In the high-stakes world of semiconductor manufacturing, every component in the supply chain must perform flawlessly. The safe handling and transportation of delicate wafers and critical dies are paramount. Contamination, physical shock, or electrostatic discharge can result in catastrophic and costly losses. This is where specialized packaging becomes not just an accessory, but a critical component of your operational integrity. For engineers, procurement specialists, and logistics managers seeking reliable solutions, the decision to buy Gel Pak boxes is a strategic one directly impacting yield and bottom line. This article delves into the key considerations, applications, and specifications to guide your procurement process, focusing on the engineered solutions from industry provider Hiner-pack.

Why Your Fab Line Needs Specialized Gel Pak Boxes

Standard packaging is insufficient for semiconductor components. Wafers and bare dies require a controlled environment from the fab to assembly or testing facilities.

Gel Pak boxes provide a unique combination of secure cushioning and secure mounting. The custom-formulated, non-outgassing gel liner securely holds products in place without abrasive pressure.

This eliminates micro-shifting during transit, a primary cause of edge chipping and micro-cracks. Furthermore, high-quality boxes are designed for use in ESD-protected and cleanroom environments.

When you decide to buy Gel Pak boxes, you are investing in damage prevention. The reduction in transit-related losses often delivers an immediate return on investment. Protecting multi-thousand-dollar wafers demands packaging of equal reliability.

Key Features of Hiner-pack Gel Pak Boxes for Semiconductor Applications

Hiner-pack has developed its Gel Pak line with the precise needs of the semiconductor industry in mind. Understanding these features is crucial for making an informed purchase.

First is the gel formulation itself. Hiner-pack uses a clean, non-slump gel that maintains its tackiness and shape across a wide temperature range. It does not dry out or transfer residue onto the wafer backside.

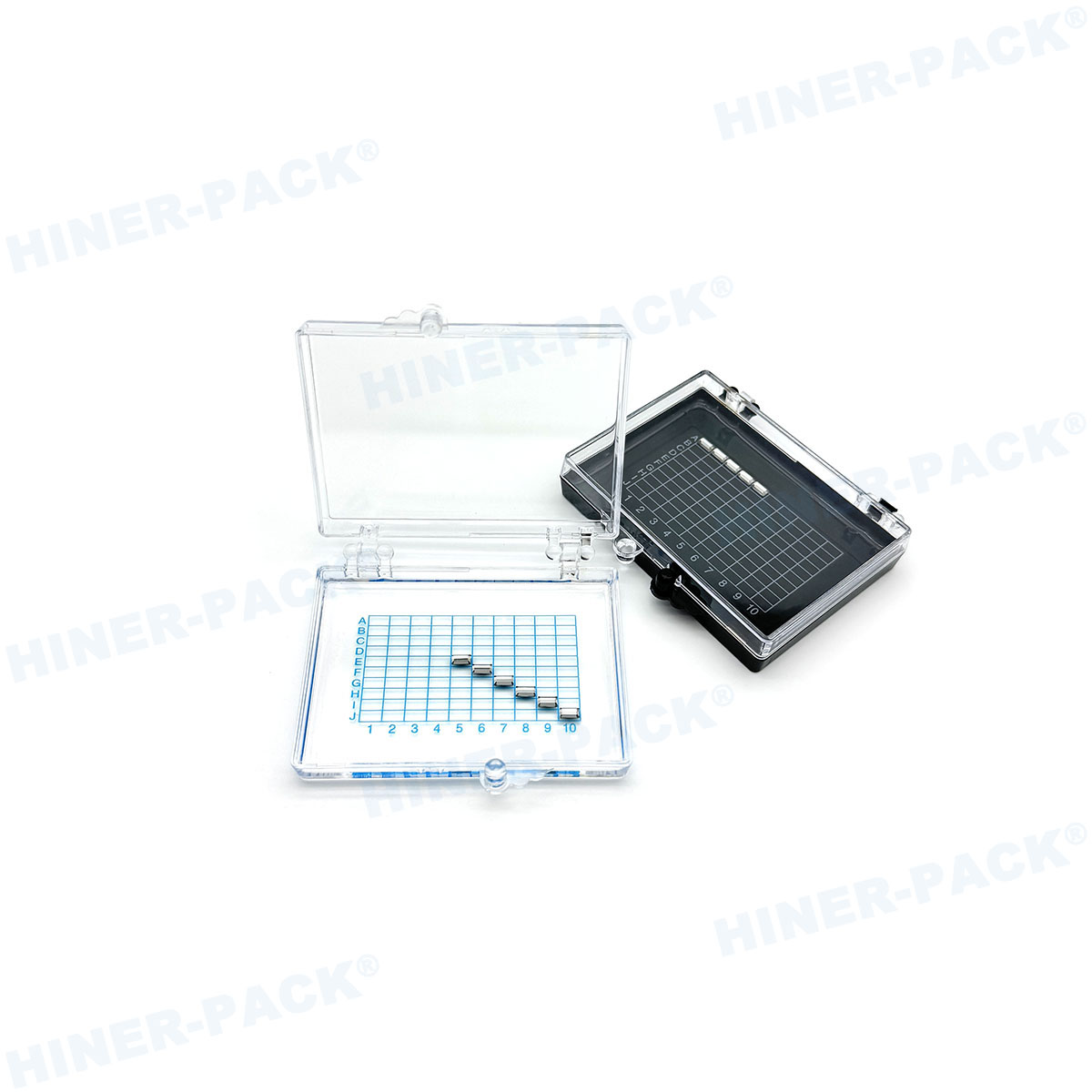

The box construction utilizes static-dissipative or conductive materials. This safely channels away any accumulated electrostatic charge, protecting sensitive devices from ESD events that can silently degrade performance.

Sealing is another critical factor. A secure, positive-latch lid ensures a particulate-free environment is maintained inside the box. This is vital for moving components between different cleanroom zones or external facilities.

Finally, durability is engineered in. The boxes are designed for hundreds of reuse cycles, withstand autoclaving or chemical cleaning, and feature clear labeling areas for track-and-trace protocols.

Selecting the Right Model: A Match for Your Wafer and Die Needs

Not all Gel Pak boxes are identical. The correct choice depends on your specific components. Hiner-pack offers a range of configurations to meet diverse requirements.

For whole wafers, rigid frame boxes with full-sheet gel liners are standard. They are available in sizes matching common wafer diameters (e.g., 150mm, 200mm, 300mm). The wafer lies flat against the uniform gel surface.

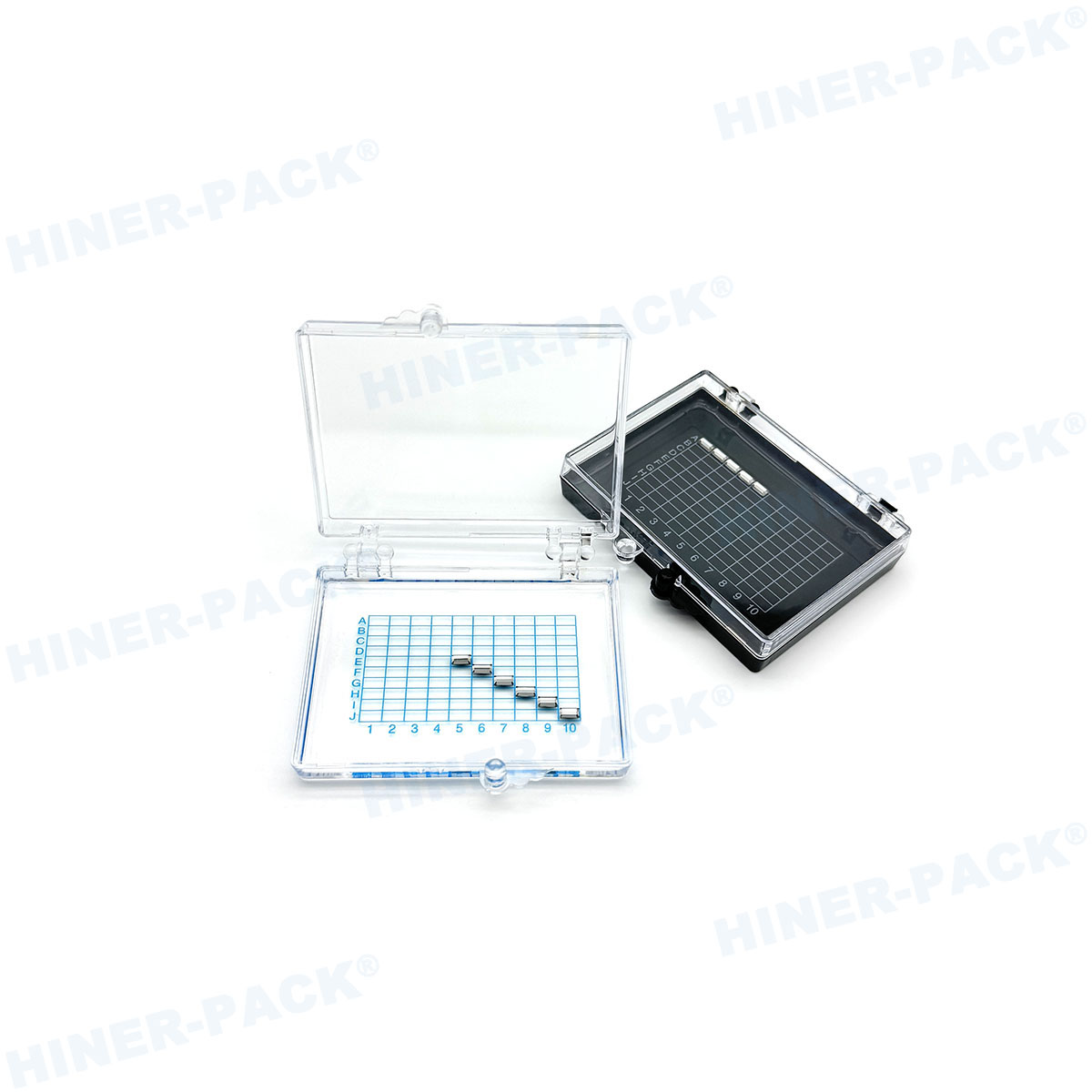

For singulated dies or smaller components, matrix-style boxes are essential. These feature pre-cut gel patterns or cavities that hold individual units securely in a defined grid. This organization prevents contact and simplifies automated pick-and-place.

Consider depth requirements. Deeper boxes allow for stacking or accommodate thicker, diced wafers on film frames. Shallow profiles are ideal for ultra-thin wafers.

Always verify the material compatibility. Hiner-pack’s materials are tested for low ionic contamination and outgassing, ensuring they won’t interfere with your most sensitive processes.

Integrating Gel Pak Boxes into Your Semiconductor Workflow

The utility of these boxes extends across multiple stages of production and logistics. Their role is integral to a smooth workflow.

In post-dicing, dies are often placed directly into a Gel Pak matrix from the expansion tape. This provides safe storage before shipment to assembly houses or customers.

For failure analysis or quality control, samples can be securely transported to lab facilities without risk of additional damage that could obscure the root cause.

They are also perfect for shipping small quantities of engineering samples or prototypes. The professional, secure presentation reflects well on your company’s attention to detail.

When you buy Gel Pak boxes from Hiner-pack, you enable a consistent, reliable handling method. This standardization reduces training time and handling errors across different teams and locations.

Maintenance, Longevity, and Total Cost of Ownership

A significant advantage of the Hiner-pack system is reusability. Proper care extends their service life dramatically, lowering the effective cost per shipment.

Cleaning protocols are straightforward. Using approved isopropyl alcohol or cleanroom wipes, the gel surface can be gently refreshed to restore tack and remove minute particles.

The boxes themselves can be washed with compatible solvents. Their robust design resists warping and latch fatigue. Periodically testing the surface resistivity ensures continued ESD protection.

Investing in a fleet of high-quality boxes eliminates the recurring cost and waste of disposable alternatives. It also supports sustainability initiatives within your fab.

Planning your procurement to include spare units ensures uninterrupted operations while boxes are undergoing cleaning or inspection cycles.

Conclusion: A Strategic Investment in Process Security

In an industry where precision defines success, the margin for error in logistics is zero. The packaging you choose is the last line of defense for valuable semiconductor components. It is a strategic element of your quality assurance program.

The decision to buy Gel Pak boxes from a trusted supplier like Hiner-pack is a commitment to operational excellence. It safeguards your products, reduces hidden costs from damage, and streamlines your material handling processes.

By focusing on quality gel formulation, ESD-safe construction, and application-specific design, Hiner-pack provides the reliable protection your wafers and dies require. Evaluate your current handling risks and consider how a robust packaging system can strengthen your supply chain from the inside out.

Frequently Asked Questions (FAQs)

Q1: Can Hiner-pack Gel Pak boxes be used in a Class 1 cleanroom environment?

A1: Yes. Hiner-pack designs its Gel Pak boxes with cleanroom compatibility as a priority. The materials are selected for low particulate generation and minimal outgassing, making them suitable for use in stringent cleanroom classifications common in semiconductor fabs.

Q2: How do I restore the tackiness of the gel if it appears to be diminishing?

A2: Surface tack can often be restored with gentle cleaning. Use a lint-free cleanroom wipe lightly dampened with high-purity isopropyl alcohol (IPA). Gently wipe the gel surface and allow it to fully air dry. The gel formulation is designed to maintain its properties, and this cleaning typically revives its holding power.

Q3: Are custom gel patterns or cavity layouts available for unique die sizes?

A3: Absolutely. Hiner-pack specializes in providing standard and custom solutions. If your die size or arrangement is not covered by standard matrix patterns, they can work with you to design and manufacture custom gel inserts that perfectly fit your specific components.

Q4: What is the expected lifecycle of a typical Hiner-pack Gel Pak box?

A4: With proper care and maintenance, including regular cleaning and avoidance of physical abuse, Hiner-pack boxes are engineered for hundreds of reuse cycles. The actual lifespan will depend on usage frequency and handling conditions, but their durability is a key part of their value proposition.

Q5: How do Hiner-pack boxes ensure protection against Electrostatic Discharge (ESD)?

A5: The boxes are constructed from static-dissipative or conductive materials. This creates a Faraday cage effect when closed, shielding the contents. The materials provide a safe path for static charges to dissipate without creating a high-voltage discharge that could damage sensitive semiconductor devices.