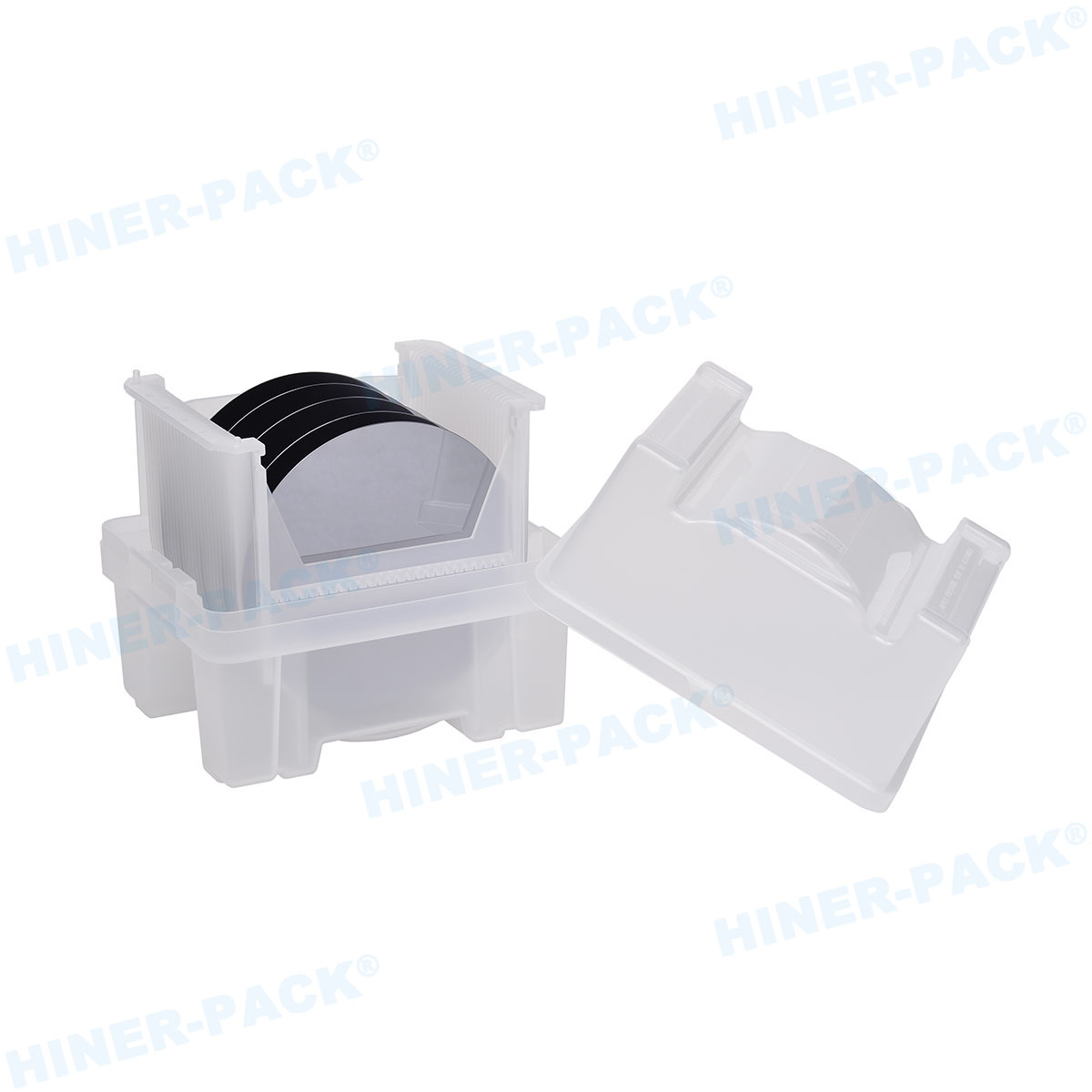

Modern semiconductor fabs are highly automated. The way a shipper is handled by a human operator or a robotic gripper can affect the throughput of a facility. The exterior design of the 152/141 mm Vacuum-Formed Hoop Ring Single Wafer Shipper includes features that facilitate easy opening and secure closing.

Hiner-pack incorporates ergonomic finger recesses and secure locking mechanisms that do not require excessive force. This is important because jarring movements while opening a shipper can cause a wafer to jump or vibrate, leading to potential edge chips. The "hoop ring" design also allows for easy interface with vacuum pens or automated pick-and-place systems.

The stackability of these shippers is another logistical advantage. In a warehouse or during transit, space is at a premium. Hiner-pack designs these shippers with interlocking features that allow them to be stacked securely without the risk of the bottom unit collapsing. This structural integrity is a hallmark of high-quality vacuum-formed products.

Sustainability in Semiconductor Packaging

As the global electronics industry moves toward more sustainable practices, the lifecycle of packaging materials has come under scrutiny. While the primary goal of the 152/141 mm Vacuum-Formed Hoop Ring Single Wafer Shipper is protection, Hiner-pack is also committed to environmental responsibility.

Vacuum-formed shippers are often more material-efficient than their injection-molded counterparts. Because they use thinner sheets of plastic to achieve the same structural goals, they reduce the overall carbon footprint of the packaging. Additionally, many of the materials used by Hiner-pack are recyclable. In many cases, these shippers are designed to be cleaned and reused multiple times within a closed-loop system between a fab and an assembly site, further reducing waste.

However, even when the shipper reaches the end of its functional life, the purity of the plastics used makes them easier to process in specialized recycling streams. This balance of high-performance protection and environmental mindfulness is a core value at Hiner-pack.

Why Industry Leaders Choose Hiner-pack

The logistics of semiconductor manufacturing leave no room for error. Choosing the right transport media is a decision that impacts yield, cost, and brand reputation. The 152/141 mm Vacuum-Formed Hoop Ring Single Wafer Shipper represents a synthesis of material science, mechanical engineering, and cleanroom discipline.

By focusing on the specific needs of hoop-ring mounted wafers, Hiner-pack provides a solution that addresses the physical, electrical, and chemical challenges of the industry. Whether you are shipping 6-inch wafers for power electronics or specialized substrates for photonics, the reliability of your packaging should be the least of your worries.

In a market where technology evolves every few months, having a stable, proven, and high-quality packaging partner is essential. The 152/141 mm Vacuum-Formed Hoop Ring Single Wafer Shipper from Hiner-pack remains the gold standard for secure, efficient, and clean wafer transport on a global scale.

Frequently Asked Questions (FAQ)

Q1: What is the primary advantage of using a vacuum-formed shipper over an injection-molded one?

A1: Vacuum-formed shippers, like the ones produced by Hiner-pack, are typically more cost-effective for specialized sizes and offer a lighter profile. They provide excellent shock absorption due to the inherent flexibility of the thin-walled plastic, which is often better for protecting delicate wafers than a rigid injection-molded case.

Q2: Can the 152/141 mm Vacuum-Formed Hoop Ring Single Wafer Shipper be used in ISO Class 5 cleanrooms?

A2: Yes. Hiner-pack manufactures these shippers using low-sloughing and low-outgassing materials. When processed and packaged under strict cleanroom conditions, they are fully compatible with ISO Class 5 and Class 6 environments common in semiconductor manufacturing.

Q3: How does the "Hoop Ring" design improve wafer safety during shipping?

A3: The hoop ring design suspends the wafer by its mounting frame rather than contacting the wafer surface itself. This prevents any mechanical abrasion on the active side of the wafer and ensures that the dicing tape remains under proper tension during the entire journey.

Q4: Is the 152/141 mm size a standard for all 6-inch wafers?

A4: While it is common, the 152/141 mm size is specifically tailored for wafers mounted on standard hoop rings (frames). Bare 6-inch (150mm) wafers typically use different styles of shippers. It is always best to verify your frame dimensions with Hiner-pack to ensure a perfect fit.

Q5: Does Hiner-pack offer ESD-safe versions of this shipper?

A5: Absolutely. We offer the 152/141 mm Vacuum-Formed Hoop Ring Single Wafer Shipper in several material grades, including carbon-filled conductive plastic and static-dissipative clear materials, to meet your specific ESD protection requirements.

Q6: Are these shippers reusable?

A6: Yes, they are designed for durability. As long as they are cleaned according to industry standards and inspected for structural integrity or particle accumulation, they can be used for multiple transport cycles between facilities.