In the fast-evolving world of semiconductor manufacturing, the spotlight often falls on large 12-inch silicon wafers. However, a quiet revolution is happening in the 100mm (4-inch) sector. This size remains the workhorse for high-value compound semiconductors like Silicon Carbide (SiC) and Gallium Nitride (GaN), as well as specialized MEMS devices. Because these substrates are significantly more expensive and fragile than standard silicon, the logistics of moving them has changed. The industry is moving away from traditional coin-stack methods in favor of the 4-inch Vertical Wafer Shipper.

Process engineers and logistics managers are realizing that legacy packaging methods are no longer sufficient for modern yield requirements. A single scratch on a SiC wafer can cost thousands of dollars, making the shipping container a critical line of defense. Brands like Hiner-pack have stepped in to fill this gap, offering precision-engineered solutions that prioritize wafer safety during global transit.

This article details the engineering necessity of vertical shipping for 100mm substrates, the material science behind the containers, and why this specific configuration is saving fabs millions in yield losses.

The Resurgence of 100mm Substrates and the Need for a 4-inch Vertical Wafer Shipper

For decades, the industry assumed 4-inch production lines would fade away. Instead, the demand for power electronics in electric vehicles (EVs) and 5G RF amplifiers has revitalized this wafer size.

Unlike silicon, SiC and GaN are incredibly hard yet brittle. They do not handle shock well. Traditional horizontal "coin-stack" shipping boxes rely on spacers and the wafers stacking on top of one another. For standard silicon, this was acceptable. For compound semiconductors, the weight of the stack combined with vibration can cause micro-fractures.

The 4-inch Vertical Wafer Shipper eliminates this compressive stress. By orienting the wafers vertically, each substrate sits in its own slot. The weight is borne by the cassette rails, not the wafer surface. This separation is crucial for substrates that have sensitive top-side structures or backside metalization that scratches easily.

Hiner-pack has analyzed shipping data and found that vertical orientation significantly reduces "chatter"—the subtle movement of wafers inside the box that creates particle contamination.

The Problem with Horizontal Stacking for MEMS

Micro-Electro-Mechanical Systems (MEMS) present a unique challenge that makes horizontal shipping dangerous. MEMS devices often have moving parts or suspended structures.

When these wafers are stacked horizontally, the slight flexing of the box during transport can compress the stack. If a spacer shifts, it can touch the active area of the MEMS device, causing "stiction" or immediate breakage of the mechanical structures.

Vertical shipping isolates each wafer. There is no load transfer from wafer to wafer. This makes the vertical shipper the only viable option for transporting finished MEMS wafers to packaging houses.

Material Science: ESD Control in the 4-inch Vertical Wafer Shipper

The geometry of the box is important, but the material it is made from is critical. Static electricity is a silent killer in semiconductor logistics.

A 4-inch wafer moving inside a plastic box generates friction. This triboelectric effect can build up a charge of several thousand volts. If that charge discharges into the wafer, it can fuse the microscopic circuitry.

High-quality shippers, such as those manufactured by Hiner-pack, utilize advanced carbon-loaded polymers or inherently static-dissipative (IDP) materials. These materials provide a controlled path for the charge to bleed off to the ground when the operator sets the box on a grounded workstation.

Standard plastics also suffer from outgassing. Volatile organic compounds (VOCs) released by cheap plastic can form a haze on the wafer surface. For optical devices or sensors often built on 4-inch wafers, this haze is catastrophic. Hiner-pack ensures low-outgassing characteristics in their polymer blends to maintain the chemical purity of the wafer surface.

Structural Integrity and Shock Absorption

Shipping a wafer from a fab in Europe to a packaging facility in Asia involves trucks, forklifts, and airplanes. The 4-inch Vertical Wafer Shipper must act as a shock absorber.

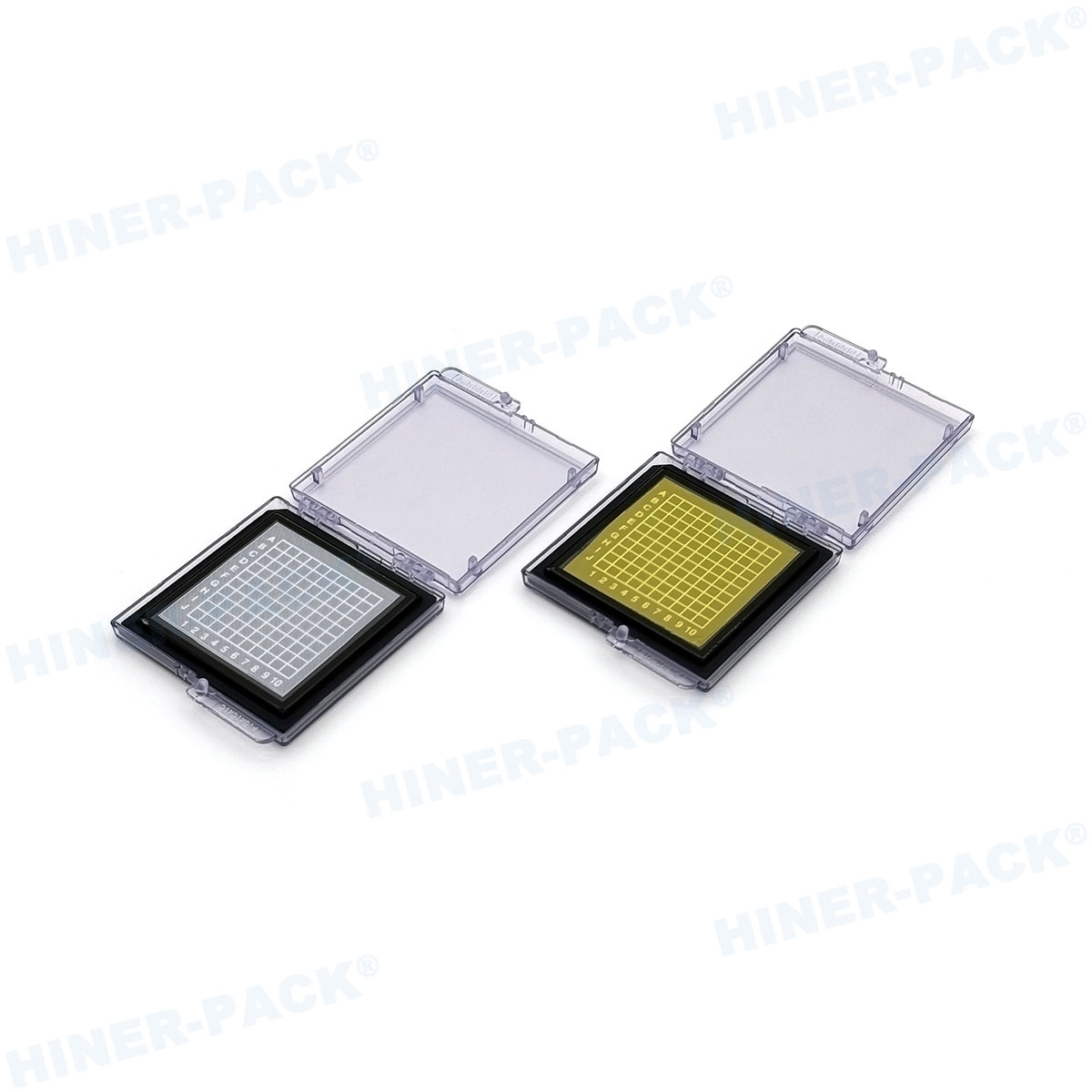

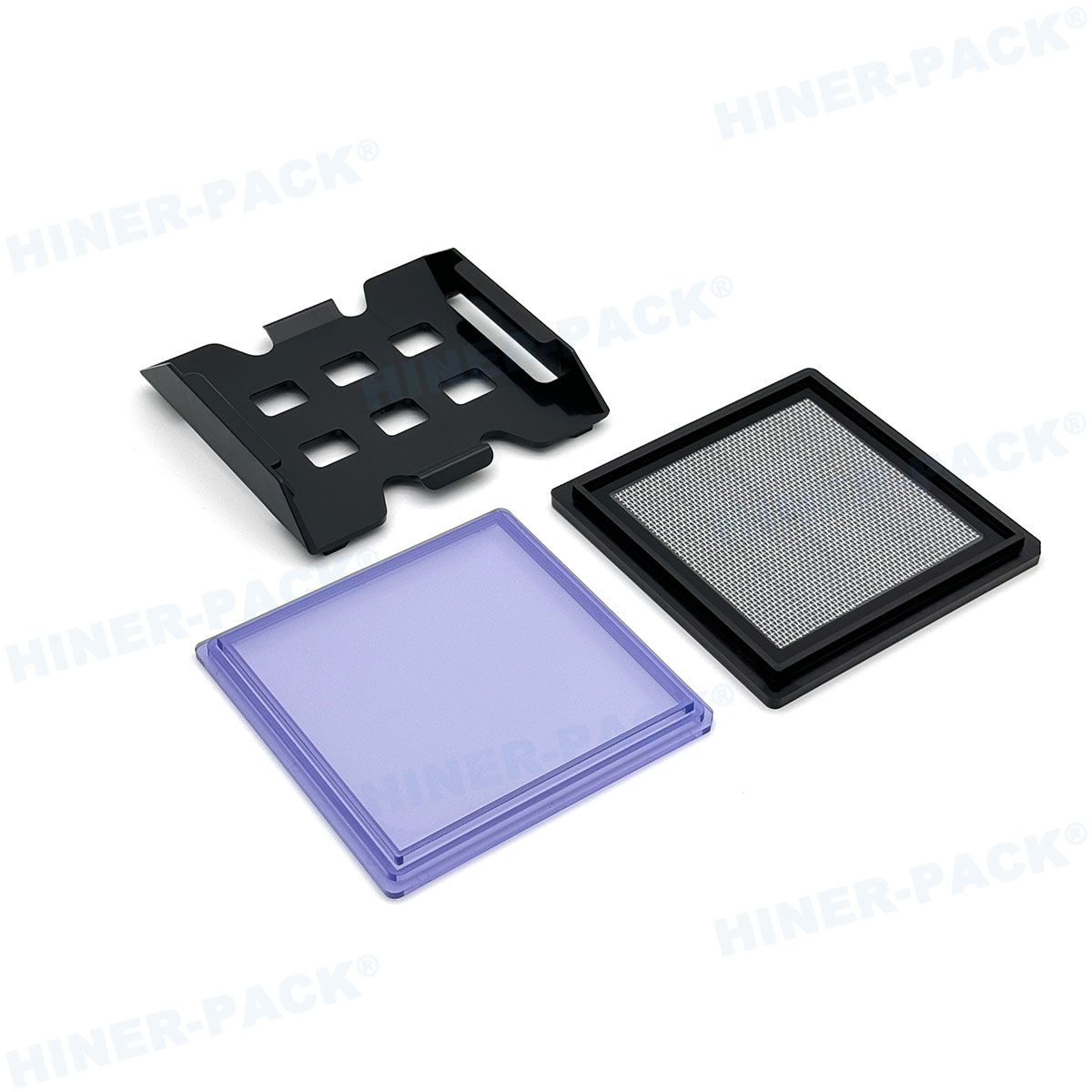

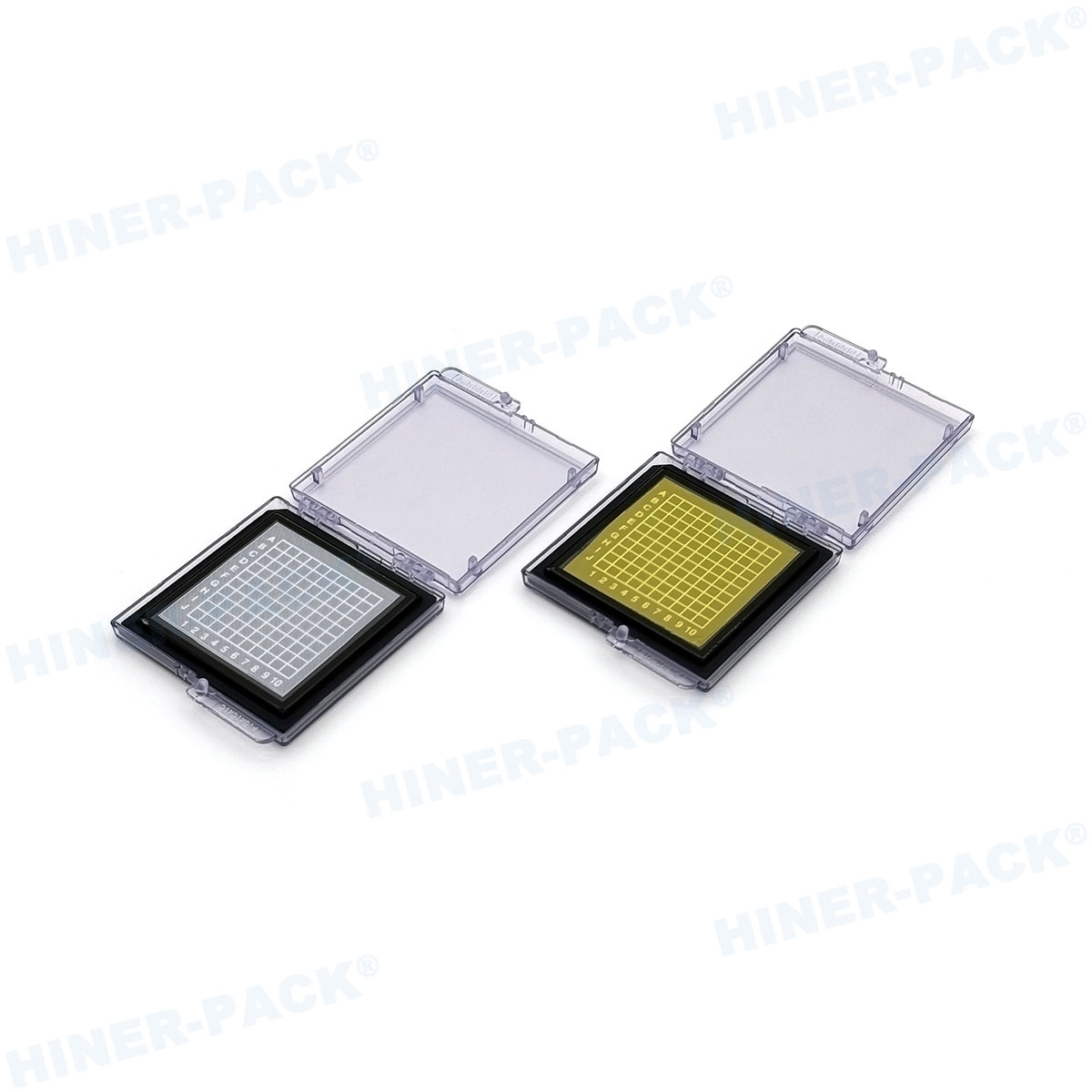

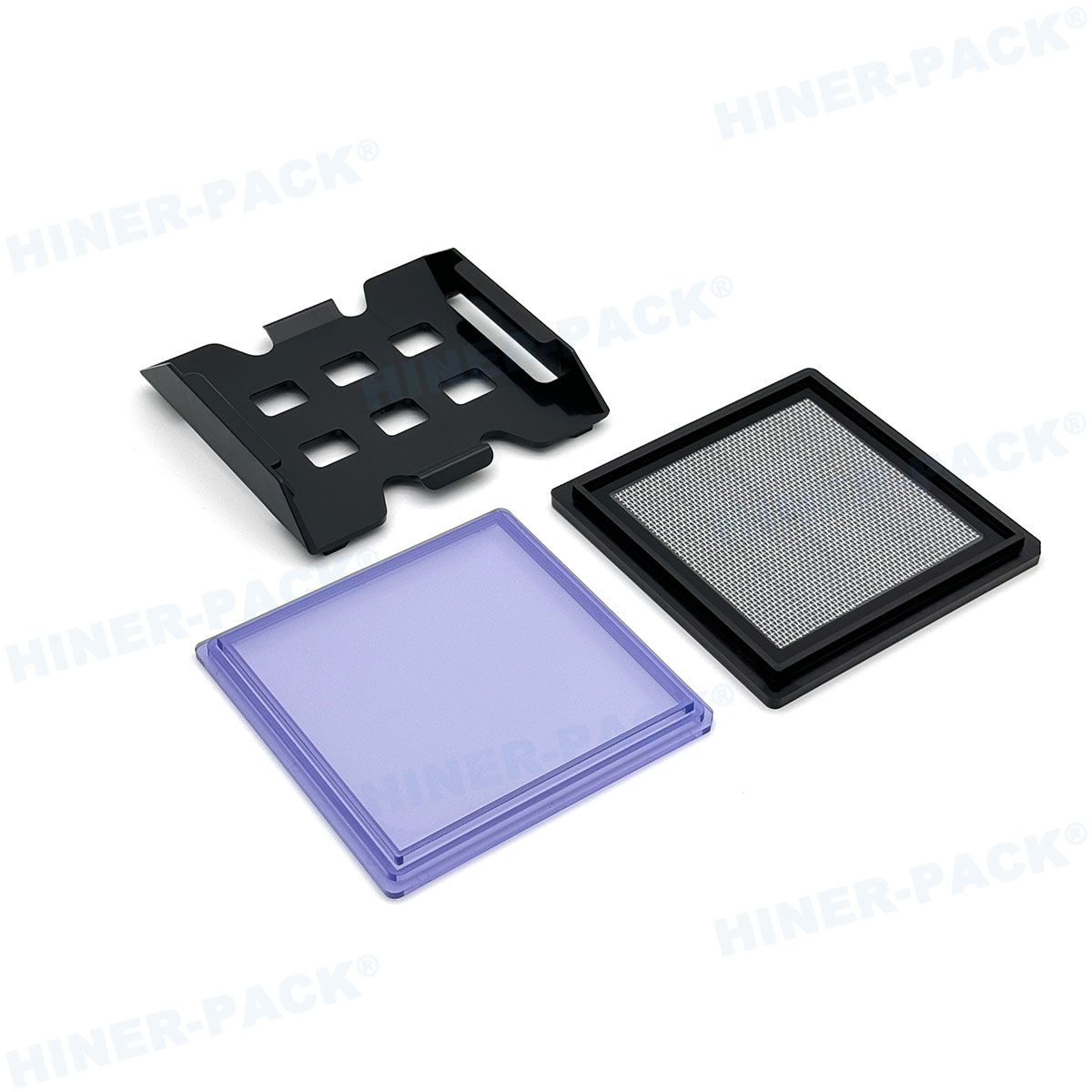

The design typically involves a two-part system: an internal cassette and an external containment box. The internal cassette holds the wafers rigidly. The external box provides a buffer zone.

The spacing between the cassette and the outer wall is often engineered to flex slightly upon impact. If the box is dropped, the outer shell absorbs the kinetic energy, dampening the g-forces before they reach the fragile silicon or SiC.

Hiner-pack engineers focus heavily on the locking mechanism. The latch must remain secure during the vibration of a truck engine but be easy enough for an operator to open without struggling. A latch that snaps open too violently can jar the wafers inside, defeating the purpose of the safe design.

Automation Compatibility of the 4-inch Vertical Wafer Shipper

Modern 100mm fabs are upgrading their legacy tools to include more automation. While not as fully automated as 300mm fabs, there is a push to reduce manual handling.

A vertical shipper functions similarly to a standard process cassette. This allows for easier integration with robotic arms and transfer tools. An operator can place the open cassette onto a load port, and a robot can map the wafers.

In contrast, horizontal stack shippers require manual unpacking. An operator must use vacuum tweezers to lift each wafer and spacer individually. This manual process is slow and introduces a high risk of human error. Using a vertical shipper streamlines the receiving process at the assembly and test facility.

Dimensional stability is key here. If the plastic warps over time, the robot will fail to find the slot. Hiner-pack utilizes reinforced ribs in their mold designs to ensure the cassette maintains its strict dimensional tolerances even after years of use.

The Role of the Retainer Bar

In a vertical shipper, the wafers sit in slots. But what keeps them from bouncing up and down? This is the job of the retainer bar or cushion.

Inside the lid of the 4-inch Vertical Wafer Shipper, there is usually a molded component that presses gently against the top edge of the wafers when the box is closed.

This component must be precise. If it presses too hard, it cracks the wafer. If it is too loose, the wafers rattle. The best designs use an elastomeric material or a flexible plastic spring mechanism.

Hiner-pack designs this interface to contact only the very edge of the wafer exclusion zone (usually the outer 3mm). This ensures that even if there is friction, it happens in a non-active area of the die.

Cost Considerations and ROI

Switching from coin-stack to vertical shippers is an investment. Vertical shippers are generally more expensive to manufacture due to the complexity of the molds and the volume of material used.

However, the Return on Investment (ROI) is calculated based on yield. If a vertical shipper saves just one SiC wafer from breaking, it effectively pays for a crate of boxes.

Furthermore, these boxes are designed for reusability. A single-use horizontal box is trash after one trip. A robust vertical shipper can be returned, washed, and reused dozens of times. Hiner-pack supports this closed-loop ecosystem by offering durable latches and hinges that withstand repeated cycling.

Cleaning and Maintenance

Because these shippers are reused, they must be washable. The complex geometry of a vertical cassette, with its many slots, can trap particles if not designed correctly.

Good engineering mandates a "flow-through" design. The slots should have drainage holes or open bottoms to allow water and air to pass through during the washing and drying process.

If moisture remains trapped in a slot, it creates a humidity microclimate that can corrode the aluminum bond pads on a wafer during storage. Hiner-pack pays close attention to the hydrophobicity of the material to ensure quick drying.

Adapting the 4-inch Vertical Wafer Shipper for Thinned Wafers

Back-end processing often involves thinning wafers to reduce the package profile or improve heat dissipation. A thinned 4-inch wafer is flexible and terrifyingly brittle.

Standard cassettes are often too wide for thinned wafers, allowing them to lean over. Specialized vertical shippers have tighter slot tolerances or use supports that prevent the wafer from warping under its own weight.

For wafers mounted on film frames, the design changes slightly, but the vertical principle remains. The shipper must grip the metal frame, not the wafer. However, for bare thinned wafers, the 4-inch Vertical Wafer Shipper provides a rigid exoskeleton that makes handling these flimsy discs safe.

Environmental Impact and Sustainability

The semiconductor industry is under pressure to reduce its carbon footprint. Logistics plays a part in this.

By moving to durable, reusable vertical shippers, fabs reduce the amount of plastic waste generated. The "cradle-to-grave" analysis of a Hiner-pack shipper shows a lower environmental impact compared to using hundreds of disposable foam and cardboard horizontal packs over the same period.

Additionally, the improved packing density of modern vertical designs allows for efficient palletization, optimizing air freight volume and reducing the carbon emissions per wafer shipped.

Labeling and Traceability

In a busy logistics hub, identifying the contents of a box without opening it is vital. The exterior of the shipper must accommodate large labels, barcodes, and increasingly, RFID tags.

Hiner-pack integrates recessed areas for labels so that they don't scrape off when boxes are slid next to each other. Color-coding is another feature. Using different colored latches or bodies can visually signal the status of the wafers (e.g., Red for scrap, Green for prime, Blue for test).

Traceability ensures that if a box is subjected to a shock event, the history can be traced back to the specific logistics provider and time.

Why Hiner-pack Stands Out

The market for wafer shipping is niche, but competition is fierce regarding quality. Hiner-pack has established itself by focusing on the specific pain points of the 100mm market.

They understand that 4-inch is no longer just for "low-tech" chips. It is the foundation of the power revolution. Their 4-inch Vertical Wafer Shipper is built with the understanding that the contents might be worth more than the truck carrying them.

From the chamfered lead-ins on the slots that prevent scratching during insertion, to the ergonomic handles that reduce operator fatigue, the design choices reflect a deep understanding of fab operations.

The shift towards vertical shipping for 100mm wafers is not a trend; it is a technical correction. As the value of wafers increases with the adoption of SiC and GaN, the risks of horizontal stacking become unacceptable.

The 4-inch Vertical Wafer Shipper offers a secure, clean, and automation-friendly environment for these critical substrates. It mitigates the risks of vibration, ESD, and human error.

Companies like Hiner-pack are enabling this transition by providing high-quality, durable, and precisely engineered shipping solutions. For any fab manager looking to protect their yield during the most vulnerable part of the manufacturing cycle—transportation—the vertical shipper is the only logical choice.

Frequently Asked Questions (FAQ)

Q1: What is the main advantage of a 4-inch Vertical Wafer Shipper over a coin-stack box?

A1: The primary advantage is the elimination of direct surface contact between wafers. In a vertical shipper, wafers are supported by their edges in individual slots, preventing the weight of the stack from causing scratches, micro-fractures, or particle contamination, which is critical for brittle materials like SiC.

Q2: Can Hiner-pack vertical shippers be used for thinned wafers?

A2: Yes, but it depends on the thickness. Standard vertical shippers are excellent for standard thickness wafers. For ultra-thinned wafers, Hiner-pack recommends specific models with tighter slot tolerances or reinforcement to prevent the flexible wafers from bowing or crossing slots during transport.

Q3: How many wafers does a standard 4-inch vertical shipper hold?

A3: The industry standard for a 4-inch vertical shipper is typically 25 wafers per cassette. This aligns with standard process lot sizes in most fabrication facilities, allowing for seamless transfer from the line to the shipping box.

Q4: Is the material of the shipper ESD safe?

A4: Yes, Hiner-pack manufactures these shippers using static-dissipative or conductive polymers (such as carbon-loaded polycarbonate or polypropylene). This ensures that static electricity does not build up and discharge into the sensitive components on the wafer.

Q5: Are these shippers single-use or reusable?

A5: The 4-inch Vertical Wafer Shipper is designed for reuse. It is built with durable materials that can withstand repeated mechanical handling and washing cycles. This makes it a cost-effective and environmentally friendly solution for closed-loop logistics between fabs and assembly houses.