In the highly orchestrated ballet of semiconductor fabrication, every component must perform with flawless precision. Among the most critical, yet sometimes overlooked, items is the wafer carrier. For mature but still vital process technologies, the 8-inch Wafer Cassette remains a cornerstone of production lines worldwide. This standardized container is far more than a simple plastic box; it is a first line of defense for high-value substrates, ensuring safe transport, storage, and processing of 200mm wafers. Its design directly impacts yield, cleanliness, and operational efficiency. Companies like Hiner-pack have refined this essential tool, engineering solutions that meet the rigorous demands of today’s fabs while supporting legacy equipment and processes.

Understanding the 8-inch Wafer Cassette: Design and Specifications

The standard 8-inch Wafer Cassette is engineered to hold twenty-five 200mm wafers. It conforms to strict SEMI (Semiconductor Equipment and Materials International) standards, ensuring interoperability across different manufacturers’ equipment.

Dimensions and spacing are precisely controlled. This prevents wafer contact, minimizes particle generation from sliding, and allows for smooth robotic handling.

Materials matter immensely. High-purity polycarbonate (PC) or polypropylene (PP) are common. These materials offer excellent cleanliness, static dissipation, and chemical resistance to common fab processing chemicals.

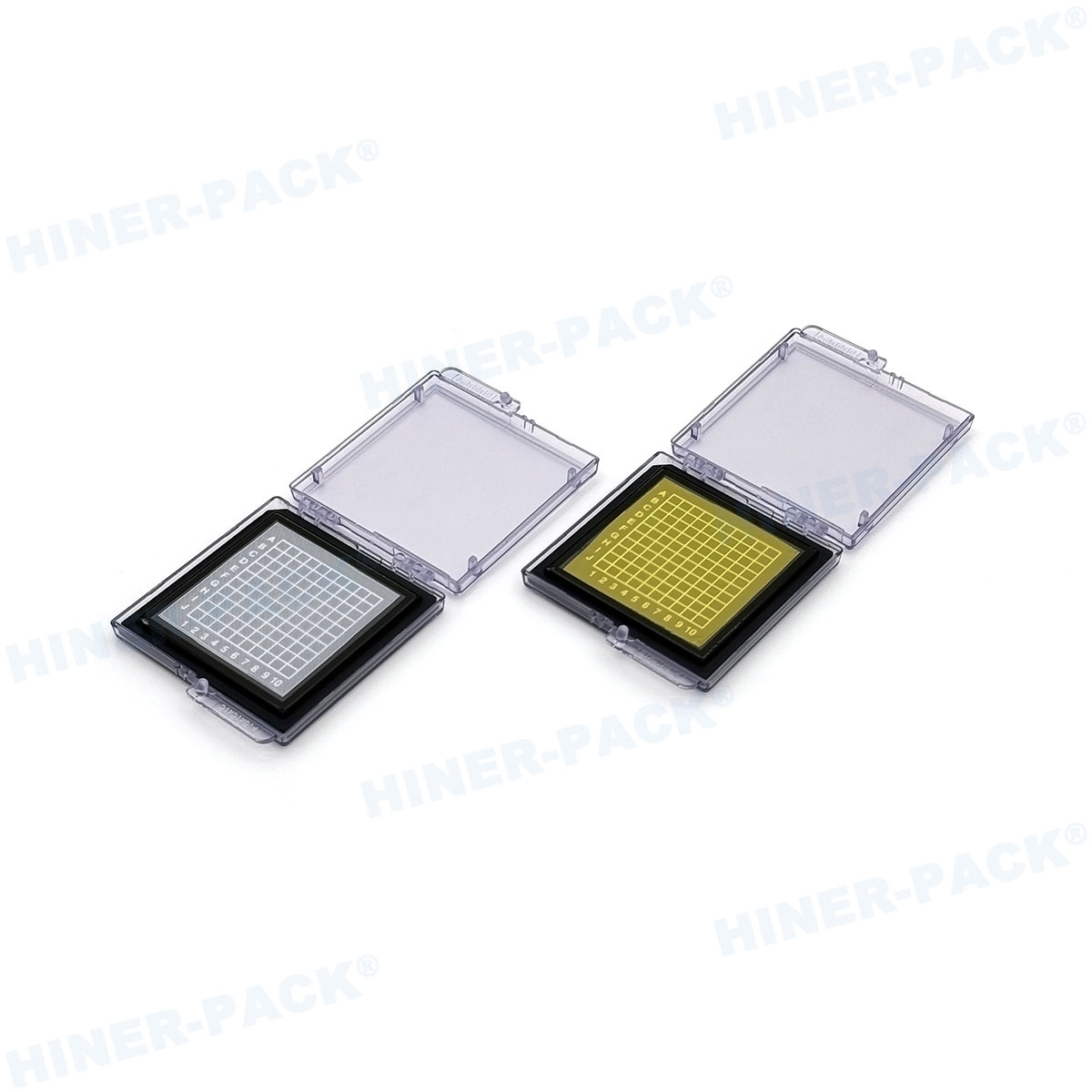

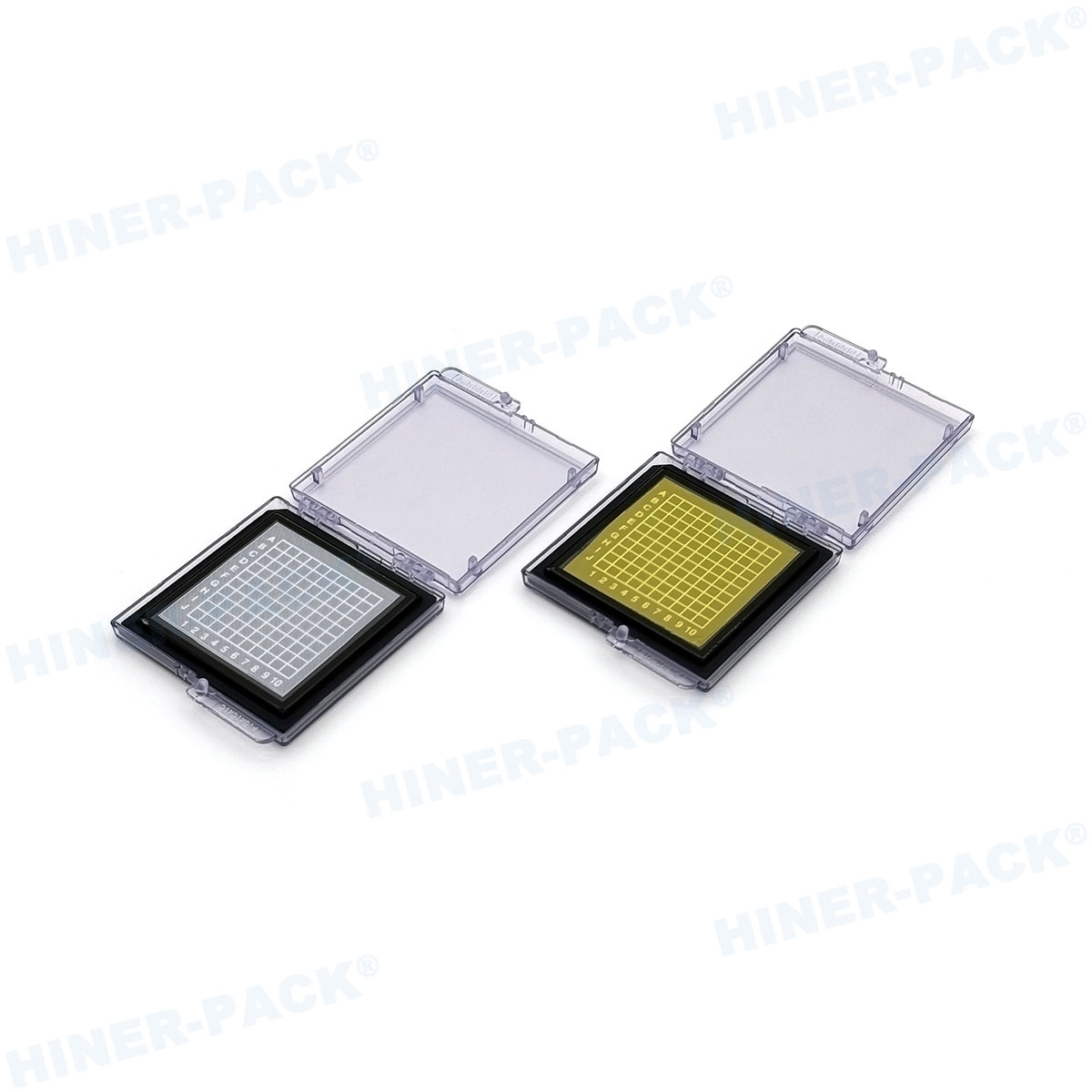

Structural integrity is non-negotiable. A robust cassette protects wafers from mechanical shock and vibration during intra-fab transport. Features like secure latching doors are essential for safe movement.

Key Applications in the 200mm Fab Ecosystem

While advanced nodes move to larger wawfers, 200mm fabs are thriving. They power markets for analog chips, power devices, MEMS, and sensors. The 8-inch Wafer Cassette is integral to this ecosystem.

It is used in front-opening unified pods (FOUPs) for certain tools. More commonly, it operates in open cassettes for wet benches, diffusion furnaces, and metrology stations. Its role begins at the wafer supplier and continues through the entire process flow.

Each cassette is tracked meticulously. Barcodes or RFID tags, often integrated into the cassette body, allow for precise wafer-level traceability. This links the physical carrier to the fab’s Manufacturing Execution System (MES).

Storage and logistics also depend on reliable cassettes. They stack safely in cleanroom carts and stockers, enabling efficient workflow and buffer management between process steps.

Selecting the Right Cassette: A Guide for Fab Engineers

Choosing a supplier is a critical decision. Not all cassettes are created equal. Fab managers and procurement specialists look for several key attributes beyond basic specifications.

Ultimate cleanliness is paramount. The best cassettes, like those from Hiner-pack, are manufactured in controlled environments. They undergo rigorous cleaning and packaging to ensure ultra-low particle counts out of the box.

Material consistency prevents contamination. High-grade polymers that resist outgassing are vital. This ensures no airborne molecular contamination (AMC) affects sensitive wafer surfaces during storage or transport.

Durability translates to cost of ownership. A cassette must withstand thousands of cycles through aggressive chemical baths, high-temperature furnaces, and robotic handling. Premium cassettes offer exceptional resistance to cracking, warping, and wear.

Ergonomic and safety features matter for operators. Smooth edges, clear visibility of wafers, and intuitive latching mechanisms reduce handling errors and improve workplace safety in the cleanroom.

Maintenance and Handling Best Practices

Even the best 8-inch Wafer Cassette requires proper care. Implementing strict handling protocols extends its life and protects wafer yield.

Regular cleaning schedules are mandatory. Cassettes used in wet processes must be cleaned to remove chemical residues and particles. Automated cassette washers are commonly employed in high-volume fabs.

Inspection is a continuous process. Operators and automated systems should check for signs of damage: cracks, discoloration, warping, or worn latch mechanisms. Damaged cassettes must be quarantined immediately.

Proper storage when not in use prevents deformation. Cassettes should be stored on designated racks in a clean environment, not stacked haphazardly.

Training cannot be overlooked. All personnel handling wafers must be trained on correct loading, unloading, and transport procedures to avoid costly wafer breakage or contamination events.

Why Hiner-pack Stands Out in Wafer Cassette Manufacturing

Hiner-pack has established a strong reputation in the niche of wafer carrier solutions. Their focus on the 8-inch Wafer Cassette exemplifies their approach to quality and customer partnership.

They employ advanced injection molding technology. This ensures dimensional precision and material purity from the very first production run to the ten-thousandth unit.

Hiner-pack invests in material science. Their proprietary polymer blends are tested for superior performance in specific fab environments, such as extreme pH or high-temperature stability.

A full-service approach sets them apart. They provide comprehensive cleaning, anti-static treatment, and vacuum-sealed packaging services. This delivers a fab-ready product, reducing the customer’s preparation workload.

Their global logistics network ensures reliable supply. In an industry where production pauses are catastrophic, Hiner-pack’s ability to deliver certified products on schedule is a critical value proposition.

In conclusion, the 8-inch Wafer Cassette is a fundamental enabler of semiconductor manufacturing. Its reliable, standardized design allows the global 200mm fab network to produce the chips essential for countless electronic devices. By partnering with experienced and quality-focused manufacturers like Hiner-pack, fabrication facilities can safeguard their productivity, protect their yields, and ensure the smooth flow of silicon through their critical production lines.

Frequently Asked Questions (FAQ)

Q1: How many wafers does a standard 8-inch Wafer Cassette hold?

A1: A standard open 8-inch Wafer Cassette is designed to hold twenty-five 200mm wafers. This capacity is defined by SEMI standards to ensure compatibility with automated handling equipment across different tool brands.

Q2: What materials are Hiner-pack’s 8-inch cassettes made from?

A2: Hiner-pack primarily uses high-purity, contamination-controlled polycarbonate and polypropylene compounds. These materials are selected for their excellent cleanroom compatibility, chemical resistance, mechanical strength, and static-dissipative properties to protect sensitive wafers.

Q3: Can 8-inch cassettes be used in fully automated material handling systems (AMHS)?

A3: Yes, when integrated into the appropriate carrier system. While open cassettes are often transferred manually or via rail vehicles between tools, they can be placed inside Front-Opening Unified Pods (FOUPs) or on standardized load ports that interface with overhead transport (OHT) systems for full automation.

Q4: How often should wafer cassettes be cleaned and inspected?

A4: The frequency depends on their use. Cassettes in high-particle or wet-process areas may require cleaning after every cycle or daily. A regular visual inspection for damage should occur with each use. Most fabs implement a formal, scheduled cleaning and qualification program based on their specific process contamination controls.

Q5: What are the key signs that an 8-inch Wafer Cassette needs to be replaced?

A5: Key warning signs include visible cracks or chips, permanent warping or deformation that affects wafer pitch, discoloration from chemical exposure, excessive wear on wafer slots causing particle generation, and malfunctioning or loose latch mechanisms. Any of these defects can pose a direct risk to wafer integrity and must trigger immediate replacement.