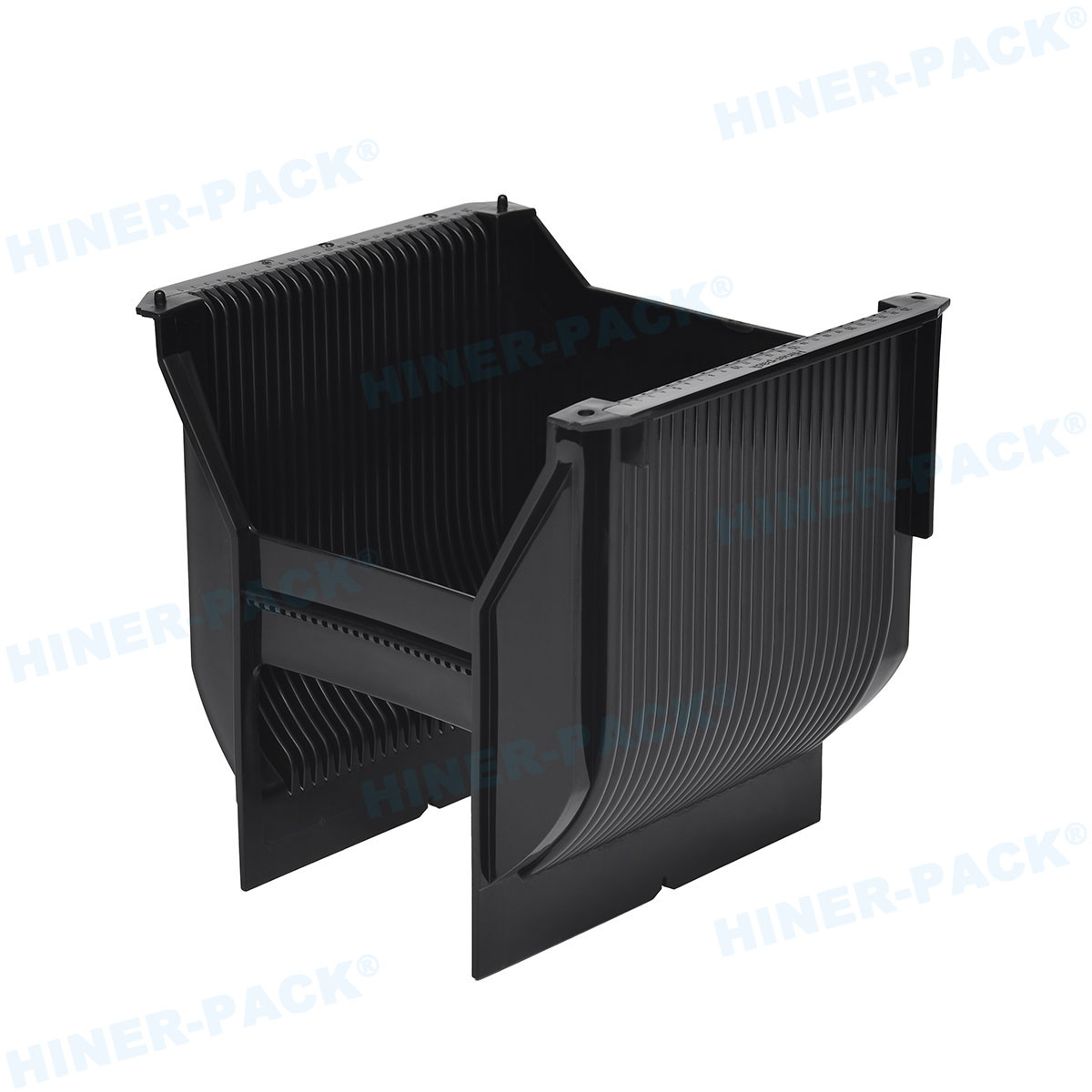

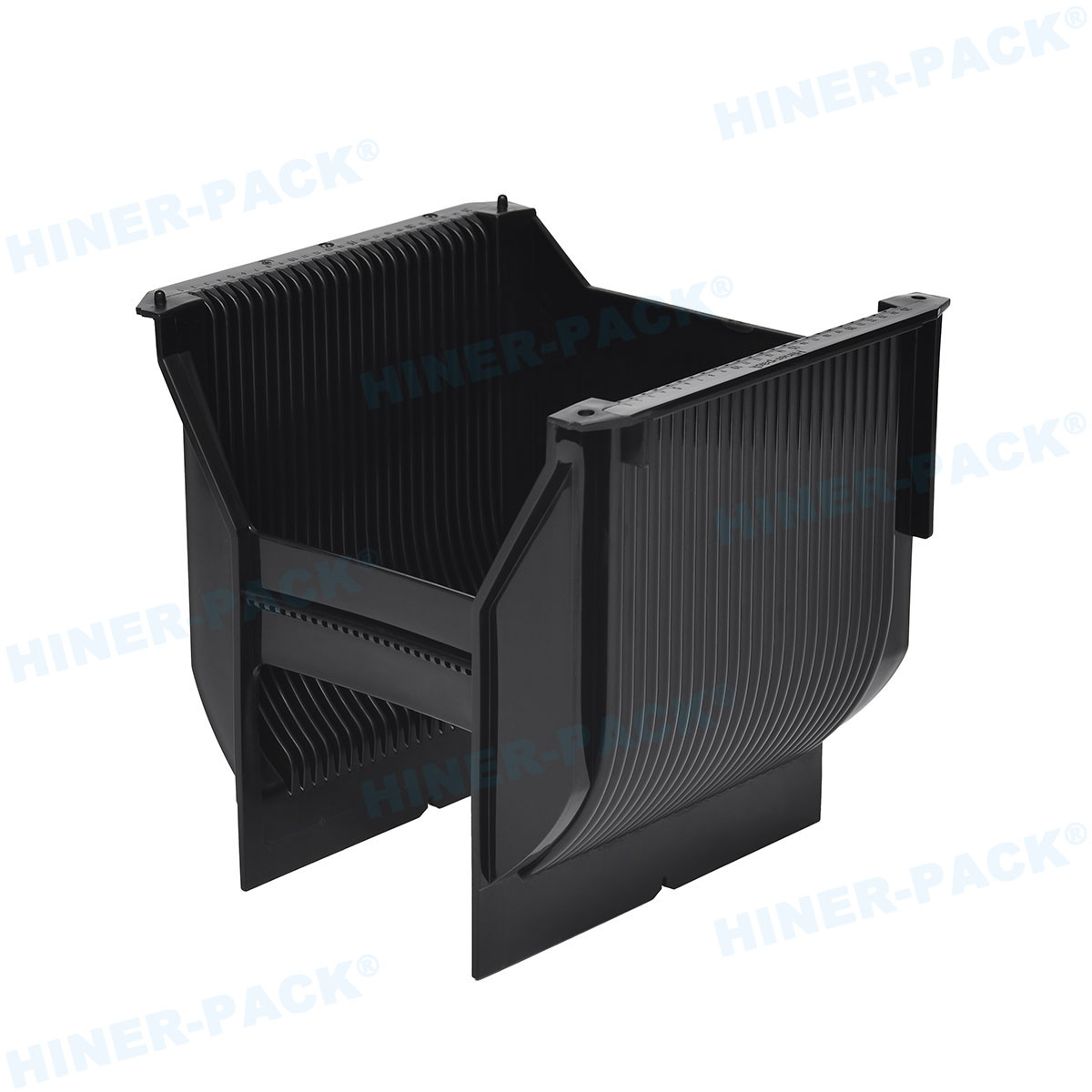

In the highly precise world of semiconductor manufacturing, every component, no matter how seemingly small, plays a critical role in safeguarding the integrity of delicate products. Among these essential components, the anti-static wafer boxes stand as the first and last line of defense for silicon wafers as they journey through the fabrication process. These specialized containers are not mere plastic boxes; they are engineered solutions designed to prevent catastrophic and costly damage from electrostatic discharge (ESD) and particulate contamination. This article delves into the world of these crucial containers, exploring where to find anti-static wafer boxes for sale, what to look for in an anti-static wafer boxes factory, the specificities of the Conductive 300mm wafer box, and the common problems that can plague their use.

What Are Anti-Static Wafer Boxes and Why Are They Indispensable?

Anti-static wafer boxes, also known as FOUPs (Front-Opening Unified Pods) for 300mm wafers or SMIF pods for smaller sizes, are rigid containers crafted from advanced polymer materials. Unlike standard plastics, these materials are either inherently static-dissipative or made conductive through the addition of carbon fibers. Their primary mission is threefold:

ESD Protection: Silicon wafers are incredibly sensitive to electrostatic discharge. A tiny, imperceptible spark can vaporize circuit pathways, creating latent defects that may cause device failure later. Anti-static boxes safely bleed away any accumulated charge, ensuring wafers remain at the same electrical potential as their environment.

Contamination Control: Semiconductor fabs are cleanrooms for a reason. A single speck of dust can ruin a die. These boxes are designed to be sealed environments with minimal particle generation and sophisticated latching mechanisms that only open in controlled conditions.

Mechanical Protection and Transport: They provide a sturdy, standardized form factor for automated handling systems (AMHS) to safely move wafers between tools without human intervention, minimizing the risk of physical damage and contamination.

The failure of a single wafer box can lead to the loss of thousands of dollars worth of product, making their quality and reliability non-negotiable.

Navigating the Market: Finding Quality Anti-Static Wafer Boxes for Sale

The market for wafer carriers is vast, ranging from OEM suppliers to third-party manufacturers. When searching for anti-static wafer boxes for sale, it’s crucial to look beyond price and consider several key factors:

Material Quality: The grade of polymer used (e.g., PFA, PP, PC blended with carbon) directly impacts performance. High-quality materials ensure consistent conductivity, low outgassing (which can create contamination), and long-term durability without cracking or warping.

Compatibility: The box must be compatible with your existing fab equipment. This includes the mechanical interface for robotic handlers, the latching system, and the overall dimensions. A 200mm box is useless for a 300mm production line.

Certifications and Documentation: Reputable suppliers provide certificates of compliance, material safety data sheets (MSDS), and data on surface resistivity (should be within 10^3 to 10^6 Ω/sq for proper dissipation).

Supplier Reputation: Whether buying directly from an anti-static wafer boxes factory or a distributor, the supplier’s track record within the industry is paramount. Look for suppliers with proven experience and positive testimonials from other semiconductor manufacturers.

The Source Matters: Choosing an Anti-Static Wafer Boxes Factory

Partnering with the right anti-static wafer boxes factory is perhaps the most critical decision. A factory is not just a source of product; it is a partner in your supply chain. Here’s what distinguishes a top-tier factory:

In-House Engineering and Mold Making: The best factories have extensive R&D capabilities. They can design custom solutions, create precise molds, and perform rigorous testing before mass production. This control over the entire process ensures higher quality.

Stringent Quality Control (QC): A superior factory will have a multi-stage QC process. This includes checking for dimensional accuracy, testing surface resistivity on every batch, conducting particle counts, and performing functional tests with automated handlers.

Cleanroom Manufacturing: The boxes themselves should be manufactured in a controlled cleanroom environment to prevent them from being contaminated before they even reach your fab.

Scale and Consistency: The factory must be able to produce large volumes while maintaining impeccable consistency. Variability in material mix or molding process can lead to disastrous batch-to-batch inconsistencies.

A direct relationship with a factory can also lead to better pricing, more responsive customer service, and faster resolution of any technical issues that may arise.

The Workhorse of Modern Fabs: The Conductive 300mm Wafer Box

The shift to 300mm wafers was a monumental step in semiconductor manufacturing, and the Conductive 300mm wafer box, or FOUP, evolved to meet its unique demands.

Scale and Weight: A full FOUP holding 25 wafers can weigh over 8 kg. The material must be incredibly strong and rigid to prevent flexing, which could misalign wafers and lead to breakage or handling errors.

Advanced Handling: 300mm fabs are fully automated. The FOUP is designed with precise features for robots to grip, lift, and place it onto the load port of processing tools. The integrity of these mechanical features is critical.

Enhanced Environmental Control: Modern FOUPs often include ports for purging with inert gases like Nitrogen to create a protective atmosphere inside the box, further preventing oxidation or moisture-related damage to the wafers.

RFID Integration: Most Conductive 300mm wafer box units are equipped with an integrated RFID tag. This allows the AMHS to track every single box and its wafer content in real-time, enabling full traceability and workflow management throughout the fab.

Investing in high-quality FOUPs is essential for maximizing uptime and yield in a high-volume 300mm manufacturing environment.

Common Problems and Challenges with Anti-Static Wafer Boxes

Even the best equipment can encounter issues. Awareness of these common problems is the first step toward prevention.

ESD Protection Failure: Over time, the conductive material can degrade. This can be caused by prolonged exposure to harsh chemicals, UV light, or simply wear and tear. If the surface resistivity rises beyond acceptable limits, the box becomes a liability, potentially exposing wafers to ESD events. Regular testing with a surface resistivity meter is essential.

Particulate Generation and Contamination: The interior of the box must be smooth and non-shedding. Low-quality boxes can generate microscopic particles through friction, especially at the latch points or where wafers rub against the slots. These particles can settle on wafers, causing defects. Choosing boxes from a factory that provides particle count data is crucial.

Mechanical Wear and Tear: Latches can break, hinges can wear out, and robotic handling features can become damaged. A broken latch can compromise the seal of the box, rendering its contamination control useless. Implementing a regular inspection and maintenance schedule for your wafer boxes is a best practice.

Cross-Contamination: If boxes are used for different process steps without proper cleaning, residues from one process (e.g., etching chemicals) can contaminate wafers in a subsequent process. A robust cleaning and management protocol is necessary.

Material Outgassing: Inferior plastics can release volatile organic compounds (VOCs) inside the sealed environment. These compounds can condense on cooler wafer surfaces, creating a film that interferes with lithography and other processes.

Compatibility Issues: Not all FOUPs are created equal. A box from one manufacturer might not seat perfectly on the load port of a tool from another manufacturer, leading to handling faults, misalignment, or even wafer breakage. It’s vital to ensure full compatibility with your toolset.

The humble anti-static wafer box is a masterpiece of engineering that plays an outsize role in the success of semiconductor manufacturing. It is a safeguard against the invisible threats of static and contamination. Whether you are evaluating options for anti-static wafer boxes for sale, vetting a new anti-static wafer boxes factory, or specifying a Conductive 300mm wafer box for your production line, a meticulous approach is required. Prioritizing quality, compatibility, and a reliable manufacturing partner over initial cost savings will pay dividends in the form of higher yield, less downtime, and greater overall operational efficiency. In an industry where perfection is the goal, the right container is not an accessory; it is a necessity.