The semiconductor industry operates on margins where a single crack or a microscopic particle can cost thousands of dollars. As wafer sizes have standardized at 300mm for high-volume manufacturing, the challenges of transporting these large, fragile substrates have grown exponentially. This is particularly true during the back-end process, where wafers are thinned and mounted onto dicing frames. Here, the standard horizontal cassette is often insufficient. The solution for many top-tier fabs and packaging houses is the 12-inch Vertical Flex Frame Wafer Shipper.

Packaging engineers and logistics managers know that moving wafers between facilities is the most vulnerable point in the production line. Vibration, shock, and static electricity are constant threats. Hiner-pack has observed a significant shift in the industry away from generic packaging toward specialized shipping containers designed to mitigate these specific risks.

This article examines why this specific shipping configuration is becoming the gold standard for 300mm wafer logistics, how it preserves yield, and what features define a high-quality shipping solution.

The Shift from Horizontal to Vertical Shipping

Historically, coin-stack (horizontal) shipping was common for smaller wafer sizes. However, as the industry moved to 300mm (12-inch) wafers, gravity became a complex variable. In a horizontal stack, the weight of the upper wafers can cause stress on the lower ones, even with spacers. Furthermore, when wafers are mounted on flex frames (dicing rings), the tape and the frame add variables that make horizontal stacking unstable.

The 12-inch Vertical Flex Frame Wafer Shipper solves this by rotating the orientation. By aligning the frames vertically, the weight of the wafer is supported by the rigid metal frame rather than the silicon itself.

This orientation minimizes the surface area contact on the wafer face. For sensitive devices with exposed topography or bumps, vertical shipping is not just a preference; it is an engineering necessity to prevent die damage.

Material Science and ESD Protection in the 12-inch Vertical Flex Frame Wafer Shipper

A shipping box is only as good as the material it is molded from. In the world of semiconductors, standard plastic is unacceptable due to outgassing and static buildup.

Hiner-pack utilizes advanced polymer blends to construct their shippers. The primary concern is Electrostatic Discharge (ESD). A 300mm wafer traveling across the globe experiences friction. Without a conductive or static-dissipative path, this friction builds a charge that can blow out sensitive gates on the chip.

High-quality shippers use carbon-loaded polypropylene or polycarbonate materials. These materials ensure that any charge generated is safely grounded when the box is placed on a workstation. The material must also be low-outgassing. Volatile Organic Compounds (VOCs) released from cheap plastics can form a haze on the wafer surface, leading to defects during wire bonding or flip-chip assembly.

The Importance of the Inner Cassette Design

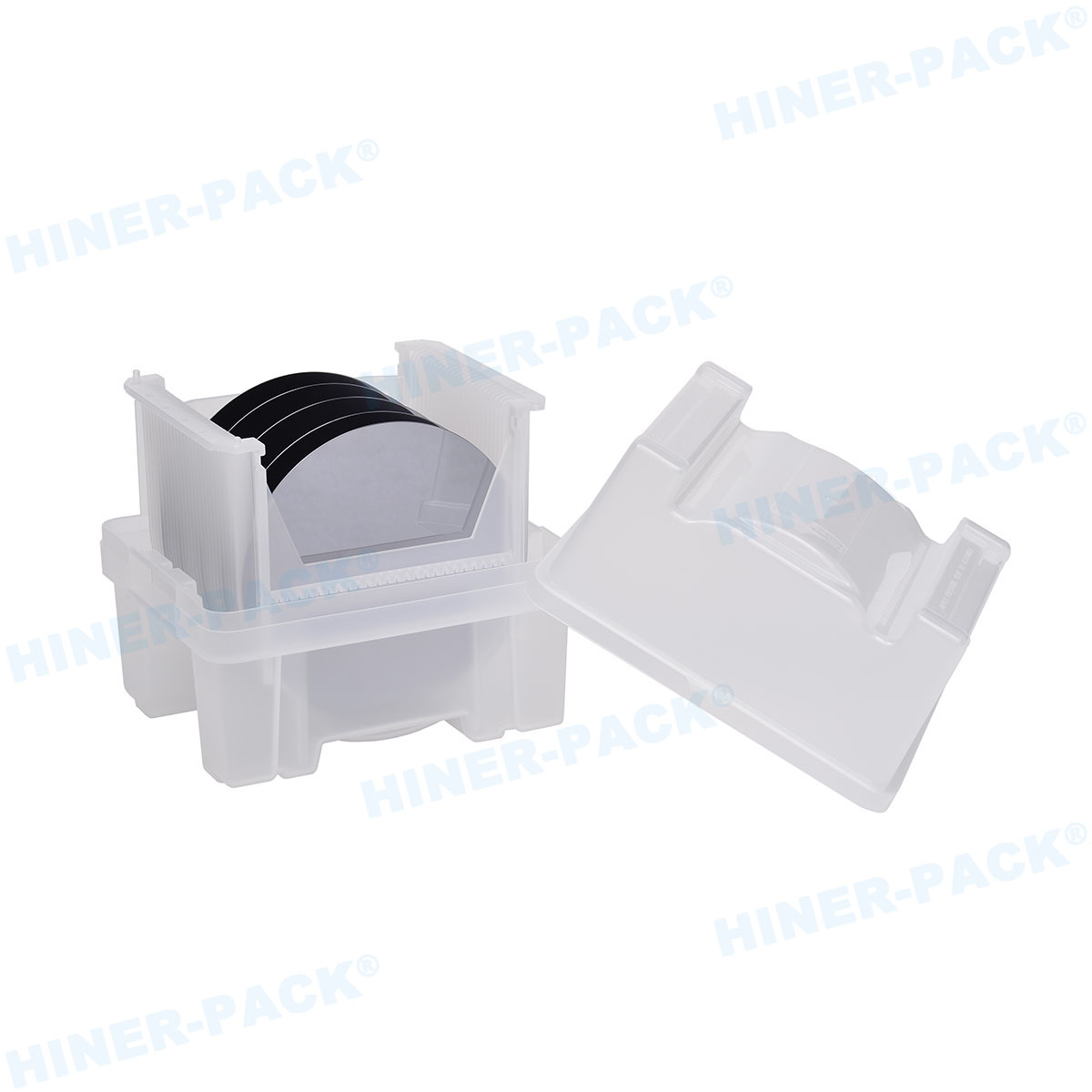

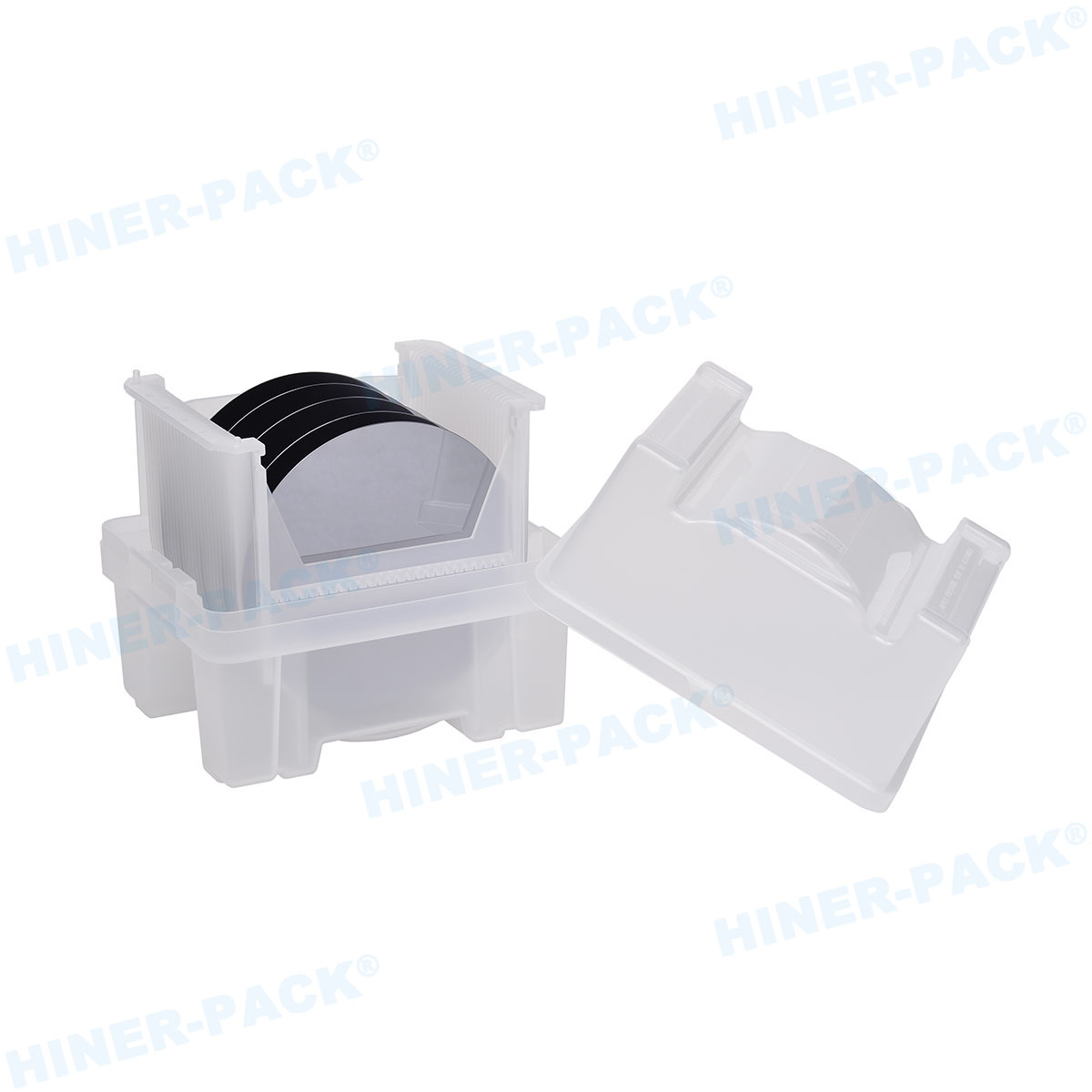

The outer box provides the armor, but the inner cassette provides the cushion. The 12-inch Vertical Flex Frame Wafer Shipper usually consists of two main parts: the outer container and the internal insert (or cassette) that holds the frames.

Precision molding is critical here. The slots in the cassette must be tight enough to hold the metal frame securely, preventing "chatter" or rattling during transport. However, they cannot be so tight that they generate particles during insertion and removal.

Hiner-pack engineers focus heavily on the "lead-in" design of these slots. A smooth, chamfered lead-in guides the operator or robot to insert the frame without scraping the sides, which is the number one source of plastic particle contamination in shipping boxes.

Handling Thinned Wafers and Dicing Frames

The back-end process involves grinding wafers down to mere microns in thickness. A thinned 12-inch wafer is as flexible as a piece of paper and incredibly brittle. Once mounted on a dicing frame, it relies entirely on the frame’s tension for stability.

If a shipper allows the frame to flex or twist, the thinned silicon will shatter. The 12-inch Vertical Flex Frame Wafer Shipper is designed with rigid sidewalls that lock the dicing frame in place.

Unlike bare wafer shippers (FOSB/FOUP), flex frame shippers must accommodate the geometry of the metal ring (typically Disco or DTF standard). The spacing between slots is also wider than a standard FOUP to ensure the dicing tape, which may sag slightly, never touches the adjacent wafer.

Automation and AMHS Compatibility with the 12-inch Vertical Flex Frame Wafer Shipper

Modern fabs are increasingly automated. While shipping boxes are often handled manually at the receiving dock, they frequently interface with Automated Material Handling Systems (AMHS) or robotic transfer units once inside the cleanroom.

The dimensional tolerances of the 12-inch Vertical Flex Frame Wafer Shipper must meet international standards. If a shipper is warped by a millimeter, a robotic gripper might fail to latch, causing a tool alarm or, worse, a drop.

Hiner-pack ensures that the external features of the shipper—handles, stacking ridges, and latch locations—are consistent. This allows for seamless integration into automated packing and unpacking lines, reducing the need for human intervention and the associated risk of human error.

Sealing Mechanisms and Contamination Control

Shipping involves trucks, airplanes, and customs warehouses—environments that are far from ISO Class 1 cleanrooms. The seal on the shipper is the only barrier between the wafer and the outside world.

A superior 12-inch Vertical Flex Frame Wafer Shipper utilizes a gasket system or a precision-molded tortuous path seal. This prevents ambient dust and moisture from entering the box.

Moisture is a particular enemy during air freight. The temperature changes in an aircraft cargo hold can cause condensation. Hiner-pack designs shippers with pressure relief valves or breathable membranes that equalize pressure without letting in humidity or particulates. This creates a micro-environment that keeps the wafers stable throughout the journey.

Cost Efficiency and Reusability of the 12-inch Vertical Flex Frame Wafer Shipper

For many companies, the initial cost of packaging is a line item to be minimized. However, smart logistics managers look at the Total Cost of Ownership (TCO).

A cheap, single-use shipper might save money upfront, but if it causes a 0.5% yield loss due to breakage, the cost is astronomical. Furthermore, the industry is moving toward sustainability.

Hiner-pack promotes the use of durable shippers designed for a closed-loop logistics cycle. These shippers can be sent to a customer, emptied, cleaned, and returned for reuse. Durability is key here. The hinges and latches must withstand hundreds of opening and closing cycles without snapping. A high-quality 12-inch Vertical Flex Frame Wafer Shipper is an asset, not a disposable consumable.

Testing Standards: Drop Tests and Vibration

How do you know a shipper will work before you trust it with $50,000 worth of silicon? You test it to destruction.

Reputable manufacturers subject their designs to rigorous ISTA (International Safe Transit Association) testing protocols. This includes rotational drop tests, random vibration testing simulating truck transport, and compression testing.

When evaluating a 12-inch Vertical Flex Frame Wafer Shipper, engineers should ask for the data on "g-force transmission." Good design dampens the energy from a drop. If the box hits the ground, the internal cassette should "float" or absorb the impact, ensuring the g-force transferred to the wafer remains below the critical fracture threshold.

The Role of Branding and Identification

In a busy logistics hub, boxes can get mixed up. Clear identification is part of the safety protocol.

The Hiner-pack design incorporates large, flat areas for labeling and barcoding. RFID tag integration is also becoming a standard feature. This allows logistics teams to track the specific location of a batch of wafers in real-time.

Furthermore, color-coding the latches or the box itself can help operators distinguish between different product types or destination fabs, adding another layer of procedural safety.

Why Hiner-pack is a Leader in the 12-inch Vertical Flex Frame Wafer Shipper Market

The market for semiconductor packaging is crowded, but Hiner-pack has distinguished itself through attention to detail. They understand that a shipper is not just a box; it is an engineering tool.

Their approach to the 12-inch Vertical Flex Frame Wafer Shipper involves constant feedback from fab managers. They address common pain points such as difficult-to-open latches that cause operator strain, or internal slots that become abrasive over time.

By focusing on the specific needs of the 300mm back-end process, Hiner-pack delivers a product that protects both the physical integrity of the wafer and the profitability of the manufacturing line.

The transition to 300mm wafers has brought immense efficiency to chip manufacturing, but it has also elevated the risks associated with transport. The 12-inch Vertical Flex Frame Wafer Shipper is no longer an optional accessory; it is a critical component of the supply chain.

From ESD protection and material purity to mechanical stability and automation compatibility, every aspect of these shippers plays a role in preserving yield. Companies like Hiner-pack are setting the standard, proving that investment in high-quality logistics hardware pays dividends in product quality and customer satisfaction.

As chips become more complex and wafers become thinner, the reliance on robust, vertical shipping solutions will only increase. Ensuring you have the right partner for your packaging needs is the first step in securing your silicon’s journey.

Frequently Asked Questions (FAQ)

Q1: What is the typical capacity of a 12-inch Vertical Flex Frame Wafer Shipper?

A1: Most standard vertical shippers for 300mm flex frames are designed to hold 13 frames. However, configurations can vary depending on the specific manufacturer and the pitch (spacing) required between the frames to ensure safety for taller components or bumps on the wafer.

Q2: Can Hiner-pack shippers be cleaned and reused?

A2: Yes, the materials used in high-quality shippers, such as polycarbonate or specialized polypropylene, are designed to withstand chemical cleaning and ultrasonic washing. This makes them suitable for closed-loop shipping programs where the boxes are returned, cleaned, and reused multiple times.

Q3: Does the 12-inch Vertical Flex Frame Wafer Shipper prevent ESD damage?

A3: Absolutely. These shippers are manufactured using static-dissipative or conductive materials. This ensures that any electrostatic charge generated during transport or handling is safely grounded, preventing damage to the sensitive electronic structures on the wafer.

Q4: Is this shipper compatible with all types of dicing frames?

A4: While they are designed for standard 300mm (12-inch) dicing frames (such as industry-standard Disco frames), it is always recommended to check the specific dimensions. Hiner-pack designs their cassettes to accommodate the most common international frame standards used in back-end packaging.

Q5: Why is vertical shipping better than horizontal for flex frames?

A5: Vertical shipping prevents the weight of stacked frames from pressing down on the wafers below. Since flex frames hold wafers on a suspended tape, horizontal stacking can cause the tape to sag and the wafers to touch, leading to scratches or die breakage. Vertical orientation utilizes the rigidity of the metal frame for support.