In the highly precise world of semiconductor manufacturing, every nanometer counts. The journey of a silicon wafer from a blank slate to a complex integrated circuit is a marvel of engineering, involving hundreds of intricate steps. While lithography scanners and etching tools often grab the headlines, there is a silent, unsung hero ensuring this delicate journey happens flawlessly: the wafer shipper for automated systems. This critical piece of packaging is far more than just a box; it is the vital link in the automated supply chain that protects multi-million dollar wafer inventories. This article explores the evolution, key features, and practical considerations of these essential carriers, focusing on the 300mm wafer shipper, the Automated wafer shipper, the AMHS compatible wafer shipper, and the growing model of Wafer shipper rental.

The Backbone of the Fab: Understanding the Wafer Shipper for Automated Systems

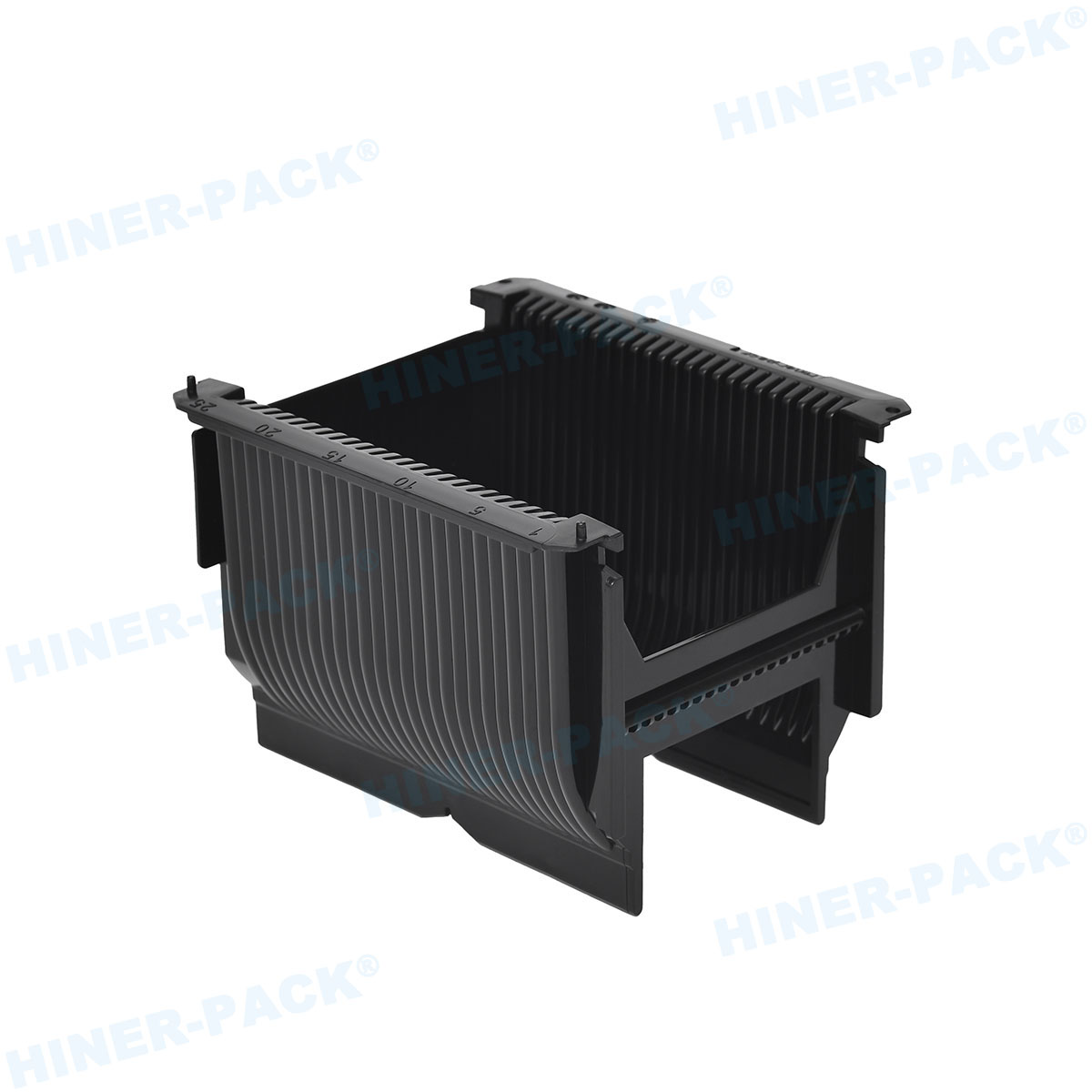

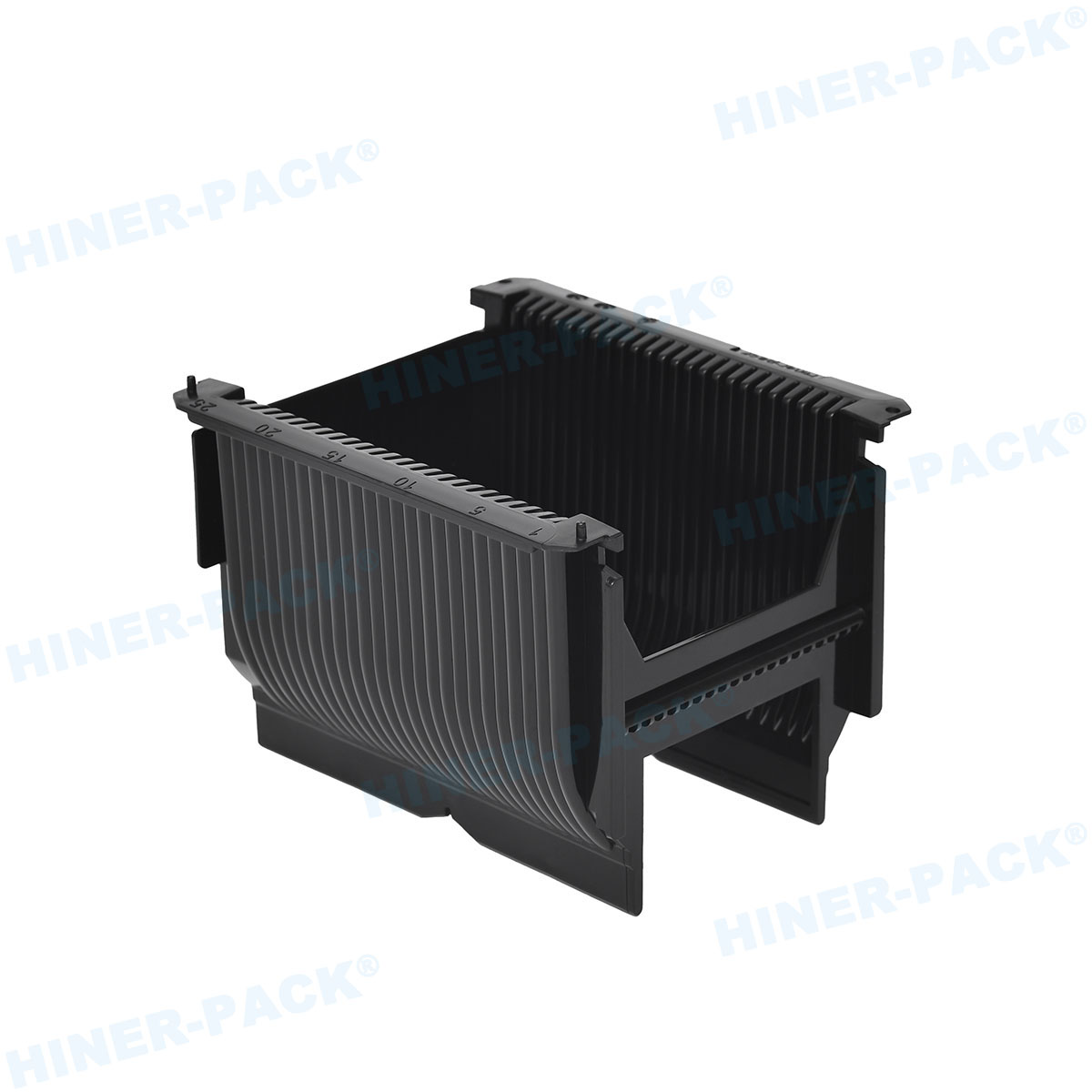

A wafer shipper for automated systems is a specialized container designed to safely transport and store silicon wafers, primarily within a fabrication plant (fab) or between different facilities. Unlike its manual counterparts, this shipper is engineered specifically for interaction with robotics and automated handling equipment without human intervention. Its primary functions are:

Protection: Shielding ultra-fragile wafers from contaminants like airborne particles (AMC), moisture, and physical damage from shock or vibration.

Containment: Acting as a secure vessel that maintains a clean mini-environment around the wafers.

Automation Compatibility: Featuring standardized dimensions, interfaces, and identification points that allow robots to reliably pick, place, open, and close the shipper.

The shift to larger 300mm wafers and the industry-wide adoption of Automation Manufacturing Systems (AMHS) have made this specialized shipper not just a convenience but an absolute necessity for achieving high yields and operational efficiency.

The Standard Bearer: The 300mm Wafer Shipper

The transition from 200mm to 300mm wafers was a pivotal moment in semiconductor history, and the packaging had to evolve in lockstep. The 300mm wafer shipper became the new standard, governed by strict international standards from SEMI (Semiconductor Equipment and Materials International).

Standardization (SEMI E62): This standard defines the exact outer dimensions, kinematic coupling features, and robotic handling interfaces for a front-opening shipping box. This ensures that any compliant 300mm wafer shipper can be used in any compliant fab across the globe, providing immense interoperability.

Capacity: These shippers typically hold 25 wafers, though 13-wafer versions exist for lighter loads or specific process tools.

Materials: They are primarily made from advanced, durable plastics like PEEK (Polyether Ether Ketone) or PC (Polycarbonate) that are static-dissipative, low-outgassing, and incredibly clean to prevent contamination.

The robustness and standardization of the 300mm wafer shipper form the foundational building block upon which fab automation is built.

Designed for Robots, Not Human Hands: The Automated Wafer Shipper

An Automated wafer shipper takes the basic standardized container and integrates features that enable seamless robotic handling. The defining characteristic of a true Automated wafer shipper is its "front-opening" design, which allows a robotic arm to access the wafers from the front without needing to lift or tilt the entire container.

Key features include:

Kinematic Coupling: A precisely molded interface on the bottom of the shipper that allows a robot to locate and seat the box with micron-level accuracy every single time.

Latching Mechanism: An automated latching system that a robot can actuate to open and close the door securely. This ensures a consistent seal and prevents accidental opening.

RFID Integration: A dedicated location for an RFID tag, which allows the Automated Material Handling System (AMHS) to identify the shipper and its contents without ever opening it, tracking its journey throughout the fab.

The Nexus of Movement: The AMHS Compatible Wafer Shipper

This is where the wafer shipper for automated systems proves its true value. An AMHS compatible wafer shipper is one that is specifically designed to interface directly with the fab's Automated Material Handling System. The AMHS is the network of overhead hoists, conveyors, and guided vehicles that move wafers between tools and stockers.

Compatibility is non-negotiable. An AMHS compatible wafer shipper must have:

Precise External Dimensions: Any deviation from the SEMI standard can cause the shipper to jam in a conveyor or be misaligned on a stocker shelf, bringing the entire automated flow to a grinding halt.

Robotic Handling Features: The kinematic couplings and latching mechanisms must be perfectly positioned and function reliably for thousands of cycles under the precise force applied by a robot.

Cleanliness: The materials must not generate particles that could be shed inside the AMHS, contaminating the entire transport pathway.

Without an AMHS compatible wafer shipper, the high-speed, lights-out operation of a modern fab would be impossible.

Flexibility and Cost Management: The Case for Wafer Shipper Rental

As fabs expand and process technologies change, the demand for these sophisticated containers can fluctuate. This has given rise to a practical and strategic solution: Wafer shipper rental.

Companies like Entegris and Miraial offer rental or managed service programs where they own, maintain, and manage the pool of wafer shippers, leasing them to fab operators as needed.

The benefits of Wafer shipper rental are compelling:

Reduced Capital Expenditure (CapEx): Fabs can avoid large upfront investments in purchasing thousands of shippers, freeing capital for core equipment like lithography tools.

Logistics and Maintenance: The rental provider handles the complex logistics of cleaning, repairing, tracking, and replacing shippers that are worn or damaged, ensuring a constant supply of "fab-ready" containers.

Scalability: A fab can easily scale its shipper pool up or down based on production volume changes, new technology nodes, or unexpected demand spikes.

Navigating Common Challenges and Problems

Even with the best technology, issues can arise. Understanding common problems with wafer shippers for automated systems is key to maintaining high yield.

Particle Contamination: Over time, wear and tear can cause shippers to generate particles. A damaged latch or a worn kinematic coupling can scrape and create debris that settles on wafers, causing defects. Regular inspection and a robust cleaning process are critical.

Mechanical Failure: The most common point of failure is the latching mechanism. If a robot cannot reliably open or close a latch, it causes tool downtime. Hinges can also wear out, and the door seal can degrade, compromising the internal environment.

RFID Tagging Errors: If an RFID tag is misread or fails, the shipper becomes "blind" to the AMHS. This can lead to misrouted lots, production delays, and a frantic search for valuable wafers on the fab floor.

Incompatibility Issues: Using a shipper that is not fully AMHS compatible or that is from a vendor whose dimensions are slightly out of spec can cause catastrophic jams in the conveyor system, requiring a full shutdown to clear.

Moisture Ingress: If the seal around the door is compromised, moisture can enter the shipper, leading to oxidation and ruinous damage to the wafers. This is often a problem that isn't discovered until the wafers are loaded into a process tool.

The Future of the Wafer Shipper

The evolution of the wafer shipper for automated systems is far from over. As the industry moves towards larger 450mm wafers (though adoption is slow) and more advanced packaging techniques, the demands on packaging will increase. We can expect to see:

Smarter Shippers: Integrated sensors to monitor internal conditions like humidity, temperature, and shock in real-time during transport.

Advanced Materials: New composites and polymers that are even lighter, stronger, and cleaner to meet the demands of sub-3nm process nodes.

Enhanced Data Integration: Tighter coupling between the physical shipper and the fab's MES (Manufacturing Execution System) through IoT connectivity, providing an uninterrupted data trail for every wafer.

The unassuming wafer shipper for automated systems is a masterpiece of engineering pragmatism. From the standardized 300mm wafer shipper to the robotic-friendly Automated wafer shipper and the seamlessly integrated AMHS compatible wafer shipper, this critical component is fundamental to the modern semiconductor ecosystem. Furthermore, the flexibility offered by Wafer shipper rental programs provides fabs with the agility needed in a dynamic market. By understanding its function, standards, and potential pitfalls, manufacturers can ensure this silent workhorse continues to reliably protect the technological heart of our digital world.