Urgent Wafer Container Delivery: Fast and Reliable Solutions for Semiconductor NeedsIn semiconductor manufacturing, production downtime is costly. When a critical wafer carrier fails or supply runs low, you need a swift response. This is where securing an

urgent wafer container delivery becomes essential. It ensures your fabrication line continues operating without interruption.

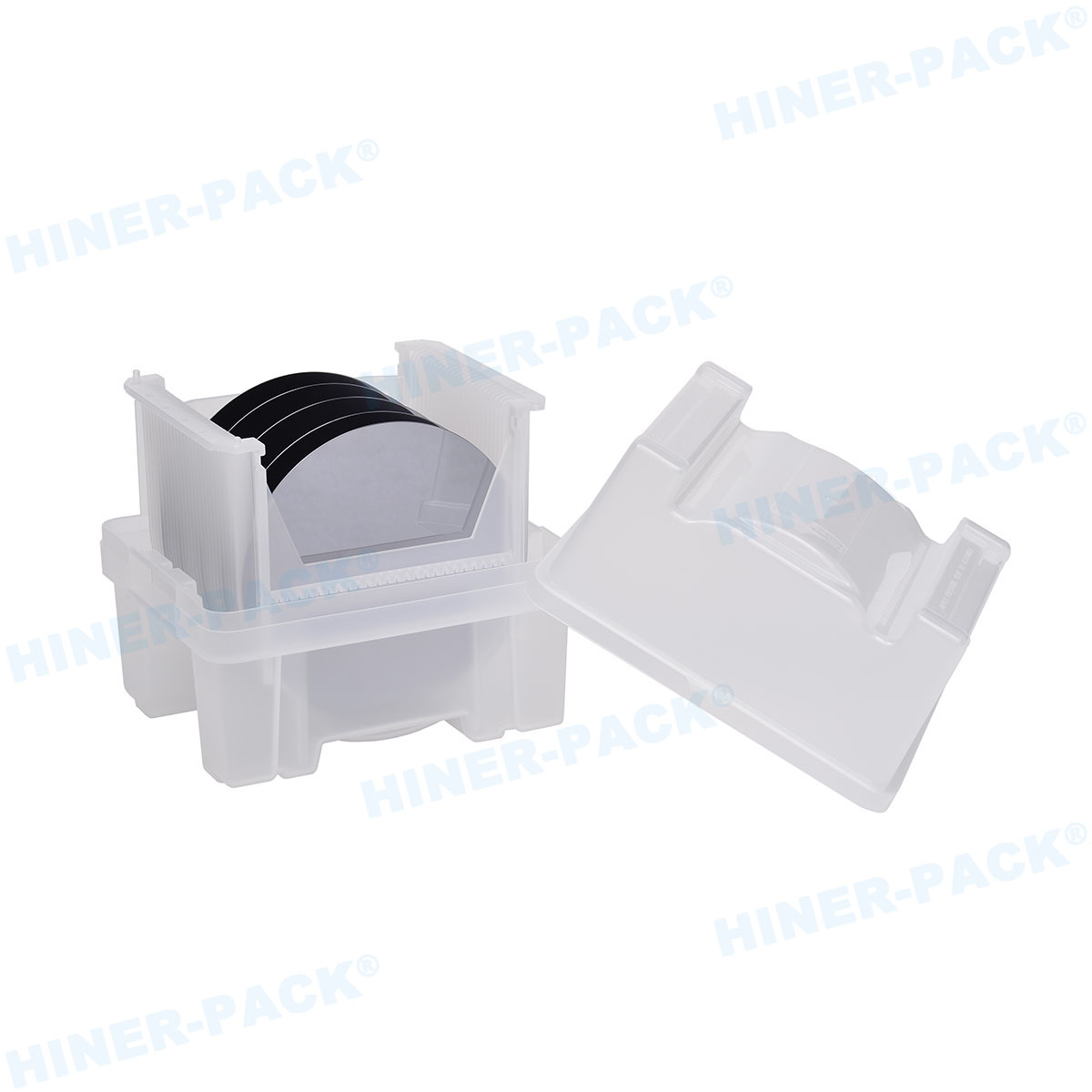

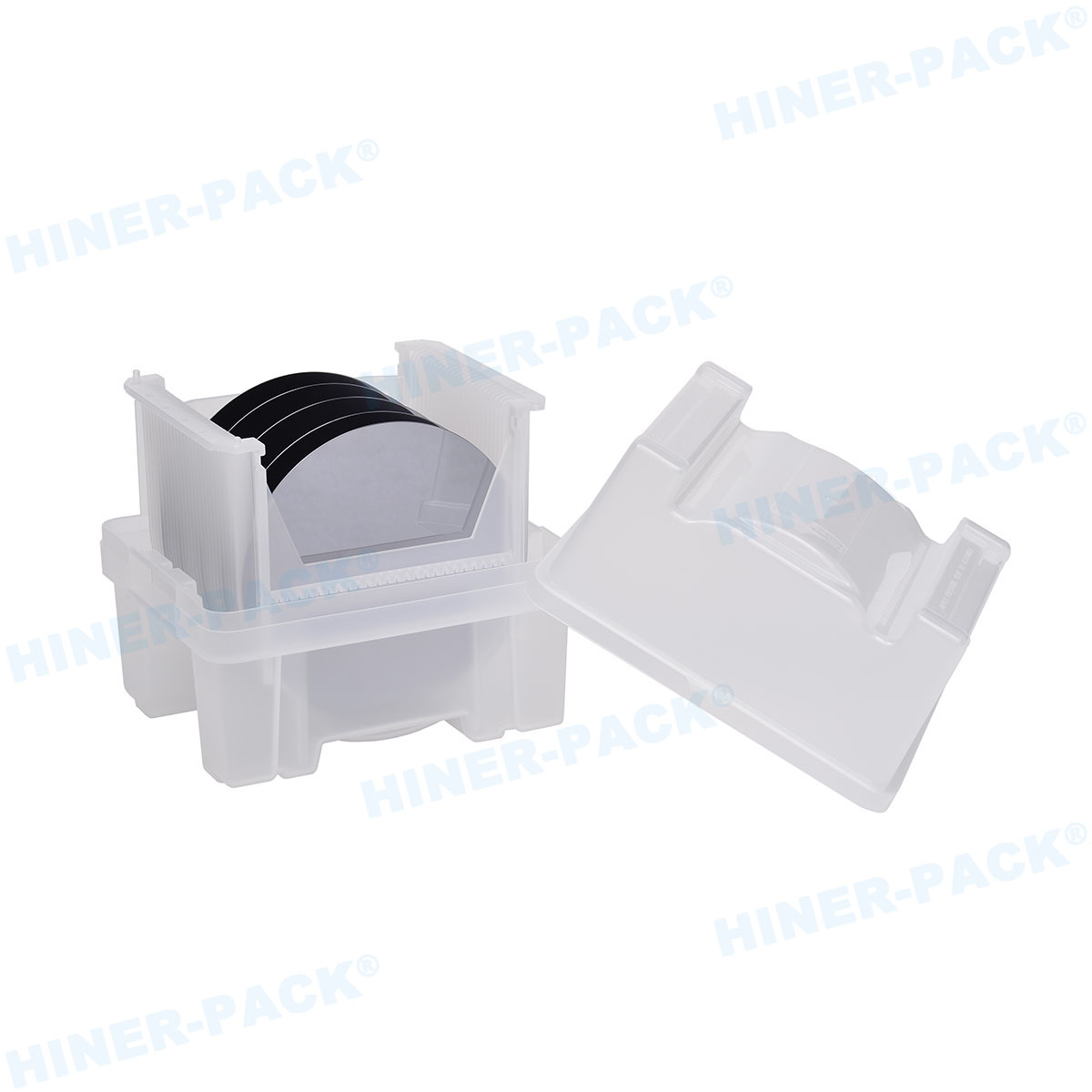

Wafer containers, such as FOUPs, FOSBs, and standard cassettes, protect valuable wafers from contamination and damage. Having a reliable source for expedited delivery is a key part of any fab's contingency planning.

Understanding the Need for Urgent Wafer Container Delivery

Several situations in a semiconductor facility can create an immediate need for wafer containers. Planning for these scenarios can mitigate risk.

Unexpected Container Damage or Failure

Containers are subject to wear, cracks, or mechanical failure. A single damaged pod can halt a tool's process queue. Replacing it quickly is vital.

Common failures include:

Broken latches or doors on FOUPs/FOSBs.

Cracks in the body from impact or stress.

Warping due to thermal or chemical exposure.

Sudden Increases in Production Volume

A new product ramp or an unplanned high-priority batch can strain container inventory. Additional carriers are needed to maintain workflow.

Without them, bottlenecks form at process tools, reducing overall equipment effectiveness (OEE).

New Process or Tool Integration

Introducing a new tool to the line often requires specific, compatible containers. Last-minute integration can create a need for fast delivery.

Ensuring the correct model and interface is delivered quickly prevents project delays.

How to Plan for and Execute an Urgent Delivery

Effective management of an urgent wafer container delivery involves several key steps, from vendor selection to logistics.

Identifying a Reliable Supplier with Express Services

Not all suppliers can fulfill urgent orders. A reliable partner maintains ready inventory and has established expedited shipping channels.

Suppliers like Hiner-pack specialize in such support. They understand the critical nature of semiconductor timelines.

Key supplier traits include:

Clear stock level information.

Dedicated express order processing.

Global logistics partnerships.

Logistics and Shipping Considerations

The speed of delivery depends on logistics. Air freight is the standard for urgent shipments, but options vary.

Factors to confirm:

Customs pre-clearance for international shipments.

Real-time tracking capabilities.

Proper packaging to prevent in-transit damage.

Working with a supplier experienced in shipping sensitive semiconductor hardware ensures containers arrive intact and ready for use.

Cost-Benefit Analysis of Expedited Shipping

Expedited shipping incurs higher costs. However, these must be weighed against the cost of fab downtime.

Even a few hours of halted production can far exceed express shipping fees. The benefit of maintaining yield and on-time delivery is paramount.

Key Features to Verify When Ordering Urgently

Speed cannot come at the expense of quality or compatibility. Verifying these aspects is crucial, even under time pressure.

Container Specifications and Compatibility

Confirm the exact specifications match your need. This includes:

Wafer size (200mm, 300mm, etc.).

Container type (FOUP, FOSB, cassette).

Tool-specific interface details.

Material (static-dissipative, high-purity, etc.).

Cleanliness and Certification

Containers must arrive clean and certified. Urgent orders should still include documentation for particle counts and outgassing.

Reputable suppliers ship urgent items from pre-cleaned, certified stock to avoid post-cleaning delays.

Partnering with the Right Provider for Urgent Needs

Establishing a relationship with a dependable provider before an urgent need arises is the best strategy. This ensures a faster response when required.

A provider like Hiner-pack offers a range of wafer carriers and shippers. Their focus on the semiconductor industry means they understand the critical timelines.

Their services often include:

Priority order processing for urgent requests.

A broad inventory of common container models.

Expert support to verify part numbers and compatibility.

Conclusion: Minimizing Risk with Reliable Urgent Delivery

Disruptions in the supply of wafer containers can significantly impact semiconductor production. Having a verified and tested plan for urgent wafer container delivery is a competitive necessity.

By identifying qualified suppliers, understanding logistics, and verifying specifications, fabs can secure their production lines against unexpected shortages. This proactive approach protects valuable output and maintains operational integrity.

Frequently Asked Questions (FAQ)

Q1: How quickly can I typically receive an urgent wafer container delivery?

A1: Delivery timelines vary based on location and stock. With express air freight, many regions can receive critical parts within 24-72 hours from order confirmation. Domestic deliveries can sometimes be even faster.

Q2: Does urgent delivery cost significantly more?

A2: Yes, expedited shipping and handling involve premium costs. However, when compared to the potential losses from production downtime, this cost is often justifiable. Suppliers can provide cost estimates upfront.

Q3: Can I get urgent delivery for custom or specialized wafer containers?

A3: Standard models are best suited for urgent delivery due to available stock. Custom containers usually require manufacturing lead time. Discussing standard alternatives with your supplier for urgent needs is advisable.

Q4: How do I ensure the containers arrive clean and ready for use?

A4: Specify that you require industry-standard cleanroom packaging and certification. Reliable suppliers ship urgent containers sealed in clean bags with certification data to ensure they are fab-ready upon arrival.

Q5: What information should I have ready to expedite an urgent order?

A5: To speed up the process, have the following details ready:

Exact part number and container type.

Quantity needed.

Shipping address and contact.

Any required certifications or compliance documents.

Providing this information immediately helps the supplier process your urgent wafer container delivery efficiently.