In the highly precise world of semiconductor fabrication, every component matters. From the cleanroom to the assembly line, protecting delicate silicon wafers is not just a step—it’s a fundamental requirement. This is where specialized packaging like the 8-inch Horizontal Wafer Shipper becomes indispensable. It is the unsung hero of logistics, ensuring that 200mm wafers move safely between facilities, fabs, and assembly sites without contamination or physical damage.

For engineers and supply chain managers, choosing the right shipper is a technical decision with direct impact on yield and cost. This article breaks down the importance, design, and selection criteria for these essential carriers.

What is an 8-inch Horizontal Wafer Shipper?

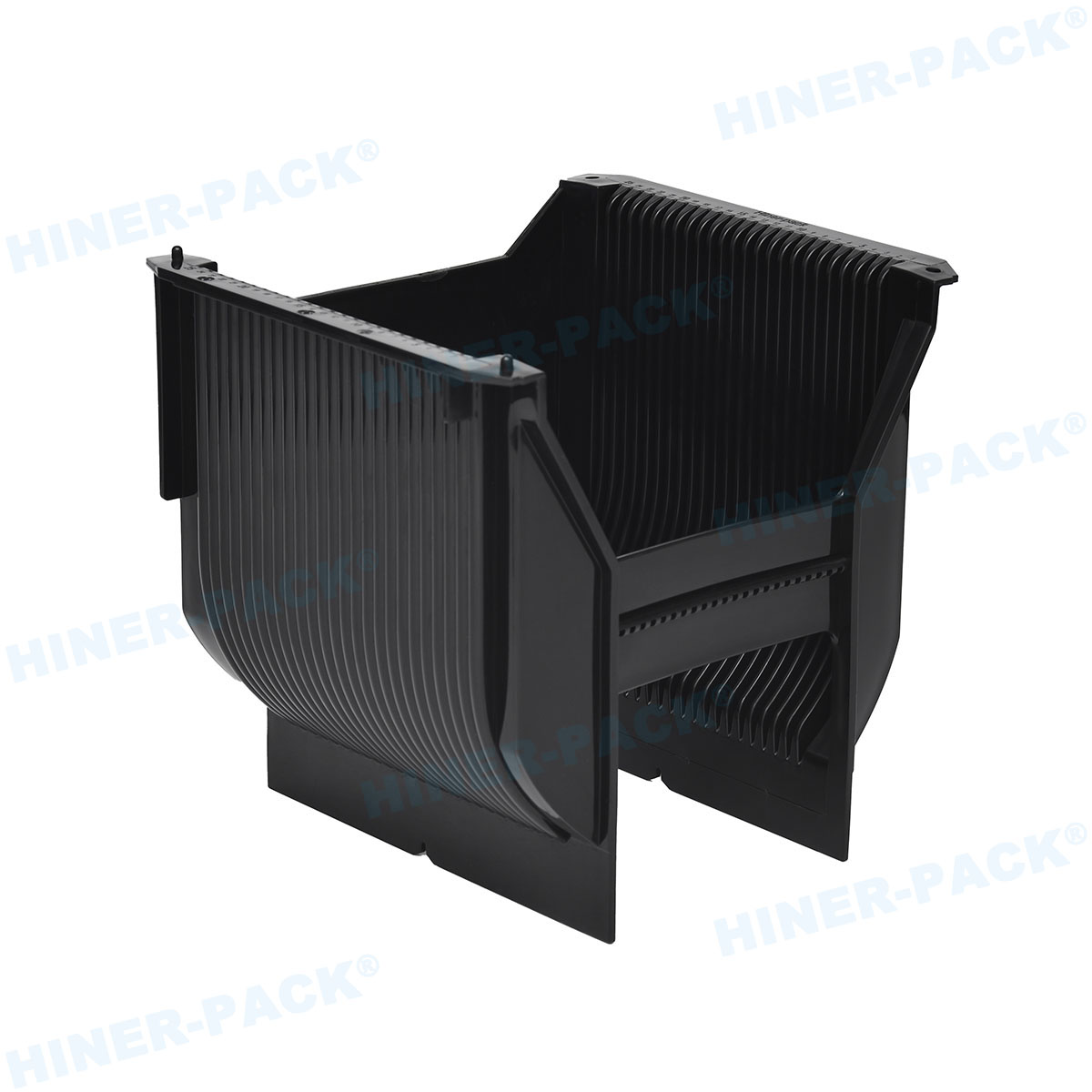

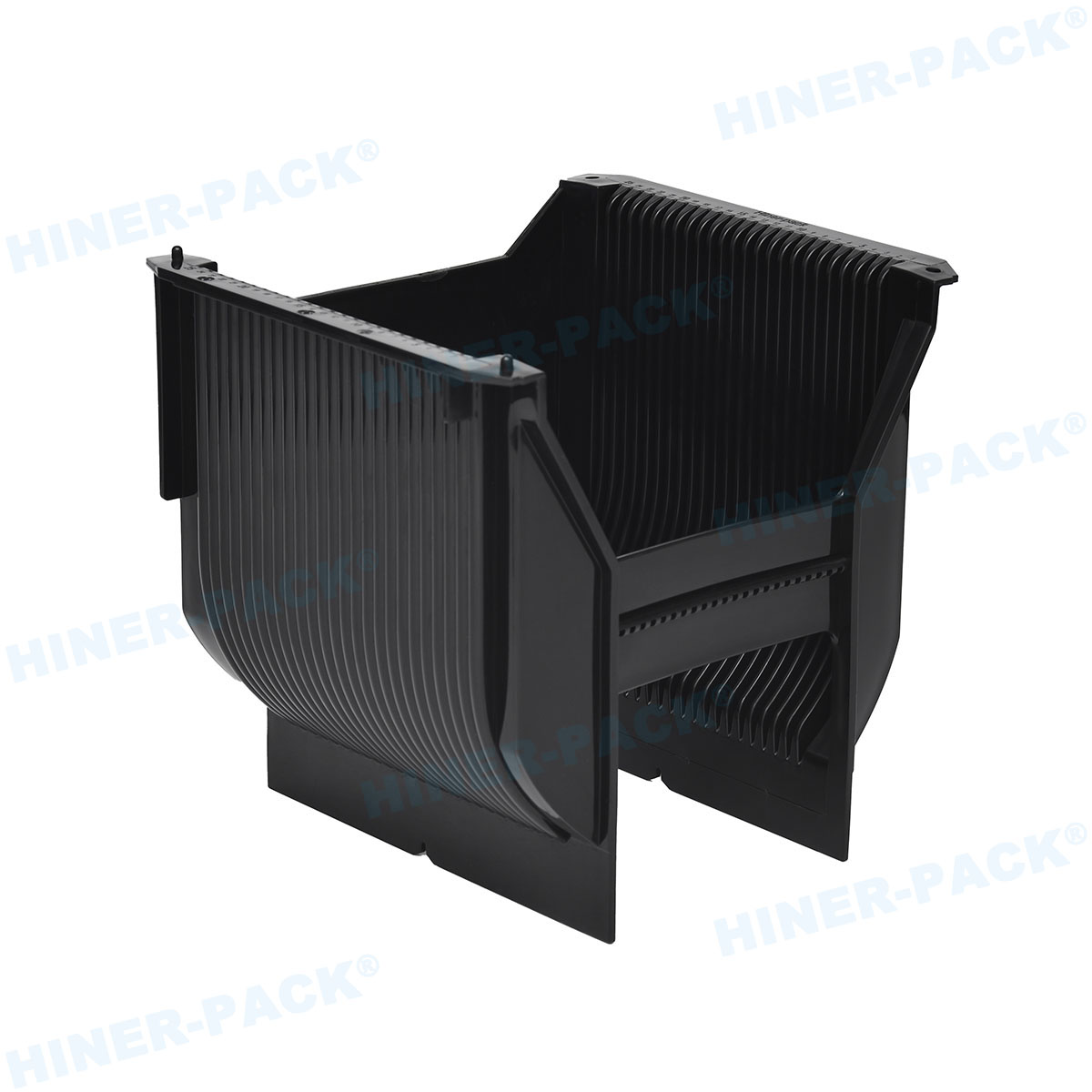

An 8-inch Horizontal Wafer Shipper is a standardized container designed to securely hold and transport twenty-five 200mm diameter silicon wafers in a horizontal orientation. Unlike vertical carriers used within process tools, horizontal shippers are built for inter-facility or inter-company transportation.

Their primary job is protection. They shield wafers from airborne particles, moisture, physical shocks, and electrostatic discharge (ESD) during transit. The design follows strict industry standards to ensure compatibility with automated material handling systems (AMHS) and wafer loading equipment globally.

Why the 8-Inch Standard Remains Vital

While newer fabs focus on 300mm and larger wafers, the 200mm ecosystem remains massive. It supports a vast array of devices: analog chips, power semiconductors, MEMS, and sensors. Thousands of legacy tools are still in operation worldwide.

This enduring demand means the transport of 8-inch wafers is a daily activity. A reliable 8-inch Horizontal Wafer Shipper is not a commodity but a precision component. Its performance directly affects scrap rates, especially for wafers that have undergone numerous expensive fabrication steps.

Key Features of a Reliable 8-inch Horizontal Wafer Shipper

Several design elements separate a high-quality shipper from a basic container.

Material and Construction: Top-tier shippers use advanced polymers like PEEK or static-dissipative polycarbonate. These materials offer excellent mechanical strength, low outgassing, and superior cleanroom compatibility. Hiner-pack, for instance, utilizes a proprietary composite that minimizes particle generation.

Contamination Control: The interior is a Class 1 cleanroom environment. Seals are critical. High-performance gaskets on the door create an airtight barrier against particles and moisture. Internal surfaces are smooth, with minimized recesses where contaminants could hide.

Mechanical Protection: The wafer cassettes inside must be immobilized. Customized foam inserts or molded plastic supports hold the cassette firmly, preventing movement during handling and transport. The outer shell must withstand stacking and rough airport baggage systems.

ESD Protection: Semiconductor devices are incredibly sensitive to static. A proper shipper provides a Faraday cage effect, dissipating any charge and shielding the wafers from external electrostatic fields. Conductive materials and proper grounding paths are essential.

Ergonomics and Compliance: Handles must allow for safe, easy lifting even when fully loaded. The design must comply with SEMI standards (like SEMI E1.9) for dimensions and features. This ensures universal handling and tool compatibility.

Applications Across the Supply Chain

The use of these shippers extends beyond the fab wall.

- Foundry to OSAT Transport: Moving finished wafers to Outsourced Assembly and Test facilities.

- Multi-Site Fabrication: Some processes may be split between different specialized fabs.

- Sample and Engineering Lot Shipping: Sending small batches for qualification or analysis.

- Equipment Service and Support: Transporting test wafers used for tool calibration and maintenance.

In each scenario, the 8-inch Horizontal Wafer Shipper provides the necessary security blanket.

How to Select the Right Shipper for Your Needs

Choosing a shipper involves more than just checking a box for size.

First, assess your contamination requirements. For highly sensitive processes, look for certified low outgassing and particle count data from the manufacturer.

Next, consider durability. How many round trips is the shipper expected to survive? A robust shipper from Hiner-pack, designed for hundreds of cycles, offers better total cost of ownership than a cheaper, single-use alternative.

Evaluate the sealing mechanism. Is the gasket easy to clean and replace? Does it maintain a consistent seal over many closures?

Finally, partner with a trusted supplier. A manufacturer with deep industry knowledge can provide critical support and customization.

Hiner-pack’s Approach to Wafer Safety

Hiner-pack has built its reputation on engineering excellence. Our 8-inch Horizontal Wafer Shipper is a product of continuous refinement. We focus on material science to achieve the optimal balance of rigidity, weight, and cleanliness.

Our designs undergo rigorous testing for shock, vibration, and seal integrity. We understand that our product is a critical link in your supply chain. Therefore, we prioritize reliability above all, ensuring every Hiner-pack shipper delivers consistent, predictable performance.

In conclusion, the 8-inch Horizontal Wafer Shipper is a cornerstone of the enduring 200mm semiconductor industry. Its role in preserving wafer integrity is irreplaceable. Selecting a well-engineered carrier from a committed manufacturer like Hiner-pack is a strategic investment in protecting valuable product and maintaining seamless production flow.

Frequently Asked Questions (FAQs)

Q1: How often should an 8-inch Horizontal Wafer Shipper be cleaned and inspected?

A1: For optimal performance, a thorough cleaning and inspection should occur after every return cycle. The gaskets, latches, and interior surfaces must be checked for wear or damage. Hiner-pack provides detailed cleaning protocols to ensure shippers maintain their protective qualities throughout their lifecycle.

Q2: What is the typical load capacity for a standard 8-inch shipper?

A2: The standard configuration holds a single 25-wafer front-opening unified pod (FOUP) or a standard wafer cassette. The total weight of a fully loaded shipper with wafers is a key design consideration for ergonomics and shipping cost.

Q3: Are there specific certifications I should look for when purchasing these shippers?

A3: Yes. Compliance with SEMI standards (such as SEMI E1.9) is fundamental. Additionally, certifications for ESD protection (e.g., ANSI/ESD S20.20) and material purity (low outgassing per SEMI standards) are critical indicators of quality and suitability for high-end semiconductor applications.

Q4: Can these shippers be customized for specific wafer types or unusual processes?

A4: Reputable manufacturers like Hiner-pack often offer customization. This can include special foam inserts for thinner wafers or non-standard substrates, unique purge valve placements for inert gas environments, or RFID tagging integration for advanced tracking.

Q5: What is the main difference between a shipper designed for air transport versus local fab-to-fab transport?

A5: Shippers designed for rigorous air transport are typically built to withstand greater extremes of pressure, temperature, and physical shock. They often feature more robust external shells, enhanced seal designs, and are certified for specific air freight regulations. Local transport shippers may prioritize lightweight design and quick access while still offering excellent basic protection.