Moving 200mm wafers safely is a critical task in semiconductor manufacturing and research. These substrates are valuable, fragile, and sensitive. Their safe passage between fabs, OSAT facilities, and research institutions hinges on one piece of equipment: the 8-inch Vertical Wafer Shipper.

Choosing the wrong container risks particle contamination, physical damage, and electrostatic discharge (ESD) events. These failures lead directly to yield loss and increased costs. This article discusses the essential features of a high-performance shipper. We focus on practical engineering and selection criteria for professionals.

The goal is to provide clear, actionable information. You will learn what separates a standard container from a truly reliable one.

Core Function and Design Philosophy

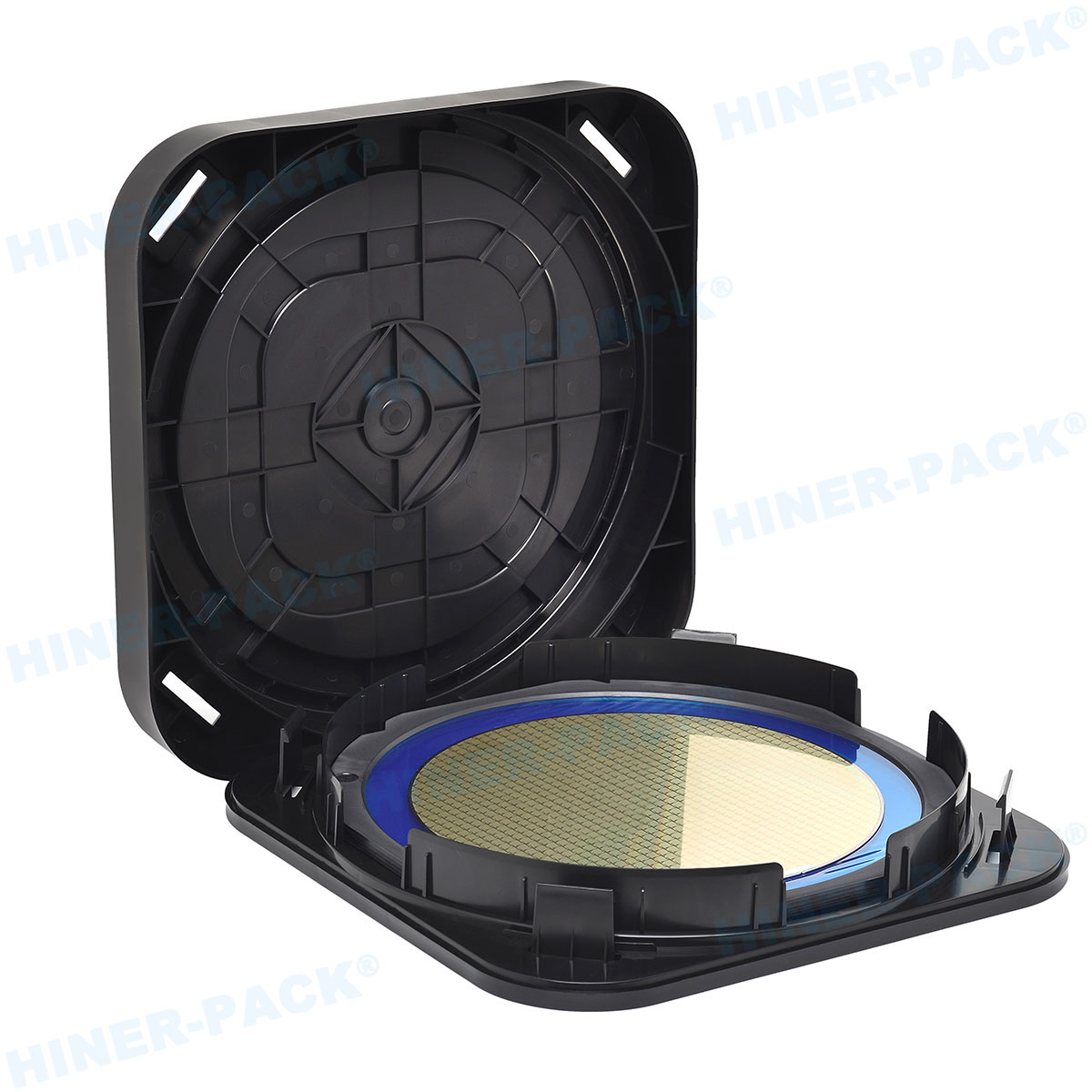

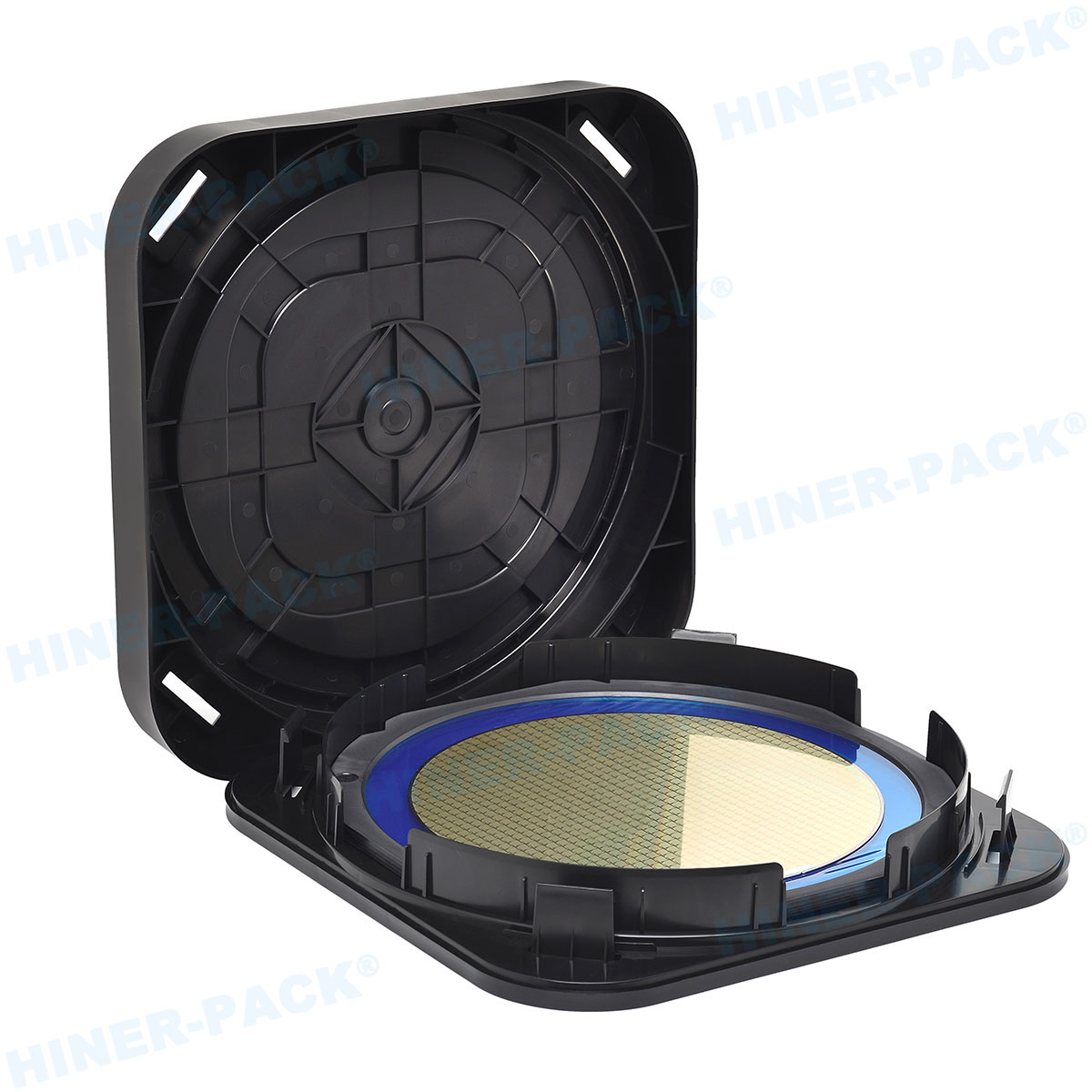

The primary job of an 8-inch Vertical Wafer Shipper is immobilization. Wafers must be held securely in a vertical position. This prevents surface contact and minimizes particle generation during transit.

The design is typically a two-part system. A polycarbonate or PFA wafer carrier sits inside a rugged outer shell. The carrier has precisely molded slots. These slots must grip the wafer's edge without excessive force.

A perfect fit eliminates movement. It also prevents stress points that could cause chipping or cracking. The outer shell provides structural integrity. It shields the inner carrier from the physical demands of shipping.

Material Selection: Purity and Durability

Materials are the foundation of performance. They must balance mechanical strength with chemical purity. Not all plastics are suitable for this environment.

High-quality, static-dissipative polycarbonate is common for shells. It offers excellent impact resistance. The static-dissipative property is non-negotiable. It safely controls ESD, protecting sensitive devices on the wafer.

For the inner carrier, especially for advanced processes, PFA (Perfluoroalkoxy) is often used. PFA exhibits extremely low levels of extractable ions and metals. It can withstand repeated aggressive cleaning cycles.

Companies like Hiner-pack use certified, cleanroom-grade polymers. Their materials are tested and validated to meet industry purity standards straight from production.

Advanced Contamination Control

Contamination is the enemy. A superior shipper is designed to be a clean environment itself. Every aspect must minimize particle generation and ingress.

Internal surfaces are smooth and free of texture. There should be no seams or cavities where particles can accumulate. The design follows a "clean by design" principle.

The sealing system is critical. Most robust shippers employ a dual-seal approach. A primary gasket on the door creates an airtight seal against the shell. This is often supplemented by a secondary, tamper-evident bag.

This bag maintains a neutral environment. It blocks external humidity, oxygen, and airborne molecular contamination. For long-distance travel, this is essential.

Mechanical and Environmental Protection

Logistics is rough. Packages face vibrations, sudden drops, and pressure changes. The shipper must be a fortress.

Good mechanical protection starts with design. Structural ribs reinforce the outer shell. Thickened corners absorb impact energy. The internal carrier must also act as a shock absorber.

Compliance with shipping standards is a key indicator. Look for testing certifications like ISTA 3A. This ensures the design has been proven against real-world parcel system hazards.

Pressure equalization is vital for air freight. Altitude changes can cause significant pressure differentials. A quality shipper includes a hydrophobic vent. This valve equalizes pressure without letting in moisture or contaminants.

Compliance and Interoperability

The 200mm ecosystem is built on standards. An effective 8-inch Vertical Wafer Shipper must align with them. This ensures smooth handling at both ends of the journey.

Key standards include SEMI E1.9 for 200mm wafer carriers. Compatibility with SMIF (Standard Mechanical Interface) pods is another important factor. This allows for automated loading and unloading at many facilities.

Using a standardized shipper reduces handling errors. It also simplifies operator training. It ensures the container will interface correctly with existing tools and racks.

The Total Cost of Ownership Perspective

The initial purchase price is just one factor. Smart procurement looks at the total cost of ownership (TCO).

A cheaper, less robust shipper may fail. The cost of losing a batch of wafers dwarfs the price of any container. Reliability is an investment, not an expense.

Consider durability. How many trips can it make? Hiner-pack designs shippers for hundreds of cycles. This spreads the cost over many shipments.

Factor in cleaning and maintenance. A well-designed shipper is easy to disassemble and clean. This reduces downtime and labor costs. Choosing a reputable supplier ensures long-term support and part availability.

Applications Across the Semiconductor Landscape

The use of these containers extends beyond simple fab-to-fab transport.

They are crucial for sending wafers to external processing houses. Examples include specialty lithography, epitaxy, or MEMS fabrication. They protect wafers during shipment to assembly and test (AT) sites.

In R&D, they enable secure collaboration. Universities and consortia use them to exchange samples. Their standardized nature is perfect for multi-partner projects.

They are also employed for secure, long-term wafer storage. In this role, their sealing integrity and material purity are just as important.

In summary, the 8-inch Vertical Wafer Shipper is a precision instrument. Its role in protecting valuable semiconductor inventory cannot be overstated. A meticulous selection process, focused on material science, mechanical design, and proven performance, is essential for supply chain integrity.

Frequently Asked Questions (FAQs)

Q1: What is the standard wafer capacity for an 8-inch shipper?

A1: The most common capacity for an 8-inch Vertical Wafer Shipper is 25 wafers. This aligns with standard front-opening unified pod (FOUP) and SMIF pod capacities for 200mm wafers, facilitating easy transfer. Carriers for 13 wafers are also available for smaller batches.

Q2: Can these shippers be used for both prime and reclaim wafers?

A2: Yes, they can. However, the required level of contamination control may differ. For prime wafers in advanced nodes, a shipper with a PFA carrier and full environmental sealing is recommended. For less sensitive reclaim wafers, a polycarbonate carrier might be sufficient. Always match the shipper's specs to the wafer's sensitivity.

Q3: How do I verify the integrity of the door seal before shipping?

A3: Perform a visual inspection every time. Check the gasket for any cuts, nicks, or permanent compression. Ensure it is clean and seated correctly. Many facilities also perform a simple "pull test" – a gentle manual check that the door is securely latched. For critical shipments, some use pressure decay leak testers for quantitative verification.

Q4: Are there specific labels or documentation required for shipping wafers internationally?

A4: Absolutely. Beyond standard shipping labels, you often need a detailed packing list and commercial invoice. It is crucial to include a Material Safety Data Sheet (MSDS) or Safety Data Sheet (SDS) for the shipper materials (especially the plastics and foams). Always check with your freight forwarder for the latest customs and safety regulations for electronics components.

Q5: How should I clean a Hiner-pack wafer shipper after use?

A5: Follow the manufacturer's cleaning protocol. Generally, disassemble the shipper completely. Clean the shell, door, and carrier separately using DI water and a mild, semiconductor-grade detergent in a dedicated sink or cleaning station. Rinse thoroughly with DI water. Dry all components in a clean, particle-controlled environment, such as a nitrogen dryer or cleanroom oven, before reassembly. Never use abrasive cloths or non-approved solvents.